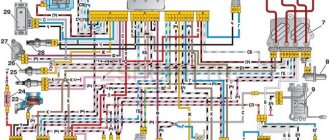

Schematic electrical diagrams, connecting devices and pinouts of connectors

The fuel pump on a car is designed to supply fuel to the combustion chamber. Its operation is controlled using a relay. On a VAZ (depending on the model), the fuel supply unit can be electrical or mechanical - it all depends on the fuel supply system. On a fuel-injected car, the fuel pump is located in the tank. When the ignition is turned on, voltage is supplied to the terminals of the unit and it begins to pump fuel. If the required pressure is created in the system, the relay automatically turns off the fuel pump - the engine is ready to start.

When the ignition is turned on, the relay creates pressure in the fuel lines by turning on the fuel pump (BN) for a couple of seconds. After this, the BN will work either when the engine is cranked by the starter, or when the engine is running.

Sometimes this system needs repairs - there is nothing complicated here, and the editors of the 2Skhema.ru website will tell you how to do it yourself. Let's start with the BN pinout, then we will indicate it on the diagrams and at the end there will be instructions for replacing the fuel supply elements.

What kind of fuel pumps are installed on VAZ 2110/2112 cars

VAZ 2110/2112 cars, depending on the year of manufacture and the type of engine installed, may differ in the method of supplying fuel to the cylinders.

Table: features of fuel supply systems to engine cylinders depending on vehicle modification

| Model/ modification | Year of issue | Engine volume, cm3 | Number of valves, pcs | Injection system |

| VAZ 21100 | 1996–2000 | 1500 | 8 | Carburetor |

| VAZ 21101 | since 2004 | 1600 | 8 | Injection |

| VAZ 21102 | since 2004 | 1500 | 8 | |

| VAZ 21103 | since 2001 | 1500 | 16 | |

| VAZ 21103M | since 2001 | 1500 | 16 | |

| VAZ 21104M | since 2001 | 1600 | 16 | |

| VAZ 21120 | 1999–2008 | 1500 | 16 | Injection |

| VAZ 21121 | 1999–2008 | 1600 | 8 | |

| VAZ 21122 | 1999–2008 | 1500 | 8 | |

| VAZ 21124 | 2004–2008 | 1600 | 16 | |

| VAZ 21128 | 2004–2008 | 1800 | 16 | |

| VAZ 21123 | 1999–2009 | 1600 | 16 |

Only the first modifications of the VAZ 2110 were equipped with a carburetor injection system. From the factory they were equipped with mechanical fuel pumps of the DAAZ brand (catalog number 2108–1106010). Previously, they had proven themselves well on cars of the Sputnik and Samara series.

A mechanical fuel pump was installed in the engine compartment of the VAZ 2110 to the right of the engine valve cover, and was driven by the camshaft.

All injection VAZ 2110/2112 are equipped with submersible fuel modules. The design of such a module includes:

- electric fuel pump;

- coarse filter;

- fuel level sensor.

The fuel module is installed directly into the vehicle tank. In other words, the gas pump is completely immersed in gasoline. Injection VAZ 2110/2112 were and are equipped with electric fuel pumps of domestic, joint or imported production. These are products of the Utes, Pekar, Saratov plant, as well as the world famous one, the pumps of which are equipped in all modern VAZs. The catalog number of the stock electric pump is 2112–1139009. There are also modifications whose numbers have two additional digits: 02 or 03. Depending on them, products may differ in length and diameter.

What is an ECU?

The first thing that catches your eye is the electronic control unit (abbr. ECU). It is installed in the cabin, under the dashboard. Its function is to monitor the operation of all sensors and actuators of the car. He also controls the operation of the VAZ 2110 fuel pump switching relay. Let's understand this issue, how does the control happen? An ECU is an electronic device; it is based on a modern (or not so modern) microcontroller. Depending on what functions the control system should have, various microcontrollers are used.

The microcontroller has input/output ports, as well as legs for connecting power, a master oscillator on a quartz resonator, etc. We are interested in the input and output ports. They are necessary for the microcontroller to receive and send signals. This, however, is clear from the name itself. In datasheets, these ports are designated by letters A, B, C, etc. In other words, they can both send a signal and remove them. But it all depends on one small detail.

The firmware (a program that runs according to a specific algorithm) determines which port is incoming and which is outgoing. In addition, it is the built-in program that allows you to determine all the operating parameters of the injection system, depending on incoming signals from the sensors. But this story is long, it won’t fit into ten articles. Let's return to the relay that turns on the fuel pump on a VAZ 2110 and similar cars.

Design features of fuel pumps for carburetor and injection fuel injection systems

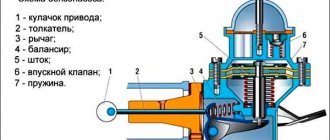

Mechanical fuel pumps, which were installed on the first modifications of the VAZ 2110/2112, have a simple design. It is based on a set of membranes made of special rubberized fabric that is resistant to the chemical action of gasoline. The pump body has two valves: inlet and outlet. The membranes are driven by a rod (pusher). It is driven by a cam mechanism rotated by a camshaft.

