Removing and installing the fuel pump Lada Kalina:

- Under the floor covering there will be a metal cover, black, as shown in the photo below. You need to unscrew 4 bolts on it:

- Next, when all the screws are unscrewed, you can safely remove it with a slight movement of your hand:

- After which the following picture opens, where we see the upper part of the Kalina fuel pump and all the fittings that are connected to it:

- Now you can begin to remove the wires and hoses and the fuel pump. First, disconnect the power plug, which is located on the left side. Push the plastic lock up a little and pull the plug to the side.

- Disconnect the fittings one by one. The lower one is removed as follows: with one hand we press on the metal locking clamp, and with the other hand or pliers we pull the fitting to the side:

- The top one is removed in the same way, only there is a slightly different latch - green. You need to press on it with one hand and pull the tip to the side with the other.

- It is advisable to clean everything around the fuel pump thoroughly so that when dismantling, no dust, dirt or other debris gets inside the tank.

- Next, you can begin to remove the large metal ring that secures the pump. The factory uses a special puller for these purposes, but you can do without unnecessary devices. Simply place a flat-head screwdriver on the end of the ring and slowly tap it in a counterclockwise direction with a hammer until the ring comes out of the mounting grooves.

- The Jonnesway screwdriver coped well with this test, its body remained intact and undamaged after numerous hammer blows! After the clip has popped out, it can be removed:

- Now you can start removing the fuel pump. Take it by the top and gently lift it up. You should be very careful not to bend the structure on which the float is attached. To do this, while lifting the pump (closer to the very top), tilt its upper part slightly towards the right rear door. And take it out, as if diagonally, so as not to catch the float.

- The photo below shows the result of the work done to remove the Kalina fuel pump:

If this part needs to be replaced, then install a new pump and perform the installation in the reverse order. Be sure to wipe the rubber and around the seat dry before doing this so that no debris gets into the tank.

To access the Lada Kalina fuel pump, you need to fold back the rear seat, remove the insulation (if any), and then begin dismantling the device.

Tool for the job

- Screwdriver with flat and Phillips blade.

- Hammer.

- Pliers.

Step-by-step work order

- Disconnect the negative terminal from the battery.

- We open access to the protective cover.

Raise the rear airbag up

Then unscrew the four bolts from the black metal cover located under the rear seat.

To avoid losing, we put the bolts in one place.

When the bolts are unscrewed, remove the cover to the side.

Under the decorative cover you can see the fuel pump and DUST!

- When the cover is removed, you will see a picture where the upper part of the fuel pump is visible, as well as the fittings that are connected to it.

- Now you can begin the dismantling itself, and first of all, disconnect the power wires. To do this, remove the plastic clamp on the block and pull it to the side.

- The next step is to disconnect the fittings; in order to remove them, you need to press on the metal clamp with one hand, and use the other hand to pull the fittings to the side using pliers.

- When dismantling the second tip, note that its retainer is made of green plastic, and in order for the fitting to leave the place of fixation, you need to press on it, and then pull the tip itself to the side with your other hand.

- Before you begin removing the fuel pump, you should thoroughly clean everything of dust and dirt to prevent any debris from getting into the fuel.

- When everything is clean, you can begin to dismantle the retaining ring that secures the fuel pump to the housing. To perform these manipulations, you can use a special puller, or using a flat screwdriver and a hammer, knock it counterclockwise from the mounting points.

- Use a hammer and screwdriver carefully so as not to damage the ring or fuel pump housing.

- Then, when the ring clip has popped out of its seat, you can take it out.

- Now is the time to start removing the fuel pump itself; to do this, you need to grab it by the top part and pull it up. In this case, you should be extremely careful so as not to bend the structure. Please note that the fuel pump is equipped with a special float indicating the amount of fuel in the gas tank, and in order not to knock it down, the fuel pump should be removed so as not to touch the body of the fuel tank.

- Here is a photo example of when the fuel pump has been successfully dismantled.

The block is marked with a red arrow, and the fittings with a green arrow.

Strikes should only be made on the ring.

How to replace the fuel pump on a VAZ 1117-VAZ 1119?

Note! The fuel pump can be changed either separately from all other parts, or it can be completely replaced with a module; replacing the entire module with the entire module will be more expensive because the new module will have a Fuel Level Sensor, a pressure regulator and many other parts (Just why would you change them if they you are already in normal condition, most likely, if your sensor has become unusable and the regulator is still acting up, then change everything together), and separately, if you replace the fuel pump, then this is only one new part, and all the others will remain in place, if If you decide to replace the fuel pump separately, then in this case, after removing the pump itself, read the article entitled: “Repairing the fuel pump” in which everything is described!

Removal: 1) At the very beginning of the operation, fold back the rear seat cushion so that it does not interfere, this is done very simply, by hand pull out the hinges from under the inside of the seat (see photo 1) and then by pulling these loops, the rear seat cushion reclines like this shown in the figure under number 2, this gives you access to the fuel pump hatch and to the pump itself. As soon as access opens, fold the standard carpet to the side (it will be cut there specifically for the fuel pump, see photo 3 for more details) and remove the four screws which secure the hatch that closes the pump itself (see photo 4) and then remove it.

