Correct and precise operation of the clutch on VAZ 2105, 2107 vehicles is ensured by certain adjustments to its drive. There are two of them: adjusting the gap between the pusher and the piston of the clutch master cylinder and adjusting the free play of the clutch pedal.

The gap between the pusher and the clutch master cylinder piston is 0.1 - 0.5 mm. It is regulated by rotating the clutch pedal free travel limiter. In this case, a certain free play of 0.4 - 2.0 mm is formed at the clutch pedal, which the driver selects when starting to press the pedal.

the gap between the pusher and the piston, free play of the clutch pedal of VAZ 2105, 2107 cars

It is measured with a ruler or tape measure, which is installed from the floor to the middle of the lower part of the pedal platform. We move the platform with our hand relative to the ruler scale by pressing the pedal. If there is a gap, at first the pedal moves very easily, and then with difficulty. If there is no gap, turn the pedal travel limiter out a little. We ensure that the free movement along the ruler fits within the required two millimeters.

This gap is necessary for the clutch to disengage completely. If it is missing, then the piston will not be able to fully return to the rear position when the pedal is released and in the working cavity of the master cylinder, and excess pressure will remain in the entire drive. As a result, the clutch will not disengage completely, since the release bearing will press on the leafs of the pressure spring, and the discs will slip (not be fully pressed against the flywheel). Increasing this gap will lead to the fact that the clutch will not disengage completely and will “drive” (the discs do not fully move away from the flywheel).

Adjusting the clutch pedal free play (the gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring)

It is adjusted by a nut on the clutch slave cylinder pusher. With proper adjustment, the free play of the clutch release fork is 4–5 mm (checked by hand: the fork is pulled away from the stop against the adjusting nut on the pusher), and the free play of the clutch pedal is 25–35 mm. It is necessary to unscrew the lock nut on the pusher and rotate the adjusting nut to set the required free play of the fork. The pedal free play of 25 - 35 mm (until the clutch is disengaged) can be checked using a ruler. It is this value that means there is a gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring.

free movement of the clutch slave cylinder pusher for VAZ 2105, 2107 cars

In the absence of this gap, the release bearing presses on the pressure spring of the “basket” - the clutch “slips”. With an increased gap, it “leads.”

The clutch pedal free play of 0.4 – 2.0 mm is included in the pedal free play of 25 – 35 mm. That is, 25 - 35 mm is the total required size.

Notes and additions

— The clutch on VAZ 2105, 2107 cars is of a constantly closed type, that is, constantly on: when the pedal is released, the driven disk is pressed by the drive disk to the flywheel and rotates with it, as well as the release bearing and the input shaft of the gearbox. There is a gap of 1.5 - 2.0 mm between the release bearing and the lining of the thrust flange of the clutch basket pressure leaf spring. This gap is selected when the driver begins to press the pedal.

— The full travel of the clutch pedal on VAZ 2105, 2107 cars is 140 mm.

— After adjusting the clutch drive, check for smooth gear shifting. Particular attention to reverse gear. The smoothness of its activation is an indicator of successful adjustment.

More articles on VAZ 2105, 2107 cars

The main purpose of the clutch mechanism is to combine the crankshaft with the gearbox and transmit torque from the engine to the wheels of the car. This device is used on the car when switching to a lower or higher gear, as well as when turning on neutral. In order for gear shifting to be carried out easily and smoothly, you will need to properly adjust the VAZ 2107 clutch, which every owner of the 7 should be able to do.

Adjusting the clutch of VAZ 2107, 2105, 2104 cars

Correct and precise operation of the clutch on VAZ 2107, 2105, 2104 vehicles is ensured by certain adjustments to its drive. There are two of them: adjusting the gap between the pusher and the piston of the clutch master cylinder and adjusting the free play of the clutch pedal.

Adjusting the clutch drive of a VAZ 2107, 2105, 2104

— Adjusting the gap between the pusher and the piston

The gap between the pusher and the clutch master cylinder piston is 0.1 - 0.5 mm.

