An engine operating at extreme temperatures will require expensive repairs or replacement. How to organize uninterrupted engine cooling? Why does the VAZ 2110 injector cooling fan not work?

A 10-minute reading will provide answers to these and many other questions. The article is based on the generalized experience of professional mechanics and auto electricians. Clear, proven tips will help you find and troubleshoot problems and avoid unwanted breakdowns.

Design and testing of the VAZ 2110 fan switch sensor

To maintain optimal temperature conditions of the car engine, a cooling system is designed. Its main elements are channels for antifreeze in the cylinder block, pipes, a thermostat, a radiator, and the electrical part includes a VAZ 2110 fan switch sensor, a temperature sensor and an electric motor with an impeller for cooling the radiator. Late detection of cooling system defects can lead to engine overheating and costly repairs.

Fan switch sensor LS 0108 (TM-108)

How to replace a temperature sensor

Before starting work, you need to partially drain the coolant from the cylinder block.

- Remove the wire.

- Using a 21 wrench, unscrew the temperature sensor.

- Take it off.

- Install the new one in reverse order.

Connection schemes

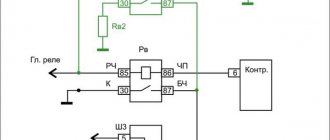

In VAZ 2110 injection and carburetor engines, the TM-108 bimetallic temperature sensor is used in different ways to control turning the fan motor on and off.

For carburetor engines it is located on the radiator on the left in the direction of travel. When the threaded part located directly in the coolant is heated, the bimetallic plate bends and closes the contacts. The voltage from the battery is supplied through a fuse to one contact of the electric motor, the second, when the sensor is triggered, is connected to the housing, setting the impeller in motion.

Fan switching sensor (carburetor VAZ 2110)

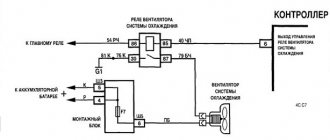

For VAZ 2110 and TM-108 injectors, it is located near the thermostat, the signal is sent to the electronic control unit (ECU). The control signal from the ECU is sent to the cooling system fan relay, which, similar to the sensor of a carburetor engine, controls the electric motor.

Injection fan switch sensor

All engines have another device in the cylinder block, the signal of which is used to indicate the coolant temperature on the panel in the cabin.

Fuse

The elementary rules of physics state that the water contained in the coolant boils at a temperature of 100 degrees.

If the fuse valve, which is located on the expansion tank, fails, and the pressure inside the tank increases, then the liquid will boil, but the fan will not start working. The cooling element will not turn on even if the electrical circuit is working properly. This all happens because the component switching sensor on the injection VAZ-2110 has a startup temperature of more than 100 degrees.

To solve the problem with the fuse, you will need to replace the cap of the expansion tank. The new part must correspond to the possible pressure inside the system and operate in a situation where the fluid temperature reaches 105 degrees. This will result in the fan blades turning on.

The fan does not turn on

There may be several reasons for this:

- Fuse. In the mounting block, fuse F7, rated 20 amperes, may be faulty - it is responsible for powering the electric fan and sound signal circuits;

- Thermostat. The liquid circulates only in a small circle, the radiator and sensor do not heat up, and accordingly, the fan does not turn on. You can check by simply probing the pipes; those connecting to the radiator should begin to warm up after opening the thermostat;

- Sensor. For a VAZ 2110 with a carburetor, the contacts are closed for testing; if the device malfunctions, the electric fan will turn on. The connector of the injection motor must be disconnected; with the remaining elements working, the ECU will detect a break in the circuit and issue a constant alarm signal to the relay, which will forcibly turn on the electric motor for cooling;

- Cooling system fan relay for VAZ 2110 injection engines. The sensor is turned off and the power contacts on the relay located in the additional fuse box are closed. If everything works, then we check the control winding: on one contact there is always a positive from the main relay, connecting the second to the body, we try to hear the operation click. But it’s better to simply replace the relay for testing, temporarily, with a known good one;

- Electric motor. During testing, the connector is disconnected; to force the impeller to turn on, voltage is supplied directly from the battery.

If all the elements are working properly, then you need to look for a break in the wires, “ringing” them one by one. Poor contact of the relay and sensor connection wire terminals with the car body is also possible. The worst case scenario would be an ECU failure, in which case the signal from “leg” 46 usually “floats” and does not reach the values of +12 volts (off) and 0 (on).

How to make a replacement

If you are convinced that the cause of the malfunction lies in the fan motor, then the easiest way to carry out repairs is to completely replace the device. In this case, there is no point in spending money on a new casing. It will be cheaper to just buy a new electric motor.

Necessary tool

No special tool is needed. The work is carried out simply using 8 and 10 socket wrenches and a Phillips screwdriver.

Step-by-step algorithm of work

You can replace the cooling fan motor without removing the radiator.

- Disconnect the connector and device wiring harness from the casing.

- Unscrew the mounting bolts using a 10mm wrench.

- Unscrew the lower fastening nut.

- Using a 10 mm socket wrench, unscrew the mounting nut from the radiator.

- Using a size 8 socket wrench, unscrew the two pressure plate nuts.

- Remove the plate.

- Remove the electric fan along with the casing.

- Let's start dismantling the electric motor. Using a 10 mm wrench, unscrew the three mounting nuts and remove the engine along with the blades.

- Using a screwdriver, pry up the lock washer.

- And take it off.

- Remove the impeller.

- Put the impeller on the new motor. Make sure that the shaft pin fits into the impeller groove.

- Reassemble in reverse order.

Checking at home

Sometimes the electric motor turns on too late, when the antifreeze temperature is already high. This may be caused by a malfunction of the valve in the radiator cap or abnormal parameters of the switch on sensor. You can check the device’s response temperature at home using a multimeter and thermometer.

