Advantages of contactless ignition

There are a lot of advantages to this type of system; among the main advantages is enviable reliability. A small number of elements is the key to long and stable operation. But the most important thing is the absence of high currents and mechanical breakers. This is the main difference between the electronic type and the classic contact type, which was installed on the VAZ 2107 of the first releases. Of course, it is far from the accuracy of a microprocessor system, but a distributor that does not have a contact breaker can improve the performance of the motor.

So, we can highlight the following advantages of using a contactless system on the VAZ 2107 and similar models:

- Reduced fuel consumption due to more correct setting of the ignition timing and greater spark power.

- Increasing the stability of the internal combustion engine. The crankshaft speed is constant, there are no interruptions.

- Increased reliability, since there is (virtually) no mechanical interaction, and there are no spark gaps.

- Reduced costs for components. The Hall sensor, for example, fails much less often than the breaker contact group.

Sparking moment

Spark formation in the ignition system of the VAZ 2109 occurs as follows:

- The rotating ignition distributor shaft simultaneously rotates the screen with slots, which has the shape of a cylinder, and part of its inner surface consists of metal. By rotating, this screen forms an electromagnetic field.

- The highest sensor signal is generated when a metal part of the screen appears in the microswitch gap, and the smallest sensor signal is formed when there is no metal part of the screen in the working gap.

- The moment of signal level changes from higher to lower lasts only from 1 to 5 micro seconds and at this time sparking occurs.

Of course, the sparking process is more complicated and largely depends on the geometry of the screen slits, but there is no point in describing complex physical processes here, since they will not be clear to many people.

Signs of a faulty switch: how to check the switch yourself.

Purpose and design features of the switch.

A switch is one of the elements of a car's electrical equipment. His task

– ensuring normal operation of the contactless ignition system. The assembly is fastened in the engine compartment.

The device is reliable, able to withstand severe vibrations and shock loads

This is very important, because the switch housing contains sensitive electronics

At the heart of the VAZ switch

– standard L 497 microcircuit, which controls an “NPN” type transistor.

>Scheme feature

– possibility of programming by the user and setting the required delay coefficient. Starting a cold engine directly depends on the correctness of this indicator.

Thanks to precise settings

, you can speed up the crankshaft rotation speed (while eliminating failures in operation) and guarantee high-quality traction of the power unit.

The main parameters of the switch device include:

Voltage range – from 6 to 16 Volts; operating voltage level – 13.5 Volts; ensuring an uninterrupted spark when the crankshaft rotates in the range from 20 to 7000 rpm; switching current – from 7.5 to 8.5 A.

Signs of a faulty switch.

One of the main symptoms of a faulty switch is loss of spark.

. The engine starts hard and stalls from time to time, causing interruptions in operation.

But don’t rush into replacing it - it’s important to make sure of the reason, because loss of spark can occur for a number of reasons - failure of the Hall sensor, broken timing belt, faulty ignition coil, poor contact in the distributor cap, wiring problems, and so on

Therefore, first of all, a comprehensive diagnosis is necessary. The fastest and most effective way in this case can be a car diagnostic scanner. Most of this type of device is quite easy to use and has an affordable price.

Of those presented on our market, we can recommend paying attention to the multi-brand scanner Scan Tool Pro Black Edition

The advantages of this model include diagnostics of not only the engine, but also other components. Compatible with 99% of new and old cars since 1993, quite easy to use and has wide functionality.

If diagnostics of other nodes does not produce results

, then we can move on to our “hero”. But how to check the switch, since the device has a very complex design?

How to check the switch yourself.

Most car enthusiasts don’t bother with diagnostics and simply install a new unit. This method has its advantages.

Firstly

, there is no need to waste time checking - just install a new part.

Secondly

, you can immediately determine whether this is the reason or not. In fact, there is no need to be afraid of the work, because checking the switch takes a few minutes.

So, to carry out work at home, a test lamp (nominal voltage should be 12 Volts) and a standard set of keys are enough.

With their help, you can verify the presence or absence of pulses, and later make a decision about the serviceability of the device itself.

Algorithm for checking the switch:

To begin work, it is advisable to disconnect the battery so as not to accidentally short-circuit the wiring that you will unscrew.

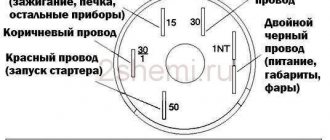

Using an eight-point wrench, unscrew the nut and remove the wiring from the ignition coil marked “K”. This wire is easy to recognize - it is brownish in color and goes to the terminal labeled one on the switch;

Connect this wire through a control light to terminal “K” on the ignition coil, and then connect the battery;

Turn on the engine starter and observe the lamp's actions. If it blinks, then the switch is working. If the light bulb does not show any signs of life, then the only way out is to replace the device.

If there are doubts about the serviceability of a part, the check should be carried out on a special stand (there is always one at the service station).

In this case, it is possible not only to determine whether the product is working, but also to measure the duration of the pulses.

When the first suspicions appear, you should not immediately change the switch or spend money on a specialist. You are quite capable of doing the job yourself.

Moreover, now you know how to check the switch on the VAZ 2109 and other models of the domestic brand. All that remains is to allocate time and prepare a minimum set of tools. Have a good trip and of course no breakdowns.

Other ways to test your switch

Despite the relatively low cost of a new switch, car enthusiasts do not always have the desire, and sometimes even the opportunity, to purchase it.

And even if the old switch is in good working order, replacing it will in no way affect the operation of the engine.

This is why many owners of VAZ 2109 cars prefer to check the old switch before replacing it with a new one.

Rice. 4 Mounting the switch on the car body.

This unit can be professionally checked at a service station using a specialized stand.