It is regulated by rotating the clutch pedal free travel limiter. In this case, a certain free play of 0.4 - 2.0 mm is formed at the clutch pedal, which the driver selects when starting to press the pedal. The gap between the pusher and the piston, free travel of the clutch pedal for VAZ 2104, 2105, 2107

It is measured with a ruler or tape measure, which is installed from the floor to the middle of the lower part of the pedal platform. We move the platform with our hand relative to the ruler scale by pressing the pedal. If there is a gap, at first the pedal moves very easily, and then with difficulty. If there is no gap, turn the pedal travel limiter out a little. We ensure that the free movement along the ruler fits within the required two millimeters.

This gap is necessary for the clutch to disengage completely. If it is missing, then the piston will not be able to fully return to the rear position when the pedal is released and in the working cavity of the master cylinder, and excess pressure will remain in the entire drive. As a result, the clutch will not disengage completely, since the release bearing will press on the leafs of the pressure spring, and the discs will slip (not be fully pressed against the flywheel). Increasing this gap will lead to the fact that the clutch will not disengage completely and will “drive” (the discs do not fully move away from the flywheel).

— Adjustment of clutch pedal free play

(the gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring)

It is adjusted by a nut on the clutch slave cylinder pusher. With proper adjustment, the free play of the clutch release fork is 4–5 mm (checked by hand: the fork is pulled away from the stop against the adjusting nut on the pusher), and the free play of the clutch pedal is 25–35 mm. It is necessary to unscrew the lock nut on the pusher and rotate the adjusting nut to set the required free play of the fork. The pedal free play of 25 - 35 mm (until the clutch is disengaged) can be checked using a ruler. It is this value that means there is a gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring.

Free movement of the clutch slave cylinder pusher for VAZ 2104, 2105, 2107 cars

In the absence of this gap, the release bearing presses on the pressure spring of the “basket” - the clutch “slips”. With an increased gap, it “leads.”

The clutch pedal free play of 0.4 – 2.0 mm is included in the pedal free play of 25 – 35 mm. That is, 25 - 35 mm is the total required size.

Notes and additions

— The clutch on VAZ 2104, 2105, 2107 cars is of a constantly closed type, that is, constantly engaged: when the pedal is released, the driven disk is pressed by the drive to the flywheel and rotates with it, as well as the release bearing and the input shaft of the gearbox. There is a gap of 1.5 - 2.0 mm between the release bearing and the lining of the thrust flange of the clutch basket pressure leaf spring. This gap is selected when the driver begins to press the pedal.

— The full travel of the clutch pedal on VAZ 2104, 2105, 2107 cars is 140 mm.

— After adjusting the clutch drive, check for smooth gear shifting. Particular attention to reverse gear. The smoothness of its activation is an indicator of successful adjustment.

Source

Hydraulic clutch release - checking and adjustment

1. Place the car on an inspection hole or overpass (see “Preparing the car for maintenance and repair”).

2. Inside the car, check the free play of the clutch pedal, which should be within 0.4-2 mm from the top position of the pedal until the pusher stops in the master cylinder piston. If necessary, we make adjustments. To do this, use a 10 mm

loosen the lock nut of the clutch pedal travel limiter and, by rotating the limiter A, set the required clearance.

3. On a car with an injection system, remove the additional mud guard (see “Splash guard - removal and installation”).

4. Clean the pusher from dirt and apply penetrating lubricant to its threads.

5. Check the free play of the working cylinder pusher, on which the free play of the release bearing depends. To do this, push the clutch fork back all the way by hand, while the free play of the pusher should be within 4-5 mm. If the spring force is too large, then for convenience it can be disconnected from the lever.

6. To adjust the free play of the pusher, 17

mm

to hold the adjusting nut of the pusher from turning, and use a

13 mm

to loosen the locknut.

7. Holding the pusher by the flats from turning it with an 8

mm wrench,

turn the adjusting nut

with a 17 mm

wrench and set the required free play of the pusher (4-5 mm).

8. While holding the pusher adjusting nut, tighten the locknut.

9. In the cabin, we check the total free play of the clutch pedal, which should be within 25-35 mm from its top position before the clutch begins to disengage. If necessary, repeat operations 2-8.

