Tell me how to change the temperature at which the fan turns on? without flashing and bk? Are there any sensors with lower t? 21099 engineer

I set the sensor to 9 at 85 or 87 degrees. At this temperature it turned on the fan!

It’s not enough, then it will constantly spin. I'd like 95 degrees.

I think they are standard 97-94 g.

It’s not enough, then it will constantly spin. I'd like 95 degrees.

Why are you not satisfied with the standard sensor?

turns on late, starts to boil

BOILING POINT OF ANTIFESTINE 115 *C.

I have a ten, the fan turns on at 104 * C, but there are no problems with boiling even in summer traffic jams.

why then am I boiling?((

nope. the temperature rises and the antifreeze in the barrel rises and pours out

Maybe your antifreeze is low? They diluted it with water, the boiling point dropped... Better replace it with a new one... Winter is just around the corner, it won't hurt

I replaced the heater radiator and refilled it with new antifreeze. so it’s not loose)) I seem to have a leak somewhere. I'm tired of topping up. although the puddles under the car are not visible. Perhaps there is a leak somewhere, air gets in and a plug is formed.

I replaced the heater radiator and refilled it with new antifreeze. so it’s not loose)) I seem to have a leak somewhere. I'm tired of topping up. although the puddles under the car are not visible. Perhaps there is a leak somewhere, air gets in and a plug is formed.

this could be the reason... The coolant level is low, so it boils... How to cool if the radiator is empty? Look for a leak.

I'll look tomorrow.

The radiator is heating up. This means there is liquid)) I installed a new thermostat. There is heat in the stove. This means there is antifreeze all around. And it’s unclear where it goes. I'll look for it

when it boils, touch all the pipes, they should all be the same temperature! most likely the pump or, in the worst case, the cylinder head gasket!

I replaced the heater radiator and refilled it with new antifreeze. so it’s not loose)) I seem to have a leak somewhere. I'm tired of topping up. although the puddles under the car are not visible. Perhaps there is a leak somewhere, air gets in and a plug is formed.

if the antifreeze goes away, and under the car, look dry in the cabin under the mats))

I found it at my place, tomorrow I will change the carpet(

not necessary. I have leaked 2 times. 1st time the tap, and 2nd time the pipe. everything was wet. I took off the seats, took the carpet out into the sun for half a day (while I changed everything) and put it back;)

why then am I boiling?((

nope. the temperature rises and the antifreeze in the barrel rises and pours out

check the cap on the tank... if it is not tight. then the antifreeze will boil before the fan starts...

On the Carlson injector, it is turned on by software (there are on and off values) can be set with the BC or software via an on-line adapter. Otherwise, there is no way. The temperature sensor shows the computer the engine temperature, and the decision to turn on and off makes the computer based on the set temperature. So replacing the sensor It won't give you anything. It's not a carburetor with a thermocouple.

If the antifreeze goes away and there are no puddles, my friend, it’s most likely the gasket has burned out! That’s why you’re boiling!

I was told that the level should then immediately rise. And on the highway or when I drive fast, it stays within 90-95 If you only stand at traffic lights in the city, it boils

if the fluid leaves in large quantities, but there are no leaks anywhere, it means the gasket. I have a friend who is driving the same thing right now. He has 16kl 10 and there is not a single drop of leak anywhere, and he already buys antifreeze by the barrel

Definitely not a gasket. I noticed something else just now. Antifreeze is already starting to pour straight out of the barrel and the fan is not going to turn on. The arrow is narrower near the red zone. I turn off the engine but the ignition is on and only then does the fan come on

did you change the sensor? and change the cover

so I don’t have a fan sensor on the injector))

I got lost)))) I’m used to the fact that I have carb

Yes, I just found out that I don’t have a sensor)) I looked around and looked for it, but it wasn’t there. Then I read that it shouldn’t exist. It seems that only firmware can be configured. But that's why the fan turns on only after I turn off the engine. Unclear

Well, if it’s an injector, then it’s all there through the brain! They control the whole process! You can go for diagnostics, they’ll tell you or change it! I changed the temperature of the fan on my equipment! Well, no matter what, people are happy)))))

It could also be the expansion tank cap. Doesn't hold the required pressure...

That could also be the case. I'll change

look for a broken cylinder head gasket. carefully examine the unscrewed spark plugs, one of them may be damp, and if you shine it into the cylinder, it will have a different shade, and the smell from the cylinder with antifreeze will also be different. And if it goes away decently, then it will start again periodically when I started it, drove it, turned it off, and then started it again later.

