The main purpose of the clutch master cylinder is that it transmits force to the slave cylinder from the clutch pedal using working fluid.

If the master cylinder is faulty, vehicle control will be impaired and it will be impossible to disconnect the transmission from the engine.

How to determine if the clutch master cylinder is faulty:

- Periodically check the level of working fluid in the tank. A sharp decrease in it will indicate a system malfunction;

- check for leaks in the main and working cylinder housings;

- failure of the clutch pedal, which occurs due to the entry and accumulation of air in the clutch system;

- underpressure of the pedal and vibration of the gear shift lever.

Main types of faults:

- there is a leak in the master cylinder;

- cuff wear;

- piston wear;

- the inside of the case is damaged (chips, scratches, etc.);

- For all classics of the Auto VAZ family, the clutch device is the same, including for 2107. The sequence of actions is the same.

There are two ways to eliminate a malfunction of the master cylinder - replacement with a new one and repair. What can be repaired:

- replace rubber cuffs;

- frame.

These actions do not always lead to the desired effect, especially on an old car with decent mileage. It is recommended to replace the master cylinder with a new one. Its cost is not high, approximately from 450 to 500 rubles. It's better to buy the original.

Replacing the clutch slave cylinder VAZ 2107

On cars, in addition to the master and slave brake cylinders, there are also clutch cylinders. Many do not even know the purpose of these devices, as a result of which the failure of one of the mechanisms forces the car owner to visit the nearest service station and pay decent money for minor repairs. In this material we will pay attention to such a device as the VAZ 2107 clutch slave cylinder, what it is, where it is located and why it breaks.

What is a hydraulic drive

The clutch in a car is controlled using a pedal. The force from it to the disk can be transmitted in two ways:

- Using a cable.

- Hydraulic drive.

The simplest and most common is the first method, while the “seven” uses the second. Its essence, without going into details, is as follows.

The hydraulic drive consists of two cylinders connected by tubes and hoses. It is designed so that pressing the clutch pedal leads to a significant increase in pressure in the system. It is mechanically transmitted to the driven disk and disconnects the transmission from the engine. The key elements of the system are two VAZ-2107 clutch cylinders: the main and the slave. One of them transforms the force acting on the pedal into excess pressure in the system tubes, the other does the opposite work, acting on the driven disk.

Device location

To find the clutch slave cylinder on a VAZ classic, you need to look for it directly in the area where the gearbox is located. The device is attached with two bolts to the gearbox housing.

The mechanism can only be seen from below or in the very depths of the engine compartment on the driver’s side. Repair work related to dismantling and replacing the clutch slave cylinder can be carried out “from under the hood,” but it is much more convenient from an inspection hole or on an overpass. The video below shows the location of this unit. What function does this product perform and is it possible to do without it? We'll find out more about this later.

Features of operation

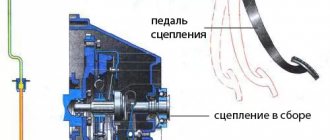

The operating principle is very simple. Below is a diagram where the slave cylinder is indicated by a green arrow.

According to this diagram, we can say that the RCS performs an important function, or rather, it activates the fork, which is connected to the clutch drum. The main element of the RCS, or rather the piston, is activated by the resulting fluid pressure coming from the main cylinder through the hose when the clutch pedal is pressed. The brake fluid pushes the piston, which in turn drives the fork, which acts on the drum, pushing the disc away from the flywheel. Many people wonder why brake fluid is used in the system? The reason is that brake fluid is incompressible, which is why it is used in such important systems as brakes and clutches.

When to replace the RCS

During the use of the unit, which happens very often, the product tends to fail. The main causes of breakdowns are chafing and wear of the cuffs, the appearance of cracks in them, which entails the leakage of liquid. Significant loss of fluid will cause the clutch system to malfunction. It is possible to repair a DCS that has become unusable, but it is easier and more efficient to replace it with a new one.