Source

Clutch adjustment in an injection VAZ 2107

The clutch adjustment carried out on the VAZ 2107 injector is somewhat different from the similar operation on the “Seven” with a carburetor engine. The fact is that on vehicles with an injection power plant, an additional shield is installed to protect against mud deposits formed from road dirt. In the frontal projection, the protective casing is secured with bolted connections, and in the rear projection - with 2 self-tapping screws.

To dismantle this protective casing, use an 8-type socket wrench to unscrew the 4 fastening bolts. We also dismantle 2 self-tapping stern fastening screws. To carry out such a technological operation as adjusting the clutch pedal of a VAZ 2107, the following work cycle is required:

- Using a scale ruler, measure the distance from the pedal to the surface of the driver's mat. Using the force of your palm, press the pedal until the resistance force of the reverse action of the pedal begins to act and measure the length of free movement of the pedal. It should be 1-3 mm.

- If the measured value does not fall within the required dimensions, then: loosen the lock nut, give the bolt a rotational movement, carry out an adjustment followed by tightening the lock nut.

After carrying out the adjustment work, tighten the fasteners, after which you need to tighten the locking nut. We turn the pusher until the desired stroke value is determined, and finally tighten the locking nut. Care must be taken to maintain the position of the pusher in relation to the main center coupling.

Upon completion of the adjustment of the VAZ 2107 clutch pedal, it is necessary to clarify that the desired length of free movement is normal. Data for control: the stroke of free movement of the pedal is 1-3 mm. The length from the driver's floor to the pedal is 90 mm.

In this material we will talk about adjusting the clutch on a VAZ 2110 car, define the main situations for carrying out such work, and also tell you about the sequence of performing the work.

How to adjust the clutch

Operating any car involves caring for it. But, without knowing the instructions and doubting the correctness of your actions, you should not climb under the hood of the car. The article will tell you how to adjust the clutch of a MAZ truck.

Clutch device

In a MAZ car, the clutch is dry, double-disc, friction-type with cylindrical springs located along the periphery. It is installed in a cast iron crankcase. It is designed to briefly separate the engine crankshaft from the gearbox, as well as to smoothly connect them while the car is moving away and during further gear changes.

How to adjust the pedal yourself

In the VAZ-2107, the clutch pedal should move completely freely - this increases driving comfort and ensures ease of control. To complete the task, the slave and master cylinders must be adjusted.

From the very beginning, it is necessary to adjust such a parameter as full stroke. Here you will need 2 13 mm keys. The work is done in the salon.

Please note that there is a limiting rod here. It is held in place by two nuts. So:

- one key should be used to hold all the mentioned fasteners;

- using the second, the lowest (located at the base) nut is slightly loosened.

When is it done?

It is necessary to adjust the clutch on a classic after any work related to the clutch. This includes removing the gearbox, replacing the clutch basket or disc, and replacing the clutch slave cylinder. Also, adjustment is made when there is a clear shift in any direction of the clutch disengagement moment. After all, all structural elements gradually wear out, which necessitates such adjustments. Do not forget to bleed the clutch before carrying out work, releasing air from the hydraulic drive.

For reference, let's look at the drive adjustment data from the manufacturer. The pedal free play should be within 25-35 mm. That is, from its top position to the moment when the pusher rests on the clutch fork, there should be exactly this distance. This is checked using a ruler. To do this, bring the ruler to the pedal and press the clutch with your hand. When you feel slight resistance, this is the desired point. If the difference between the top position and the moment of switching on is greater or less, you will have to make adjustments.

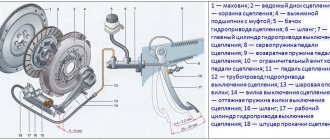

Clutch elements

. Before you start adjusting, you need to decide what and where you need to adjust. In the cabin, the pedal travel is adjusted, sometimes drivers limit themselves to this work, believing that this is enough and if the pedal is adjusted correctly, everything will return to normal. This is partly true. But in practice this does not always happen.

Clutch adjustments

Clutch adjustment is usually carried out after installation work to replace the clutch mechanism. Correct adjustments will make it possible to continue operating the unit components without failure. Before starting these technological operations, it is necessary to test the hydraulic drive system of the unit for the presence of air in it. If there is an “air lock” in the system, it must be removed. In this case, it is better to replace the vehicle's hydraulic fluid.