Professional equipment can show not only the presence or absence of an impulse from the switch to the ignition coil, but also their cyclicity and stability.

Malfunction of the ignition system of the VAZ 2109

Checking the ignition system.

Malfunctions of the VAZ 2109 ignition system are determined by the presence of a spark discharge on high-voltage wires and spark plugs. To check the spark discharge for safety and clarity purposes, it is better to use a spark gap. With its help you can adjust the spark gap, which cannot be done with a spark plug. The ignition system is considered operational if the spark penetrates a distance of 10 mm. and has a blue color.

The first step is to check the spark on the center wire. If available, check on any two spark plug wires. If there is a spark on only one wire, then the reason is that the slider is turning and it needs to be replaced. If there is no spark on any spark plug wire, then the reason is a breakdown or cranking of the distributor slider. To check, remove the distributor cover and slider. In the runner bushing, with which it is mounted on the shaft, check the integrity of the boss, which fits into the slot of the shaft and prevents the runner from turning on the shaft. If it is working properly, put the slider in place, remove the central wire from the cover socket, holding it with pliers at a distance of 2 - 5 mm from the slider, and crank the engine with the starter. The presence of a spark discharge between the wire and the slider indicates its breakdown.

There is no spark on the center wire.

Let's return to checking the spark on the central wire if there is a malfunction in the ignition system of the VAZ 2109 and consider the case of the absence of a spark on the central wire. The reason for this may be a malfunction of the switch, a hall sensor in the distributor, a lack of power to the electrical equipment of the ignition system, a broken timing belt, a malfunction of the ignition coil, a break or short circuit between each other or to the housing of the connecting wires.

Checking the switch.

You can most likely check the switch using the arrow of a voltmeter if it is installed on the instrument panel or connect a voltmeter to the supply wires of the ignition system. When the ignition is turned on, the voltmeter begins to show the voltage of the on-board network, and after a while, about 10 - 15 seconds, the needle should deviate even further indicating an increase in voltage. This occurs due to the switch disconnecting the ignition coil, which occurs if the crankshaft does not start rotating.

If there is no voltage increase, then you need to check the presence of power at the ignition coil terminal of the switch. To do this, disconnect the connector from the switch, turn on the ignition, connect one end of the indicator lamp to the car body, and touch pin 4 on the connector with the other. If the control lamp is on, then power is supplied to the switch. Touch the test lamp to pin 1 of the switch connector. If the control lamp is on, then there is power to the ignition coil and the primary winding of the coil is intact. If the warning light does not light, check the power at the ignition coil terminals. The presence of power at terminal “B” and absence at the second terminal indicates a break in the primary winding of the ignition coil, and the presence of power at both terminals indicates a break in the wire from the coil to the switch.

If there is no power at pin 4 of the connector and terminal “B” of the ignition coil, it is necessary to check the contact group of the ignition switch. To do this, check for power on the blue wire with a black stripe. If there is power on it, eliminate the break in the wires or poor contact in the connections in the circuit from the ignition switch to the ignition coil and the switch.

SZ scheme

The ignition system used on the VAZ 2109 includes the following components:

- Switch;

- Candles;

- Distributor sensor;

- Ignition coils;

- Switch;

- Locking device. It does not allow the starter to turn on until the ignition is completely turned off;

- Locking and anti-theft device;

- Hall Sensor;

- The sensor-distributor roller, which is located horizontally and receives torque from the camshaft;

- System of spontaneous ignition shutdown, which is activated after 2-8 seconds;

- Switched current equalization system, which is required when the network voltage changes within the range of 6-18V;

- The system built into the switch, which regulates the time of energy accumulation in the coil, limits the current strength at low motor operating frequencies.

The ignition system operates with a voltage of up to 26 kV, the spark charge has a duration of 1.6-2.0 milliseconds, and the energy released during this time is 35-50 MJ.

Service

If you do not monitor the state of the system and lose sight of the presence of malfunctions and malfunctions, this can lead to certain consequences. Namely:

- Reduced reliability of the operation of the protective equipment, the occurrence of failures;

- Reduced technical characteristics of the engine, such as acceleration dynamics, maximum speed;

- A sharp increase in the amount of fuel consumed;

- Failure of SZ elements or the entire system.

Before you carry out maintenance on the SZ yourself, take into account several important recommendations.

- Do not touch the ignition coil with your hands while the engine is running. This applies to wires, switch and other components.

- Do not test the SZ for performance using the “spark” method, as this can lead to injuries and costly repairs of the entire vehicle;

- Under no circumstances should you start the engine with a spark gap between the central terminal of the distributor sensor and the high voltage.

Replacing the ignition switch on a VAZ 2108, VAZ 2109, VAZ 21099

Where is the ignition system switch located? Its location is very simple, and all because it is located at the very top of the car engine, and it is very easy to get to. The switch is located near the vacuum booster, and it is attached to the car body with two nuts, so that you visually know its location, see the photo below:

When do you need to change the ignition system switch? If it fails, the engine may experience the following malfunctions:

- Firstly, the car’s engine may not operate steadily, both at idle and when driving the car.

- And secondly, very often there can be a loss of car throttle response; in other words, the car will drive worse.

Switch design and malfunctions

The VAZ 2109 switch is one of the key elements of the car’s ignition system. The device is designed to switch current pulses of the required amplitude and duration in the primary winding of the ignition coil, depending on the control pulses of the Hall sensor. It also stabilizes the current from 6 to 18 V, protects semiconductors from overloads and ensures that the ignition system is turned off when the engine is stopped.