At what engine temperature should the cooling fan operate?

Well, it’s okay to make fun of a person, the New Year seems to be over.

At what temperature should the thermal sensors on the radiator operate (the fan turn on)?

Rezo is right as always.

At 92 degrees, the contact in the sensor on the radiator should close, and, accordingly, the fan should turn on. When the temperature drops to 87, the contact in the sensor opens and the fan turns off. This is what it says in the repair manuals.

I had a domestic sensor 92/87 in 21061. The engine seemed to be overheating in traffic jams. At some point I changed the sensor to Vernet with the same temperatures of 92/87. The engine overheated, just like with the domestic one. So I drove, suffered, adjusted the ignition, carburetor, nothing helped.

At some point, Vernet died, it started turning on at 60-70 degrees, the fan was spinning without stopping. I changed the sensor again to a domestic one. I thought it said 82/87. The fan started turning on at a lower temperature. Previously, the temperature gauge in warm weather in traffic was kept midway between 90 degrees and the red zone. After the replacement, the needle began to stabilize 1mm to the right of 90 degrees. So that’s what it’s all about, I decided and started shopping around in search of domestic 82/87 sensors. I decided that these are the sensors that are needed for the classics. Salespeople in stores looked at me like I was an idiot and explained that there were no 82/87 sensors.

In short, I reviewed a lot of temperature sensors for the classics. All of them were stamped with 92/87 (or 87/92? I don’t remember). But, there were often those on which the number “9” was printed so that it looked like “8”. Maybe the one on my radiator is also 9, similar to 8. It’s hard to see now.

And the fact that after replacing the sensor my temperature regime became a little milder is apparently explained by the variation in switching temperatures. Perhaps my switching temperature is not 92, but, say, 90.

The moral is this: if the switching temperature is critical for someone (I suspect that in the summer this is important for many classicists), then you can try to select a specific copy from those available in the store. But you can try to do what I couldn’t do - find the 82/87 sensor.

Source

Checking the functionality of the sensor

Checking the functionality of the device should begin with monitoring the response temperature. To do this you will need a thermometer and a multimeter. All actions can be performed independently, without resorting to a visit to the service center. If the multimeter is equipped with a thermocouple, then there is no need for a thermometer. To check the sensor, follow the instructions below:

If there is a critical deviation of the response limit, the sensor must be replaced. After purchasing a new device, you must check its suitability. Defective products are very common on sale, so checking whether the sensor turns on correctly is the responsibility of every car owner.

Why is an engine cooling system needed?

Imagine, in order to cool the engine. Thanks, Cap! But everything is not so simple. The engine operates completely correctly only in a certain temperature range - usually 80-110 degrees Celsius. The cooling system not only cools, but maintains the engine temperature within these limits. In addition, it also serves as a heat source for the car heater. So, in addition to overheating, it also saves the engine from cold. And at the same time for you when you dive into the cabin from the cold.

Possible causes, their search and solution

There may be several reasons why the cooling fan turns on on a cold VAZ 2114 engine. The most likely of them are:

- low level of coolant in the system;

- sensor failure;

- fan short circuit;

- thermostat failure.

You should start your search with the first reason, since it is the most probable and at the same time the most quickly resolved. When the coolant level is low, the sensor can operate almost immediately after starting the engine, thus turning on the fan. This is due to the fact that a small amount of liquid heats up very quickly, while the engine itself is still “cold”. In order to solve this problem, you just need to add coolant to the required level.

It should be remembered that a low coolant level can lead to overheating and even engine failure, so the amount of fluid should be regularly monitored and replenished if necessary.

If it turns out that there is enough antifreeze in the system, and this is not the reason, then you should check the sensor itself. It happens that it “sticks” in the closed position, as a result of which the fan circuit is always on. You can check the functionality of the device using a multimeter.

If you measure the resistance at the sensor contacts with the engine off, the tester should go off scale or show 0, depending on the model of the device (that is, the resistance will tend to infinity). If the multimeter shows very specific numbers, then the sensor is permanently closed, and it should be replaced with a new, similar one.

It is very convenient to check the cooling system using a special diagnostic tester. It will show all possible faults, including a breakdown of the fan sensor (each element has its own error code).

