Clutch design and operation

The clutch is single disc, dry, permanently closed, with a central pressure diaphragm spring and a torsional vibration damper on the driven disk.

The leading part of the clutch is a non-separable assembly placed in the crankcase 7 and includes casing 1 (Fig. 60), pressure plate 4, pressure spring 2 and a number of other parts. This unit is attached to the flywheel with 6 bolts 8. Between the flywheel and the pressure plate on the splines of the drive shaft 9 of the gearbox there is a driven disk 5 with friction linings, which is connected to the hub through a torsional vibration damper.

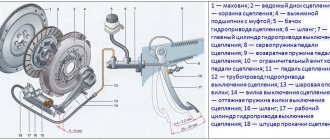

Rice. 60. Clutch:

1 — clutch casing; 2 - pressure spring; 3 - stepped rivet; 4 — pressure disk; 5 — driven disk; 6 - flywheel; 7 — clutch housing; 8 - bolt; 9 — drive shaft of the gearbox; 10 — clutch release bearing clutch; 11 — clutch release fork; 12 — ball joint fork; 13 — clutch release bearing; 14 — thrust flange of the pressure spring; 15 — clutch release fork cover; 16 - spring; 17 — support ring of the pressure spring; 18 — clutch release fork pusher; 19 — adjusting nut; 20 - lock nut; 21 — protective cap; 22 — clutch release cylinder (working); 23 — fork release spring; 24 — spring bracket; 25 — fitting for bleeding.

The clutch release bearing 13 acts on the petals of the pressure spring through the thrust flange 14, which is connected to the clutch housing through connecting plates and rivets 3.

The clutch drive is hydraulic. The clutch master cylinder is mounted on bracket 11 (Fig. 61) of the clutch and brake pedals, and the slave cylinder 22 (see Fig. 60) is mounted on the clutch housing.

Rice. 61. Pedal and clutch release master cylinder:

1 — main cylinder body; 2 - compensation hole; 3 — fitting gasket; 4 - fitting; 5 — lock spring washer; 6 — piston of the main cylinder; 7 - seal; 8 — pusher piston; 9 - hook; 10 — axis of the clutch and brake pedals; 11 — bracket for clutch and brake pedals; 12 — clutch pedal reinforcing spring (servo spring); 13 — clutch pedal release spring; 14 — clutch pedal travel limiter; 15 — clutch pedal; 16 — pusher; 17 — protective cap; 18 — retaining ring; 19 — bypass hole; 20 — sealing ring (ring valve); 21 — piston bypass hole; 22 — working cavity of the cylinder; 23 - spring; 24 - gasket; 25 - plug; 26 — inner pedal bushing; 27 — outer pedal bushing; 28 — spacer sleeve; 29 — brake pedal.

A pusher 4 rests against the piston 13 (Fig. 62), the working length of which is adjusted by a nut 5.

Rice. 62. Slave cylinder and clutch release fork:

1 — clutch release bearing; 2 — ball joint; 3 — clutch release fork; 4 - pusher; 5 — adjusting nut; 6 - lock nut; 7 — tension spring; 8 — housing plug; 9 — fitting for bleeding; 10 — cylinder body; 11 - sealing ring; 72-protective cap; 13 - piston; 14 - seal; 15 - plate; 16 - spring; 77 — support washer; 18 — retaining ring.

When the clutch is released, the force from the pedal 15 (see Fig. 61) through the pusher 16 is transmitted to the pistons and 6, which, moving in the main cylinder, compress the spring 23. In this case, the front o-ring 20 covers the compensation hole 2, and the cylinder cavity is disconnected from tank. Liquid under pressure through a tube and hose enters the cavity of the working cylinder, moving the piston (see Fig. 62) and pusher 4. Rotating relative to the ball joint 2, the fork moves the clutch release bearing clutch, which, through the bearing and thrust flange 14 (see Fig. 60) bends the pressure spring on the support rings 17. The outer edge of the spring through the clamps removes the pressure disk 4 from the driven disk 5 and the transmission of torque to the gearbox stops.

When the pedal is released, all parts return to their original position under the action of springs. O-ring 20 (see Fig. 61) moves away from compensation hole 2 and restores communication between the cavities of the main cylinder and the tank.

From July 1972 to November 1978, the vehicles described were equipped with a clutch and brake pedal bracket manufactured specifically for these models. Since December 1978, a bracket unified at the mounting location has been installed, which made it possible to install a bracket with or without a vacuum booster on the same body. The clutch pedal from a VAZ-2103 is installed on standardized brackets.

