Purpose

In an injection engine, fuel must be supplied to the combustion chamber under pressure; this is necessary so that the fuel injectors accurately spray the fuel into small particles for easier mixing with air. The pressure is pumped up by the fuel pump, which has quite powerful characteristics and is capable of pumping up pressures of up to 10 bar. Of course, this pressure is not used in a car, it is regulated by a special sensor that resets it at 4 bar.

Gasoline pump for carburetor VAZ 2107

One of the mechanisms of the power supply system of any engine is the fuel pump. The startup and operation of the power unit directly depends on its performance. Mechanical fuel pumps of the diaphragm type DAAZ 2101 were installed on carburetor “sevens”. Thanks to the simple design, the mechanism is repairable. However, it often causes problems for Zhiguli owners. Therefore, it is worth dwelling on the operation and malfunctions of this unit in more detail.

Main functions

The job of the fuel pump is to move fuel from the tank to the carburetor.

The design of the unit is not ideal, so it is one of the weak points in the car. This is explained by the fact that the impact of constant loads and low quality gasoline lead to natural wear and tear of the elements. This is what causes the device to fail. If a problem occurs with the pump, the engine begins to work intermittently or stops functioning altogether.

Design and operating principle

The mechanism is made of several parts connected to each other by fastening elements. There are two fittings in the upper part of the body through which fuel is supplied and pumped into the carburetor. The design includes a lever that allows you to manually pump gasoline from the tank into the fuel system, which is important after the car has been parked for a long time. The main elements of the node are:

- pusher;

- spring;

- balance;

- lid;

- cover screw;

- screw;

- mesh filter;

- membranes (working and safety);

- lower and upper plates;

- stock;

- valves (inlet and outlet);

- manual pumping lever.

The principle of operation of a classic fuel pump is based on creating the pressure necessary to maintain the required fuel level in the carburetor chamber. Thanks to the diaphragm, the flow of gasoline stops or decreases when a maximum pressure value is established in the fuel line. On carburetor “sevens” the fuel pump is located under the hood on the left side of the cylinder block. It is secured to two studs through a thermal spacer and gaskets, which are also used for adjustment. The spacer is also a guiding part for the pump rod.

The device operates in the following order:

- the pump pusher is driven by a drive cam operating from the gas distribution mechanism;

- the membranes located inside the gas pump move and alternately create pressure and vacuum in the chamber;

- if the pressure decreases, the outlet valve closes and fuel flows through the inlet valve;

- when the pressure increases, the valve at the pump inlet closes, and gasoline is supplied through a hose to the carburetor.

Which fuel pump is better

When there are problems with the fuel pump, the question of choosing a new device often arises. Owners of Zhiguli cars mainly prefer products of two. If problems arise with the factory mechanism, for example, when it overheats, many change it to the second option, explaining that Pekar pumps do not have a tendency to form a vapor lock, which causes defects in the operation of the device in hot weather. In fact, this opinion is wrong, since they also have this problem, as evidenced by numerous reviews from car owners. It is also worth considering that Pekar costs 1.5–2 more than DAAZ. Therefore, a standard fuel pump is the best choice based on criteria such as reliability, price and quality. The cost of a factory pump is 500–600 rubles.

Table: parameters of different fuel pumps

| Test results | "Baker" | DAAZ | QH | OTA |

| Zero supply pressure (at a crankshaft speed of 2 thousand rpm), kgf/cm² | 0,26 | 0,28 | 0,3 | 0,36 |

| Capacity for free drainage (at a crankshaft speed of 2 thousand rpm), l/h | 80 | 76 | 92 | 74 |

| Suction period at a crankshaft speed of 2 thousand rpm, s | 4 | 13 | 9 | 6 |

| Valve tightness at a pressure of 0.3 kgf/cm² (fuel leakage within 10 minutes), cm³ | 8 | 12 | 8 | 8 |

| Place | 3 | 4 | 1–2 | 1–2 |

QH petrol pumps are manufactured in the UK, while OTA petrol pumps are manufactured in Italy. However, these devices have some features: the QH pump does not have a lever for manual pumping of fuel, and the housing is non-separable. The Italian mechanism has excellent parameters compared to others, but its price is almost 3 times higher than Russian products.

Design

The fuel pump is an internal part that contains a special electric DC motor, on the shaft of which a fuel pump is mounted. The fuel pump is made of metal and plastic, it is sealed, this is necessary so that fuel does not get inside the electric motor.

In the picture you can see in detail what the VAZ 2107 fuel pump looks like inside.

Diagnostics

The very first thing when diagnosing, as noted above, listen when you turn on the ignition to see if there is any noise from the fuel pump. The absence of a characteristic buzzing may indicate that:

- VAZ 2107 fuel pump fuse is faulty;

- relay malfunction;

- open circuit of the fuel pump;

- motor malfunction;

- ECU malfunction.

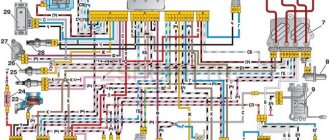

Below is a simplified connection diagram for a VAZ 2107 injector fuel pump:

You can check the fuel pump on a VAZ 2107 injector simply by checking the voltage at its connection block with a tester. The presence of voltage will indicate a malfunction of the electric motor. Instead of a tester (multimeter), you can use a test lamp to diagnose a malfunction.