If the sensor also turns out to be working, then you should check the fan. Sometimes (especially if the housing is poorly screwed on or the wires are poorly insulated), it shorts to ground, as a result of which the fan starts working directly from the battery, without the participation of an electronic circuit with a sensor. This cause can be eliminated by checking and tightening all fasteners, as well as insulating exposed wire sections.

It should be remembered that such a malfunction is quite serious and can cause:

- Rapid fan wear.

- Battery discharge (if you leave the ignition on without the engine running).

- Car fires (due to strong heating of wires).

That is why special attention should be paid to searching for possible faults (exposed sections of wires).

The last reason that can lead to spontaneous turning on of the fan is a breakdown of the thermostat (or rather the control sensor installed on it). The bottom line is this: if the thermostat sensor fails, the electronic unit automatically starts a fan to cool the system, since the electronic unit cannot accurately control the temperature of the liquid. A kind of “reinsurance” is performed in case of possible overheating.

In order to identify a sensor failure, you will again need a multimeter. When checking, you should measure the resistance between the sensor contacts (with the engine off, of course). Normally, it should be no less than 100 and no more than 500 Ohms. If the values obtained during measurement are outside the limits of this norm, then the sensor should be replaced with a new one. Finishing the conversation about the possible reasons for the fan turning on spontaneously, we should say a few words about how to prevent them.

To do this you will need:

- promptly monitor the coolant level in the system;

- periodically check the condition of the electronic wires of the cooling system;

- clean the sensor contacts from emerging oxides (it is recommended to carry out a similar procedure twice a year - in autumn and spring).

If you notice that the fan begins to turn on on its own, then the search for a breakdown cannot be put off until later, since the consequences (in some cases) can be extremely serious. Published September 29, 2019

Many motorists during the operation of the VAZ-2114 have encountered the fact that the engine cooling fan turns on. But not everyone knows at what temperature it should operate. This indicator is inextricably linked by the design of the cooling system and the embedded ECU program.

[custom_ads_shortcode2]

What should I add? Antifreeze (and what color) or antifreeze?

First, let's resolve the issue of confusion in terms. Antifreeze is not a type of technical fluid. This is the brand under which antifreeze is produced. That is, once again, antifreeze is antifreeze.

Another question is about antifreeze colors. Here the answer is simple: the color of antifreeze is determined by the dye. And the working qualities do not depend on the color, but on the so-called tolerance. Antifreeze approval is some mysterious numbers with letters, like “G12++”. The car manufacturer must write in the documentation for the car what tolerance the antifreeze poured into the cooling system must have. So if you have red antifreeze with G12++ approval, you can safely add green antifreeze with the same approval to the system - everything will work normally. The resulting brown color will only be a little disappointing - but this only affects aesthetics.

Replacement with draining antifreeze

If you discover that the device is not functioning correctly or is completely inoperable, you need to replace it with a new one. To perform dismantling, you must follow the instructions:

- If the engine is hot, it must be allowed to cool;

- De-energize the vehicle ground by disconnecting the negative terminal of the battery;

- Remove the expansion tank cap;

- Remove the radiator cap;

- To prevent contamination, it is necessary to place a container under the drain hole;

- Drain the antifreeze from the radiator. There is no need to drain antifreeze from the cylinder block. To unscrew the drain plug, just a hand is enough, so no tools are needed;

- When the liquid stops flowing out, you should return the plug to its place to avoid its loss;

- Remove the terminal with wires;

- Use a wrench to carefully unscrew the sensor.

To install a new sensor you must:

- Check the condition of the copper sealing washer. In most cases, it will require replacement with a new one. Using an old gasket is fraught with antifreeze leaks;

- Screw in the new sensor, making sure that the sealing washer fits evenly;

- Connect the terminals with wires;

- Pour antifreeze into the expansion tank. If the drained antifreeze is of good quality, you can return it. Otherwise, fresh fluid must be used;

- To eliminate air pockets in the cooling system, it is necessary to purge it;

- Replace the radiator cap;

- Close the expansion tank;

- Connect the negative terminal of the battery;

- Warm up the engine until the sensor responds.

If after these steps the fan does not turn on when the required temperature is reached, it is necessary to continue troubleshooting in other possible places. Before continuing to search for a breakdown, it is advisable to read the error log from the ECU using a diagnostic scanner.

Is it possible to pour water into the cooling system?

