01/26/2022 21,085 VAZ 2107

Author: Ivan Baranov

The problem of failure of the clutch fork in a VAZ 2107 car can be considered a disease of these car models. This kind of breakdown often occurs among owners of “Sevens”, and they have already learned how to solve it without dismantling the gearbox. Therefore, now we will tell you how to replace the clutch fork without removing the VAZ 2107 gearbox.

[Hide]

How to install the clutch fork without removing the box

The clutch on a car with a manual transmission is an important and responsible unit. At the same time, large loads on the clutch and natural wear lead to the fact that during operation, individual elements fail.

Not often, but in addition to the basket, clutch disc and release bearing, the clutch fork may also need to be replaced. Next, we will look at what a clutch fork is, why it fails, as well as how to change the clutch fork and how to install the clutch fork without removing the gearbox.

Basic clutch elements

To replace the clutch, you should accurately understand its structure. In the VAZ-2107, this unit is controlled using a pedal located under the steering wheel. Pressing it disconnects the clutch from the gearbox, and releasing it reattaches it. The unit in question is easy to adjust and easy to change.

The VAZ-2107 model is equipped with a single-disc clutch equipped with a central spring. This scheme has a number of advantages:

- reliability;

- low cost;

- ease of care.

It is not difficult to replace the “original” wheels with those that are installed on other VAZ models. Fully matched parts for:

- 2103 (engine capacity up to 1.5 liters);

- 2121 (up to 1.7 l).

The VAZ clutch driven disc is called the “drum”. It has pads and special slots on both sides that increase elasticity. There are also 8 springs that reduce dynamic load.

The gearbox is attached to the driven disk, and the basket is attached to the power unit. When moving, both parts are pressed tightly against each other and rotate synchronously.

For model 2107, driven discs from 2106 or 2103 can be used. Some craftsmen replace the drum with a part from 2121 (Niva).

The next clutch element is the release bearing. Usually it is he who fails most often. The element is attached to the pedal using a fork. Any pressure significantly increases the load on the part, and therefore it breaks relatively quickly.

To change the bearing, in any case, you will need to disassemble the disks. Instead of the standard element (designated 2101), many take the one intended for the VAZ-2121.

Such a bearing is more reliable, but it will be necessary to change the basket, otherwise the pedal will become too hard.

The next part of the clutch is the fork. With its help, the release bearing moves and the clutch is retracted. Failure of this part makes it impossible to turn off the entire unit. It is recommended to change the fork, even if the clutch continues to work, albeit unstable, because otherwise it will soon completely fail.

When and how to replace the clutch fork?

First of all, if the clutch fork fails, you will not be able to drive the car normally, since the clutch simply will not work. Of course, you can get to the repair site if you know how to drive without a clutch. However, we are not talking about normal operation of a vehicle with such a breakdown.

The clutch actually connects the engine and the gearbox, and this connection can be interrupted by pressing the clutch pedal in the passenger compartment. It is necessary to interrupt the transmission of torque from the engine to the gearbox to change gears. The clutch also reduces shock, vibration and other loads, protecting the engine and gearbox.

A single-disc clutch consists of the following main elements:

- pressure and driven disk;

- release bearing and its coupling;

- diaphragm spring;

- clutch forks;

Simply put, one side of the clutch assembly is attached to the engine flywheel, and on the other side the gearbox shaft is connected through a splined connection. This clutch is always closed (the discs are pressed against each other). In this case, to open the clutch (in fact, to distribute the pressure and driven disks), the clutch release drive is used.

So, after pressing the clutch pedal in the cabin, the force is transferred to the clutch drive, resulting in the movement of the clutch fork. This fork, in turn, transmits force to the release bearing, which moves, influencing the petals of the diaphragm spring of the pressure plate (clutch basket).

The petals of the spring are pressed, the outer edge of the basket moves away from the pressure plate, and tangential springs also help it press out. As a result, the disks open, and torque from the motor is not transmitted to the box. After the driver releases the clutch pedal, the diaphragm spring exerts force, the pressure and driven disks close, the torque is again transmitted from the flywheel and the transmission of torque to the box resumes.