The principle of carrying out such adjustment measures is to create the required dimensions between the rod and the piston of the mechanism cylinders, as well as the required dimensions between the release bearing and the friction ring on the drive disk of the unit. In the drive mechanism of the unit, the following adjustments are made to the VAZ 2107 clutch:

- Setting the required clearance in the master cylinder (MCC) in the amount of 0.1-0.5 mm in the pusher-piston pair. It is necessary to adjust the clutch to operate in full cycle, which takes place when installing the pedal stop. These dimensions are adjusted by moving the clutch pedal in the free range, which is within the measurement range of 0.4 to 2 mm.

- Setting the required size of movement of the pusher in the working cylinder (WCC) in free mode, which is 4-5 mm. It is achieved by adjusting the nut pair, the top of which is secured with a lock nut. The linear dimension of the pusher movement value is determined by a special standard.

Clutch slave cylinder repair

To repair the control center, it must be removed from the vehicle. For this you will need:

- round nose pliers or pliers;

- wrenches 13 and 17;

- container for draining liquid;

- clean dry rag.

Dismantling of the RCS

Dismantling of the RCS is carried out in the following order:

- We install the car on an inspection hole or overpass.

- From the inspection hole, using a 17mm wrench, unscrew the tip of the connection between the hydraulic drive hose and the working cylinder.

Disassembly and replacement of faulty parts of the control center

To disassemble and repair the cylinder you will need:

- wrench 8;

- slotted screwdriver;

- clean dry cloth;

- some brake fluid.

The working cylinder is disassembled in the following sequence:

- We clamp the cylinder in a vice.

- Using an 8-mm open-end wrench, unscrew the air bleed valve and inspect it for damage. If a malfunction is suspected, we purchase a new valve and prepare it for installation.

Before replacing the piston cuffs and protective cover, the metal parts of the cylinder must be cleaned of dirt, dust, and traces of moisture using brake fluid and a clean rag. New seals and a cover are installed during the assembly of the RCS. First, the front cuff is put on the piston, then the rear one. In this case, the back cuff is fixed with a washer. The protective cover is installed together with the pusher. Assembling the device and installing it is done in the reverse order.

Video: repair of the VAZ 2107 clutch slave cylinder

Bleeding the hydraulic clutch

After any work related to depressurization of the clutch mechanism, as well as when replacing the fluid, the hydraulic drive must be pumped. For this you will need:

- brake fluid (0.3 l);

- rubber hose;

- key to 8;

- a vessel for collecting liquid (a 0.5 liter plastic bottle is suitable).

In addition, you will need an assistant for pumping. The procedure is as follows:

- After installing the control center and connecting the hose to it, fill the hydraulic drive reservoir with liquid to a level corresponding to the lower edge of the neck.

- We put one end of a pre-prepared hose onto the valve fitting to bleed air, and lower the other end into a container to collect liquid.

Setting the clutch drive

After bleeding, it is recommended to adjust the clutch drive. For this you will need:

- a caliper or (as a last resort) a ruler;

- wrenches 8, 10, 13, 17;

- round nose pliers or pliers.

The procedure for setting the clutch on carburetor and injection VAZ 2107 models is different. In the first case, the clutch pedal free play setting is adjusted, in the second - the amplitude of movement of the working cylinder rod.

For carburetor VAZ 2107, the drive is configured as follows:

- We measure the amplitude of free play (play) of the clutch pedal using a caliper. It should be 0.5–2.0 mm.

- If the amplitude goes beyond the specified limits, use a 10mm wrench to unscrew the locknut on the travel stop pin and, turning the stop in one direction or another, set the required backlash.

For injection VAZ 2107, the drive adjustment is carried out in the following order:

- We install the car on an inspection hole or overpass.

- Using pliers from below, remove the tension spring from the clutch fork.

- We determine the backlash of the working cylinder pusher by pressing the clutch fork all the way back. It should be 4–5 mm.

- If the play does not fall within the specified interval, use a 17 wrench to hold the rod adjustment nut, and use a 13 wrench to unscrew the fixing nut.