Such a mechanical fuel pump can serve for decades until the drive rod wears out or one of the membranes breaks. And even then, if this happens, you can replace these elements in half an hour.

The first modifications of the VAZ 2110 with a carburetor injection system were equipped with mechanical fuel pumps

With an electric fuel pump, things are much more complicated. Its design is based on a small electric motor. It is no different from a regular one, although it works completely immersed in gasoline. The pressure in the system here is created not by a membrane (although there are such pumps), but by a specially shaped impeller mounted on the electric motor shaft.

The service life of the electric fuel pump is 150–200 thousand km. But it can fail much earlier. The main cause of breakdowns when the resource is not used up is additives added to gasoline, as well as various kinds of mechanical impurities. The former destroy the brushes and commutator, while the latter clog the valve mechanisms.

In the injection VAZ 2110/2112, the fuel pump has an electrical design and is part of the submersible fuel module

Purpose

Electric fuel pump VAZ 2110

The principle operation of an electric fuel pump is based on pushing fuel under pressure into the engine. Conventional VAZ fuel pumps suck gasoline from the gas tank; a small gap from the pump to the carburetor allows it to operate at low pressure. Electric fuel pumps of the first VAZ cars worked at the same speed. The industry has launched the production of pumps that meet the growing requirements of the automotive industry; now their operation is completely dependent on the speed of the engine.

Note. The vehicle's electronic system controls the operation of the fuel pump. It corresponds to several factors: ambient temperature, what position the throttle is in, and the composition of the exhaust gases.

Electric fuel pumps operate under pressure, resulting in increased noise and rapid heating. For these reasons, they are installed in the gas tank. Gasoline cools and muffles the sound of the running pump.

Signs of a faulty fuel pump VAZ 2110/2112

Signs of pump malfunction appear the same, regardless of its design and type of injection system. These include:

- difficulty starting the engine;

- unstable engine operation at idle speed (vibration, tripping, stopping of the power unit);

- failures during acceleration in motion;

- reduction in power and traction qualities of the engine;

- absence of the characteristic sound of a fuel pump starting (for injection engines);

- presence of traces of fuel leakage (for carburetor power units).

Determining a fuel pump malfunction on your own is quite problematic, because the first three signs, which are the main ones, may indicate other problems in the fuel system, such as:

- fuel filter clogged;

- problems with sensors for mass air flow, throttle position, oxygen level, etc.;

- clogging of one or more nozzles;

- failure of the pressure regulator.

In addition, similar symptoms are observed when problems with ignition occur. It can be determined that the cause of the listed symptoms is the fuel filter by checking the device.

Article: 346027

Order code: 095401

- Buy with this product

- show more

- Buy analogues

- There are no reviews for this product yet.

Schematic electrical diagrams, connecting devices and pinouts of connectors

The fuel pump on a car is designed to supply fuel to the combustion chamber. Its operation is controlled using a relay. On a VAZ (depending on the model), the fuel supply unit can be electrical or mechanical - it all depends on the fuel supply system. On a fuel-injected car, the fuel pump is located in the tank. When the ignition is turned on, voltage is supplied to the terminals of the unit and it begins to pump fuel. If the required pressure is created in the system, the relay automatically turns off the fuel pump - the engine is ready to start.

When the ignition is turned on, the relay creates pressure in the fuel lines by turning on the fuel pump (BN) for a couple of seconds. After this, the BN will work either when the engine is cranked by the starter, or when the engine is running.

Sometimes this system needs repairs - there is nothing complicated here, and the editors of the 2Skhema.ru website will tell you how to do it yourself. Let's start with the BN pinout, then we will indicate it on the diagrams and at the end there will be instructions for replacing the fuel supply elements.

How to Test a Mechanical Fuel Pump

To check a mechanical fuel pump, you will need the following tools and tools:

- screwdriver with Phillips bit;

- slotted screwdriver;

- key (head) 10;

- key to 13;

- 2 clean dry plastic bottles with a volume of 2 liters;

- a piece of hose (50 cm) of the same diameter as the fuel one;

- 1–1.5 liters of gasoline;

- caliper (ruler);

- stopwatch (clock).

Let's start with performance. A working VAZ 2110 mechanical fuel pump with a obviously clean filter should pump at least 1 liter of fuel per minute. The verification algorithm is as follows:

- We lift the hood and find the pump.

- Using a screwdriver, unscrew the screw of the pump outlet hose clamp. Loosen the clamp and remove the hose from the pump fitting.

A performance test involves measuring the amount of fuel pumped over a specified period of time.

If the amount of fuel pumped in 1 minute is less than 1 liter, the fuel pump is faulty

If the amount of fuel pumped per minute is less than a liter, the pump is faulty. The reasons for this may be:

- faulty valves;

- rupture of one or more membranes;

- clogging of the pump grid;

- wear of the drive rod (pusher).

We carry out further checks in the following order:

- Disconnect both fuel line hoses from the pump.

Disconnect the inlet and outlet hoses

When you press the manual pumping lever, you should feel a vacuum at the inlet fitting, and a pressure of air at the outlet

The mesh filter should not show signs of damage or deformation

Unscrew the two nuts and remove the fuel pump from the studs.