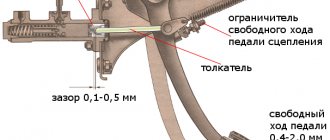

If the car's clutch does not respond well to pedal pressure, problems with the fork should not be ruled out. At the initial stage, you can adjust the free play of the clutch fork, but you must remember that this is a temporary measure. After a short period of time, malfunctions in the clutch on/off mechanism will appear again.

If the clutch is not worn out, and there is no noise or vibration during its operation, and the clutch drive does not cause any other complaints, then the fork is often the source of problems. As a rule, a crack appears on the plug, after which the element is actively damaged.

- To verify that the fork is causing the problem, it is recommended to inspect the mechanism. To do this, the car is driven into a pit or raised on a lift, then the dirt boot is moved, which covers the clutch fork. Having adjusted the lighting (control lamp, flashlight, etc.), it is possible to inspect the plug.

- If cracks and obvious defects are visible, then they will be noticeable. Often the fork cracks in the part where the part transitions into a smooth flat surface of the part where it transitions into a flat plane. However, even if there are no cracks, the fork may still be severely worn in other places.

- Also, the clutch fork breaks in some cases (when driving, the clutch pedal drops sharply). The fork also bends from mechanical stress, that is, physical deformation of the clutch fork occurs. This occurs as a result of breakdowns of the clutch itself, since in order to bend the part, the force required is quite large.

- The clutch fork legs themselves often wear out. This often happens on cars with high mileage, where the clutch fork has not been changed for a long time. The fork legs directly affect other clutch elements, and defects at the point of their contact with the clutch inevitably lead to malfunctions.

- We also note that even a new fork may have defects, that is, when purchasing spare parts (especially non-original ones), you need to immediately inspect the product for possible defects.

Replacing the clutch fork yourself

As a rule, many car service centers may separately indicate that to replace the clutch fork you need to remove the gearbox. In fact, this is often not the case, and the service simply intends to receive additional income, taking into account the complexity and labor-intensive work of dismantling the checkpoint.

Moreover, if you know how to replace the clutch fork without dismantling the gearbox, you can do all the work yourself in a regular garage. Naturally, the guide below is general, that is, the possibility of such a plug replacement needs to be clarified depending on the specific car model.

Turning will allow you to install a new fork under the pressure spring located on the release bearing hub. Also, for ease of installation, you need to place a special hook under the spring, which you can use to lift the spring and insert a new fork.

To remove the old plug you will need:

- dismantle the clutch slave cylinder. The cylinder is removed along with the rod. After removal, the cylinder is moved to the side along with the hose to which it is attached;

- remove the protective cover from the old fork, remove the fork from the clutch housing. Then you need to inspect the casing and clean it of dirt;

- prepare for installing a new plug. Replacing the clutch fork without removing the box with your own hands does not seem difficult. To do this, you need to find a spherical pin in the clutch housing, under which the fork retainer petals are inserted;

- Next you need to locate the release bearing hub and wire spring. You need to insert the turned fork legs under the spring, and the hook mentioned above is used to tighten the spring.

- after installation, the fork should stand between the spring and the release bearing hub;

- the final stage is the reassembly and installation of all parts that were previously removed to replace the clutch fork;

- After assembly has been completed, you need to check the quality of the clutch by test driving the car. If necessary, you may also need to adjust/bleed the clutch to get the best results.

What's the result?

As you can see, during the operation of the car the clutch fork is subject to wear. Although a high-quality part lasts quite a long time, by 100 thousand km the fork may fail. Even if during the inspection it was not possible to find cracks or other defects, there is a high probability of wear of the paws. In any case, the part requires replacement.

Finally, we note that quite often, along with the clutch fork, the clutch will also require replacement. The area where the fork contacts the surface is also where wear occurs. For this reason, you should make sure in advance that it is advisable to solve the clutch problem only by replacing one fork. Otherwise, you will need to re-disassemble the clutch mechanism, install a release bearing, etc.

The clutch pedal is tight, the clutch is pressed hard: the main causes of the malfunction. Diagnosis of clutch problems and repair. Tips and tricks.

The clutch pedal has fallen: why does this happen? The main reasons why the clutch pedal fails, what should the driver do if the clutch fails.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems have arisen with the clutch: causes and repair of major faults.

How to adjust the clutch pedal, what adjustment is needed for: clutch functions, clutch pedal adjustment (free play and total travel).