The housing provides a connection to ground through a radiator. When the device operates, a significant amount of heat is generated through its radiator. During operation, the radiator should be regularly cleaned of all kinds of contaminants to maintain heat transfer.

Signs of a faulty switch may include the following:

- when the starter is turned on, the engine does not start, there is no spark at the spark plugs;

- the engine starts, but soon stalls at idle;

- The engine runs unsteadily and the spark sometimes disappears.

A malfunction of the VAZ switch is not the only possible reason for the appearance of such symptoms. Such signs can be observed when the distributor fails or contact is lost.

To carry out repairs correctly, a thorough diagnosis is necessary.

How to replace the ignition system switch on a VAZ 2108-VAZ 21099?

Removal: 1) First remove the negative terminal from the battery. (You can read how to do this in the article: “Replacing the battery”, in the “first” paragraph)

2) Then disconnect the wire block from the switch by hand.

3) Next, use a wrench to unscrew the two side nuts that secure the switch to the car body.

Note! There will be a ground terminal under the left nut, so when the nut is unscrewed, disconnect this terminal from the switch!

4) And at the end of the operation, when the block is disconnected and the two side nuts are unscrewed, remove the switch from the car.

Installation: 1) First, install the new switch in its place, and then tighten the side nuts that secure it.

Note! Before you start screwing the left nut, install the ground terminal in the place where it will be screwed first, and only after that screw the left fastening nut!

2) Next, insert the wire block into the connector of the new switch.

3) And then, finally, install the “minus” terminal that you removed earlier on the battery.

Checking the ignition system switch for serviceability:

1) To do this, first disconnect terminal “K” from the ignition coil by unscrewing the nut that secures it with a wrench

(Be sure to read the “Important” paragraph at the end of the article)

2) Next, using a test lamp, which is designed for “12 Volts”, with a power of “3 W”, check the coil for serviceability for this:

- First, connect the previously disconnected terminal to the control lamp.

- And then connect the other contact that comes from the control lamp in place of the “K” terminals on the ignition coil.

And then, turning the engine over with the starter, check whether the lamp lights up or not.

Note! If it does not light up, then replace the ignition coil with a new one!

Important! On the very first ignition coils, instead of the “K” marking, the “+” marking was drawn, and therefore, if this is the case on your coil, then in this case, disconnect the wire next to which the “+” marking is located and not “K”!

Verifying switch operation

Every car enthusiast with a sufficient level of desire and minimal technical skills can check the operation of the switch.

The easiest way to check is to replace the unit with a new one that is known to be good. If after this the problems in the engine operation have disappeared, then we can conclude that the old switch has already served its purpose.

Every car enthusiast can replace the switch independently. First of all, you need to find it under the hood of the car.

The switch is located in the area of the left (driver's) pillar. It is connected by wires to the coil.

Rice. 3 Engine and organization of the engine compartment of the VAZ 2109.

1 – front glass of the shock-absorbing strut; 2 – water tank; 3 – air filter; 4 – fuel pump; 5 – steering rack; 6 – camshaft sensor; 7 – vacuum brake booster device; 8 – master cylinder of the brake system and its barrel; 9 – switch; 10 – fuses; 11 – engine cooling system tank; 12 – battery; 13 – hood fastening; 14 – ignition coil; 15 – starter; 16 – high-voltage wires; 17 – neck for oil; 18 – engine; 19 – candles; 20 – windshield washer system.

Next, disconnect the negative terminal from the battery. Then you should carefully disconnect the plastic bracket with wires from the switch. To do this, you need to release the spring clip.

Tip: Any actions with plastic brackets and fasteners should be done with the utmost care so as not to break the latches.

Then we unscrew the nuts that secure the aluminum switch housing to the car body. Under the left nut there will be a ground terminal.

Remove the switch from the studs and replace it with a new one. The new one is installed in the reverse order.

How to check a VAZ 2108-2109 switch

Warm Siberian greetings to everyone. I want to share with you that the switch is different from the switch. A new one, just from the store, may be worse in terms of parameters than the replaced old one, which was previously thrown into the trunk. I will also show how the switch is responsible for the power and duration of the spark.

After the release of my videos on YouTube on repairing, adjusting carburetors and diagnosing injection cars. I started getting a lot of questions. In order to communicate more closely with my subscribers and viewers, I began to conduct these streams. Subscribe. Press the bell. Ask your questions - I will be happy to answer them in more detail than in writing.

Sources

- drive2.ru/l/564176184837932184/

- vaz-russia.com/remont-vaz-2108/zamena-kommutatora-zazhiganiya-na-vaz-2108-vaz-2109-vaz-21099.html

- twokarburators.ru/kommutator-vaz-2108-2109-21099/

- ladaautos.ru/vaz-2109/kak-mozhno-proverit-kommutator-vaz-2109.html

Ignition coil

The VAZ 2109 car is equipped with an ignition coil whose operating principle is based on the principle of an open magnetic circuit.

Like many ignition coils, model 27.3705 consists of a core, primary and secondary windings. The coil body is filled with transformer oil.

A design feature of this ignition coil is the presence of a special one-time emergency safety valve. This valve is activated only when the oil pressure in the housing becomes higher than the standard one.

If the valve is triggered, immediately replace the ignition coil. If there were no such valve, the coil would simply rupture with the ensuing consequences.

ABOUT THE POSSIBILITIES OF MODULE REPAIR

Most breakdowns of this device lead to its replacement, but sometimes it is possible to repair the ignition coil to return it to service. This is especially true in cases where moving or tapping changes the behavior of the motor. If you have the ability to use a soldering iron and a multimeter, you can try to get it back into operation.

You need to remove the metal back cover, under which the electrical parts of the module are filled. You need to try to carefully get rid of the silicone and its “insides” will be revealed to your eyes. Find broken or “bad” contacts and solder them.

