To achieve correct and accurate operation of the car's ignition system, a special device is provided, which is called a distributor or distributor of the ignition system. This important part was used on old carburetor engines, and nowadays it is also used on new injection engines. Unstable operation of this element leads to deterioration in the performance of not only the ignition system, but also the entire vehicle. In this article you will learn what a distributor is in a car and how the process of repairing a distributor occurs.

Distributor device

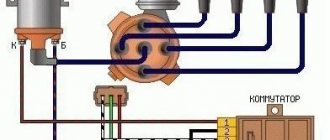

So, the ignition distributor-interrupter is a device that opens the circuit with low-voltage current. This circuit is formed on the primary winding of the ignition coil in order to create a magnetic field and high current on the secondary winding, and then it distributes it to the cylinder spark plugs. Ignition of a gasoline engine without a distributor is almost impossible, since it is this mechanism that provokes the ignition of the fuel mixture. The device is based on two main elements: a distribution sensor and an electrical charge breaker, which is supplied to the cylinders.

Let us analyze the design of the distributor in detail, examining its components. All distributors have a similar design. The only difference may be the presence of contacts or sensors. The device consists of the housing itself, a shaft (the shaft consists of two parts that are connected to each other), a movable plate, a capacitor, a vacuum octane corrector (consists of springs of different stiffness and cams), cams (depending on the design, they can be located on top or below and their number depends on the number of cylinders).

To understand the device in more detail, let's look at how the distributor works. The operation of the distributor is not complicated and consists of the following operations: a magnetic field appears on the primary winding as a result of opening the contacts, which affects the appearance of high-voltage current. That, in turn, goes from the inductor to the breaker cover, which has a charge and touches the slider. Thus, the current is distributed across the contacts of the cover and goes further through the wires to the spark plugs.

Malfunction of the contact distributor.

Malfunction of the distributor during contact ignition is due to a change in the gap in the contacts or their contamination. The operation of a contact distributor, in contrast to a non-contact distributor, is greatly influenced by the condition of the contacts, which must be checked after 10,000 km. Distributor malfunctions include wear of the shaft cams and the stop of the contacts sliding along them, wear of the bushings in which the shaft rotates, destruction of the bearing of the movable contact plate, weakening of the contact spring, jamming of the contacts on the axis, burning, erosion or contamination of the contacts.

All these faults lead to a change in the gap or a violation of contact between the contacts. As a consequence, loss of engine power, engine idling stops, throttle response decreases, jerking is possible when the gas pedal is sharply pressed.

In case of significant wear or destruction of the bearing of the movable contact plate, critical wear of the bushings, breakage of the negative shunt, a violation of the contact of the contact pair lever and the contact itself leads to popping noises in the intake manifold and muffler. This is also possible if the radio interference resistor located in the distributor runner burns out.

Repair and restoration

Failure of this mechanism can occur for several reasons:

- One of them may be his old age. Such a breakdown is typical for many machine parts;

- The second reason may be moisture that gets inside the mechanism when washing a car or when the car runs into a large puddle. If the mechanism is not protected, it soon stops working;

- The third reason is that the distributor has mechanical damage on the surface;

When your car stalls or won't start at all, I recommend checking the fuel supply to the carburetor.

In the case when the fuel supply is in order, you need to check the formation of a spark. In the case when current flows to the breaker, but does not pass further, the reason is immediately clear - the distributor is faulty. The reasons why the current does not pass further may be the following: burnt contacts, damaged cover, faulty slider, faulty Hall sensor, jammed bearing of the ignition detection regulator.

Once the problem is detected, you can begin to correct it. You can solve the problem either at a service station or yourself in your garage. The ease of operation is that the distributor is located in an accessible place (at the top of the car engine). To thoroughly check and investigate the problem, you need to remove the cover on the breaker. It can be removed quite easily, as it is secured with two bolts or two latches. The cover must be thoroughly inspected for mechanical damage. The presence of a thin dark stripe on its surface indicates that it is damaged and must be replaced, since it cannot be repaired. The springs in the cover that press the central contact may burst. The contact and spring must be replaced with new elements.

If no problems are found on the cover, then you should check the slider. A sign of a faulty slider may be dark stripes or a melted surface (it needs to be replaced). Next you need to check the contacts. In a contact distributor, the contacts must be replaced if they are burnt out. In the case where the distributor is non-contact, the Hall sensor must be replaced if it fails.

A sign that the ignition timing regulator bearing has failed is uneven operation of the vehicle at high speeds. In this case, it must be replaced with a new one. This bearing is replaced along with the disk on which the contacts are located. Distributor repair instructions:

- Remove the device;

- Disconnect the distributor from the battery. To do this, you need to remove the wire from the negative terminal;

- Disconnect the high-voltage wires from the distributor;

- Disconnect the vacuum hose from the vacuum corrector;

- Remove the throttle cable from the holder;

- Disconnect the wires from the bracket to which they are attached. To do this, you need to unscrew the nut; It is important not to lose the washer, which is located under the nut. Remove the bracket from the spire and set it aside along with the nut, washer and wires separately;

- In order not to confuse anything during assembly, make some marks of the parts in a way convenient for you. This will allow for correct assembly during installation;

- Next, you need to disconnect the wiring harness connector from the ignition distributor. To do this, you need to lower the spring clamp using a screwdriver;

- We remove the rubber plug from the clutch housing hatch and install the piston of the first cylinder at dead center. This can be done while turning the gear ring of the crankshaft flywheel. It is best to use a long screwdriver;

- And the last step is to remove the distributor by unscrewing the last nuts from its fastening.