Car clutch and design overview: clutch pressure plate, driven disc, release bearing. Types of clutch drives on manual transmissions and manual transmissions.

Car clutch: purpose, types, design, principle of operation. Frequent clutch malfunctions in the vehicle transmission system, signs of problems.

Important Tips and Recommendations

Experienced drivers and mechanics recommend following simple rules to extend the life of the device.

- Do not overpress the pedal. This causes the disc to heat up and can cause it to wear out quickly.

- Use only high-quality brake fluid.

- Check the functionality of the device in a timely manner.

- If extraneous sounds or plugging occur, it is necessary to diagnose the mechanism.

Specialization : Graduated from the State Automobile University, worked for 20 years at GAZ-56, now I drive a Zhiguli.

Source

How to change the clutch fork of a VAZ 2107

Every gearbox has a clutch, but sometimes it fails due to the fork. Its task is to connect and thereby disconnect the torque from the wheels. This is an important thing to do in design.

In principle, all the parts in a car are important and they work together with each other. The motor transmits its torque to the gearbox, and that in turn to the axle. That is why, if something goes wrong, then everything will not work correctly. There is a clutch between the power unit and the gearbox, the quality and serviceability of which affects the speed and smoothness of gear shifting.

The fork itself is designed to help shift gears and often it wears out and needs to be replaced. This is exactly what we will tell you about, but first we will understand the principle of operation, the symptoms of the malfunction, and finally, we will touch on the replacement process.

Clutch check

To check the clutch bleeding, just follow a simple sequence.

- Raise the handbrake all the way.

- Depress the clutch and start the engine.

- Try to change gears, but no extraneous sounds or blockages should appear.

- Engage a random gear and smoothly release the pedal.

- Approximately halfway through the stroke, the engine should begin to twitch and stall. This indicates proper operation of the coupling device.

How does the clutch work?

The clutch, as we have already said, performs a very important function; it connects the gearbox with the engine and its main task is to transmit torque. But in addition to this, its task is to increase the service life of the engine and gearbox by protecting them.

The principle of operation varies, but the most famous and common is frictional. The system is simple, the work occurs using friction. But in addition to it, there is a hydraulic principle system, a fluid that drives the entire system. There is also an electromagnetic system that uses an electromagnetic field to make the entire system work. Combined mechanisms are very rare.

There is a release disk system, which is also called a basket. It's placed between the springs and the flywheel, and in the center of it all is a thrust bearing. There is also a driven disk, which is attached to the clutch, clutches and springs. In addition to all this, there are pedals, levers and the fork itself, but everything listed above is the most important.

If the pedal is released, the driven disk rubs and thereby transmits torque to the box. But if the pedal is pressed, the disc no longer rubs, but instead the fork begins to work, which goes into the flywheel.

Clutch selection

When purchasing a new clutch kit for the VAZ 2107, experts recommend being guided by the following criteria. When assessing the driven disk:

- the surface of the linings must be smooth and uniform, without scoring, cracks or chips;

- all rivets on the disk must be the same size and located at an equal distance from each other;

- there should be no oil stains on the disc;

- there should be no play in the places where the linings and springs are attached;

- The manufacturer's logo must be applied to the product in one way or another.

When choosing a basket, you should pay attention to the following points:

- the casing must be stamped, without cuts or scratches;

- the surface of the disk must be smooth and uniform, without cracks or chips;

- the rivets must be identical and strong.

What is a clutch fork?

The clutch fork (hereinafter referred to as BC) is an important component of the transmission system of any vehicle. Scientifically speaking, this element transmits pressure from the slave cylinder or clutch cable to the release bearing. ensuring the movement of the car. The bearing itself is the transmission component between the clutch and the drive, which is physically located on the release clutch. It is the clutch fork that ensures the movement of the clutch and bearing.

In most cases, VAZ 2107 cars are equipped with a single-plate clutch, the operation of which is ensured by a special drive. Double-disc clutches are usually installed on more powerful vehicles and trucks. But this does not mean at all that the VAZ 2107 cannot have a double-disc element.

In any case, when you press the clutch pedal, the drive ensures the movement of the aircraft, which, in turn, acts on the bearing. The latter, as a result of moving the fork, presses on the petals of the spring element of the pressure plate. The spring bends towards the flywheel, simultaneously disconnecting from the pressure plate, thereby freeing it. At this moment, special tangential springs press the pressure plate, as a result of which the transmission of torque from the vehicle engine to the gearbox unit stops.