2) Now disconnect the block of wires from the pump itself, this is done by hand, that is, the latch that holds the block is pressed by hand and then the block is disconnected (see small photo below), then disconnect the two fuel pipes, to do this, press the latch with one screwdriver fastening one of the tubes, and with the other, slide the tube along the fitting and thereby disconnect it (see large photo), carry out exactly the same operation with the other tube and most importantly, after disconnecting them, do not confuse the tubes with each other, because they must be connected strictly in their places and if you connect them the other way around, the car simply won’t start, by the way, on some models (Depending on the year of manufacture of the car), the fuel pipes are secured not using plastic clamps on which you need to press and remove the tubes, but using metal spring clamps, So, if you have metal clamps, then you will need to wring them out and then disconnect all the tubes.

Note! Before disconnecting the pipes, do not forget to relieve the fuel pressure, this can be done in several ways, one of them is to remove the fuse that goes to the fuel pump (This fuse is not located in the mounting block where all the others are located, but under the cover which is located next to the gearshift knob, you can lift this cover with a screwdriver and the pump fuse is located in the very middle) and start the car and let it run until it stalls, the second method is described in detail in the article entitled: “Bleeding the pressure in the fuel rail on a VAZ”, well the last third method (Actually there are a little more of them, but these are the most basic of them) is very simple, disconnect the wire block as shown in the small photo above and start the car in the same way and wait until it stalls, when it stalls you can again just in case, start it up and the pressure in the power system after these procedures will be 100%!bled (The time you spend on bleeding off the pressure is a little more than one minute, but not everyone does this, but in vain, it’s safety first thing, just if you don’t bleed off the pressure in system, when the fuel pipes are disconnected, a little gasoline will flow out of them and your car will get dirty due to this, in addition, if a spark gets on the gasoline, then this will already ignite, which will not lead to anything good)!

3) Then, using two screwdrivers, rotate the plate that holds the fuel pump in one place counterclockwise until its cutouts align with the protrusions on the flange (see small photo below), once aligned, remove the plate and put it aside, and then After that, remove the fuel pump itself from the tank, but only remove it carefully without damaging the Fuel Level Sensor (The sensor just has a float, so you will have to carefully remove this float from the tank), by the way, as soon as the fuel pump is removed from the tank, look in that place where it was attached with a plate, a sealing rubber ring, if it is damaged in any way (compressed, everything is in cracks, for example, or even torn in some place), then in this case replace the ring with a new one because this ring is responsible for the tightness and if it will be damaged, then when driving over strong bumps, gasoline will flow out little by little (drop by drop) through this ring to the outside.

Installation: The new fuel pump is installed in its place in the reverse order of removal, the plate that secures the fuel pump during installation will need to be tightened a little more with light blows of a hammer through a drift and something else, there is an arrow on the fuel pump (you will see it right away), so install the new pump on its place so that this arrow points clearly to the rear of the car.

Additional video: You can briefly see the process of replacing the fuel pump with a new one in the video below, everything is shown there in pictures and in descriptions.

Note! If you want a live video clip, and not pictures, then in this case watch another video in which the fuel pump is removed using the example of a VAZ 2110 car (On Kalina it is removed a little differently and it is not secured by a plate but by nuts , but you have to look at everything so that you at least know approximately how to replace the fuel pump on a car)!

In order to get to the location of the fuel pump on the Lada Kalina, you must first recline the rear seats and remove the insulating trim on the floor.

We find the lace between the rear seat belt buckles and pull it up, raising both seats. Below I will tell you what tools may be needed for this repair:

- Phillips and flathead screwdrivers

- Hammer

- Pliers

REASONS FOR REPLACEMENT

Characteristic signs of a fuel pump malfunction:

Before you begin replacing the fuel pump, it is important to make sure that engine interruptions are related to the fuel supply and not to the ignition system, ECU, or power supply to the pump motor. It is necessary to measure the pressure in the fuel rail. If the value obtained at the time of interruptions in engine operation differs from the standard values, you can begin diagnosing the power system.

The symptoms described above can be caused not only by a faulty fuel pump, but also by a clogged mesh or fine fuel filter. Also, do not forget that the cause of interruptions in the fuel supply may be poor contact in the motor power supply circuit (torn wires, oxidation, etc.). For personal diagnostics, it is important to know the structure and operating principle of the fuel pump.

WHERE IS TN?

On the vast majority of passenger cars, the fuel pump is located inside the tank. A fuel pump with a coarse mesh, a fuel pressure regulator, a fuel level sensor and a critical fuel level sensor, and in some cars also a fine filter, are held inside the tank by the fuel section.

DESIGN FEATURES OF SOME VEHICLES

After reading the guide on how to replace the fuel pump yourself using the example of a specific car, you can easily replace it on any other car. But do not forget that in some cases the power system design will make adjustments to the replacement method.

For example, on the Ford Focus I and Chevrolet Cruze, there is no technological hole under the rear seat cushion for access to the fuel section cover, so to replace the mesh and the fuel pump itself, the tank will have to be removed. For ease of further maintenance, owners often cut holes above the fuel module themselves.

On the same Chevrolet Cruze, the manufacturer does not suggest a separate replacement of the motor and even the fuel filter (they are simply not in the catalog of original spare parts), so if the fuel pump fails, the fuel module will have to be replaced entirely. If you want to save money, you can pick up the engine, for example, from the related Opel Astra, but it will have to be adjusted a little. You can learn about this kind of design features from the repair and operation manual or from publications on specialized forums of the owners of your car model.