After this, close the back cover and check its functionality. If the repair result is positive, you need to open it again and fill the inside with silicone.

If the result is negative, then the block must be replaced. True, owners with extensive amateur radio experience continue to “dig” further. You can try replacing the electronic switches. Basically, these two elements become the culprits of failures of the engine starting system.

Spark plugs

The VAZ-2109 ignition system uses spark plugs A17DVR, A17DVRM where:

The importance of spark plugs in the overall operation of a car's ignition system cannot be underestimated.

It’s not for nothing that many drivers, out of habit that remains from past times, carry a spare set of spark plugs with them. This may be unnecessary, since modern candles are quite reliable, but breaking any habit is not so easy, even this one.

Read here what to carry in your trunk...

During operation, the spark plug endures huge ranges of loads, which are expressed in high operating temperatures, mechanical, electrical and chemical influences.

For example, in the combustion chamber, the operating temperature can vary from 60 to 2800 degrees, pressure up to 10 MPa, voltage up to 30 kV, not to mention the constant chemical effect on the spark plug from combustion products.

During the operation of the spark plug, carbon deposits form in all its areas, which leads to loss of current, and the gap between the contacts in the spark plug can increase from 0.012 to 0.016 mm or more for every 1000 km of travel.

Using the spark plug, you can simply diagnose the condition of the engine, but as a rule, we pay attention to the spark plugs only when malfunctions begin in the engine or when it’s time for scheduled maintenance.

The engine is in good condition if:

- No phlegm on the threads;

- A thin layer of soot on a dark rim;

- All electrodes are light grey, light brown, whitish or light yellow.

Signs of engine problems:

- There are oil or gasoline residues on the threads;

- There is loose black carbon deposits with spots on the rim;

- All electrodes are dark brown with spots;

- The candle is wet with dark soot;

- A dark rim on the outer part of the candle (if the candle is not sealed).

The use of only spark plugs of the A17DVR, A17DVRM brands in the ignition system of the VAZ 2109 is not a panacea, of course there are alternative options, but you need to be able to choose the right spark plugs for your car, and for this you should familiarize yourself with these concepts:

- What are hot and cold spark plugs and what engines are they used on?

- What is heat number;

- What is the compression ratio and a number of other indicators.

Therefore, if you do not understand these issues, then before replacing the spark plugs recommended by the manufacturer with others, seek recommendations from specialists.

Malfunctions of the contactless ignition system of VAZ 2108, 2109, 21099 cars

Sometimes when diagnosing a carburetor gasoline engine of a passenger car, difficulties arise in determining the cause of a particular malfunction. This happens because the symptoms of their manifestation are very similar. For example, carburetor malfunctions and ignition system malfunctions will have almost the same effect on engine performance. In this article we will try to understand what problems in the operation of a car engine arise due to a malfunction of the ignition system.

Car engine does not start

— Battery is faulty

— The switch is faulty

— Hall sensor is faulty

— The insulation of high-voltage wires is “broken”

— The distributor cover is “broken” or is heavily oxidized, its contacts are destroyed

— Ignition distributor rotor (slider) burnt out

— The ignition coil is faulty or its cover is “broken”

— High-voltage wires are connected in the wrong order

— Defective spark plugs, their insulation is “broken,” the gap between their electrodes does not correspond to the norm

— Incorrect ignition timing

Ignition is either too early or too late. How to correctly set the ignition timing on VAZ 2108, 21081, 21083 engines is described in detail on the page “Setting the ignition timing of VAZ 2108, 2109, 21099 cars.”

— The low voltage circuit of the ignition system is faulty (contacts have oxidized, wires are broken, connectors have come off...)

Read more about the inability to start the carburetor engine of VAZ 2108, 2109, 21099 cars in the article “The carburetor engine does not start (reasons related to the ignition system).”

For comparison, you can see what reasons exist that the engine cannot be started due to a carburetor malfunction.

The car engine runs erratically (troits) or stalls at idle

— The gap between the electrodes of the spark plugs does not correspond to the norm

— Heavy carbon deposits on the spark plug electrodes

— Defective spark plugs (“insulator broken”)

— Incorrect ignition timing

— The switch is faulty

— The centrifugal ignition timing regulator in the distributor is faulty (weights stick, their springs are weakened or broken, damper rings are lost)

Causes of rough idle related to the carburetor are outlined on the “Rough Idling” page.

Dips and jerks in engine operation

— Incorrect ignition timing

— The gaps between the electrodes of the spark plugs do not correspond to the norm

— Defective spark plugs

— The noise suppression resistor in the rotor (runner) of the distributor burned out

— Wear or damage to the contact carbon in the distributor cover

— Current leakage through “broken” insulation of high-voltage wires, spark plug insulator, ignition coil cover

For the causes of malfunction related to the carburetor, see the page “Failure when pressing the gas pedal.”

The engine does not develop full power, its throttle response is reduced

All of the above causes of malfunctions lead to loss of power, throttle response of the car engine, and increased fuel appetite. You can only add

— Malfunction of the vacuum ignition timing regulator in the distributor due to jamming of its plate

Notes and additions

Five more articles on the site on the ignition system of VAZ cars

Using a strobe to check ignition

The most acceptable way to check the ignition on a VAZ 2109 is to use a strobe light.

Although the name of this device confuses some drivers, there is nothing complicated in its operation.

To check you need:

- Connect the wires “+” to “+” and “-” to “–” of the strobe light with the battery, and connect the wire of the device sensor to the high voltage wire suitable for the first cylinder.

- We start the car, with the engine idling, we direct the flashing beam of light emanating from the strobe into the clutch housing hatch.