In order not to wait until the pressure in the clutch pedal disappears, you need to periodically inspect the unit. If there is a leak in the fuel fluid, it is necessary to immediately carry out the appropriate repairs on the VAZ 2107. Before carrying out repairs, you need to make sure that this particular element is faulty, since the main circulation system may also fail. The main signs of failure of the RCS are:

- decrease in the level of fuel fluid in the tank;

- visible brake fluid leaks from the device body or from under the rubber boot;

- “failures” of the clutch pedal, which can be periodic or constant;

- difficulty changing gears.

But most often the malfunction is determined by detecting a brake fluid leak.

Features of replacing the RCS

Replacing the VAZ 2107 clutch slave cylinder begins with the need to remove all fluid from the reservoir. Further actions are carried out in order:

- First you need to loosen the fastening nut that connects the hose to the cylinder. There is no need to unscrew the nut completely, just loosen it at this stage.

- Using pliers, you need to remove the tension spring.

- After this, you should unclench the cotter pin and remove it from the tip of the pusher.

- Using a key set to “12”, you need to unscrew the two bolts that secure the product to the gearbox housing.

- After unscrewing the bolts, you can disconnect the bracket from the cylinder, which is intended to secure the spring.

- Holding the working cylinder body, you should dismantle it. During dismantling, pay attention to the pusher, which is located in the fork.

- After disconnecting the product from the crankcase, you can continue unscrewing the nut connecting the hose to the device. After unscrewing the nut, brake fluid will begin to flow out of the hose, so you should prepare a special container in advance.

After the device is dismantled, it should be replaced with a new one, since repairing it is irrational. The cost of the product is insignificant, so it is easier to replace it with a new one than to try to carry out repairs. Installation of the product is carried out in the reverse order of removal. After installation, it is necessary to carry out the system bleeding procedure. In conclusion, it should be recalled that regular car maintenance helps prevent various unforeseen consequences along the way, such as the “disappearance” of the clutch.

Source

Replacing the clutch slave cylinder on a VAZ 2101-VAZ 2107

Welcome! Clutch slave cylinder - not all people know what it is, but still from time to time you have to replace it, but how can you replace it if not everyone knows what it is? In short. In the car we are currently considering a classic, there are two clutch cylinders, one of which is the main one and the other is the worker. They perform almost the same function; when you press the clutch pedal, the piston (Indicated by a green arrow) which is located inside the clutch master cylinder moves and thereby pushes the brake fluid further.

What reasons will indicate a malfunction?

The following signs will help you understand that the clutch master cylinder is malfunctioning:

- a sharp decrease in the level of working fluid in the tank;

- traces of leaks in the area where the working and main cylinders are located;

- a kind of “failure” when pressing the clutch pedal;

- inability to fully press the clutch pedal.

Among the main types of malfunctions noted by experts, it is worth highlighting the following:

- malfunction of the cylinder itself;

- worn cuffs or piston;

- filling the system with low-quality brake fluid, which may contain both numerous dust particles and an excess of moisture.

To eliminate the causes of the malfunction of the main element, it is time to use two methods - replace the one that has become unusable with a new one or eliminate a minor breakdown by repairing it yourself. However, it is worth understanding that only rubber cuffs and the body can be repaired, and besides, repairing components will not always give the expected result. It should also be noted that as for the boot, it also needs to be inspected for the presence of large contaminations. According to experts, it is best to completely replace the cylinder, especially since its cost does not exceed 550 rubles.

How to replace the clutch slave cylinder on a VAZ 2101-VAZ 2107?

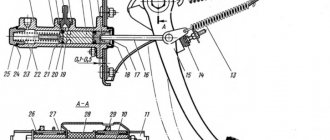

Removal: 1) To remove, first you will need to stock up on a wrench and, using the wrench, loosen the nut that secures the hose to the cylinder.

Note! Please note that you only need to loosen the tightening of this nut, and not completely unscrew it, and then disconnect the hose from the cylinder, this does not need to be done yet, this is just below!

2) Then put the wrench aside, and then use pliers to pull back and then completely remove the release spring from the cylinder.

3) Next, without removing the pliers, straighten and then remove the cotter pin from the hole located in the tip of the pusher of this cylinder.

Note! The cotter pin is one of those parts that is very often lost, so put it in a visible place so that later you can easily find it and install it back!