Tools

Replacement often requires only a socket with a wrench, Phillips and slotted screwdrivers, and pliers. In some cars, the cover of the service hole under the rear row of seats is mounted on a sealant, which will need to be cut off to access the fuel section (in most cases, the plug is screwed on with screws).

It is highly advisable to stock up on clean rags with which you can clean the hose connections and the section’s seat in the fuel tank. When replacing, it is important to prevent dust and dirt from getting inside the hoses and into the tank itself.

IMPORTANT POINTS

- After stopping the engine, pressure remains in the fuel lines for a long time. Before you begin manual replacement, the system must be emptied. To do this, you can pull out the fuel pump fuse with the engine running. Stopping the fuel supply will stop the engine, after which replacement can begin.

- Modern fuel hoses are secured with self-clamping fittings. To remove them, you need to press the clamps on the sides of the latches, after which the hose should come out of the fitting relatively easily.

- If the fuel pump is replaced in cold weather, you should be extremely careful when unsnapping the plastic clips and removing the electrical connectors. At sub-zero temperatures, plastic becomes very fragile.

- The fuel section must be removed with care, since the free exit will be hampered by the FLS float.

- When disassembling the fuel module and removing the fuel pump, pay attention to the presence of sealing collars, which must be installed during assembly without distortions or deformations.

- After you have replaced the fuel pump and installed all the elements back, turn on the ignition a couple of times so that the fuel pump pumps gasoline into the line and ramp. At this time, you can check the tightness of the connected hoses.

Many drivers immediately try to start the engine, and then complain that after replacing the fuel pump, the car does not start.

Advantages and disadvantages of a fuel pump

Despite its apparent simplicity, understanding the purpose of the fuel pump requires some explanation. The fact is that in most cases, this also applies to cars of the Lada Kalina family, the gas tank is located on the opposite side of the car from the engine. Therefore, efficient operation of the fuel pump is required to ensure that the fuel travels a significant distance at the required pressure.

The design of the Lada Kalina uses an electric fuel pump as a more modern and efficient device.

Among the main advantages of a fuel pump are several:

- ensuring the supply of the required amount of fuel taking into account the needs of the engine;

- high reliability and simplicity of design;

- high level of safety, since the pump stops working immediately after the engine stops.

At the same time, the electric fuel pump has a number of disadvantages that can affect its operation:

- noise during operation;

- need for cooling;

- demands on fuel quality.

It is the use of low-quality gasoline and untimely replacement of fuel filters that lead to a decrease in performance or failure of the gasoline pump.

REPLACEMENT GUIDE

Let's look at how to change the fuel pump yourself using the Hyundai Solaris as an example.

- Unscrew the mounting bolts and remove the rear seat cushion.

- Cut off the sealant with a utility knife.

- Remove the power plug.

- Using pliers, loosen the self-tightening clamp and remove the gasoline vapor removal hose to the adsorber.

- Remove the fuel supply hose.

- Release the ventilation hose going to the gasoline vapor adsorber from the bracket.

- Unscrew the fastening screws and remove the pressure plate.

- Pull out the fuel module.

- Remove the rubber seal.

- Disconnect the power plugs.

- We recommend removing the FLS to avoid damaging it during module disassembly.

- Remove the fuel pipe tip stopper.

- Remove the tube and O-ring.

- Press the latches of the metal guides, and then separate the parts of the housing.

Changing the mesh with your own hands

So, the mesh located in the fuel pump is forced to constantly come into contact with dust and dirt, because the pump itself is located between the seats, and dust constantly settles on its body.

That is why experienced motorists are not lazy to wipe the pump body with a damp cloth from time to time to avoid untimely clogging of the system.

To replace the mesh you need to go through several steps:

- The very first thing we do is buy a new filter.

- Raise the rear seats to provide access to the pump.

- We unscrew the four fasteners on the hatch cover to the pump and put it aside.

- Carefully remove the hoses. They are dismantled in the following way: press on the latch (you can use a screwdriver) and pry up the hose itself (with another screwdriver) in the direction of the arrow. We judiciously balance our strength so as not to break fragile parts and remove the hose. Unfasten the connector.

- We thoroughly wipe the pump from dust and continue to disassemble the structure. Remove the retaining ring. Let us warn you right away that the ring is difficult to remove, you will have to work hard here or even use a hammer, but again, do not overdo it.

- We remove the pump (in order not to flood the interior with gasoline, lay some unnecessary cloth).

The first part of the work is completed. Let's proceed to the most important part, disassembling the pump:

- There is a sensor and wires attached to the pump; you need to disconnect them.

- Next, we remove the intake tube and bend the clamps (there are 4 of them) in order to be able to remove the glass.

- We check the glass for dirt, if there is any, clean it.

- And now we’re doing what we did such a large-scale job for – we’re removing the mesh. She usually looks creepy. But don’t be scared, just replace it with a new one and assemble the system in reverse order.

Fuel pump device

Modern cars use two types of fuel pumps - mechanical or electric. The former are used in carburetor engines, the latter in injection engines.

The mechanical pump is usually installed on the body of the gas tank, while the electric pump is installed inside the tank. Some automakers use both types of pumps at once.

Mechanical pump

The mechanical fuel pump is quite large. Its main elements are:

The fuel supply system of the VAZ 1118 Lada Kalina car has 2 stages of fuel filtration - coarse and fine cleaning. The first is a fine mesh made of plastic, the second is an “accordion” made of porous paper. Both cleaning elements gradually become clogged during operation and after a certain period of time require replacement. Many car enthusiasts perform this operation on their own, because it is quite simple. You too can take on this work once you have read the instructions for its implementation.