Ignition without a distributor is practically impossible, so it is very important to monitor the correct operation of this mechanism. I recommend carefully monitoring your car so as not to stall somewhere on the highway. From time to time, diagnose your iron friend.

VAZ 2109 distributor slider

Replacing the distributor slider

I drove a nine-wheeler for 2-3 days after repairing the starter relay, that is, not repairing but replacing the wires, and then the car began to stall at idle... then sometimes it wouldn’t start at all, and I got out of the car that I thought this had happened, I opened the hood, I looked, I thought , again the starter relay is floating or the switch started... or even some kind of wires from the starter or fuses I thought... every time when I couldn’t start I went out, opened the hood and tapped the starter relay, the switch pulled the wires from the starter and started just like that... but not always this trick worked... sometimes I had to leave the car and after work come and try again and somehow it would start. And after that I looked, opened the distributor and there... In short, I bought a slider for 250 tenge, changed everything in the photo...

Old runner

New slider

dust screen

All! changed! Ready!

About the drive mechanism

To transmit torque to the distributor shaft on the “six”, a helical gear is used, rotated by a timing chain (in common parlance – “hog”). Since the element is located horizontally and the distributor roller is vertical, there is an intermediary between them - the so-called fungus with oblique teeth and internal slots. This gear simultaneously turns 2 shafts - the oil pump and the distributor.

Both transmission links - the “hog” and the “fungus” - are designed for a long service life and are replaced during engine overhauls. The first part is removed after disassembling the timing chain drive, the second is pulled out through the upper hole in the cylinder block.

The VAZ 2106 distributor, equipped with a contact breaker, is a rather complex unit consisting of many small parts. Hence the unreliability of operation and constant failures of the spark generation system. The non-contact version of the distributor creates problems much less frequently, but in terms of performance characteristics it still falls short of modern ignition modules, which have no moving parts.

Source

Advantages of BSZ

The task of the ignition system is to provide the ignition spark with sufficient energy at the right moment to ignite the fuel mixture. The more accurately this process is performed, the greater the engine's power and efficiency. Correctly set ignition allows you to increase engine power, reduce fuel consumption and emissions of harmful substances.

In recent years and decades, these goals have become increasingly relevant. The contact ignition system could not cope with the demands placed on it. The maximum transmitted energy required to ignite the working mixture could not be increased, although this was necessary for engines with high compression and power, the rotation speed of which became increasingly higher.

In addition, due to constant wear of the contacts, it is not possible to ensure exact compliance with the specified ignition moment. This caused interruptions in engine operation, increased fuel consumption and emissions of harmful substances into the atmosphere.

Thanks to the development of electronics, it was possible to initiate the ignition process without contact, thereby solving wear and maintenance problems. In this case, the specified ignition timing is precisely maintained throughout almost the entire service life.

First of all, this is achieved thanks to inductive signal formation (contactless transistor ignition system with energy storage in inductance) and signal formation by a Hall sensor (TSZ-h).

Because both of these systems are economical and relatively inexpensive, they are still used today on some small engines.

The main advantages of a contactless ignition system:

- no wear or maintenance,

- constant ignition moment,

- absence of contact bounce and, as a consequence, the possibility of increasing the rotation speed,

- regulation of energy storage and limitation of primary current,

- higher secondary voltage of the ignition system

- DC switch off.

Important nuances when bulkheading

Overhauling the ignition distributor is necessary for various reasons. As a rule, during the operation of the car, its owner notices slight shaking of the engine at idle. After replacing the spark plugs and putting the carburetor in order, he realizes that the reason is different, because the problem could not be eliminated. And then the armored wires, the ignition and, finally, the distributor itself come into question.

If its slider moves freely in the working area without stopping in the extreme position, then the motor will twitch. And here a knowledgeable car enthusiast will sort out the distributor on his own, saving a considerable amount of money on services at a service station.

Distributor bulkhead

It is important to wash all metal elements of the distributor in gasoline or kerosene. Submit the moving part for inspection; if there is uneven rotation and there is no preload of the weight springs, then during reassembly you should try to select a specific, correct location for the bearing. You should know that the manual advises changing the position of the bearing every 25 thousand km. Obviously, this is prescribed solely for one purpose - to eliminate problems with its operation. You can also do this: bend the spring ears on the CTR weights of the regulator, selecting XX of the small spring. That is, the distributor cam returns to its original position. Just remember to bend the springs with pliers or pliers.

The distributor shaft should also be inspected carefully. If there is no play, but the cam shows signs of wear, that's okay. Lubrication will help solve everything.

A couple more important tips for bulkheading:

- The spring should ensure that the weight adheres to XX, i.e., not create advance. To do this, you will need to bend the small spring strut.

- At the same time, for similar purposes, the post of the large spring should also be bent, but to the position of the half-maximum stroke of the mini-spring.