4) Next, using a wrench, remove the two bolts that secure the cylinder to the clutch housing of the gearbox.

5) Now disconnect the bracket from the cylinder, which was also bolted together with the cylinder itself and which serves to secure the tension spring.

The design and principle of operation of the VAZ 2107 clutch

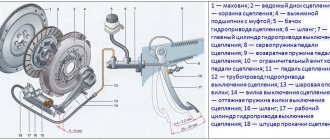

The VAZ 2107 is equipped with a single-plate dry clutch with a hydraulic drive. The drive design includes:

- tank with a stopper and built-in liquid stabilizer;

- suspended pedal with pusher;

- master and slave cylinders;

- metal pipeline;

- hose connecting the pipeline and the working cylinder.

When the pedal is pressed, the force is transmitted through the pusher to the piston of the clutch master cylinder (MCC). The main fluid circulation pump is filled with brake fluid coming from the hydraulic drive reservoir. The piston pushes out the working fluid, and it flows under pressure through a pipeline and a rubber hose into the clutch slave cylinder (CSC). In the RCS, the pressure increases and the fluid pushes the rod out of the device, which, in turn, actuates the clutch fork. The fork, in turn, moves the release bearing, disengaging the pressure and driven discs.

Hydraulic drive installation

Replacing a mechanism involves purchasing it in a retail network or via the Internet. Installation work is performed in the following sequence:

- The clutch master cylinder of the VAZ 2107 is put on the studs and pushed all the way to the base.

- The nuts are screwed onto the fasteners and tightened with a wrench to “13”.

- The union nut of the pipeline laid to the working hydraulic drive is screwed into the main cylinder.

- The rubber tube is connected to a plastic connecting element and secured with a clamp.

- The expansion tank is filled with brake fluid, which enters the main and slave cylinders of the clutch through tubes. Replacing the fluid in the system is mandatory due to wear products.

Clutch slave cylinder VAZ 2107

The RCS is the final link of the clutch hydraulic drive. Its more frequent failure compared to other components of the mechanism is associated with increased loads resulting from high fluid pressure.

RCS device

The working cylinder of the VAZ 2107 consists of:

- housings;

- piston;

- rod (pusher);

- springs;

- protective cap (case);

- two cuffs (o-rings);

- valve for bleeding air;

- retaining ring with washer.

Location of the RCS

Unlike the main circulation center, which is located in the interior of the VAZ 2107, the working cylinder is located on the clutch housing body and is screwed to the bottom of the “bell” with two bolts. You can only get to it from below, after first removing the engine protection (if any). Therefore, all work is carried out on an inspection pit or overpass.

Symptoms of a malfunction of the control center

Failure of the RCS is accompanied by the following symptoms:

- unusually soft clutch pedal travel;

- periodic or constant failure of the clutch pedal;

- a sharp decrease in the level of working fluid in the tank;

- the appearance of traces of liquid under the car in the area of the gearbox;

- Difficulties when changing gears, accompanied by a crunching (grinding) noise in the gearbox.

These symptoms may also be the result of other malfunctions (the entire clutch mechanism, main clutch, gearbox, etc.). Therefore, before starting work on replacing or repairing the RCS, you need to make sure that it is he who is “to blame”. To do this, it should be carefully examined. If traces of working fluid are found on the cylinder body, on its rod or hose, you can begin dismantling the control center.

Main malfunctions of the RCS

The main part of the RCS is made of durable steel, so it is completely replaced only in case of serious mechanical damage. In other cases, you can limit yourself to repairs. Most often, the cylinder fails due to wear of the piston o-rings, protective boot, malfunction of the air release valve and damage to the hose connecting the cylinder and the pipeline.

Repair kit for RCS

Any failed part can be purchased separately. However, when replacing cuffs, it is more advisable to buy a repair kit, which includes three rubber seals and a protective cover. For classic VAZ models, repair kits are produced under the following catalog numbers:

The cost of such a set is about 50 rubles.

Clutch slave cylinder repair

To repair the control center, it must be removed from the vehicle. For this you will need:

- round nose pliers or pliers;

- wrenches 13 and 17;

- container for draining liquid;

- clean dry rag.