Lada 2108 Charoit › Logbook › Popular about the fuel pressure regulator

Probably, many people know that injection cars use a fuel system with excess pressure released, i.e. returning excess fuel back to the tank. The pump pumps fuel constantly, it enters the ramp under pressure, and a fuel pressure regulator is installed at the outlet of it. The detail is inconspicuous and generally not annoying during the work process.

The regulator didn’t bother me either, but one day while inspecting the hoses in the engine compartment, I noticed that the vacuum hose going to the regulator (hereinafter referred to as the RTD) had a crack. An experiment was immediately carried out: what if the crack in the hose is slightly opened? Nothing in the engine's performance has changed. I removed the hose altogether - and again no reaction. Naturally, the first question arose: is the RDT even working?! And then the second: how does this crap work? No, well, I knew it in general, but I wanted to understand it exactly. So, here’s the drawing:

The RTD has an inlet hole (in the drawing below), it is not visible, it looks into the ramp. Fuel comes here from the ramp under pressure. There is an outlet through which the fuel returns to the tank. And there is a pipe (3) connecting the vacuum cavity (B) through a hose to the inlet manifold, in which there is a vacuum when the engine is running. Pressure regulation occurs in two ways: a spring-loaded valve (5), set to a constant certain pressure, and through a diaphragm (4 ) a vacuum that changes depending on the load on the engine. The valve always maintains constant pressure, its operation does not depend in any way on the engine. But with a vacuum it is more interesting. You can find many different descriptions and diagrams of regulators, and they only confuse. Let's try to figure it out to make it clear.

We are essentially interested in 2 modes: XX and load.

At idle, the throttle valve is closed and maximum vacuum is maintained in the intake manifold. This vacuum reduces the RTD spring force, retracting the valve, and the valve opens earlier, at lower fuel pressure, thus lowering fuel pressure at idle.

Under load, the throttle valve opens, exposing the intake manifold to the atmosphere, and the vacuum decreases (i.e., air pressure increases, becoming closer to atmospheric pressure). In this case, the spring force increases, and as a result the valve opens later, and the fuel pressure increases.

In this case, the maximum pressure will be if you remove the vacuum hose from the RTD. That is. the valve does not increase pressure during load, but decreases it during idle, which may not be immediately obvious.

So now it’s clear why, in my case, removing the hose had no effect on the operation of the engine - the pressure increased, reached a maximum, and did not fall.

Source

Selecting new filter elements

To purchase fuel purification system parts for VAZ 1117-19 models, you need to know what they look like:

- The coarse filter is a flat mesh bag made of chemically resistant plastic that captures large particles of 80-100 microns. In the center of the element there is a plastic fitting that fits onto the counterpart of the gasoline pump.

The mesh element is equipped with a pipe that fits onto the fuel pump fitting

The element is equipped with clamps for fastening fuel line connections

All modifications of the Lada Kalina, including the second generation, are equipped with absolutely identical filter elements - a “barrel” and a mesh catcher. The dimensions of the spare parts are also identical.

There are no tricks in choosing a coarse mesh - the parts are made according to a single sample and cost from 30 to 45 rubles. The only caution: in order not to purchase a low-quality product or a fake, contact well-established stores. Although the fuel pump mesh costs a penny, it plays an important role in the fuel system: it catches large debris that can quickly clog the filter paper of the next cleaning element.

In operation, the plastic case is not inferior to the metal one in terms of reliability.

The material from which secondary filters are made does not play a big role. What is important is the contents of the “barrel”, which cannot be seen or touched. Therefore, there are only 3 selection criteria:

- correspondence between the body dimensions and the diameter of the fittings;

- the presence of plastic clamps;

- brand (manufacturer).

The mounting clamp on the Kalina is designed for a case diameter of 56 mm

In order for the spare part to fit the mounting clamp, the case diameter must be 56 mm. The internal size of the gasoline pipes put on the fittings is 8 mm.

There are many different fuel filters sold in stores, and not all of them are equipped with clamps (in other cars, the hoses can be secured with clamps). The part for “Kalina” must have latches, otherwise the tubes cannot be secured.

A plastic latch secures the hose to the filter fitting

In the countries of the former USSR, the following manufacturers of gasoline filters have proven themselves best:

At the moment, second-generation Kalina machines are equipped with fine filters made of polyamide. But users are not very complimentary about the factory spare parts: after disassembly, it was discovered that the paper “accordion” was poorly glued to the body. As a result, half of the fuel passed through the gas pipeline without filtering. At the same time, based on the practice of isolated cases, it cannot be unequivocally stated that metal filters are better than plastic ones.