How to adjust the pusher on a VAZ-2107

It is also important to adjust the free play of the pusher correctly. For this stage, you need to climb under the bottom - this is where the working cylinder is located in the VAZ-2107.

Take pliers and use them to remove the spring located on the clutch fork. In principle, you can skip this step, but in this case you will need to put in much more effort during adjustment.

Now define free play:

- press the fork with your hand until it stops moving;

- measure the indicator with a ruler;

- release the element;

- record how much it has risen.

If everything is correct, then the move will be no more than 3-5 millimeters. This parameter has a direct impact on the wear rate of such a key part of the VAZ-2107 clutch as the release bearing. If there is no movement, an excessively high load is placed on it. An incorrect indicator indicates the need to adjust the fork. The procedure is as follows:

- fix the lower nut with a 17 wrench;

- Loosen the lock nut with a 13 mm tool;

- clamp the pusher and cylinder rod with pliers;

- lift the bottom nut a couple of turns.

Next, it remains to make sure that the free play of the fork corresponds to the norm and finally secure everything in the correct position. After the spring is returned to its place, it is advisable to double-check whether the previously set values on the pedal have been violated.

How to adjust the clutch on a VAZ 2106

Welcome!

Clutch adjustment - thanks to this small procedure you can reduce the risk of wear of clutch parts such as the release plate, but only if the clutch is not adjusted, if it is adjusted, then if it works correctly, the risk of wear of clutch parts will be minimal during moderate driving. Therefore, if your clutch is not adjusted, we recommend that you read this manual so that you can adjust it in the future.

To make adjustments, you will need to stock up on: A basic set of wrenches, and for more correct adjustments, it is recommended to take a ruler or square with you.

You will also need to use: Cobra-type pliers and pliers!

Where are the clutch slave and master cylinders, which are used to adjust the clutch?

The slave cylinder can be easily seen by looking under the bottom of the car; it is located at one end on the gearbox itself and the other end is inserted into the clutch fork; for more details on the location of the slave cylinder, see the photo below:

Diagnosis of clutch faults VAZ 2107

There are a number of breakdowns that indicate that the car requires urgent repairs.

Clutch slipping

This occurs during sudden acceleration. The engine steadily picks up speed, but the car is “late” in accelerating. The process may also be accompanied by jerking, jerking and extraneous noise.

The situation greatly wears out the friction disc and negatively affects fuel consumption.

Clutch leads

This is caused by improper adjustment or airing of the system. The friction linings do not move completely away from the basket and gears are difficult to engage.

Jerks when starting and changing gears

It requires pumping and adjustment of the mechanism, when the car jerks when you put it in gear. The disc may slip at the start or rapid acceleration due to its wear.

Noise when clutch is disengaged

When the car vibrates slightly and an extraneous sound comes out when the pedal is fully depressed, the clutch basket and clutch disc do not completely separate.

This occurs when the device settings fail.

Noise when clutch engaged

The cause and consequences are the same as above.

Pedal failure and lack of clutch

Here the matter is more serious. The pedal can only fail if the mechanism is severely damaged. In 90% of cases, the cause is hidden in the head cylinder or basket. Operating a car with such a problem is strictly prohibited.

The clutch disengages, but the pedal does not return to its original position

This malfunction is often solved in a trivially simple way - the return spring may fly off or burst. The hydraulic system in the VAZ 2107 is a design where there are no return devices, except for mechanical parts.

When to adjust the clutch drive

The standard adjustment procedure is required as routine maintenance or emergency repairs. Usually the reason for performing the operation is such problems.

- Gear shift violation - positions are engaged with knocking, crackling or extraneous sounds.

- The clutch switch response threshold has been violated. A dip of 25 to 35 mm is considered optimal.

- Increased fuel consumption. If the mechanism is faulty, excess gasoline consumption can be up to 20% of the reference value.

- Knocking out positions. During acceleration of the vehicle, the gears “fly out”.

- Dissonance when revving the engine. When you press the gas pedal, the internal combustion engine spins up, and the car lags behind.

- Clutch lever failures, this also includes an increase or absence of operating play in the system.

- Early or late operation of the mechanism when the pedal is pressed.