To disassemble the pump you need to unscrew 6 screws around the circumference of the housing.

The length of the pusher should be 82.4 mm

Features of the VAZ 21124 (l,6i) engine power system

Location of elements of the engine power system* VAZ 21124 (l,6i) in the engine compartment

: 1 - intake module;

2 — throttle assembly; 3 — air supply hose to the throttle valve; 4 — air intake; 5 — air filter; 6 — fuel rail; 7 — throttle valve drive cable; 8 — fuel rail fitting; 9 — adsorber check valve; 10 — adsorber * VAZ 21124 (l.6i) engine with the plastic cover removed.

VAZ 21124 (1.6i) engine power supply system diagram

: 1 - nozzles; 2 - fuel rail; 3 — diagnostic fitting of the fuel rail (for checking the fuel pressure, closed with a threaded cap); 4 - adsorber; 5 - check valve; 6 — throttle assembly; 7 - gravity valve; 8 - separator; 9 — fuel line tube connecting the fuel filter to the tee; 10 — fuel line tube connecting the fuel filter to the outlet pipe of the fuel module; 11 — fuel module; 12 — fuel filter; 13 - filler pipe; 14 — fuel tank; 15 — hose connecting the fuel filter and the fuel module with the fuel line; 16, 18 — metal fuel pipes; 17 — connecting hose; 19 - fitting for connecting the fuel rail to the fuel line

useful tips for motorists

Checking the electrical circuit

Unlike a carburetor engine, where the fuel pump is mechanically driven, on the injection VAZ 2110/2112 a special relay and fuse are responsible for the operation of this device. Therefore, before moving on to diagnosing the pump itself, it is necessary to check the indicated elements. If any one of them is faulty, the pump will not work at all.

Turn on the ignition without starting the engine and listen. When the fuel pump is running, it emits a characteristic “whistle” when started. If it is not there, it means that either the pump itself has failed, or one of the elements of its power supply circuit has failed.

The pump relay and fuse are located in an additional mounting block located inside the vehicle's center console. It can be accessed by removing the plastic trim (near the front passenger's left foot). It is secured with several screws. Under the cover you will find three relays and three fuses. Typically, the fuel pump circuit protection elements are located centrally.

The relay and fuse are located in an additional mounting block under the cladding

To check the fuse, remove it from its socket and “ring” it with a tester. If necessary, replace it, observing the rating (15 A). It is unlikely that it will be possible to check the relay for functionality without special equipment. But you can take another relay, for example, the radiator fan (far left), and install it in place of the one being diagnosed. Turn on the ignition and listen to see if the fuel pump starts working. If yes, buy and install a new relay. If the problem persists, continue diagnostics.

To check the fuel pump relay, you can install the radiator cooling fan relay in its place.

Additional block

It is located under the center console and is covered with a lid. One part is accessible from the right side.

Designation

p, blockquote 27,0,0,0,0 —>

- 15A - Ignition module, controller

- 15A - Canister purge valve, vehicle speed sensor, oxygen concentration sensor (heating), air flow sensor

- 15A - fuel pump, fuel pump fuse, injectors

- Electric fan relay

- Fuel pump relay

- Main relay (ignition relay)

The other part is on the left side of the console:

Decoding

p, blockquote 31,0,0,0,0 —>

- Central locking control unit

- Immobilizer block

- Relay for turning on rear fog lights.

On our channel we also prepared a video on this publication. Watch and subscribe.

p, blockquote 33,0,0,0,0 —> p, blockquote 34,0,0,0,1 —>

Do you know how to make the material better? Write in the comments.

Checking the fuel rail pressure

But even the fact that the fuel pump starts pumping when the ignition is turned on does not mean that it is working properly. The main indicator of its operation is the pressure in the system. You can check it using a regular pressure gauge with a measurement limit of 5–7 atmospheres, which is used to measure tire pressure. In addition, you will need a piece of gas-resistant hose with an internal diameter of 9 mm and two clamps of the appropriate size.

The verification procedure is as follows:

- We relieve the pressure in the system. To do this, disconnect the negative terminal from the battery. We remove the plastic lining of the additional mounting block, which contains the relay and fuse for the gasoline pump. We remove the fuse from the socket. Connect the removed terminal to the battery. We start the engine and let it run until it stalls. After that we put the fuse in place.

- On the fuel rail we find a fitting specially designed for measuring pressure. Using the wheel valve cap, unscrew the spool valve from the fitting.

The fitting is designed specifically for measuring pressure

A regular tire pressure gauge is suitable for measuring fuel pressure in the rail.

For engines with a volume of 1500 cm 3 it should be 2.8–3.2 atmospheres, and for power units with a volume of 1600 cm 3 – 3.6–4 atmospheres. If the device indicators are lower, the pump is unsuitable for further use.

How to change filters

The filter mesh often becomes clogged with dirt - this leads to unstable operation of the fuel system. To remove it, the pump does not need to be disassembled, but it must be removed. Next, the mesh will need to be changed or simply cleaned.

First reduce the pressure in the system, otherwise gasoline will spread throughout the cabin. To do this, pull out the fuse, start the engine and let it stall.