The dimensions of the main mating parts of the clutch and the limits of permissible wear are given in table. 6.

Source

The clutch is one of the most important parts of a car; if the clutch fails, it becomes almost impossible to use the car.

Installing the clutch master cylinder repair kit

It is not difficult to determine when it is necessary to repair the master cylinder; the main signs of its malfunction are:

- Insufficient clutch release (clutch drives)

- Any type of leakage, whether from under the nuts securing the hose and tubes, or from the end from under the rubber seals

- Master cylinder stuck in pressed position

In my situation, the main leak was due to a worn out sealing ring, in other words, fluid flowed down the clutch pedal into the passenger compartment.

I started the repair by dismantling the reservoir hose, unscrewed the clamp on the main cylinder and quickly removed it from the main cylinder, turned it up and pinched it behind the reservoir cap so that the liquid did not flow out of the reservoir. Next, I unscrewed the tube that goes to the working cylinder, I did this with a special key, it’s a pity there is no photo, but you can buy one without any problems at any auto store. All that remains is to unscrew the main one itself, it is secured with two 13 nuts and remove it from under the hood.

The boot was removed and it was noticeable that fluid was flowing from here.

Having picked up the boot with a screwdriver, I saw exactly where the liquid was flowing from; the assumption was absolutely correct.

Next, you need to wipe the cylinder, remove dirt and rust.

Attention. Do not use gasoline or similar liquids for washing, as they will very quickly ruin the new rubber bands. To flush the clutch and brake elements, use clean brake fluid.

After cleaning the dirt, you can begin disassembling. To do this you will need an awl or similar object.

Next, you need to carefully remove the insides, keeping in mind that the piston is under the action of a spring.

Next, you need to clean the master cylinder body, you cannot scrape the parts with a screwdriver, sandpaper, etc., this is just in case, I use a rag with brake fluid. In repair manuals, I often came across such expressions that if rips, scratches, etc. appeared on the parts, then it is unusable. But despite all this, practice shows that despite all the risks, provided that a high-quality repair kit is installed, the master cylinder works without problems. I used this kit:

Repair kit for clutch master cylinder VAZ

We remove the old rings, clean all the grooves and holes. There should be no dust or debris there.

The ring is removed, clean the piston, install a new one

And by the way, here is the reason for the clutch cylinder leaking:

The ring is not worn evenly

After cleaning and replacing the rings, you can assemble the cylinder, below is a photo of what should be there and how:

Here is a photo not cleaned, I added it here to show the correct assembly

Having assembled the cylinder, install the corkscrew ring

Bleeding the clutch on a VAZ 2106

After the repair has been made, it is necessary to bleed the clutch. In all repair manuals you can find standard instructions for bleeding the clutch, but it may not always help.

- The first bleeding option is standard; it consists of filling the tank with liquid, unscrewing the bleeding fitting, putting a hose on the fitting, and lowering the other end into a container with clean liquid. Then, by pressing the pedal, we monitor when the air stops being released, and also do not forget to control the level in the tank.

- The second method is to use an assistant - one person presses the pedal 4-6 times and keeps it pressed to the floor. The second unscrews the bleeder fitting; air bubbles should come out of the fitting; as soon as they stop coming out, you need to screw the fitting in and then release the pedal. And so on until normal operation of the pedal is restored and air bubbles stop coming out.

- There is also the simplest method of pumping, but which does not always work - to implement it you just need to pour liquid into the reservoir and unscrew the fitting on the working cylinder. The liquid will flow by gravity through the entire system and when it begins to flow steadily out of the fitting, it can be closed and the pumping can be considered complete.

Source

Basic faults

It should be noted right away that the driven disk and release bearing are consumables, the long service of which should not be counted on. The integrity of the flywheel is much more important; its price is much higher and replacement is more difficult.

The main clutch malfunctions on a VAZ:

- Difficulty changing gears;

- Clutch slips;

- Jerks during operation;

- Vibration during operation;

- Creaking and other extraneous sounds during operation;

- The clutch doesn't work.

Difficult gear shifting means that the clutch does not disengage completely, that is, the driven disc continues to turn when the pedal is pressed. There may be several reasons for this situation:

- There is a problem with the driven disk: it began to jam on the splines of the input shaft, or the fixing rivets began to come out of their seats and cling to the flywheel and pressure plate, or the damping springs failed;

- Problem with the release bearing: it is too far from the clutch basket, as a result it does not press it with enough force;

- Hydraulic problem: low fluid or air lock.