- The ignition timing is set correctly if the mark on the clutch housing coincides with the mark on the flywheel, which corresponds to the initial ignition timing.

To change the ignition timing angle (IAF), you must:

- Position yourself so as to look at the sensor-distributor cover;

- To increase the SOP, turn the housing of the sensor-distributor clockwise;

- To reduce the OZ - counterclockwise.

How to check a VAZ 2109 switch

The switch is the very part of the car’s ignition system that can easily fail, but is difficult to diagnose. Is this really so? Let’s find out using the example of a VAZ 2109 car. Let’s consider why it is needed and how to check it in case of a malfunction of the ignition system.

Purpose of the VAZ 2109 switch The switch is an electronic unit that is responsible for programming and controlling the vehicle’s ignition system. Its basis is the well-known L497 microcircuit, which is used to control transistors. The advantages of using a switch over conventional contact ignition are reliability, since the electronics make it easier to start the engine even at the lowest temperatures, which indicates good sparking. In addition, the switch is securely mounted, which ensures trouble-free operation. With proper adjustment of the switch, you can increase the rotation speed and speed of the engine crankshaft and directly influence its traction properties. Correct operation of the switch is ensured through the use of a Hall sensor installed on the engine distributor. Signs or symptoms of a bad switch? Perhaps the main symptom of a block failure is the absence of a spark when starting the engine. This happens as follows: the starter successfully rotates the engine, but the mixture does not ignite. The engine shows absolutely no signs of life at all. Spark plugs are usually wet and quickly fail. First of all, all other elements of the system are checked - these are armored wires, Hall sensor, ignition coil and spark plugs. In addition, it is necessary to ensure that the timing system is in good working order. If everything is in order, it’s time to check the switch on the VAZ 2109. How to check the switch? First, you need to find out some characteristics of the device in order to avoid mistakes during diagnostics.

The device voltage ranges from 6 to 16 Volts. Operating (standard) voltage is at least 13.5 Volts. Switching current is 7.5-8.5 Volts. Guarantee of a good spark at rpm from 20 to 7000.

This is what characterizes the good performance of the device. If at least one of these points is missing, then the switch has become unusable. And now about checking the device. First you need to take a size 8 key and unscrew the nut securing the wire to contact “K” on the ignition coil. As a rule, it is brown in color. Try not to let it come into contact with the car body, as this may cause a short circuit. Now you need to take a 12-volt test lamp and connect one end of it to contact “K” and the other to the brown wire. Ensure good contact - this will be the key to competent diagnosis of the problem. Make sure the lamp is visible from inside the car. Get behind the wheel, turn on the ignition and try to start the engine. If the light blinks while the engine is cranked by the starter, it means the switch is working. If the lamp does not light up at all, then the device must be replaced. If you have the slightest doubt about the serviceability of the device, you can take it to a service station. There is a special stand that will not only determine the operation of the switch, but also measure the length of the pulses and compare them with the nominal value. High-precision instruments allow for broader diagnostics, but this costs a lot of money. Fortunately, the cost of a new device is not so high - only 300-400 rubles. It is recommended to carry a spare switch in the glove compartment of your car. This will help avoid many troubles in the event of a sudden breakdown of the device. We wish you good luck on the roads!

VAZ switch check video

Signs of a broken switch

During the operation of the car, unpleasant symptoms may occur, indicating a malfunction of the ignition system.

A possible reason for this may be incorrect operation of the switch. Here are the most common symptoms that should suggest a possible breakdown of this device:

- Can't start the engine. There is no spark when the starter is running.

- The engine starts and runs normally at low and medium speeds, but cannot be revved up at high speeds. The engine is not running at full power.

- The car stalls when moving away, although it idles stable.

- The engine starts, but does not run for a long time and immediately stalls.

- The engine begins to operate unstably - “triple”, reaching a certain speed level. When cold it can start quite normally.

- The engine may periodically, without any pattern, stall, then work normally again. The battery discharge indicator lights up. The tachometer needle shows sharp changes in the number of revolutions.

Tip: Signs of a malfunction in the ignition system can arise not only from the switch, but also from failure of other components. Replacing a switch with the above symptoms does not always help fix the problem. Therefore, it is advisable to carry out diagnostics of the ignition system in a comprehensive manner, step by step checking the serviceability of all components.

Electronic ignition connection diagrams: VAZ 2101-VAZ 2107

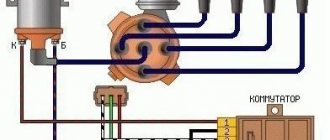

Scheme of a contactless ignition system for VAZ cars:

1 - switch; 2 — ignition coil (bobbin); 3 — distributor; 4 — ignition key; 5 - Hall sensor.

How contactless ignition works

The sequence and principle of operation of the BSZ is as follows:

- The driver turns the ignition key.

- The circuit is closed and constant voltage from the battery is supplied to the primary winding of the ignition coil. The energized primary winding forms a magnetic field around itself.

- When the starter starts, it begins to rotate the crankshaft of the internal combustion engine and rotates the shaft, which is located inside the distributor along with the slider.

- The hall sensor detects how the distributor shaft rotates (along the protrusion on the shaft) and transmits a signal to the switch.

- The electronic unit turns off the voltage supply to the primary winding based on the signal from the Hall sensor.

- When the voltage supply circuit is interrupted, at that moment a high voltage pulse of up to 24 kilovolts appears in the secondary winding of the coil, which is transmitted through a thick wire to the slider (the moving part of the distributor).

- Fixed contacts are built into the roof. The runner throws an impulse onto one of these stationary contacts. From the contact that received the high voltage pulse, it is transmitted through high-voltage wires to the spark plugs of those cylinders in which the pistons are at top dead centers.