Replacing the mesh is done as follows:

- turn off the ignition;

- raise the rear seat;

- remove the hatch (fixed with two screws);

- open the connector with the wires;

- Use a wrench (17 mm) to unscrew the fuel hoses;

- unscrew the nuts securing the pump (8 pcs.);

- remove the plate;

- pull out the assembly (along with the gasket);

- change the mesh;

- Reassemble in reverse order.

Performance check

Checking its performance will help make sure that the fuel pump has failed. For this you will need:

- screwdriver with Phillips bit;

- a piece of gas-resistant hose (50–80 cm) with a clamp;

- key to 17;

- empty 2 liter plastic bottle;

- a piece of insulated wire;

- stopwatch.

Performance testing is carried out as follows:

- We remove the back seat. We lift the carpet and find the gas tank hatch under it. Unscrew the two screws (diagonally).

- Once you remove the hatch, you will see the top of the fuel module. Using a 17 wrench, unscrew the nut of the outlet fitting. We put a hose on it and secure the connection with a clamp. We lower the other end of the hose into an empty bottle.

- Disconnect the pump power connector. Using a piece of wire, we supply power to the positive contact of the device from the corresponding battery terminal. We connect the negative one to ground.

- We begin counting the time from the moment the pump starts.

A working fuel injection pump for a VAZ 2110/2112 should pump 1.5 liters of fuel in one minute. If this indicator is lower, the pump must be replaced.

No power supplied

As the pinout indicates, there are 4 wires going to the pump:

- in the center - plus and minus;

- at the edges – fuel level control.

To check whether current is flowing, connect a light bulb (12 V) to the negative and positive contacts and turn on the ignition. If everything is in order, it will flare up. If there is no result, the plus and minus removed from the pump connector are connected in turn to its ground, and then to the relay block.

- the lamp (when the negative wire is connected to ground and the ignition is turned on) blinks, then this contact is damaged;

- the improvised indicator did not flash - there are problems with the plus.

If the wire is installed on the relay and the lamp lights up, there is a break between it and the pump. Disassemble the harness and replace the faulty wire. You don’t need pinouts in this situation either.

When it turns out that it was the pump motor that burned out, it will have to be replaced - it cannot be repaired.

Replacing the fuel pump on injection vehicles VAZ 2110/2112

- screwdriver with Phillips bit;

- thin slotted screwdriver;

- key to 17;

- key to 7;

- key to 5.

Procedure for replacing the fuel pump:

- Disconnect the negative terminal from the battery.

- Open the gas tank cap for a few seconds to reduce the pressure inside.

- Remove the rear seat, unscrew the screws, and open the hatch.

Unscrew the two screws securing the protective hatch

Disconnect the electrical connector

Using a 17 wrench, unscrew the nuts of the pump fittings

Using a 7 wrench, unscrew the 8 nuts securing the fuel module flange

Using a screwdriver, unscrew the 2 screws securing the fuel level sensor

Use a screwdriver to remove the clamps on the guides

Using a slotted screwdriver and a 5mm wrench, unscrew the bolts securing the fuel pump cover

We remove the fuel pump from the housing and install a new one in its place.

Having completed the assembly, we check the operation of the new fuel pump.

The process of replacing a VAZ 2110/2112 fuel pump, regardless of its design, does not require any special skills and can be done independently. However, if you are not particularly confident in your own abilities, it is better to contact the nearest car service center.

On any passenger car with a gasoline engine, the gas pump serves to supply fuel under pressure from the fuel tank to the metering device - depending on the modification of the engine on VAZ cars, the fuel system can be carburetor or injection.

The fuel pump (BN) on carburetor internal combustion engines of the 2110 car is located behind the valve cover, next to the distributor-distributor; on a car with an injection engine, it is located in the fuel tank (submersible type). If the BN begins to malfunction, the engine does not pull or develop speed, and in many cases the engine cannot be started at all.

Reasons for failure and replacement

VAZ 2110 connecting an electric fuel pump

Fuel pump failure occurs for several reasons:

- driving with an empty gas tank;

- failure to replace the fuel filter on time and much more.

Due to non-compliance with such simple rules, the electric fuel pump wears out. Therefore, malfunctions in the fuel system occur prematurely.

Note: it is necessary to change fuel filters on time, especially when filling with low-quality gasoline. Follow the main rule: the gas tank should always be more than half full.

Preparation for repair

Before starting repairs and replacing the electric fuel pump, you must:

- disconnect the negative terminal on the battery;

- remove the cap from the gas tank to prevent the creation of rarefied vapors;

- check the fuel level, it should be at the middle level in the gas tank, but no more;

- You should also place a fire extinguisher nearby, just check its expiration date in advance.

To relieve pressure in the pipeline, you must start the engine and leave it running until it stops completely.

Note: work must be carried out using a lamp with a protective cap. You need to prepare clean rags and plastic containers in advance for the fuel pump to be removed, as there will be residual fuel in it.

After completing the preparatory work, recline the rear seat and remove the protective cap of the gas tank.