Inside the filter element there is porous paper that traps small particles

Table: cost of VAZ 1118 filters

| Brand name | BOSCH | FRAM | FILTRON | SCT Germany | UFI | MANN |

| Price in rubles as of autumn 2022 | 390 | 340 | 335 | 230 | 280 | 410 |

Video: comparison of cleaning elements from different brands

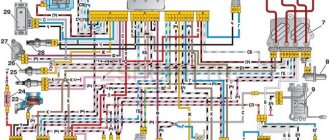

Connection diagram

Fuel pump relay diagram

Above is a standard connection diagram for a fuel injection pump engine. The ECM (controller), after successfully polling the immobilizer, energizes the coil winding of the fuel pump relay (pins 85, 86). Under the influence of electromagnetic induction, power contact 30 (constant “+” from the battery, protected by fuse X) and contact 87 close, which leads to the inclusion of the fuel pump. Main faults:

fuse blown; Attention! Replace the burnt-out fuse-link with a fuse of standard rating. Installing an insert designed for high current may result in a vehicle fire. formation of oxides inside the connectors, burning of power contacts of the fuel pump relay

Parasitic resistance leads to a drop in current in the circuit and a decrease in the performance of the nose; chafing, breaking wires; breaking off the latch of the power connector going to the fuel module. Often in this case, contact is broken when driving over uneven surfaces.

Location of Kalina fuel filters

To replace filter elements on VAZ 1117-1119 series cars, you need to know where they are installed. The location of the parts is as follows:

- mesh bag - a trap for large particles is attached to the suction pipe of the gasoline pump, immersed in a tank of fuel;

A screen for catching large particles is located in the fuel tank along with the pump.

The fine cleaning element is hidden in a niche to the right of the tank

The location of the filter elements is the same for all modifications of Kalina and does not depend on the body type. That is, on the “station wagon” and “hatchback” you will find parts in the same places as on the “sedan”.

Causes of gasoline pump malfunction

If Kalina’s fuel pump does not pump, then the reasons will be in the equipment itself or in other parts of the system. First, you should make sure that there is fuel in the tank, a spark in the spark plugs, the battery is charged, and the starter is working. If everything is in order, then you need to continue checking. If the cause of the malfunction is identified, for questions regarding the purchase of auto parts to eliminate it, you can contact the specialized online store automechanika38.rf.

Electromechanical equipment may not function correctly or stop working due to a malfunction in either the mechanical or electrical components of the system.

- The fuel pump fuse has blown - you should remove the element from the fuse box (located in the engine compartment). If the contact has visible damage, the part needs to be replaced.

- The equipment relay is faulty - check the electrical wiring, contacts between the unit and the diagnostic block, as well as the relay. Using a test lamp or multimeter, check the presence of voltage at the pump chip. A correctly operating relay makes clicks when the ignition is turned on, after the required pressure has been reached in the fuel line.

- There is no contact of the equipment with “ground” - it is necessary to apply ground to the part chip. The wire is located under the instrument panel and runs through the interior of the car. It is worth checking it, cleaning the contacts, and fixing them securely on the pump.

- The electronic control unit is faulty - the ECU needs to be repaired or replaced.

- A breakdown in the car alarm, poor installation of the security system - electrical wires may be mixed up, errors may have been made when connecting the alarm.

- Insufficient pressure in the fuel line may be the result of contamination of the gasoline filter or the filter mesh of the pump itself.

Many car owners prefer to drive with a half-empty fuel tank. However, the fuel pump in this case often overheats, which will ultimately lead to equipment malfunction. The reasons why the fuel pump on Kalina does not turn on may be the breakdown of individual parts of the unit. To determine the problem, it is necessary to remove the equipment and diagnose it.

How to change the coarse mesh

The work package for replacing the first stage filter consists of several stages:

- Buying a new part.

- Preparation of tools and repair site.

- Disassembly, removal of the gasoline pump and replacement of the mesh catcher.

To replace the old dirty mesh, you need to remove the fuel pump

How to choose a Kalina mesh filter is described in the previous section. The location for repair work does not matter, since you do not need a car overpass or inspection ditch - disassembly is carried out from the interior.

Preparatory stage

In warm weather, disassemble the car directly on the street, but in windy weather, find a quiet place, otherwise dust will blow into the interior. In winter, it is more convenient to work in an insulated garage or box.

The tools you need to prepare are:

- a Phillips and flathead screwdriver;

- pliers;

- a small chisel or metal point;

- hammer;

- clean rags.

To disassemble and dismantle the fuel pump you will need a modest set of tools

Before starting work, remove unnecessary objects from the rear row of seats, and then remove the seats themselves. They block access to the technological opening with a hatch leading to the fuel tank. The latter is attached to the bottom of the car from the outside.

To reduce the risk of breathing dust during disassembly, it is recommended to vacuum the body covering under the seat.

Removing the fuel pump and replacing the mesh

The first step is to relieve excess pressure in the fuel line, otherwise when the pipes are removed, a stream of fuel will splash around the trim and the pungent smell of gasoline will “linger” in the cabin for a long time. There are 2 ways to relieve pressure:

Repair parts

It is worth carrying out independent equipment repairs if you are completely sure that the malfunction lies precisely in it. A large number of plastic elements make the pump very fragile. For this reason, care must be taken when disassembling.

- Using a screwdriver, you need to pry up and remove the drain module of the part.

- The ground wire will be disconnected from the equipment.

- The intermediate wire connector is disconnected (from the inside).

- The pressure regulator is removed.

- The gasoline element module is removed by pressing the plastic retainer.

- The filter mesh is removed from the housing. If it is dirty, it can be cleaned. But it is more advisable to install a new mesh.

Damaged elements must be repaired or replaced with new parts. At the same time, it is advisable to replace the fine fuel filter. It is located near the jack cup in the right rear wheel arch. The equipment is assembled in the reverse order.

If Kalina's fuel pump does not work, the reasons often lie in a malfunction of the part itself. This equipment is inexpensive. It is quite possible to remove the unit and replace it with a working one yourself. It is better to purchase original spare parts.