- When voltage is applied to the spark plug, the working combustion chamber of the cylinder already contains fuel and air in a compressed state for ignition.

- The distributor slider rotates to spark all spark plugs according to a certain sequence pattern: 1-3-4-2. Depending on how to install the slider, the entire operation of the system depends, early ignition or later, we learned to determine in another material.

- The car engine starts.

Diagram of an outdated VAZ ignition system (without switch)

1 — distributor (distributor); 2 - breaker; 3 - capacitor; 4 — ignition coil (bobbin); 5 - battery; 6 — ignition switch; 7 - spark plugs.

This scheme is in systems where there is no switch. The circuit is broken mechanically using a breaker.

Disadvantages of contact ignition:

- The contacts burn and oxidize, which reduces the power to create a spark.

- There are wear parts that are recommended to be changed every 20 thousand km. mileage

- Converted power in contact systems is up to 18 kilovolts. For electronic or contactless ones - up to 24 kilovolts.

Wiring diagram for VAZ-2109 carburetor

- Headlight.

- Electric motor for headlight glass cleaning system. An optional part, used mainly on export vehicles.

- Limit switch for powering the engine compartment lamp.

- Klaxon.

- An electric motor drives a fan installed on the radiator of the cooling system.

- Temperature indicator that provides a control signal for the electric drive of the fan impeller.

- Alternator.

- Fluid supply valve for headlight glasses. Used in conjunction with paragraph 2.

- Fluid supply valve for the glass of the fifth door.

- Fluid supply valve to the front glass.

- Spark plugs.

- Hall sensor used to distribute ignition pulses.

- Coil.

- Limit switch for reverse gear lights.

- Fluid temperature meter in the cooling system.

- Starter.

- Accumulator battery.

- A sensor that measures the fluid level in the brake booster.

- Switch that controls the ignition system.

- Sensor for determining the position of the top dead center of the piston of the first cylinder. Installed on some export VAZ 2109 with a diagnostic system. Found only on cars before 1995.

- Diagnostic block. Optional element, installed together with item 20.

- Controller for controlling the solenoid valve installed in the carburetor.

- Starter switch contact block.

- Limit switch on the carburetor.

- Economizer valve.

- Sensor signaling an emergency decrease in oil pressure.

- Washer pump drive.

- Fan impeller motor for ventilation and heating systems.

- Resistance providing additional fan speeds.

- Speed shifter.

- Windshield wiper drive.

- Cigarette lighter.

- Illumination system for levers for adjusting heater operating parameters.

- Socket for additional equipment.

- Lamp for auxiliary lighting of the engine compartment.

- Illumination system for the glove box on the instrument panel.

- Relay and fuse link mounting block.

- Instrument panel light switch.

- Parking brake lamp limit switch.

- Brake lamp limit switch.

- Steering column switch lever block.

- Exterior lamp switch.

- Hazard switch.

- Turn on the rear fog lamp.

- Bimetallic fog lamp fuse.

- Heated glass switch on the fifth door.

- Turn signal repeaters on the front fenders.

- Central interior lighting.

- Individual lampshade.

- Switches for backlight operation on the middle pillars.

- Ignition switching unit.

- Egnition lock.

- “Low” type instrument cluster.

- Choke limit switch on the carburetor.

- Rear lights.

- Fuel level meter in the tank.

- Heated glass.

- Rear wiper drive.

- Two lamps for room illumination.

Switch Specifications

The VAZ switch circuit is based on the L497 microcircuit, which controls the output NPN transistor. A special feature of the microcircuit is the ability to program the recovery time of the delay coefficient, which is important for trouble-free starting of a cold car power unit. This feature of this electronic component of the switch allows for rapid acceleration of the crankshaft speed without failures in operation, which ensures constant engine traction.

Analogues that are sometimes used in the design of the VAZ 2108 switch are the KR1055HP1, KR1055HP2, KR1055HP4 microcircuits. However, these electronic components are found quite rarely in the design of the device. Main technical parameters of the device:

- optimal operating voltage 13.5 V;

- voltage range for normal operation 6-16 V;

- switching current 7.5-8.5 A;

- the range of ensuring uninterrupted sparking is from 20 to 7000 crankshaft revolutions.

https://youtube.com/watch?v=PUSP30fdAqM

The design of the device is designed for use in single-wire power circuits on cars in which the body plays the role of a negative terminal. Installation of a device mounted on the L497 chip is carried out in a specially designated place using standard fasteners.

Switch Purpose

The switch is designed to interrupt the electric current flowing through the primary winding of the ignition coil, according to a signal from the Hall sensor. The interruption results in a high voltage current flowing to the spark plugs.

In addition, the switch automatically regulates the period of current accumulation in the ignition coil depending on the crankshaft speed. It also turns off the current supply through the ignition coil when the engine is not running but the ignition is on.

Existing types of switches

There are two main types of devices: AC CDI and DC CDI. The first switches were small and simple, using a high-voltage generator in their circuitry. The latter are more common, equipped with four contact groups with minus and plus, as well as separate outputs for the coil and Hall sensor. But the latter function only in the presence of high voltage supplied from an external source.

Switches are also usually classified according to their functional features:

- traditional or stock devices that strictly correspond to the parameters of the car - as a rule, they are installed from the factory;

- sports - they have the ability to increase the upper limit of the number of revolutions of the internal combustion engine, however, this type is the lot of experienced specialists and has the risk of accidents;

- with the ability to adjust the phases of the UZ - an excellent option when you need to equalize the torque of the power plant, improve acceleration characteristics and stabilize engine operation at different speeds.