Replacement

VAZ 2110 electric fuel pump diagram

Carry out work carefully, legibly and consistently:

- disconnect the gas tank connector;

- loosen the clamp;

- unscrew the tubes using special wrenches;

- remove the rubber gaskets;

- unscrew the eight bolts on the body;

- remove the sealing ring;

- remove the fuel pump.

Note: replace the rubber gaskets on both pipeline fittings using a repair kit. The fuel pump must be placed on a pre-prepared rag or in a plastic container.

VAZ 2110 electric fuel pump and its removal

The pump is gradually pulled up and tilted towards the backs of the seats to avoid deformation of the float. Remaining gasoline may spill during this work. The last thing is to remove the rubber gasket. When replacing not the entire module, but only the fuel pump, you will have to spend time and effort:

- remove the locking spring from one guide;

- compress the fixation plates;

- disconnect the module;

- remove the fence mesh;

- disconnect the terminals from the pump and fuel level sensor;

- remove the polypropylene fuel pipe, it is connected securely, so you will need to act carefully, but with effort;

- remove and replace the pump.

Note: replacing the fuel pump must be done with replacing the fuel filter.

Assembly

VAZ 2110 fuel pump wiring diagram

VAZ 21102 electric fuel pump

The operation of the new fuel pump is checked. The engine starts, you need to let it run at low speeds. Drive through the territory using different modes, increasing the speed, decreasing it, within the limits allowed by the space. Return to the garage. On site, check the tightness of the disconnected parts again.

Note: all repair work must be carried out in compliance with fire safety measures.

Replacing an electric fuel pump with your own hands is not difficult. You just need to carefully study the instructions and be patient and attentive. Before carrying out this work, you need to view the video and photographs. Photos can also be used during work. Place them in the required sequence. The price of a fuel pump, repair kit, fuel filter is within 2000 rubles. Carrying out work on replacing a fuel pump does not require great qualifications. Therefore, a motorist of any category can handle it. After completing the work, all rags must be collected and disposed of. Old cuffs and pads must also be disposed of.

Fuel pump circuit (electric)

The design of the electric fuel pump 2110 itself is quite simple - the unit is an electric motor, which is supplied with 12 Volt power. The BN is mounted in a housing, and a mesh is installed at its inlet - a coarse filter. The filter element prevents dirt particles from penetrating into the pump housing, thereby protecting the device from clogging and possible breakdown.

The electrical circuit of the VAZ fuel pump contains the following elements:

- ignition;

- fuse;

- relay;

- wiring;

- the engine control unit.

When you turn the ignition key, power is supplied through the relay to the BN terminals, and the pump begins to pump gasoline. After the input line of the fuel line is filled with gasoline, the ECU (control unit) through a relay gives a command to turn off the voltage - the fuel system is ready to start the engine, all that remains is to crank the engine with the starter.

Work process

Electric fuel pump for VAZ 2110

The driver turns on the ignition switch, a signal is sent from the on-board computer to the electric motor of the pump, in which an electric charge occurs. A motor starts working inside the pump itself, creating a working pressure level in the fuel supply system in a few seconds. After three seconds, the on-board computer does not give a signal to start the engine, and the pump motor automatically turns off. At this time, you can hear the operation of the electric fuel pump. In the first seconds of the pump starting to operate, gasoline enters it through the tube. The fuel exits through a special one-way valve installed by the manufacturer, which traps debris and impurities.

Where is the fuel pump relay for VAZ 2110 injector?

Often, due to a relay failure, the engine stops starting; to fix the problem, it is necessary to replace the faulty part. The fuel pump relay (RB) of the VAZ 2110 injector is located in the car interior, under the instrument panel, next to the center console. To get to the pump, you need to unscrew the two screws of the protective plastic casing and dismantle it - of the three elements located here, the “relay” responsible for the operation of the pump will be located in the center (in the figure below, number 5).

Device

First of all, you should know the very structure of the heating system in order to clearly understand what and how to repair, because for the VAZ 2110, interruptions in the operation of the heater are a typical phenomenon, and from time to time requiring the intervention of reliable hands - be it a driver or a service station worker.

For stable and high-quality driving in a car, it is recommended not only to be able to use the heating system, but also to understand the heater’s structure. The operating principle of the system can be found here: https://vazweb.ru/desyatka/otoplenie/otopitel.html

So, the heating system consists of: 1. The actual heater unit, which provides heating for the interior

It is represented (by importance of details):

- An electric motor on which a fan is also attached to pump hot air;

- A radiator, without which the entire system does not work. Moreover, unlike the old heater, the radiator of the VAZ 2110 stove of the new model does not have a tap that shuts off the flow of antifreeze (antifreeze) through the radiator. Thus, it is always (whether in winter or in summer) heated. This was done supposedly in order to eliminate leaks that were often observed through this tap, and also to heat the interior as quickly as possible when necessary. In the summer, the supply ventilation goes past the radiator, but still some VAZ 2110 owners, when repairing the stove, add this tap to the system;

- There are three dampers. One is responsible for air intake recirculation, the second opens/closes the heater duct, the third, the most important for the interior, controls the heater;

- A resistor that regulates the blowing speed.

All parts are packaged in a block with additional valves, shields, and fittings. This entire device is housed in a housing and is located under the hood closer to the instrument panel.