Yes. But it is very undesirable. Besides the fact that this is only permissible in the hot season, water will be very reluctant to live at a temperature of 110 degrees. Modern engines are designed specifically to work with antifreeze. So you can add water only in extreme cases - when, for example, you use a liter or two of fluid in a day, and you still have a month to go before repairs (this happens, after all). Then yes - in order not to go broke, you will have to pour water. But only distilled! It is sold in spare parts stores and is inexpensive. Ordinary tap water contains all sorts of salts and other impurities that cause active corrosion of the cooling system channels. Once you fill it with tap water, you run the risk of encountering a bunch of unpleasant surprises after a while.

Installing a new sensor without draining the coolant

In the injection engine of most car models, the sensor is located high in the cooling system, which allows it to be removed without a significant spill of antifreeze. To do this, you must follow the instructions below:

- Do not unscrew the sensor completely. In this case, a slight leakage of antifreeze will begin;

- Check the copper washer on the new sensor;

- Unscrew the old device with one hand and quickly bring the new one in with the other;

- After tightening the regulator, thoroughly wipe the area from any coolant drips;

- Check the quality of installation for leaks.

With this method, the car owner can significantly save time. The disadvantage of this method is the need to make a replacement quickly, which can cause difficulties for inexperienced car enthusiasts. If the circumstances are unfortunate, a large amount of antifreeze may spill from the cooling system.

Keeping all elements of the cooling system in working order will protect the engine from overheating and unpleasant consequences. It is necessary to carry out timely monitoring of the operation of the regulator, especially when the first symptoms of overheating appear. Since the work requires the presence of heated fluid, all manipulations should be performed on a cooled engine. This will protect the car owner from thermal injuries.

Automotive cooling systems with an electric fan drive automatically turn the fan on and off when the coolant temperature changes. The main role in the system is played by the fan switch sensor - you can learn everything about this component from this article.

What other maintenance does the cooling system require?

In addition to flushing the system “inside” (with replacing antifreeze), it is necessary to monitor the condition of the radiator. It gets clogged with dirt flying from the road, which over time turns into a kind of “fur coat” that does not allow air to blow through the radiator and effectively cool the engine. To avoid this, it is advisable to flush the radiator from the outside once every couple of years: usually this requires removing it and washing it with a low-pressure washer so as not to damage it.

When should the cooling system fan turn on?

The fan turns on even when the car is not warmed up, if the air conditioner is running: in this case, it rotates at the first, reduced speed. This is the normal mode.

In addition, it will turn on at a second, high speed if the engine temperature is close to maximum: it will cool the liquid, the motor temperature will drop by 10-20 degrees, and the fan will turn off the second speed. Then, when the engine warms up again to the upper operating level, the fan will turn on again. And so on - this is normal operating mode.

How to lower your scores

As a rule, most users begin to think about the temperature after the laptop begins to behave unstable: it reboots for no reason, turns off, and “brakes” appear in games and videos. By the way, these are the most basic manifestations of device overheating.

You can also notice overheating by how the PC starts to make noise: the cooler will spin at maximum, creating noise. In addition, the device body will become warm, sometimes even hot (at the air outlet, most often on the left side).

Let's look at the most basic causes of overheating. By the way, also consider the temperature in the room in which the laptop is working. In extreme heat 35-40 degrees. (as it was in the summer of 2010) - it will not be surprising if even a processor that was working normally before starts to overheat.

Eliminate surface heating

Few people know, much less look at, the operating instructions for the device. All manufacturers indicate that the device should be operated on a clean, level, dry surface. If, for example, you place your laptop on a soft surface that blocks air exchange and ventilation through special openings. It’s very easy to fix this - use a flat table or stand without tablecloths, napkins or other textiles.

Is it possible to drive if the cooling fan is faulty?

Oddly enough, in some cases it is possible. The fan sucks air through the radiator grille onto the radiator itself, that is, when you drive, the incoming air flow cools the engine in the same way as the fan does. You just need to turn off the air conditioner - it generates excess heat, and without a fan the incoming air flow may not be able to cope. In addition, in this case, it is highly not recommended to get into dense traffic jams - as soon as you stop, the cooling disappears, and the engine will immediately “boil”.

Source

Diagnostics using ODB-2 scanner

The general technical condition of the car can always be checked using a personal diagnostic car scanner.