Dismantling of the RCS

Dismantling of the RCS is carried out in the following order:

- We install the car on an inspection hole or overpass.

- From the inspection hole, using a 17mm wrench, unscrew the tip of the connection between the hydraulic drive hose and the working cylinder.

Disassembly and replacement of faulty parts of the control center

To disassemble and repair the cylinder you will need:

- wrench 8;

- slotted screwdriver;

- clean dry cloth;

- some brake fluid.

The working cylinder is disassembled in the following sequence:

- We clamp the cylinder in a vice.

- Using an 8-mm open-end wrench, unscrew the air bleed valve and inspect it for damage. If a malfunction is suspected, we purchase a new valve and prepare it for installation.

Before replacing the piston cuffs and protective cover, the metal parts of the cylinder must be cleaned of dirt, dust, and traces of moisture using brake fluid and a clean rag. New seals and a cover are installed during the assembly of the RCS. First, the front cuff is put on the piston, then the rear one. In this case, the back cuff is fixed with a washer. The protective cover is installed together with the pusher. Assembling the device and installing it is done in the reverse order.

Video: repair of the VAZ 2107 clutch slave cylinder

Bleeding the hydraulic clutch

After any work related to depressurization of the clutch mechanism, as well as when replacing the fluid, the hydraulic drive must be pumped. For this you will need:

- brake fluid (0.3 l);

- rubber hose;

- key to 8;

- a vessel for collecting liquid (a 0.5 liter plastic bottle is suitable).

In addition, you will need an assistant for pumping. The procedure is as follows:

- After installing the control center and connecting the hose to it, fill the hydraulic drive reservoir with liquid to a level corresponding to the lower edge of the neck.

- We put one end of a pre-prepared hose onto the valve fitting to bleed air, and lower the other end into a container to collect liquid.

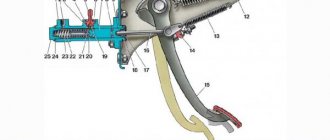

Setting the clutch drive

After bleeding, it is recommended to adjust the clutch drive. For this you will need:

- a caliper or (as a last resort) a ruler;

- wrenches 8, 10, 13, 17;

- round nose pliers or pliers.

The procedure for setting the clutch on carburetor and injection VAZ 2107 models is different. In the first case, the clutch pedal free play setting is adjusted, in the second - the amplitude of movement of the working cylinder rod.

For carburetor VAZ 2107, the drive is configured as follows:

- We measure the amplitude of free play (play) of the clutch pedal using a caliper. It should be 0.5–2.0 mm.

- If the amplitude goes beyond the specified limits, use a 10mm wrench to unscrew the locknut on the travel stop pin and, turning the stop in one direction or another, set the required backlash.

For injection VAZ 2107, the drive adjustment is carried out in the following order:

- We install the car on an inspection hole or overpass.

- Using pliers from below, remove the tension spring from the clutch fork.

- We determine the backlash of the working cylinder pusher by pressing the clutch fork all the way back. It should be 4–5 mm.

- If the play does not fall within the specified interval, use a 17 wrench to hold the rod adjustment nut, and use a 13 wrench to unscrew the fixing nut.

Dismantling the hydraulic drive

To perform the operation we will need:

- container for operating fluid and a large-volume syringe.

- set of wrenches and sockets;

- screwdriver and pliers.

The order of work is as follows:

- Brake fluid is pumped out from the expansion tank of the master cylinder of a VAZ 2107 car using a syringe. A rubber tube is disconnected from the drive, from which the remains are also poured into the prepared container. If liquid gets on paint surfaces, they must be wiped with a damp cloth.

- Using an open-end wrench set to “10”, unscrew the fitting of the pipeline connecting the main and working hydraulic drives.

- Using a “13” socket and an extension adapter, unscrew the nuts holding the assembly to the engine compartment panel.

- To remove the master cylinder from the studs, simply press the clutch pedal, this will move it out of place, after which you can pull it out by hand.

The work on removing the unit is completed, and you can begin installing the spare part.