Instructions for replacing the fine filter

To change the second stage filter element, you will need an overpass or inspection hole. It is quite difficult to get to the part by climbing under the car. When entering the overpass, take it as far to the left as possible, this will ensure easy access to the filter (it is located to the right of the tank).

The filter is located to the right of the tank and is held in place by a clamp

From the tool kit you will need a 10 mm wrench and a flat-head screwdriver. The procedure for performing the work is similar to the previous algorithm for replacing the fuel pump grid:

- Relieve pressure in the fuel system in one of two ways (described in the previous section).

- Go under the car and disconnect the gasoline hoses from the filter. The tubes are removed by pressing the levers of the plastic clamps.

The pipe is removed after pressing the lock button

The filter element is removed after loosening the clamp

As a rule, all threaded connections located under the bottom of the machine rust and are difficult to unscrew. Therefore, before dismantling the old part, you should treat the clamp bolt with WD-40 aerosol lubricant.

The new filter is put in place taking into account the direction of fuel movement (indicated by the arrow on the housing) and connected to the system in the reverse order. The replacement technology for a car with a 16-valve engine is generally no different from repairs for an 8V engine. While working, you may encounter minor differences in small details:

- the tube with the gasoline pressure relief valve comes out from the same side, but closer to the cylinder head and slightly at an angle;

- The fine cleaning “barrel” is held in place by a plastic clip rather than a metal clamp.

On the latest Kalina models, the filter element is attached to a plastic clip

If, after dismantling the old part, you find that the fuel pipe clamps are in good condition, you can reuse them.

Video: quick installation of the VAZ 1117 filter element

Procedure for servicing the fuel pump, possible malfunctions

You should not always resort to immediate replacement of the Kalina fuel pump, because first you can repair it. But for this you need to select the right tool in advance.

For this device, two parameters are usually monitored: operating pressure and operating performance. After removing the device, you can check the current consumption at rated and full load. But for such measurements you will need a specialized stand.

The initial point of control will be the voltage of the connector that supplies the fuel pump from the vehicle’s on-board power system. Not only should it be equal to 12 V or even slightly exceed this value, but also when the machine is operating, the noise of the operating device should be clearly audible.

The disadvantage of this control method is the inability to detect unreliable contact in the electrical circuit on the way to the connector. Any loose connection in the fuse box, fuel pump relay, will result in the 12 V received at the terminals upstream of the pump showing the same 12 V. But a working pump will receive only a few volts and will not be able to work normally.

Also, a malfunction in such a situation may be a breakdown of the fuel pump relay. This malfunction is easy to diagnose, since special symbols are displayed on the instrument panel, which allows the driver to see an error in the operation of this part.

All control relays are located inside the car and, when malfunctioning, distinguish themselves with characteristic clicks. Replacing the fuel pump relay yourself is not difficult; it is enough to recognize the location of its installation by the special printed symbols.

Fuel pump parts disassembled

Checking the pressure created consists of monitoring this parameter in the pump pumping mode, when it turns on after turning the key for 1.5-2 seconds to add fuel to the pipeline system. For Lada Kalina this figure is 0.8-1.2 kgf/cm2. If the pressure turns out to be underestimated, then you should look for the cause of this phenomenon, checking each link in turn: filter, mesh, fuel pump. Ultimately, the part that prevents the pressure from quickly building up to normal will be replaced.

How often is replacement done?

There are clear regulations for replacing consumables, which include fuel filters. According to the requirements of the machine's operating instructions, they must be changed every 30 thousand kilometers. But given the different quality of fuel at gas stations and the operating conditions of the car, experienced auto mechanics recommend reducing the maximum interval to the following values:

- for a fine filter - 20 thousand km;

- for coarse mesh - 70 thousand km;

- when operating in northern regions, the service life is reduced by half from the regulations, that is, it is 15 and 35 thousand km, respectively.

Some motorists who carefully care for their Kalina offer their own replacement intervals. The principle is as follows: all consumables are updated simultaneously, along with the addition of fresh oil. With such a scheme, the interval is reduced to 7-15 thousand km, depending on the quality of the engine lubrication.

Compared to its predecessors, the Lada Kalina has a more modern and complex design. But the gasoline filtration scheme, inherited from the “tenth” VAZ family, remained unchanged. Thanks to this, it remains possible to change the cleaning elements yourself and not pay money for car service services.

«>

Why might the mesh need to be replaced?

Two grids - dirty and clean

First of all, because of bad gasoline. If you regularly refuel at dubious gas stations, then it’s only a matter of time before the fuel pump fails . Purification of gasoline from impurities in the gasoline pump occurs in several stages, and the mesh of the gasoline pump is the first line of defense, so to speak. It is the first to absorb all large particles of impurities and dirt. After passing through the mesh, gasoline enters the fine fuel filter, then passes through another mesh (which is located near the fuel pressure regulator), and finally goes through the third mesh (located directly in front of the injectors). If problems arise in any of these areas, you won’t be able to go far. The car engine simply will not start. Or it will start, but will work unevenly and jerkily.

recommends changing fine filters every 30,000 kilometers . But he doesn’t give any recommendations about the fuel pump mesh. Therefore, many car owners forget to change this grid, and remember about it only when the engine begins to behave strangely.