When the driver releases the clutch pedal, the pressure plate begins to interact with the driven components as well as the flywheel. At this time, torque is transmitted from the engine to the gearbox, which occurs due to friction forces. This process of clutch functioning is in no way possible without a working fork. The BC for the “classics”, which is 2107, is shaped like a slingshot.

New and old forks for VAZ 2107

When to adjust the clutch drive

- Gear shift violation - positions are engaged with knocking, crackling or extraneous sounds.

- The clutch switch response threshold has been violated. A dip of 25 to 35 mm is considered optimal.

- Increased fuel consumption. If the mechanism is faulty, excess gasoline consumption can be up to 20% of the reference value.

- Knocking out positions. During acceleration of the vehicle, the gears “fly out”.

- Dissonance when revving the engine. When you press the gas pedal, the internal combustion engine spins up, and the car lags behind.

- Clutch lever failures, this also includes an increase or absence of operating play in the system.

- Early or late operation of the mechanism when the pedal is pressed.

Looking for problems

So, you understand that the fork is an important part and that is why you need to be able to determine whether it is faulty or not. The easiest way is knocks and noises, but it also happens that a burning smell appears. This is due to the fact that the disk has undergone deformation for some reason, but sometimes this is due to poor mounting of the engine and gearbox. Your task is to replace this part and improve the fastening.

Parts that are damaged must be replaced. In the event that there is towing, you can immediately blame the cylinders or fluid. Hydraulic fluid has most likely leaked or there are problems with the correct operation of the cylinders. If you have poor pedal response, the problem is most likely a bearing or lever issue. In this case, only replacement will help.

How to change the clutch fork on a VAZ 2106

The mistake is that speeds begin to deteriorate greatly and fork is often adjusted to adjust the free wheel. It moves further away from the compression bearing at the crack, and adjustment is delayed for several days, sometimes even a day, depending on the condition of the fork break.

Typically, this replacement is done by removing the gearbox from the machine, which is time-consuming and time-consuming. However, there is a way to replace the clutch plug

without removing the gearbox, which seems more acceptable to motorists.

The operation of replacing the clutch fork does not apply to the arch complex and is fully capable of any motorist, provided that he is not afraid of work and is confident in his abilities.

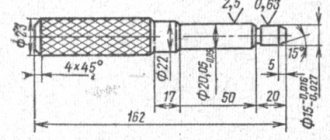

To replace the clutch fork , you need to buy a new fork and treat it in a special way, viz. The ends of the forks must be sanded at an angle (about 45°) so that the plug can be inserted under the clamp spring on the output bearing hub. In addition, for convenience, it is necessary to make a hook to support the wire spring with the thrust bearing when installing the fork.

Before carrying out any work, ensure that the coupling sleeve is properly cracked. To do this, remove the clutch suspension cylinder with the rod and pull it out of the hose to the side. Then remove the protective cap from the plug and use a flashlight or pen.

How to replace the clutch plug without removing the transmission.

how to replace clutch fork

VAZ cars

-2101-2107 without removing the gearbox. full repair teams.

VAZ 2101-2107 Replacing a cracked clutch fork.

2101-2107 Replacing cracks in the clutch fork

.

And this. Show! Please show me how to change

This is

a fork

.

If this crack is not visible, you should place your hand on the fork leg in the direction it is running, which immediately shows where the crack is. Once the plug is cracked, it can be safely removed from the clutch cover window.

In addition, to be conscious when working on the clutch fork, take a look inside the clutch housing again. When you first turn the clutch fork, you will see a spring steel strip in the shape of a rounded "P" that serves to secure the fork to the clutch cover.

Now when you look inside the housing you will see the ball head fork support pin. Therefore, your task. get the fork petal of the castle under this ball.

Let's look further. At the steering shaft input of the transmission shaft, see bearing hub bearing and hub spring. Your task. remove the pointed ends of the fork under this spring so that the fork legs are between the spring and the hub. In this case, first press the clamping fork under the strut head (ball), and then hook the fork under the spring hub bearing.

If you have an old gearbox in your garage, you can practice on it, where all your actions will be clearly visible.