Of the options available on the market, we recommend paying attention to the Korean-made scanner Scan Tool Pro Black Edition. This model is perfectly compatible with most domestic and foreign cars

A special feature of the device is comprehensive car diagnostics. Unlike analogues, this auto scanner is capable of diagnosing not only the engine, but also ABS, gearbox, transmission, airbag, air conditioning system, etc. The device is also great when used as an on-board computer: in real time it displays speed, revolutions, readings from all available sensors, oil pressure, temperature and much more.

The design of the cooling system and the principle of turning on the fan

Engine temperature indicator

Before we begin to directly consider the temperature at which the cooling fan turns on, it is worth understanding the operating principle itself. So, coolant circulates through the system and removes heat from the engine to the radiator. This element, in turn, conducts natural cooling of the liquid with a counter flow of air.

If natural cooling is not enough, the fan turns on. This happens under certain conditions.

Before considering all the factors and the temperature at which the fan turns on, it is worth understanding the design of the cooling system and the circulation of coolant:

1 – element in the form of a plug for the expansion tank; 2 – expansion tank; 3 – hose for draining liquid from the pipe; 4 – hose passing between the radiator and the expansion tank; 5 – hose leading from the radiator; 6 – tank to the left of the radiator; 7 – aluminum tube; 8 – plug systems; 9 – tank to the right of the radiator; 10 – drain plug; 11 – middle of the radiator; 12 – casing for electric fan; 13 – plastic wings of the electric fan; 14 – electric motor; 15 – toothed pump pulley; 16 – pump impeller; 17 – camshaft drive belt; 18 – engine block; 19 – pump pipe; 20 – radiator hose with supply function; 21 – heater radiator hose with drain function; 22 – hose supplying coolant to the throttle pipe; 23 – exhaust pipe; 24 – hose for refilling; 25 – heater radiator hose with supply function; 26 – thermostat; 27 – coolant temperature sensor; 28 – coolant level indicator sensor.

What should the engine temperature be?

According to the international automobile convention of December 1, 1992, where 92 representatives of the auto industry gathered, it was decided to establish a single standard for engine operating temperature.

This indicator is 90 degrees Celsius with a maximum permissible deviation of no more than 3 degrees Celsius.

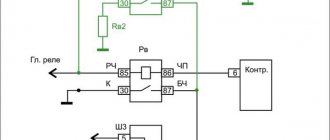

Cooling fan connection diagram

But, given the region of operation and the ambient temperature, this temperature tends to rise. It is for this purpose that automakers came up with a cooling system fan, which provides additional cooling of the fluid in the system. It is driven by a temperature sensor, which detects it in the engine and is located directly on the power unit.

When the fan on the VAZ-2114 turns on

According to the decision of the convention and internal regulatory documents of the AvtoVAZ plant, the limit values for the coolant temperature are 85-105 degrees.

Thus, for normal engine operation, the system temperature should not rise above 105 degrees. This indicator is the starting point for turning on the cooling system fan. This data is stored in an electronic control unit, which regulates the operation of the fan.

The fan switching circuit looks something like this: the engine temperature reaches 105 degrees Celsius, then the sensor sends a signal to the ECU, which turns on the fan and stops it when the temperature in the system reaches 93-99 degrees Celsius.

Cooling temperature sensor

In summer and winter, as practice shows, the fan turns on at different temperatures and for different periods. In summer, forced cooling will turn on more often as the radiator is cooled by the hot air flow. In winter, the fan almost does not turn on or its operation is limited to a short period, since natural cooling is quite sufficient. Therefore, the main radiator breakdowns occur in the warm season.

The only nuance when cooling will often turn on in winter is if the thermostat is faulty (see “replacing the thermostat on a VAZ-2114”).

conclusions

It was determined that the normal operating temperature of the VAZ-2114 coolant is 85-105 degrees Celsius.

In this case, the temperature at which the cooling fan turns on will be 105 degrees Celsius.

The internal combustion engine has a narrow operating temperature range. Exceeding it leads to serious consequences, including failure of the power plant. To prevent engine overheating, its temperature is monitored by the fan switch sensor and the injector brains.

Why the Fan Doesn't Work on 2112

The fan does not work cooling the VAZ-2110. Cooling fan circuit diagram

Precise operation of the cooling system is necessary to ensure safe and stable thermal conditions of the internal combustion engine. The slightest failure will lead to overheating of the engine, which can lead to burnout of the head gasket or failure of the piston group elements.