Of course, switches are usually divided into main types.

Electronic

This type of switch is also called a microprocessor switch with transit keys. It is used to control the converter voltage and reduces the load on the connections, thereby increasing the current capacity.

- possibility of better filling of internal combustion engine cylinders;

- efficient engine output at all speeds.

Hybrid

These systems additionally use a mechanical part - a cam distributor. The electronics are represented by the switch itself and the coil. The unit is very reliable, economical and convenient. For example, if a switch fails, you can switch to an old converter with a slider.

Contactless

A group with transistors, widely used since the early eighties. It replaced the antediluvian classical contact systems. At one time it was considered the most effective, since its performance indicators were much higher than those of other switches.

Dual channel

The same contactless system, but significantly modernized. For example, a conventional BSZ has the same disadvantages of a KSZ - loss of spark energy, instability of idle speed, limitation on adjustment of the SPD, high sensitivity to pollution and humidity. A two-channel system or DBSZ eliminates these disadvantages from the ignition system, providing even higher spark energy through the use of additional coils. Also, problematic moving elements - a slider and a coal - are not used here, and the lid serves only as a protective element. Therefore, it is not subject to burnout.

Interestingly, two-channel ignition was used before. This was implemented on export VAZ-21083. However, switches of this type, also called dual-circuit switches, were not widely used due to the poor quality of the electronics of that time.

One more nuance regarding switches. They may have different outputs. Those with the default number “1” are extremely dangerous for the ignition coils at the moment they experience malfunctions. But the advantage of such devices is that standard converters for contact ignition can be integrated with them.

How to check and ring the ignition module of a VAZ-2114

In a car, each part is assigned certain functions. The ignition module also performs a number of important tasks, for example, when it breaks down, the engine is not able to work properly and it becomes difficult to start the car.

Functions of the VAZ-2114 ignition module

The ignition module in the VAZ-2114 solves important problems in the functioning of the car:

- first creates pulses passing through high voltage;

- then transfers them to the spark plugs.

The power supply of the unit involves operation starting from the on-board system of the vehicle, the minus wire is controlled by the body of the car. The subtlety of the module’s operation is that it simultaneously produces 2 sparks, one of which occurs at the moment of maximum compression of the air-fuel mass, and the other depends on the release, which is why it is called idle.

As for the connection method, the spark plugs are connected to the 1st and 4th cylinder, and the idle sparks fit to the 2nd and 3rd cylinder structure.

What does the ignition module consist of?

The ignition module built into the VAZ-2114 consists of 2 high-power transformers and the same 2 electronic-based control units. One side of the product has 4 outputs at once; they are responsible for connecting the candles. To keep the structural components in their original form and protect them, the manufacturer provides a plastic coating. The weight of the entire structure slightly exceeds 1 kg.

The spark plugs suitable for the engine are fixed together with the ignition module by running high-voltage wiring. A device called a “controller” controls the process. First, he takes the performance indicators of the structure, then analyzes them and, finally, decides what should be changed to achieve optimal performance - the crankshaft rotation speed, the temperature reached by the coolant in the VAZ-2114, or the engine load.

Frequent malfunctions of the VAZ-2114 ignition module

The following malfunctions occur in the VAZ-2114 ignition module:

- intermittency is formed at idle;

- power indicators leave much to be desired;

- the engine is not working correctly;

- in the paired operating mechanism, the cylinders are acting up (that is, the functioning of only one pair of cylinders can be heard);

- if the Check Engine light comes on.

If you suspect a faulty factory module in your car, then it's time to check the ignition module. It doesn’t hurt to make sure with your own hands that the wires are connected correctly and firmly; check that the spark plugs remain intact and are not damaged. Before you begin diagnostics and repair work, you need to stock up on protective equipment that will protect you from dangerous situations - the tool must be treated with insulating material, and gloves are required.

Contactless ignition system

In total, there are three huge groups of systems - contact, contactless, microprocessor. The first is divided into two subgroups - contact and using a transistor operating in switch mode. Transistors are also used in the design of a contactless ignition system. This scheme began to be actively used in the early 80s of the last century. And it has a number of advantages, which will be discussed below. The switch circuit is simple; it can be implemented both on transistors and on a controller.

But the contactless ignition system also has many disadvantages when compared with a microprocessor one. The latter allows you to control almost all engine parameters. BSZ does not allow this; it also cannot be used normally on injection engines. The reason for the obsolescence of the contactless system lies not only in the development of electronics and the automotive industry, but also in the adoption of stringent measures to ensure the environmental friendliness of internal combustion engines. Unfortunately, only microprocessor control can reduce the amount of harmful substances in the exhaust.

Contact SZ

The ignition power in this system comes from the battery or generator (mostly) - this is a classic.

However, the contact SZ, over time, during operation, ceased to be reliable.

The reason for this was the emergence of more modern engines, which began to operate under different load conditions, with different fuel mixtures and had a larger number of cylinders.

Therefore, in the mid-60s of the last century, the contact ignition system completely outlived its usefulness and was replaced by a contact-transistor SZ.

What is and what is the principle of operation of the ignition switch

Even on the very first cars, battery ignition systems were used to ignite the combustible mixture, the functional diagram of which is shown in the figure. This

figure makes it possible to understand that its operation is based on the principle of self-induction. When the current flow circuit in the winding of bobbin 3 is broken, a high-voltage EMF is induced in the secondary, causing a spark to appear on the contacts of spark plug 2. The circuit break is caused by the opening of the contacts of breaker 6.

Without touching on the advantages or disadvantages, it should be noted that this scheme worked on the car for a long time. And only the emergence of a new element base gave impetus to the further development of such a device, preserving the original principle of its operation.

