Clutch problems can cause serious trouble for owners of cars with a manual transmission. The VAZ 2107 is no exception. However, most faults can be quite easily fixed with your own hands.

- Clutch slave cylinder VAZ 2107

RCS device - Location of the RCS

- Symptoms of a malfunction of the control center

- Main malfunctions of the RCS

- Repair kit for RCS

- Dismantling of the RCS

Video: repair of the VAZ 2107 clutch slave cylinder

The design and principle of operation of the VAZ 2107 clutch

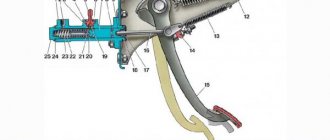

The VAZ 2107 is equipped with a single-plate dry clutch with a hydraulic drive. The drive design includes:

- tank with a stopper and built-in liquid stabilizer;

- suspended pedal with pusher;

- master and slave cylinders;

- metal pipeline;

- hose connecting the pipeline and the working cylinder.

When the pedal is pressed, the force is transmitted through the pusher to the piston of the clutch master cylinder (MCC). The main fluid circulation pump is filled with brake fluid coming from the hydraulic drive reservoir. The piston pushes out the working fluid, and it flows under pressure through a pipeline and a rubber hose into the clutch slave cylinder (CSC). In the RCS, the pressure increases and the fluid pushes the rod out of the device, which, in turn, actuates the clutch fork. The fork, in turn, moves the release bearing, disengaging the pressure and driven discs.

The VAZ 2107 clutch has a single-plate dry design with a hydraulic drive

About the causes of cuff malfunctions and how to eliminate them

Among the reasons may be leaks of working fluid due to depressurization, contamination in the hydraulic system, airing, loss of performance characteristics of the working fluid. If such problems are observed and they are related to the brake fluid, then everything can be solved by replacement and bleeding.

More difficult to solve are problems associated with leakage. Often, depressurization occurs due to wear of the seals. First of all, you need to check if there is a leak.

Clutch slave cylinder VAZ 2107

The RCS is the final link of the clutch hydraulic drive. Its more frequent failure compared to other components of the mechanism is associated with increased loads resulting from high fluid pressure.

The slave cylinder is subjected to constant loads and fails more often than other elements of the clutch mechanism.

About replacing the VAZ 2106 clutch master cylinder: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/glavnyy-cilindr-scepleniya-vaz-2106.html

RCS device

The working cylinder of the VAZ 2107 consists of:

- housings;

- piston;

- rod (pusher);

- springs;

- protective cap (case);

- two cuffs (o-rings);

- valve for bleeding air;

- retaining ring with washer.

The clutch working cylinder has a fairly simple design

Location of the RCS

Unlike the main circulation center, which is located in the interior of the VAZ 2107, the working cylinder is located on the clutch housing body and is screwed to the bottom of the “bell” with two bolts. You can only get to it from below, after first removing the engine protection (if any). Therefore, all work is carried out on an inspection pit or overpass.

The slave cylinder is attached to the bottom of the clutch housing

Check out the engine tuning options: https://bumper.guru/klassicheskie-modeli-vaz/tyuning/tyuning-dvigatelya-vaz-2107.html

Symptoms of a malfunction of the control center

Failure of the RCS is accompanied by the following symptoms:

- unusually soft clutch pedal travel;

- periodic or constant failure of the clutch pedal;

- a sharp decrease in the level of working fluid in the tank;

- the appearance of traces of liquid under the car in the area of the gearbox;

- Difficulties when changing gears, accompanied by a crunching (grinding) noise in the gearbox.

These symptoms may also be the result of other malfunctions (the entire clutch mechanism, main clutch, gearbox, etc.). Therefore, before starting work on replacing or repairing the RCS, you need to make sure that it is he who is “to blame”. To do this, it should be carefully examined. If traces of working fluid are found on the cylinder body, on its rod or hose, you can begin dismantling the control center.

One of the signs of a malfunction of the working cylinder is traces of leaks of working fluid on its body

Main malfunctions of the RCS

The main part of the RCS is made of durable steel, so it is completely replaced only in case of serious mechanical damage. In other cases, you can limit yourself to repairs. Most often, the cylinder fails due to wear of the piston o-rings, protective boot, malfunction of the air release valve and damage to the hose connecting the cylinder and the pipeline.

Repair kit for RCS

Any failed part can be purchased separately. However, when replacing cuffs, it is more advisable to buy a repair kit, which includes three rubber seals and a protective cover. For classic VAZ models, repair kits are produced under the following catalog numbers:

- 2101–1602516;

- 2101–1605033;

- 2101–1602516.

The repair kit for the VAZ 2107 clutch slave cylinder includes a protective cover and three cuffs

The cost of such a set is about 50 rubles.

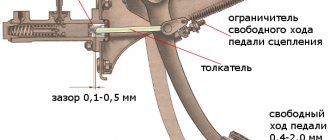

How to check pedal free play

Clutch free play is the period of pedal movement from the moment it is pressed to the moment it is activated. You can notice that when you press the clutch, at first there is no proper resistance, and somewhere in the middle of the stroke an increase in rigidity appears.