Once the cause has been found, you can solve the problem: replace the driven disk, troubleshoot the input shaft, install the release bearing at the required distance from the clutch basket, add hydraulic fluid and bleed the system.

Clutch slipping is the asynchronous movement of the flywheel and driven disk when the clutch is fully engaged (when the pedal is not pressed). Causes:

- Oil has got onto the working surface of the driven disk;

- The problem is with the release bearing: it fits against the clutch basket and presses on the spring;

- The clutch drive requires adjustment;

- The bypass channel in the master cylinder is clogged;

- The clutch pedal does not move back.

Depending on the problem, the solution will be appropriate: checking and replacing oil seals from which oil may leak, adjusting the clutch, repairing and cleaning the master cylinder.

Jerking and vibration when the clutch operates is a rather unpleasant sign. Possible causes of jerking when moving:

- The disc is jammed on the gearbox shaft splines. In this case, it cannot move freely along them, which means there will be no “soft docking” with the flywheel;

- Problem with the basket and drive disk. With prolonged use, the springs wear out and the drive disk becomes deformed;

- The driven disk is worn;

- The drive requires adjustment.

With such a problem, diagnostics is needed. In the best case, everything can be done by replacing the driven disk; in the worst case, the entire clutch will have to be changed.

If, when engaging or disengaging the clutch, you hear grinding, rattling, knocking and other sounds that should not be there, this may be a manifestation of the following problems:

- The bearings are jammed - pressure or drive shaft. This may be due to wear and tear over time or lack of lubrication. In this case, the sound appears when the clutch is engaged;

- There is a problem with the driven disk - the springs or splines connecting to the gearbox shaft are worn out. Knocking and rattling noises appear when you press the pedal;

- The clutch fork return spring does not work.

After diagnosis, broken parts must be replaced with new ones. If the problem is in the spline connection of the driven disk, it is necessary to check the condition of the gearbox shaft.

And finally, if you release the pedal and the clutch does not engage, the reason must be sought in the hydraulics:

- Airlock;

- Insufficient hydraulic fluid;

- The clutch cylinder seals are worn out.

The easiest way is to add fluid to the reservoir and bleed the clutch system. If the problem is not solved, it is necessary to dismantle the master and slave cylinders and replace the repair kits.

Clutch drive system

There are only two main components in the VAZ-2106 clutch system. The clutch master cylinder allows pressure to be created in the pipes using the driver's muscular strength. The worker acts on the fork, which drives the release bearing. Briefly, the operation of the entire system can be described as follows:

- When you press the pedal, the rod in the master cylinder moves. Since the system is closed, the pressure rises sharply.

- Under the influence of this pressure, the piston is extruded in the working cylinder, which is installed on the clutch housing.

After releasing the pedal, the reverse process occurs:

- When the pedal is released, the master cylinder rod returns to its initial position, as a result of which the volume inside the system increases and the pressure decreases.

- A return spring acts on the working cylinder, which allows the rod to move to its initial position.

- The system has an expansion tank into which liquid is filled.

DOT-3 type brake fluid is used as the working fluid. It contains many additives, they contribute to the normal operation of the mechanism. These additives have a beneficial effect on the metal and allow the cylinders to cool better.

Try to fill the system only with those fluids recommended by the manufacturer. Effective operation depends directly on the quality of the liquid that is poured into the system. Never allow the level to drop to the minimum level. Add fluid if necessary.

Which one is better to put

On the VAZ 2101 it is necessary to install a hydraulic clutch designed for the VAZ 2101–07. Cylinders designed to work in UAZ, GAZ and AZLK vehicles are not suitable for installation on a “penny” car. The situation is similar with imported analogues. It will be quite problematic to introduce a GVC from any foreign car, which is due to different mounting of the unit, different threads and tube configuration. However, a hydraulic drive from a VAZ 2121 or from a Niva-Chevrolet is suitable for the “classic”.

Manufacturer's choice

Today there are many companies that manufacture clutch master cylinders. However, when choosing and purchasing the unit in question, preference should be given to the following manufacturers:

When choosing GVCs, it is better to give preference to well-known manufacturers

The average cost of a hydraulic clutch is 500–800 rubles. However, there are products that cost about 1,700 rubles, for example, cylinders from ATE.