After disconnecting the electrical connector, the sensor is unscrewed with a key. To avoid burns, remove the device only from a cold engine, after draining the antifreeze. When reinstalling, it is advisable to use a new sealing copper washer and not apply too much force when tightening.

The switching temperature is engraved on the end; it can be from 92 to 95 degrees. To check, you need to connect the multimeter in resistance measurement mode and immerse the threaded part in a container of water.

While heating the water and monitoring the readings of the multimeter, we use a thermometer to record the moment it turns on, and when it cools down, the temperature it turns off. Standardly, these are 92 and 87 degrees; with significant deviations, late operation is especially critical, the device requires replacement.

To improve cooling, it is possible to install a double fan from Niva. There are two modifications for placement: after the radiator or in front of it.

Nivovsky injection radiator 21214-1300024-43 (placed in front of the radiator)

On the VAZ 2110, any of the options can be installed with minimal modifications to the fasteners on site. When electric motors are connected in parallel, the current consumption increases to 40 amperes, which requires replacement of the wiring.

Nivovsky suction radiator (placed after the radiator)

Monitor the engine temperature. If you notice overheating too late, then in addition to boiling of the antifreeze and a forced stop, more serious consequences are possible: deformation of the cylinder head, jamming of the camshaft. If there are defects in the operation of the cooling system fan of the VAZ 2110, the faults can be diagnosed independently by checking the thermostat, electric motor, relay, and switch sensor.

Didn't find the information you are looking for? on our forum.

Common faults

Since the fan is spinning, it needs to be forced to stop and turn on only when there is a real need for it.

There are several main reasons why cooling system fans may turn on when the engine is cold. This is related to:

- switch on sensor;

- coolant;

- mass;

- thermostat;

- temperature sensor;

- contacts;

- air conditioning.

Each of the points may be the reason why the fan turns on and starts rotating when the engine is cold.

Power sensor

One of the most common reasons why a fan runs on a cold engine is a short circuit in the controller, that is, the sensor.

Quite often it happens that the fan starts when the ignition is turned on. If this occurs at the same time, the contacts on the controller have probably shorted. As a result, the airflow works constantly.

Although the breakdown is the most common, it is also the most harmless and safe. The worst consequence of this phenomenon is considered to be a complete discharge of the battery. This will happen if you leave the ignition on for a while.

To check whether the short is at fault or not, you will need to use a multimeter to check the resistance by applying probes to the terminals. When the sensor is working, the multimeter shows infinite resistance, that is, it displays the corresponding value on the display.

If you see that the resistance is less, then the contacts are probably closed. The controller will need to be replaced. Such a malfunction is displayed as a separate code during computer diagnostics.

Coolant

Sometimes there is no need to look for all sorts of reasons why the cooling fan suddenly turns on on a cold engine. Experienced motorists advise starting with a simple check of the coolant.

The thing is that quite often the sensor reacts by activating the fan to a lack of coolant in the system. The amount of antifreeze that is available heats up too quickly, which leads to the fan starting when the engine is still cold.

Therefore, it is not so rare that the cause of such a malfunction is the banal inattention of the car owner. Some drivers simply forget that they need to monitor the fluid level and periodically add fresh antifreeze to the expansion tank. It will gradually evaporate, so reserves need to be replenished. When the radiator is half empty, the sensor will indeed begin to react accordingly. To cool the motor, it will use air cooling, implemented using a fan.

Due to a shortage of cooling liquid, it heats up faster than with a completely filled system. And the coolant temperature does not match the engine temperature. As a result, it turns out that the engine has just been started, it has not yet warmed up, and the fan is already rotating its blades at full speed due to the high temperature of the quickly warmed up liquid.

Possible causes and their diagnosis

The main reasons why the fan on the VAZ 2114 does not work are as follows:

- the electric motor of the fan burned out;

- fuse is blown;

- the relay is broken;

- there was a break in the wiring;

- the sensor contacts have oxidized;

- The sensor has failed.

In order to check the fan motor, it is enough to disconnect it from the control unit and power it directly from the battery. If the propeller starts to rotate, then the motor is working; if not, then the fan itself will have to be replaced.

The next step in finding the problem is to check the fuse. To do this, you should find a 20 amp fuse F4, located in the common block. It should be checked with a multimeter and, if necessary, replaced with a new, similar one. At the same time, you should also clean the contacts in the fuse socket, because their oxidation can also cause a malfunction.

There is an easier and faster way to check the serviceability of fuse F4 - just honk the horn. If the signal works, then the fuse is also good - after all, they are both connected to the same fuse.

If the fuse is working, you should check the fan relay 2114. This can be done in two ways - ring the relay with a tester (for this the relay must be in the closed position) or replace the relay with a new, working one.

The second method is the most preferable, since testing with a multimeter may not always give an accurate result. If the relay turns out to be broken, then it should be replaced with exactly the same one (installing any other devices instead of the standard relay is extremely undesirable, since in most cases their operation will be incorrect).

If the relay is also working properly, then you should check the wiring. To do this, it is enough to ring all the wires included in the electrical circuit of the fan. If a break is detected, the faulty wire should be replaced, but if no breaks are found, then there will be only one possible cause - the VAZ 2114 fan sensor.

Before checking the sensor itself, you should check and clean its contacts - because if they oxidize, the device will not work correctly or will not work at all. To check the sensor itself, it should be disconnected from the power supply.

If it is operational, the fan will turn on and operate continuously (in emergency mode). After this, you should disconnect the sensor connector going to the controller and start the engine.

If the fan rotates, the sensor is faulty and should be replaced.