2. The next block represents the air ducts of the VAZ 2110. They extend directly from the stove and provide:

- Interior ventilation through central nozzles;

- The air distributor works to supply heat (or regular air for ventilation);

- Two air ducts are directed to the rear of the cabin;

- There is a whole system of five nozzles for heating the feet;

- Two side air ducts provide heating for the side windows and part of the interior, providing better heating;

- Two nozzles for ventilation.

This, in a nutshell, is the principle of distribution of hot or cold air inside the VAZ 2110.

3. The electronic control unit for the stove operates from the passenger compartment. It includes:

- Controller handle. This device allows you to set the temperature in the cabin that the stove unit should produce. It turns on by turning the knob and sets the temperature from the air, the temperature of which will correspond to that outside, up to 30°C. Most often, this part is called the ACS controller (automatic heater control system);

- The temperature sensor is responsible for turning on the heater when the temperature in the cabin drops by 2 degrees against the set one. The sensor has a microfan, and if the control knob is in position A, then the micromotor in the stove block turns on and the damper begins to operate, ensuring proper heating. Therefore, before starting repairs of the heating system, the operation of this sensor is usually checked. It is located next to the heating lamp on the ceiling of the VAZ 2110. Since it is not repairable, in the event of a breakdown this device should be replaced immediately.

This material will help you quickly and efficiently replace the stove fan in a VAZ 2110: https://vazweb.ru/desyatka/otoplenie/zamena-ventilyatora-pechki.html

Ceiling interior air temperature sensor

Gasoline pump VAZ 2110 injector price

Electric fuel pumps 2110 are produced by various manufacturers; they can be sold either assembled with a housing, or the electric motors themselves can be sold separately. It makes sense to change the BN assembly only when the bulb (body) of the device is damaged; more often than not, only the fuel pump motor itself requires replacement, since it basically stops working.

Main manufacturers of fuel pumps 2110-2112:

For VAZ 2110 injector fuel pumps, the cost may vary; on average, BN can be purchased at a price from 700 to 4500 rubles. The most inexpensive products are produced by Hofer and Pekar; the average price of an electric fuel pump (motor) complete with a Pekar mesh filter is about 800 rubles. The most expensive are Bosch BNs; the cost of the assembled device is 4300-4600 rubles.

Video instructions for replacement

In this short article you will learn about the VAZ 2110 fuel pump relay. Such a device can be found not only on tens, but also on nines (injection), as well as more modern Priors and Grants. But why is this relay needed and what to do if it fails? This is what we will now try to figure out. But it’s worth starting with the principle of operation of the fuel supply system of the VAZ 2110 car.

Replacing the fuel pump mesh for VAZ 2110 injector

Russian fuel does not always meet quality requirements, and over time, due to poor gasoline, dirt accumulates in the gas tank in the form of sediment. The debris also clogs the filter screen of the electric fuel pump; due to the accumulated dirt, the fuel does not fully enter the fuel line, causing interruptions in the operation of the internal combustion engine. To eliminate the malfunction, it is necessary to clean or replace the coarse filter, but to get to the mesh, you need to remove the BN.

Before starting disassembly, you should reduce the pressure in the fuel system, otherwise, when unscrewing the fuel line fittings, gasoline may escape in a stream and flood the entire interior of the car. To relieve the pressure, remove the fuse responsible for the operation of the BN, start the engine and wait until it stalls. We replace the VAZ 2110 injector fuel pump mesh as follows:

- turn off the ignition;

- in the back seat in the cabin we find hinges, and by pulling them, we fold the lower “seats” forward (right and left);

- there is a hatch on the bottom under the seat, it is secured with two self-tapping screws;

- unscrew the screws and dismantle the hatch;

- disconnect the plug from the wires that supply power to the electric fuel pump; to do this, bend the latch and forcefully pull the parts of the connector away from each other;

- unscrew the fittings of the fuel pipes - main supply and return (17 mm wrench);

- unscrew the nuts of the pressure plate of the used pump (there are 8 fasteners here, 7 mm wrench);

- The nuts are small, it is better to put them in some kind of jar so as not to lose them. Remove the plate and remove the pump assembly from the gas tank. You need to remove the fuel pump together with the rubber sealing ring and lift the pump carefully so as not to damage the fuel level sensor. When removing the BN housing, it is necessary to tilt it, otherwise it will not come out of the tank;

- remove the screen from the fuel pump and install a new part;

- We install the electric fuel pump in place. Here it is important to put the housing in the old places - if you move the used pump, it will be impossible to tighten the fuel line fittings.

Causes of malfunctioning fuel pump

Fuel pumps are different. It all depends on the specific brand of car and the characteristics of the pump itself.

Knowing the causes of problems in the vehicle’s fuel system is a necessary condition for its successful repair. Problems may arise for the following reasons:

- Wiring problems: Wires have become dirty, rusted, or melted. As a result, the electric voltage decreases and fuel pumping becomes more difficult.

- Debris and dust getting into the gas tank. Rust in the tank. As a result, the fuel becomes unclean and causes problems. Poor quality fuel also pollutes the gas tank.

- Filter dirty. Fuel pressure decreases and the functions of the device are weakened.