This is of course ideal, but in reality you will have to make several attempts before you can install the plug.

Clutch fork replacement process

The whole system has a fairly important mechanism, this is the clutch fork. Its task is to move the spring from the clutch, thereby turning off the mechanism. If the plug fails, you just need to change it, and this is not so difficult to do. The point is that there is no need to disassemble the box, since everything happens through the hatch.

At the very beginning, you need to initially purchase. Approach this correctly, pay attention to quality and precision. The part must be initially ground down so that the bolts can be tightened without much effort. Then, your task is to start making replacements and you need to do this carefully, since the part can be damaged.

The solution to this problem is divided into two parts, in the first we remove the old part. It is necessary to remove the return spring, then bend the cylinder and finally remove the fork. But very often there is a protective coating that also needs to be removed.

Now we need to insert a new part, but before that we need to insert the spring into the hatch and carefully push it to the end. Now we insert the fork itself and make sure that everything passes by the spring, clutch and bearing without catching them. At the end you will be greeted by a recess with spring petals that should surround the new part. If necessary, you can use a hammer, but it is better to be extremely careful with it. And finally, you need to assemble everything and tighten it well, installing it back afterwards.

Replacing an element

Replacing the aircraft in a VAZ 2107 car can occur in several ways. In the first case, it is necessary to remove the gearbox, which is a rather labor-intensive process that cannot be accomplished by any driver. In the second case, you can change the element without removing the gearbox. Domestic motorists encountered this breakdown so often that they found a simpler way out of this situation.

Therefore, today you will learn how to replace the clutch fork without removing the box. But how can one determine whether the aircraft is really out of order?

How to determine an aircraft malfunction?

It's very easy to do. You just need to pay attention to all the nuances that occur while the car is moving. In particular, this is evidenced by unsatisfactory clutch performance. Often, even after adjusting it, malfunctions appear again after 1-2 days.

New fork for VAZ 2107

There are several criteria that may affect the movement:

Such a breakdown cannot be allowed to continue for a long time. Faults associated with the aircraft must be eliminated as quickly as possible, otherwise the entire system will be subjected to very heavy loads. These loads can either “finish off” the fork or negatively affect the entire clutch mechanism.

Old VAZ fork with a crack

As a rule, in such cases a crack forms on the BC 2107. As a result of its appearance in the vehicle, free movement increases and this, in turn, can affect the inclusion of gearshift lever speeds. In addition, the aircraft freewheel may need to be adjusted. Even when an element jams even slightly, the load on it increases. As a result of an increase in load, the aircraft may simply break, and its components may get caught in the clutch mechanism. Therefore, it is better to carry out work to replace the part immediately after identifying a breakdown.

To understand whether an aircraft replacement is really necessary, you need to go to an inspection pit or overpass. It is necessary to find and remove the protective boot of the fork under the bottom of your car and inspect it. It's best to do this with a flashlight so you can see the crack exactly. As a rule, it forms closer to the place where the part itself goes into the plane.

Tools

Before you begin the process of changing an element, prepare everything you might need. In addition to the new clutch fork, these are:

- set of wrenches;

- mount;

- sandpaper;

- bricks or other supports;

- flashlight.

Read more: Selling gearbox VAZ 2108 2109 used

We change the aircraft with our own hands

As stated above, we will consider the option of replacing the aircraft without dismantling the gearbox, which will greatly facilitate the work of the motorist. However, this will require disassembling the clutch. In addition, you will also have to sand the new element. On the side of the fork where the two ends are located, it is necessary to grind off the ends of the corners a little, about 45 degrees. This must be done so that the edges of the element can fit between the curved edges of the spring component and the so-called release bearing bearing.

- First you need to crawl under the bottom of the car and disconnect the driveshaft.

- After this, you need to disconnect the wiring from the reverse sensor.

- Take a wrench and unscrew the screws securing the clutch casing on the head of the cylinder block (cylinder block) and remove the car bottom cross-member.

- Now take the key to “13” and unscrew the nuts that hold the gearbox mount.

- Take a pry bar or crowbar and move the gearbox to the side opposite the engine until the gearshift lever is at the rear edge of the hole in the bottom of the car. As a result, the vehicle's transmission assembly must be located on the receiving tube. Please note that bricks or other support should be placed under the knot. This is done to prevent the element from slipping.