In the absence of one, this can be done by disconnecting the connection block for the fuel pump and fuel level control and applying voltage with wires from the battery to the place where the gray wire is connected +12 and to the place where the black wire is connected - minus. A humming pump will indicate a faulty fuse, power circuit or ECU.

Symptoms of a problem

A breakdown of the fuel pump on a VAZ 2107 significantly affects the operation of the car’s engine. It should be noted that the fuel pump does not immediately fail; most often this happens gradually, accompanied by the following symptoms:

- The car accelerates poorly;

- The car jerks when driving at constant gas;

- Power is lost;

- The engine does not start well;

- Unstable idle;

The signs of a “dying” fuel pump are similar to the signs of running out of fuel.

Examination

Checking the fuel pump is quite simple, since the fuel tank in the 2107 is easily accessible and access to the fuel pump glass is very convenient, checking the fuel pump will not be difficult.

Checking this part consists of measuring the fuel pressure and the performance of the pump itself.

Electrical check

To make sure the pump is working, turn on the ignition and listen for a characteristic buzzing sound in the tank. If this does not happen, the fuel pump fuse may have blown, or the pump itself may have failed.

The fuel pump fuse on the VAZ 2107 is located under the glove box of the car and has the number F3, and the rated current of the fuse is 15A. It is necessary to install a fuse only of equal rating.

If the fuse is intact, then you need to check the presence of power at the pump connector; to do this, you need to remove the block and use a multimeter to measure the presence of voltage.

Pressure check

To check the fuel pump, you need to check the pressure that it pumps into the system; for this you need a pressure gauge, which is connected to the fuel rail fitting through a rubber hose.

- To do this, remove the cap from the fuel rail and unscrew the spool from it;

- We connect the pressure gauge through the hose and fasten it with a clamp;

- We start the car;

The pressure in the system should be from 2.7 to 3.3 bar, if less the fuel pump needs to be changed. It should also be noted that the culprit of low pressure may be the RTD.

What fuel pumps were equipped with classic VAZ models?

Classic VAZs include all models of the Zhiguli family, produced from 1970 to 2012 and their modifications:

- VAZ 2101;

- VAZ 2102;

- VAZ 2103;

- VAZ 2104;

- VAZ 2105;

- VAZ 2106;

- VAZ 2107.

Depending on the year of manufacture, the engines of these vehicles were equipped with different fuel systems. In all the first Zhiguli models, the fuel mixture was injected into the cylinders using a carburetor, and the fuel was supplied by a mechanical fuel pump. The latest modifications of the VAZ 2104, 2105 and 2107 had an injection system and an electric fuel pump.

Carburetor cars of the Zhiguli family were equipped from the factory with mechanical fuel pumps of the diaphragm type DAAZ 2101 (catalog number 1106010) produced by the Dimitrovgrad Automotive Unit Plant. Thanks to their simple design, reliability and maintainability, they have proven themselves well not only on the “classics”, but also on cars of the Sputnik and Samara families, which were equipped with their modified versions.

Carburetor VAZ 2101–2107 were equipped with DAAZ mechanical fuel pumps

Injection Zhiguli models were equipped with domestically produced electric fuel pumps. They were produced by the Pekar and Utes enterprises under catalog number 21073–1139009. The latest modifications of the Zhiguli were equipped with products (catalog number 2112–1139009). The same devices were installed on all models of the Samara and Lada families.

Injection models of classic VAZs were equipped with electric fuel pumps “Pekar”, “Utes”, “Bosch”

Price

The price of a fuel pump for a VAZ 2107 can reach 2,000 rubles for an original part, but there are many analogues on the market that cost from 1,000 rubles.

Article and characteristics

| Parameter name | Data |

| vendor code | 21073.1139 |

| Operating voltage, (V) | 13,5 |

| Productivity, (l/hour) | 60 |

| Maximum pressure, (bar) | 10 |

| Rated operating current, (A) | 6,5 |

Replacement

Replacing the fuel pump on a VAZ 2107 will not cause any difficulties if you follow the instructions below, even for a person far from car repair.

To replace you will need:

- Open-end wrench “7” mm;

- Open-end wrench “10” mm;

- Open-end wrench “17” mm – 2 pcs.;

- Flat and Phillips screwdrivers;

Replacement instructions

Relieve the fuel pressure in the system. To do this, remove the fuel pump fuse F3, then start the car engine and let it run until it stalls;

- Remove the negative terminal of the battery;

- We unscrew the fuel tank fastenings for ease of work;

- We unscrew the fuel pipes with two “17” mm wrenches;

- Remove the excess pressure relief tubes;

- We move the fuel tank to the side;

- Disconnect the power connector from the fuel pump glass;

- Unscrew the nuts securing the cup to the fuel tank body with a 7 mm wrench;

- We take out the glass along with the fuel pump;

- Unscrew the fuel hose clamp from the pump;

- We install the new fuel pump in the reverse order, not forgetting to install a new mesh;