- Driving with an empty tank. This leads to a decrease in pressure and overheating. It dries out and becomes damaged.

To effectively treat a living organism, it is important to know not only the symptoms, but also the causes of the disease. It’s the same with the operation of car systems: you need to find out the causes of problems in the operation of the fuel pump

The gasoline pump is one of the key elements of the automobile fuel complex. It is responsible for transferring fuel under pressure to the injectors (when the car uses a system in which fuel is injected) or to the carburetor. Like other parts of the car, the pump may stop working properly.

The device can be mechanical or electrical. It all depends on its functional characteristics and structure.

How to check functionality

This is easy to do at home. First you need to remove the pump and place it in a vice. Then connect a hose to each branch pipe. One hose must be directed into an empty container, and the other into a container with gasoline. The mechanism must be pumped by hand. If the fuel moves from hose to hose, then you can be happy. This means everything is fine. If this does not happen, then most likely the part needs to be replaced.

Knowledge of the operation of all vehicle systems and experience in troubleshooting them will help save money and provide invaluable assistance in the event of a breakdown far from populated areas.

Malfunctions of the electric fuel pump 2110

If the pump stops working, there may be several reasons for the malfunction:

- electrical wiring is damaged;

- fuse burned out;

- the relay stopped working;

- BN motor burned out;

- The engine control unit has failed.

When a driver in a car with a VAZ 2110-12 injection engine turns on the ignition, the electric motor starts working - a characteristic buzzing sound is heard. If no sounds are noted, it means that the BN is not pumping fuel.

The easiest way is to check the electric fuel pump fuse, which is located almost in the same place as the relay, located to the left of the RB.

If the fuse is blown, it must be replaced. It often happens that when replacing a fuse, it immediately blows. The main reasons for the malfunction of this phenomenon:

- the fuel pump itself “shorts”;

- There is a short circuit in the electrical wiring.

Another characteristic malfunction of the electric fuel pump is that fuel is pumped, but the operation is accompanied by loud noise. A noisy fuel pump is a sure sign that this device will not “live” for long and will soon fail.

Basic principles

Regardless of the type of engine used, the basis of the wiring used in the VAZ 2110 car is the same. It's easy to find a diagram, but not so easy to understand.

Let's look at the basic principles of wiring.

- All equipment and devices powered by electricity in the VAZ 2110 are based on a single-wire connection. VAZ designers specially provided for wires of certain colors to each be responsible for their own functions. Therefore, certain equipment is connected using wires of their own color. This allows you to independently understand the wiring, make it easier to carry out repair work and not spend money on car repair services.

- The downside to the VAZ 2110 is that the mass is the car body itself.

- The positive wire of the batteries on the top ten always comes only in red. Therefore, when making repairs, try not to change the color of the wire, so as not to confuse yourself.

- For each system that is connected to the electrical system, it is equipped with its own separate wiring harness.

- The VAZ 2110 is designed in such a way that when the battery is turned on, all electrics and electrical equipment are energized. This is related to the most common recommendation, which you have seen more than once in our materials, where we described the repair or replacement of certain components - disconnecting the negative terminal from the battery.

- Do not forget about the existence of the so-called contactless system. This system is required to create a high-quality spark, which is simply necessary to ensure combustion of the air-fuel mixture. In order for a contactless system to function, high voltages are indispensable.

How to test a relay

If the electric fuel pump does not show any signs of life when the ignition is turned on, this does not mean that it has burned out. The cause of the malfunction may also be a relay. The easiest way to check the RB by ear is that when you turn on the ignition, the relay should click. If you don’t hear a click, there is a high probability that the “relay” is faulty.

But not everything is so simple - the problem can be “tricky”, for example, the car does not start the first time. The cause of the malfunction may be hidden in burnt relay contacts. It’s quite simple to check the functionality of the pump itself; proceed as follows:

- remove the protective casing, under which there is a block with relays and fuses;

- we unscrew the fastenings of the block, remove it, it remains attached to the wires;

- we pull the RB out of the block, place a jumper between two opposite contacts, thus directly supplying power to the BN;

- If, with such a connection, the electric motor of the pump begins to make noise, it means that the BN itself is working, most likely, the malfunction is hidden in the relay.

If there is no voltage on any of the contacts on the RB block, you should look for a break in the wiring; there may also be poor contact at the place where the wire is attached to the terminal.

When should you check your fuel pump?

It is necessary to check all potentially faulty components one by one, and the fuel pump first.

Problems when starting and running the engine are not always associated with the fuel pump. Sometimes the signs of a fuel pump breakdown are the same as those of a faulty fuel pressure regulator , injectors or jets, spark plugs and high-voltage wiring. Even experienced specialists who know by heart all the signs of a “dying” pump cannot unambiguously determine the type and cause of the breakdown the first time, and it is necessary to check all potentially faulty components one by one. In this case, the fuel pump is usually checked first. In this case, there are two types of malfunction - the fuel pump does not work at all or does not produce the required pressure. In the first case, the malfunction can be recognized by ear, since it should start when the ignition is turned on. In the second case, you need to know how to check the pressure of the fuel pump. Here you need to use a special pressure gauge. We list the main symptoms of a fuel pump malfunction:

- the engine does not start;

- the engine is unstable;

- the engine lacks traction during sharp acceleration;

- The engine lacks traction at low speeds.