VAZ cars: repair, maintenance, tuning

Failures in the clutch operation of the classic VAZ 2107 - VAZ 2101 must be eliminated immediately. The clutch hydraulic drive system is not too complicated, maintenance work does not take much time, so removing, disassembling and repairing the VAZ clutch master cylinder will not be difficult even for novice drivers. Let’s find out how to deal with problems in the VAZ clutch right now.

Bleeding the system

The design of the VAZ-2106 clutch master cylinder is approximately the same as on a similar element of the brake system. Pumping is done in the same way:

- The entire system is assembled, threaded connections are tightened.

- Liquid is poured into the expansion tank to an average level.

- A tube is put on the bleeder fitting and lowered into a small container with brake fluid.

- An assistant presses the clutch pedal several times and then locks it in the pressed position.

- At this time, unscrew the bleeder fitting a little so that the air comes out.

Repeat the last two steps several times until air stops escaping from the system. Be sure to monitor the brake fluid level. Otherwise, the mechanism will run dry, and it may be necessary to disassemble the VAZ-2106 clutch master cylinder for repair.

Dismantling the hydraulic drive

Replacing the clutch slave cylinder

To perform the operation we will need:

- container for operating fluid and a large-volume syringe.

- set of wrenches and sockets;

- screwdriver and pliers.

The order of work is as follows:

- Brake fluid is pumped out from the expansion tank of the master cylinder of a VAZ 2107 car using a syringe. A rubber tube is disconnected from the drive, from which the remains are also poured into the prepared container. If liquid gets on paint surfaces, they must be wiped with a damp cloth.

- Using an open-end wrench set to “10”, unscrew the fitting of the pipeline connecting the main and working hydraulic drives.

- Using a “13” socket and an extension adapter, unscrew the nuts holding the assembly to the engine compartment panel.

- To remove the master cylinder from the studs, simply press the clutch pedal, this will move it out of place, after which you can pull it out by hand.

The work on removing the unit is completed, and you can begin installing the spare part.

Bleeding the clutch

In order to eliminate the possibility of failure of the clutch mechanism, the hydraulic drive system must be pumped after the repair is completed. To carry out the procedure, the car must be placed on an overpass or inspection hole, and the following must be prepared:

- brake fluid;

- wrenches for loosening brake pipes;

- rubber tube of suitable diameter;

- transparent container.

What kind of liquid to fill

For classic Zhiguli cars, the factory recommends using RosDot 4 brake fluid in the hydraulic clutch system. A 0.5 liter container will be sufficient for repairs. The need to fill the fluid may arise not only during repair work, but also when replacing the fluid itself, since over time it loses its properties.

It is recommended to fill the clutch system of classic Zhiguli cars with RosDot 4 brake fluid.

How to bleed the clutch

It is better to do the work with an assistant. The liquid level in the tank should be below the neck. We perform the following steps:

- We pull one end of the hose onto the fitting of the clutch slave cylinder, and lower the other into the container.

- An assistant presses the clutch pedal several times until it becomes tight and holds it down.

An assistant in the cabin presses the clutch pedal several times and holds it in the pressed position.

We unscrew the fitting and drain the liquid with air into the container, after which we tighten the fitting.

To bleed the hydraulic drive system, you need to unscrew the fitting and release the liquid with air bubbles

- We repeat the procedure several times until the air is completely removed from the system.

Video: bleeding the clutch on classic Zhiguli cars

During the pumping process, fluid will leave the clutch reservoir, so its level must be monitored and topped up as necessary.

In the process of bleeding the clutch, you need to monitor the fluid level in the reservoir and top it up in a timely manner.

To bleed the clutch or brake system, I use a transparent tube, which allows you to visually assess whether there is air in the fluid or not. There are situations when you need to bleed the clutch, but there is no assistant. Then I unscrew the fitting on the clutch slave cylinder, unscrew the reservoir cap and throw a clean cloth, for example, a handkerchief, over its neck, create pressure with my mouth, i.e. I simply blow into the reservoir. I blow it several times to bleed the system and completely remove air from it. I can recommend another fairly simple pumping method, in which the liquid passes through the system by gravity, for which it is enough to unscrew the fitting on the working cylinder and control the liquid level in the tank. When the air is completely released, tighten the fitting.

Failures of the VAZ 2101 clutch master cylinder are a rare occurrence. If problems do arise, they are associated with damage to the boot or the use of low-quality fluid. If the mechanism malfunctions, you can restore functionality on your own. To carry out repair work, you need to prepare the necessary tools and read the step-by-step instructions, which will eliminate possible mistakes.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.