- After this, you will need to remove the clutch basket from the flywheel of the engine of your “seven”. To do this, you will need to take a crowbar and fix the flywheel in place, and then use a 13mm wrench to unscrew the clutch basket mounting screws one by one.

- After unscrewing the bolts securing the basket, use a crowbar to move it to the side and carefully remove the clutch disc, without putting heavy loads on it.

- Next, you need to align and remove the clutch basket.

- After this, you will have access to the aircraft. Once the basket is dismantled, the damaged aircraft can be pulled out with its protective cover. We take a new part, install it in place of the old one, assembling everything in the reverse order. Remember to then center the clutch disc relative to the crankshaft bearing. If the disc is in the correct position, the frame will slide in and out of the bearing without any problems.

To make sure that you did everything correctly, get behind the wheel and start the car. Pump the clutch pedal several times, then engage all gears one by one. Take a test ride: it is advisable to drive at all speeds, or at least up to four. After this, climb under the car, move away the protective cover of the aircraft and look at it.

Why and how to bleed the clutch on a VAZ 2107 in your garage

The reason for bleeding the clutch is air in the hydraulic system. Air bubbles tend to shrink, which reduces the performance of the device. It’s easy to bleed the clutch in a VAZ 2107 at home. To do this, it is enough to have a set of primitive tools and a little patience.

Motorists prefer to do their own repairs because the procedure is expensive, and performing the entire process on your own is not difficult.

Preparing to bleed the clutch system

To bleed the line and do it correctly, preparation must be done.

- Drive the car onto a viewing hole, overpass or lift, where you secure it.

- Clean the expansion tank cap and fitting from dirt. Garbage entering the system is unacceptable.

Stages of the clutch bleeding process

The procedure is performed in a certain sequence.

- The protective cap is removed from the fitting and the hose is put on it.

- The second end of the tube is lowered into a bottle with TJ previously poured into it.

- Brake fluid is also poured into the expansion tank to the maximum mark.

- Next, the assistant gets into the car and presses the pedal several times; during the last push, you should press the lever to the floor and hold it.

- After this, use wrench No. 8 to unscrew the fitting on the working cylinder and the waste with air bubbles is squeezed out into the bottle. After the pressure has dropped (the pedal has failed), the valve must be closed.

- The procedure is repeated until the air is completely removed from the system.

Replacing the bearing and clutch release fork Hyundai Solaris

Auto News

Cars will become more expensive despite the strengthening of the ruble

Prices for new cars in Russia will increase by 15-20% by the end of 2022, and the strengthening of the ruble will offset the losses incurred by automakers at the height of the pandemic. This forecast was presented by experts and market participants in a conversation with Autonews.ru. 22 May 2020 13:25:00 +0000

There's no way they can sell 4,000 hail-damaged cars in Australia

The world's largest car auction, Mannheim Auctions, has been unable to find a buyer for several months for 4,000 Australian cars damaged by heavy hail in early 2022.

Lada Xray may leave the AvtoVAZ model line

It’s worth noting right away that there has been no official information about the upcoming discontinuation of the Lada XRay.

Sales of new generation KamAZ tractors have started

The Kama Automobile Plant has launched sales of the flagship KamAZ-54901 tractor, which crowns the new K5 line. The initial cost of the car is 7.09 million rubles. The truck is designed for towing semi-trailers on paved roads.

They told how much AvtoVAZ bought the GM-AvtoVAZ joint venture for

Previously, the amount of the transaction for the acquisition of a 50% stake in the GM-AvtoVAZ joint venture was not disclosed. In December 2022, AvtoVAZ bought from its partner, the American concern General Motors, half of the shares of the general enterprise GM-AvtoVAZ, becoming the sole owner of the factory.

Renault presented the updated Kaptur for Russia

Renault has presented the updated Renault Kaptur for the Russian market. Having shared platform components and a turbo engine with Arkana, the crossover received a modified interior, a navigator from Yandex and many other options it previously lacked.

The production of passenger cars in April in Russia fell by 79.2%

The production of passenger cars in Russia, against the backdrop of quarantine restrictions, in April 2022 fell 5 times (by 79.2%) to 30 thousand units, according to Rosstat data.