The radiator fan is one of the key components of a car's cooling system. Its role is to quickly cool the liquid in the radiator. Problems turning it on. a common occurrence for our cars.

In this article we will talk about possible reasons why the cooling fan does not work in the VAZ-2110, and also consider options for removing them. But first, let's look at its design and working principle.

What is a radiator fan

Structurally, the radiator fan consists of:

- frame (frame);

- drive (electric motor);

- Impellers.

The shaft-mounted impeller motor is mounted inside a rectangular metal frame that secures it to the rear of the radiator. When voltage (12V) is applied to the actuator contacts, it begins to work, rotating the blades and creating a directed air flow that actually cools the antifreeze or antifreeze.

Fan circuit for carburetor and injection engines

The control of forced radiator purging in carburetor and injection engines of the VAZ-2110 is significantly different. Heater fan not working - forum. First, the fan switch located on the radiator housing is responsible. Set the specific coolant (coolant) temperature. Usually this is 105-107 o C. Why the fan does not work on the VAZ 2114 | auto. When the coolant reaches this temperature, the sensor is activated, sending a signal to the fan relay. It completes the electrical circuit, controlling the electric motor.

The cooling fan of the VAZ-2110 with an injection engine turns on a little differently. Do not turn off the Lada Grant VAZ car and the radiator fan. Why is the fan and temperature sensor not working, Ford. For engines equipped with an electronic control unit, there is no sensor on the radiator. It was replaced by a temperature sensor located on the thermostat nozzle. The cooling fan on the VAZ 2112 does not turn on. Why the cooling fan on the VAZ-2112 does not work. When the coolant reaches 105-107°C, it sends a signal directly to the controller, which decides to turn on the fan. It transmits an electrical impulse to a relay, which turns on the drive.

If the VAZ-2110 cooling fan does not work, do not rush to contact the service center. You can determine the cause of the error yourself. Moreover, you don't need to have any special skills.

Procedure. Step-by-step instruction

If after completing the next step the problem goes away, further checks are stopped.

- Open the hood.

- Wait for the engine to cool down.

- Perform an initial visual inspection: integrity of the hoses, reliability of the clamps, absence of leaks or cracks.

- Make sure that the expander cover elements are in good condition. Remove scale, rust, clear holes, wipe, assemble. The absence of noticeable damage to parts gives hope that the product will work.

The valve design is elementary. The cover contains a spring. Functionally, it is designed to regulate the pressure in the cooling circuit. A hot engine increases it, a cold engine decreases it.

Compressing at a value of 1.1 atmospheres, the spring relieves excess pressure and prevents the destruction of hoses and the tank. As the motor cools, it creates a vacuum effect. The tank will begin to flatten. The valve equalizes the pressure.

The lid screws tightly on the thread, eliminating distortions. There should be a gap between it and the body. An overtightened valve will not work. It is difficult to test the device's operation in road conditions. You can check by replacing it with a known good one.

Inspect the electrical wiring elements to ensure a reliable connection

Possible factors for damage to electrical circuits:

- vibration;

- oxidation;

- burning;

- breakage, fraying of electrical wires;

- insulation aging, short circuit.

Switch the tester to resistance measurement mode. Remove it with special tweezers and ring the fuse link F7 located in the mounting block.

Fuse box diagram

Replace the burnt-out element with a serviceable one with a rating of 20A. Inspect and clean the nest. Insert fuse.

It was not possible to find out the reason, the protection triggered again - look for a short circuit.

Disconnect the fan plug. Use a tester to measure the circuit of the electric motor windings. Zero resistance or a break indicate the need to replace the radiator blower electric drive.

Interturn short circuits that cause multiple replacements of fuse links cannot be measured with the device.

Sensor check

Start the car. Pull out the coolant temperature sensor connector. The fan starts working - the sensor needs to be replaced. Secure the disconnected wire. Drive to a nearby service station.

Relay test

There is a hatch on the floor at the front passenger's feet.

Below it is a built-in panel with three relays of the same type:

- fan installation;

- fuel pump;

- ignition (main thing).

By replacing each other, try to start the airflow. The VAZ 2110 fan does not work - go to the next step.

Check the electric motor

Winding measurements did not reveal a malfunction. Apply voltage briefly from the battery using additional insulated conductors. The operation of the fan indicates a malfunction of the controller, which does not output a signal to the relay.

- The only correct solution is to turn on the airflow directly and urgently visit a service station.