The general rule is: if the car has traveled 60,000 kilometers, the mesh should either be cleaned or replaced. It is advisable to clean it only if there is no serious mechanical damage to it. But if the machine has traveled the distance indicated above, then the mesh in the pump is often worn out to such an extent that it is easier to throw it away than to clean it.

Diagnosis procedure

After you are convinced that the fuel pump has failed, you can proceed to the next stage. In particular, it is necessary to understand what exactly the problem is. There can be many options here. The easiest way is to check the integrity of the fuses. Let us remind you that the fuel pump itself in the “fourteenth” is located in the fuel tank. After the ignition is turned on, voltage is supplied to its terminals through fuse F3 and relay R2 - the latter are located in the cabin under the panel on the passenger side.

If the fuel pump fails, the first thing to do is remove the cover located under the panel on the right side of the console. This is not difficult to do - it is secured with two self-tapping screws. Under the cover you will see 3 fuses and 3 relays. The integrity of the above-mentioned F3 should be checked. Also, do not forget to inspect the contacts into which this fuse is inserted. If no problems are found here, move on to checking the fuel pump relay. The easiest way to do this is to borrow something that is known to work from someone you know and try how the car works with it.

If the fuse and relay are good, we move on. The next stage of diagnosis will be to inspect the terminals of the fuel pump itself. To get to them, you must first lift the rear seat cushion. Once you have access to the cover located on the bottom, unscrew the screws holding it. A hatch will open in front of you, in which there are 3 terminals

Please note that black and gray wires lead to the two positive ones. The third terminal is negative

Through them, power is supplied to the fuel pump itself. You will need to check whether there is voltage at the positive terminal, for example, using a test lamp. It should light up for 3-5 seconds after you turn on the ignition.

The light is on, but the fuel pump does not show any signs of life - which means we arm ourselves with a tester and check the voltage level. There should be at least 10 volts here. This is the minimum required value to start the fuel pump. Note that the reason why the voltage has decreased is quite often the oxidized contacts of the positive and negative wires. Accordingly, to fix the problem, you just need to wipe them. By the way, there is another verification option. Take long wires and apply voltage to the fuel pump terminals directly from the battery. In this case, everything will become immediately clear.

Don't forget to also check the ground of the fuel pump - it is attached near the parking brake lever, under the dashboard. This reason is quite common, this point also needs to be checked. With constant use of the handbrake, the mass may well be shifted slightly to the side. Just in case, remove the plastic casing covering the lever, disconnect the mass, clean the contacts and return it to its place.

These are all “external” reasons. If no problems are found here, then you will need to remove the fuel pump and look for the “internal” ones. One of the most common problems is worn or stuck brushes. Another fairly common cause is the motor. You can check it using the same test lamp, having first supplied power to the fuel pump.

How to check fuel system pressure

Once you know the fuel pump is delivering fuel, a fuel system pressure test can sometimes identify the source of the problem. In the next series of tests, you will use the fuel pressure sensor to check the pressure in the system.

1. Relieve pressure in the fuel system.

If your vehicle's fuel system has a Schrader valve or test port (similar to the air valve on your tires), cover the valve with a shop rag and gently press the valve with a small screwdriver. Use a rag to catch the fuel. This valve is similar to the air valve on your tires. If your fuel system does not have a test port, you can remove the fuel pump fuse and start the engine. He will die in a few seconds due to lack of fuel. Reinstall the fuel pump fuse.

- Connect the fuel pressure sensor to the test port. If you do not have the correct adapter to connect the sensor to the Schrader valve, try removing the valve and connecting the sensor to the fitting; however, if there is no test port, disconnect the fuel line from the rail (this is the line coming from the fuel filter) and connect a T-adapter to the line so you can reconnect the line to the fuel rail and connect the sensor as well.

- Start the engine and let it idle. NOTE: The repair manual for your specific vehicle may include a power-on test. Check your manual if necessary.

- Compare fuel pressure to specifications. Check the pressure reading on the pressure gauge and compare it to the specification in your vehicle's repair manual (if the vehicle does not start, turn the ignition key to the ON position and read the fuel pressure. Compare the reading to the specification in your manual for the pressure switch). The injection system typically produces 15 to 40 pounds per square inch (psi) (100-280 kPa) or more, depending on the application. The reading includes pressure from the fuel pressure regulator (FPR). So if your readings are out of specification, you may have a problem with your FPR, so keep measuring.

NOTE. New modern fuel systems do not use FPR in the injection system; rather, they vary the voltage at the pump or use an internal pump valve to regulate system pressure.

A. What to do if the pressure is correct

- With the fuel pressure sensor still connected and the engine idling, disconnect the vacuum line from the fuel pressure regulator (FPR - the small metal cylinder that connects to the fuel rail).

- Make sure the vacuum line is completely dry. If you find traces of fuel inside the hose, it is sucking fuel from the pressure regulator because the diaphragm is torn. Replace the fuel pressure regulator.

- Fuel pressure should increase from 3 to 10 psi. Otherwise, check the vacuum line: if there is no vacuum in the line, check that the hose is properly connected and not damaged, and that the vacuum port is not restricted; If there is vacuum in the line, but the pressure does not increase when you disconnect the vacuum hose, replace the fuel pressure regulator. For best results, perform the test described in the next section, Testing FPR with a Vacuum Pump.

- Stop the engine and wait at least 5 minutes. Compare the pressure reading with the specification (for pressure holding) in the repair manual. If the pressure drops below the specified value within five minutes, you may have detected a leak somewhere: check the fuel lines, fuel pump, injector or pressure regulator for leaks.