Ignition coil malfunctions

The most common faults are:

- Interturn short circuit between the primary and secondary windings;

- Open circuit in the 1st or 2nd windings;

- Insulation breakdown of the second winding on the coil body.

The main signs of a faulty ignition coil:

- There are traces of oil leakage on the cover;

- Cracks and scabs on the lid;

- The ohmmeter readings are not correct (read on).

If these problems are detected, the ignition coil should be replaced.

Low and high voltage wires:

High voltage wires:

1. High-voltage wires serve to transmit high-voltage current from the ignition coil itself and to each cylinder spark plug.

2. Cars of the Samara family are equipped with high-voltage wires with a distributed resistance of 2550±270 Ohm/m.

3. Under no circumstances try to start a car with a broken high-voltage voltage circuit, that is, to put it simply: The car’s engine does not need to be started with the high-voltage wires removed, as well as with the ignition distributor cap removed. Such actions can lead to failure of the ignition system elements, as well as breakdown of the insulation, so be careful.

4. It is also not recommended to handle or touch high voltage wires when the car engine is in working condition, because this can lead to electrical injury.

Note! When checking high-voltage wires for the presence of a spark, it is recommended to disconnect the wires with the engine turned off, and if the engine is started, the wires should be secured at a distance of 5-10 mm from the mass of the car, and these wires should not be in your hands, even in only if you hold them with a tool!

Low voltage wires:

1. Every person has encountered such wires in his life; they are most often of small thickness and have a very flexible shape, unlike high-voltage wires.

2. And most often, low-voltage wires have a combined color, that is, they come in both red and blue, and have many other colors.

3. A striking example of where the low voltage wires are connected is the same ignition coil, because if you look at it carefully, then on its side you can see two wires, one of which is “red” and the other “blue”. (see photo above)

This is interesting: Why Vesta turned out to be more popular than X-Ray: comparative analysis

Table: cost of switches

| Switch models | Price in rubles |

| Switch GAZ 131.3734 Rhombus | 400 |

| Transistor 1302.3734 | 450 |

| 133.3774 (analogue 3620.37740) VAZ 2108-099, Tavria (Energomash) (20) | 450 |

| Switch for cars VAZ 2108-2110, VAZ 2121 “SOATE” | 500 |

| 0529.3734 Vinnitsa VAZ 2121 - 21214 NIVA | 500 |

| 12.3774-01 (an.76.3774-02) ` Switch ZIL-130, -43410, AZ-53, PAZ, LIAZ, KAVZ (Energomash) | 600 |

| Energomash Switch VAZ-2108-10, 2121,1111 (96.3734,3620.3734,76.3734) (Energomash) with emergency mode and diagnostics | 700 |

| Switch GAZ 131.3734 SOATE | 700 |

| 131.3734 Switch Volga, GAZ, UAZ, IZH, ZIL-130, Moskvich, PAZ, KAVZ (SOATE) | 800 |

| Switch with modern electronic base for GAZ, UAZ "SOATE" vehicles | 850 |

| Ignition system switch TK-200-0 / TK-200-01-0 (analogous to BU931) | 1000 |

How does the scheme work?

The contactless ignition system of the VAZ 2109 has a fairly simple operating principle, based on the sequential inclusion of various elements in the design. The electronic components of the circuit regulate the formation and supply of sparks to the working bodies. All this works according to the following principle:

- The rotation of the starter drives the camshaft, which in turn starts the distributor.

- The distributor contains a Hall sensor, near which there is a device with a hole. It serves to create a signal under the influence of a magnetic field.

- The electrical signal from the distributor goes to the switch.

- From the commutator, energy is supplied to a coil of two windings. There is a multiple increase in the charge, after which it goes to the ignition distributor.

- The current is distributed through the spark plugs, and the air-fuel mixture ignites.

To ensure proper spark distribution, the following occurs:

- A sensor located near the crankshaft transmits a signal to system monitoring devices.

- The controllers, in turn, process the received information and create the order in which current is supplied from the coils to the spark plugs.

- The coils create sparks - one to ignite the air-fuel mixture, the second to idle.

Return to contents

Verification procedure

If you detect one or more signs of “dying” of the coil or if it is impossible to start the engine, you should definitely check its performance. This is necessary in order to find out what nature of the breakdown occurred, and, therefore, begin to eliminate it. Can this be done without instruments? Unfortunately no. Unless you immediately replace the coil with a known good one. At the very least, a regular multimeter will suffice. Such a tester must be kept in the car - its cost is almost symbolic.

In general, verification is relatively easy. It is enough to follow the steps described below, and even a completely inexperienced car enthusiast can handle it.

First of all, you need to inspect the ignition unit itself. If the engine does not start at all, then you need to find out if there is a spark. You need to do this:

- disconnect the main wire from the distributor (located in the center);

- connect a candle to it;

- holding it with pliers, apply it to the motor housing or to the breaker;

- turn on the ignition.

If there is no spark, there is only one conclusion - failure in the coil. Next, you need to find out whether electricity is supplied to it.

The check is carried out with a multimeter. One of its probes is applied to terminal “B” on the coil, the second to ground. If there is no voltage after turning on the ignition, the fault is looked for directly in the lock.

In addition, it is also possible to power the coil using an emergency circuit. Here the wire from the positive terminal of the battery is connected to contact “B”. In this situation, you can be absolutely sure that voltage is supplied. However, when these actions did not lead to a spark, you will have to test the primary winding for integrity.

- the wiring located on its sides is disconnected (they are low-voltage);

- the multimeter is set to Ohms and the resistance is measured;

- The secondary winding is also ringed in the same way.