Volkswagen will begin producing three new models in Russia

Volkswagen will begin producing at least three new models in Russia by 2028. Their production must be mastered within the framework of the SPIC, published in the register of federal special investment contracts for the GIS Industry, which RIA Novosti reviewed.

Replacing the clutch VAZ 2110 2114

First of all, we drove into the pit and removed the engine protection. There shouldn't be any problems here. All the bolts came off with a bang. The oil can be drained to reduce the weight of the box. We will not pull the drive out of it, so there is no need to drain it.

Loosen the front wheels. Unlock both hub nuts and unscrew. It's better not to put the old ones back. Buy new ones. They cost about 70 rubles.

Raise the car and place blocks or sawhorses underneath it. Remove both front wheels.

DO NOT work on a jack without reliable insurance.

Remove the clutch cable from the fork and unscrew it from the bracket located on the box. You will need two 17 keys. For convenience, it is better to remove the battery.

Disconnect the speed sensor connector.

Remove the air filter housing, having first disconnected the chip from the mass air flow sensor.

Unscrew the bolt securing the ignition module to the gearbox and another bolt nearby. It is one of those that connect the gearbox to the engine.

Unscrew the nut on the starter that holds the positive wire. Disconnect the terminal from the traction relay.

Unscrew the upper and lower starter mounting bolts, then remove it.

For prevention, you can treat Bendix with a small amount of lithol and similar lubricant.

There is another bolt at the top that holds the gearbox. It is located in the thermostat area. It is covered by fuel pipes.

This completes the work at the top.

Many people write that the “saber” needs to be removed, but we took a different route. We unscrewed the ball from the hub and the bolt that connects the lever and the stabilizer. Then simply bent the lever down. This method is suitable if the hole allows it and you are not going to completely remove the gearbox.

Move the left hub and remove the drive.

Unscrew the flywheel protective shield. There are three bolts. I don’t know why, but they were different for me. Two were unscrewed with a 10 head and the third with an eight. I still don’t understand.))) Maybe someone can tell me why this is so?

Then disconnect the shift linkage by loosening one bolt. It is recommended to pre-mark the position of the rod to make it easier to adjust the speeds later. I used this advice, but during subsequent setup, for some reason it did not work. This is such additional information)))

Now loosen one gearbox mounting bolt, which is located under the starter (it has already been removed), but not completely.

And another bolt is located in the area of the right drive. We didn't notice it during disassembly and spent a long time trying to figure out why the box wouldn't come out. Take this bolt off too, but don’t unscrew it completely. This required a good extension cord and a reliable head.

Now you need to take a jack and install it under the engine. When we start unscrewing the pillows, the motor will remain on only one and may fall, breaking the heating hoses. Place a small piece of wood between the jack and the engine to prevent damage to the crankcase. It should be installed closer to the checkpoint. It’s also better to put a block under the box, just in case.

When the engine is securely fixed, remove the cushions.

First, let's remove the rear support. You can simply unscrew it from the body. It is held on by two studs, but this method is suitable if you are sure that the nuts will unscrew easily and will not break. We didn’t experiment; we did this: There is a bolt on the pillow itself, it points towards the interior. It needs to be loosened and unscrewed a little. Then disconnect the cushion bracket from the gearbox and move it as far as possible to the side. Maybe this is the wrong way, but the studs remained intact, and we are happy)))

Now unscrew the left pillow of the box. There are two nuts, one at the top and the other at the bottom. The fastening looks like a threaded pin on both sides. Unfortunately I didn't take a photo.

Now the two of you need to move the box away from the engine and lower it onto the bent lever. Do this carefully, without damaging the pipes and wiring. The box is heavy, about 30 kg if I'm not mistaken. We had enough))).

When you move the gearbox, make sure that its guides do not fall out. They are located in the lower holes of the gearbox mounting. They look like tubes.

The box will move back about 10 - 15 cm. This is enough to replace the clutch basket and disc, as well as the bearing and fork.

When we moved the box away, we saw that three petals of the basket had fallen inside. It immediately became clear that it was due for replacement.

Let's start removing the basket. It is bolted to the flywheel with six 8mm bolts. For us, they were unscrewed with great effort. I had to use leverage. Before unscrewing, secure the flywheel from turning. To do this you will need a screwdriver or something similar.

Having unscrewed the basket and taken out the disk, we decided to change both.