- What to do if your blood pressure is low

- Place a rag over the fuel return line.

- Pinch the hose using suitable pliers to block the flow.

- Watch the pressure gauge; If the pressure remains low, the fuel pump is not getting enough voltage or the pump is worn out. However, if the pressure increases, replace the FPR.

- What to do if your blood pressure is high

- First, perform the test described in the next section, “How to Test FPR with a Vacuum Pump.”

- Then turn off the engine.

- Disconnect the fuel return line.

- Blow through the return line to ensure it is not blocked. If the return line is blocked, find where it is.

NOTE. The video below provides an idea of how to check the voltage and ground at the fuel pump electrical connector.

FakeHeader

Comments 17

Congratulations! You bought an excellent original UTES module (an old model, it says “UTES” in big letters, I had exactly the same one in my car from the factory, only 21101-1139009, manufactured in 2008), with an ORIGINAL Bosch pump 0 580 454 035 ( Now there are a lot of fakes)! Today I had a hard time finding and buying the original “UTES” module 21101-1139009 in Kharkov

There is the same one for Kalina:

I looked for it all over Ukraine, in Kyiv I went around the entire car market, called all the companies, then I started calling different offices in Kharkov, Dnepr and Zaporozhye - there is no original UTOS anywhere at the moment. Complete fakes under the guise of UTYOS or Chinese bullshit. The best thing that can be found now under the guise of UTOS is ATK (Avtotekhprom), but I was looking for the original UTOS in original packaging.

I accidentally came across the Losk104 website and there I bought exactly what I was persistently looking for!

Regarding DUT, Kalina is equipped with DUT-K, DUT-17 and DUT-10.

I can’t tell you which one for which tank. Like DUT-K of the “universal” type. I have a VAZ 21093 (2009) with a 1.6 Kalino engine, my module 21101-1139009 has a DUT-K2 sensor, it is completely interchangeable with DUT-11, there is no difference.

Dnepr auto dealers are still the same. They are purchased from Ukravtovaz (they recently opened their online store) shop.ladaukraine.com/ Now the fuel pump modules come from the DCK assembly line (the same was in my car)

Yes, in DneprAuto the prices are great, I just gave their links as an example, it’s easy to search on their website, it’s easy to look at the photo.

PS In UkrAvtoVAZ I see that the prices are also crap... A module like ours, only with a metal cover (for 1.5 engines) costs 2050 hryvnia shop.ladaukraine.com/prod...enzonasos/21101113900900/

You can buy it in Kharkov. where I bought mine for 1235 hryvnia

PS In DSK the inserts seem to be not Bosch ones, but Czech “Aisans” 3J, they seem to be worse than Bosch ones

You need to find out the price there, it differs. For example, Kalinovsky steering tips are indicated on the website for 430 UAH, but I paid 413 in fact

Yes, in DneprAuto the prices are great, I just gave their links as an example, it’s easy to search on their website, it’s easy to look at the photo.

PS In UkrAvtoVAZ I see that the prices are also crap... A module like ours, only with a metal cover (for 1.5 engines) costs 2050 hryvnia shop.ladaukraine.com/prod...enzonasos/21101113900900/

You can buy it in Kharkov. where I bought mine for 1235 hryvnia

PS In DSK the inserts seem to be not Bosch ones, but Czech “Aisans” 3J, they seem to be worse than Bosch ones

In my factory there was a 1 in 1 Bosch, the same as in Utes, but after so many years they could have changed the supplier.

Well, from the factory, our cars should be equipped with such Utes, with Bosch inserts and precisely with the number 0 580 454 035, or SEPO modules (they also come inside with the same Bosch ones and some other inserts from another manufacturer, like Aisan) or same DSK. Having deeply delved into this topic, studying forums and topics for a long time, I realized that there is nothing better than the UTOS module inside with the original Bosch.

Important points

Where is the gazelle fuel pump fuse located?

The procedure outlined above seems quite simple, but, nevertheless, there are a couple of nuances that should be mentioned.

Firstly, gasoline. When the gas lines are unscrewed, it begins to flow directly onto the cap (this happens especially often if the car owner forgot to relieve the pressure in the gas line using the breather, as mentioned above). Yes, a little gasoline leaks out, but the smell of gasoline in the cabin is not what a car owner needs, right? Therefore, before removing the fuel lines, you should put a cloth on the pump cover and carefully insert it with a screwdriver into all the cracks. The rag will absorb the leaked gasoline, then you can throw it away, which will help get rid of the smell in the cabin.

Secondly, the fuel pump retaining plate. As practice shows, this is a fragile thing, and breaking it by carelessly prying it with a screwdriver is not just easy, but very easy. But it’s difficult to find this part on sale; it is only sold complete with a complete fuel pump, and this is a waste of money. The matter is further complicated by the fact that it is not always possible to move this plate out of place with just a flat screwdriver (especially if the car owner is trying to disassemble the pump for the first time), so sometimes you have to resort to using a hammer and chisel, and this, in turn, increases the risk many times over plate breakage.

As you can see, there are no difficulties with independently replacing the pump grid on the Lada Kalina, and if you strictly follow the above instructions, even those who are doing it for the first time will not have any problems. The main thing is to be patient and follow safety precautions. It is imperative to remove the terminal from the battery! Otherwise, a banal mesh replacement can turn into a fire.