- Prevention of breakdowns of the cooling system of the VAZ 2110 injector 16 valves.

- Periodically inspect the components of the cooling system.

- Monitor the cooling temperature on the device, listen to the operation of the fan.

- Maintain coolant level. Replace after 2 years or 30,000 km.

- Use the solution to remove rust and scale.

- Signs of a change in the properties of the coolant are a change in color, an increase in fluidity.

- Check the density with a hydrometer.

- Do not mix coolants.

- Every twelve months, rinse the expansion tank cap with water and check it on a stand with a pressure gauge.

- Avoid contact of aggressive liquids with electrical wiring and electric motor windings.

Procedure. Step-by-step instruction

If after completing the next step the problem goes away, further checks are stopped.

- Open the hood.

- Wait for the engine to cool down.

- Perform an initial visual inspection: integrity of the hoses, reliability of the clamps, absence of leaks or cracks.

- Make sure that the expander cover elements are in good condition. Remove scale, rust, clear holes, wipe, assemble. The absence of noticeable damage to parts gives hope that the product will work.

The valve design is elementary. The cover contains a spring. Functionally, it is designed to regulate the pressure in the cooling circuit. A hot engine increases it, a cold engine decreases it.

Compressing at a value of 1.1 atmospheres, the spring relieves excess pressure and prevents the destruction of hoses and the tank. As the motor cools, it creates a vacuum effect. The tank will begin to flatten. The valve equalizes the pressure.

The lid screws tightly on the thread, eliminating distortions. There should be a gap between it and the body. An overtightened valve will not work. It is difficult to test the device's operation in road conditions. You can check by replacing it with a known good one.

Inspect the electrical wiring elements to ensure a reliable connection

Possible factors for damage to electrical circuits:

- vibration;

- oxidation;

- burning;

- breakage, fraying of electrical wires;

- insulation aging, short circuit.

Switch the tester to resistance measurement mode. Remove it with special tweezers and ring the fuse link F7 located in the mounting block.

Replace the burnt-out element with a serviceable one with a rating of 20A. Inspect and clean the nest. Insert fuse.

It was not possible to find out the reason, the protection triggered again - look for a short circuit.

Disconnect the fan plug. Use a tester to measure the circuit of the electric motor windings. Zero resistance or a break indicate the need to replace the radiator blower electric drive.

Interturn short circuits that cause multiple replacements of fuse links cannot be measured with the device.

Sensor check

Start the car. Pull out the coolant temperature sensor connector. The fan starts working - the sensor needs to be replaced. Secure the disconnected wire. Drive to a nearby service station.

Relay test

There is a hatch on the floor at the front passenger's feet.

Below it is a built-in panel with three relays of the same type:

- fan installation;

- fuel pump;

- ignition (main thing).

By replacing each other, try to start the airflow. The VAZ 2110 fan does not work - go to the next step.

Check the electric motor

Winding measurements did not reveal a malfunction. Apply voltage briefly from the battery using additional insulated conductors. The operation of the fan indicates a malfunction of the controller, which does not output a signal to the relay.

- The only correct solution is to turn on the airflow directly and urgently visit a service station.

- Prevention of breakdowns of the cooling system of the VAZ 2110 injector 16 valves.

- Periodically inspect the components of the cooling system.

- Monitor the cooling temperature on the device, listen to the operation of the fan.

- Maintain coolant level. Replace after 2 years or 30,000 km.

- Use the solution to remove rust and scale.

- Signs of a change in the properties of the coolant are a change in color, an increase in fluidity.

- Check the density with a hydrometer.

- Do not mix coolants.

- Every twelve months, rinse the expansion tank cap with water and check it on a stand with a pressure gauge.

- Avoid contact of aggressive liquids with electrical wiring and electric motor windings.

Improvements to the fan start control circuit for the VAZ 2110 injector

The smooth functioning of the engine worries factory designers, auto mechanics, and car enthusiasts. Folk craftsmen change the design of valves and electrical circuits.

Installation of three position toggle switch:

- continuously on: the VAZ 2110 cooling fan does not work;

- constantly switched off: warming up the engine when starting in the cold season, automatic control is faulty;

- automatic mode: controlled by the controller, the equipment is working properly, the algorithm is executed correctly.

When choosing an installation location, consider the following conditions:

- prevent accidental switching;

- not to be confused with other controls.

It is important to remember when modifying the design about the safety of the changes made.