If the vehicle starts moving immediately when you touch the pedal, then it is better to make the adjustment urgently, since there is no free play at all. Otherwise, the pedal can be pressed to the floor, but the car does not move.

Free play is required for all manual transmissions, since it indicates clearance between the fork, bearing and disc levers and prevents constant contact of the bearing with other elements of the mechanism. It is important to monitor the size of the free play, because if it is too large, full pressure will not be enough to transmit sufficient force to squeeze the drive disk.

A separate reason for checking free play is noise and jerking when interacting with the clutch. You can measure this indicator yourself using a ruler.

It is necessary to measure the perpendicular distance from the floor to the pressure pad. Next, when you gently press the pedal, you should measure the stroke until resistance first appears. The result must be checked against the data in the vehicle's operating manual.

The general average clutch stroke for a car is 160 mm. It is recommended to carry out preventive maintenance and adjustment every 20 thousand km.

Clutch slave cylinder repair

To repair the control center, it must be removed from the vehicle. For this you will need:

- round nose pliers or pliers;

- wrenches 13 and 17;

- container for draining liquid;

- clean dry rag.

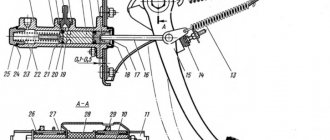

Dismantling of the RCS

Dismantling of the RCS is carried out in the following order:

- We install the car on an inspection hole or overpass.

- From the inspection hole, using a 17mm wrench, unscrew the tip of the connection between the hydraulic drive hose and the working cylinder.

The tip of the hydraulic drive hose is unscrewed with a 17 wrench - We place a container at the end of the hose and collect the liquid flowing from it.

- Using pliers, disconnect the tension spring from the clutch fork and remove it.

The tension spring is removed using pliers - Using pliers, pull out the cotter pin from the cylinder rod.

The cotter pin is pulled out from the cylinder rod using pliers - Using a 13mm wrench, unscrew the two bolts securing the control center to the crankcase.

The clutch slave cylinder is bolted to the crankcase with two bolts - Disconnect the spring bracket and remove it.

The tension spring bracket is mounted on the same bolts as the cylinder - We remove the working cylinder rod from engagement with the fork.

The working cylinder rod is connected to the fork - We remove the cylinder and use a rag to remove traces of working fluid and dirt from it.

What's next?

To bleed, unscrew the cap of the expansion tank. Next, liquid is drawn into the syringe and the air is expelled from it. The hose is connected to the valve at one end, and to the syringe at the other. Unscrewing the valve with a key, press on the syringe and inject liquid. Next, without removing the hose, tighten the valve so that no air gets into it. After this, you need to sit in the cabin and create pressure in the system. To do this, press the clutch pedal several times (but not less than five or six). Then we go under the hood and smoothly unscrew the valve.

If the hose is transparent, you will see airy liquid coming out of it. At the same time, its level in the expansion tank will drop. We need to support him. Therefore, fill in new brake fluid again to the maximum mark. Then the procedure is repeated again. They sit back in the cab and create pressure in the clutch system by pressing the pedal several times. Then unscrew the valve and look at the condition of the liquid. There should be fewer bubbles. The procedure is repeated until the air is completely removed from the system (this is why it is so important to use a transparent hose).

What to consider when choosing

Almost every automaker creates working cylinders exclusively for their cars. Comparing the cylinders from Ssang Yong and Nissan, you can see that they have different shapes, are mounted differently, and the first one even has a release bearing mounted on it. They also probably have different rod lengths and connections to the actuator. So you can choose the right working cylinder in three ways:

- VIN code of the car

. Contact the store and use the transport code when selecting. So you will find both the original cylinder and its analogues. There is zero chance of making a mistake; - Car data

. Their list includes body, make, engine data, year of manufacture. The year of manufacture is especially important. Even within the same line of cars, those produced in different years may have different RCS; - Old part code

. It's very simple: find out the code of the already installed working cylinder and select the same one. It is also possible that in this way you will be able to find compatibility sheets for working cylinders, which will contain the code for an existing part and identical analogues.

In general, the choice will not be difficult. However, you should not forget: even similar external parts may have different “fillings”. Collect as much information as possible, or better yet, search directly by VIN code - you won’t go wrong.

Brand tour

The best option would be an OEM part. It fully meets all quality requirements. It will last a very long time and installs without problems. True, it costs a lot of money.

If your budget is limited, take an analogue. The best are produced by the following companies: LUK, Sachs, TWR (Germany). They are not very different from the originals. They cost significantly less. If the working cylinder of these companies is selected and then installed correctly, it will travel at least 150 thousand kilometers.

Inexpensive analogues are offered by these companies: JP Group (Denmark), Profit (Czech Republic), ABE (Poland). The quality is inferior to both the originals and more expensive analogues from the same LUK. However, you will still save money even if you replace it faster.