We recommend: Replacing front and rear brake pads on Lada Kalina

Fuel check valve

The electric fuel pump of the VAZ “Ten” has good performance, but it creates too much pressure in the fuel system. In order to bring the pressure back to normal, a VAZ 2110 fuel pump valve is built into the fuel line; it is located in the “outlet” fitting of the BN housing. On the “tens”, a pressure regulator is also installed, which is located behind the fuel rail.

A valve malfunction involves a ball sticking in the open position, and the fuel pressure in the system may drop to zero. If such a problem occurs, the car is very difficult to start, since all the gasoline from the fuel lines goes back into the gas tank when the ignition is turned off. Is it possible to somehow repair the valve?

Drivers of 2110 cars claim that you can try knocking on the fitting in the BN flask so that the shut-off ball falls into place. If the malfunction cannot be eliminated in this way, the electric fuel pump bulb must be replaced, since this housing itself is non-separable.

Master node of the system

The VAZ-2110 fuel pump is equipped with an electric drive. Its body is lowered into the fuel tank. Gasoline is both a pumpable fuel and a coolant. It should be remembered that traveling with an empty tank is fraught with overheating of the VAZ-2110 injector fuel pump.

This electrical device is an independent unit. Accordingly, its operation does not depend on the state of other mechanisms. A necessary condition for rotating the VAZ-2110 fuel pump rotor is maintaining normal voltage on the on-board network.

The voltage comes through the ignition switch. When the key is moved to position 1, the circuit is closed to turn on the drive. The VAZ fuel pump fills the fuel rail. The engine is ready to start.

If symptoms of poor fuel system performance occur, the pump should be checked. We list the signs that make it possible to replace the VAZ-2110 fuel pump:

- the car is malfunctioning;

- accelerates poorly;

- twitches while driving;

- won't start at all

- gasoline does not flow to the ramp.

First of all, a hearing test is performed. After turning the ignition key to position No. 1, there should be a noise under the rear seat. The sound lasts for a couple of seconds. This means that the pump has pumped up the required pressure.

Mechanical fuel pump malfunctions

All parts of a car engine are subject to wear and aging, and the life of a mechanical fuel pump also depletes over time. Main malfunctions of the mechanical device:

- warping of hulls;

- cracking of the diaphragm;

- valve failures.

If the diaphragm allows air to pass through, the pump may stop pumping gasoline into the carburetor; through the torn diaphragm, fuel enters the crankcase and mixes with the engine oil. When gasoline gets into the oil, fuel consumption increases sharply, and the engine itself starts poorly, especially when warm. Checking the presence of gasoline in the crankcase is quite simple - if you light the oil dipstick with a lighter, a fire will occur, and a gasoline smell will come from the oil crankcase.

A common defect that occurs in mechanical gasoline pumps is warping of the surface at the point where the pump is attached to the body of the auxiliary units. If the surface is deformed, engine oil begins to leak at the joint between the planes.

CAUSES OF ENGINE OVERHEATING

Overheating can be caused by many reasons, all of them are related to a malfunction of the cooling system, or the quality of the coolant, as well as contamination of the cooling system jacket, which impairs the fluid throughput

It is important to use high-quality spare parts, otherwise the reasons below will happen suddenly. Let's consider each of the reasons

LOW COOLANT LEVEL

The most common problem is a lack of coolant in the system. Coolant, in the form of antifreeze or antifreeze, constantly circulates through the system, removing heat from heated engine parts. If the coolant level is insufficient, the heat will not be removed sufficiently, which means an increase in temperature will be inevitable.

If it is not possible to add coolant, then turn on the heater to reduce the likelihood of overheating. As a last resort, add regular or distilled water, after which the cooling system must be flushed and then filled with fresh antifreeze. At temperatures above 90 degrees, you should immediately stop the car, turn off the ignition, and allow the engine to cool.

ELECTRIC COOLING FAN FAILED

The electric fan forces cool air onto the radiator, which is especially necessary when driving at low speeds when there is insufficient air flow. The fan can be installed either in front or behind the radiator. If the temperature arrow starts to rise, stop the car and check the fan for serviceability. Reasons for fan failure:

- electric motor failed

- connector oxidized

- fan relay burnt out

- The internal combustion engine temperature sensor has failed.

To check the fan, remove the connectors from it and connect the wires directly to the battery, which will allow you to determine the cause of the failure.

THERMOSTAT FAULT

The thermostat is one of the main elements of the cooling system. The cooling system has two circuits: small and large. A small circuit means that fluid circulates only through the engine. In a large circuit, fluid circulates throughout the system. The thermostat helps you quickly reach and maintain operating temperature. Thanks to the sensitive element, which opens the valve at 90 degrees, the liquid enters a large circle, and vice versa. The thermostat is considered faulty in two cases:

- operating temperature of the coolant is not reached

- the power unit tends to overheat.

The thermostat can be located directly in the cylinder block, in a separate housing, or as one unit with a temperature sensor and pump.

BROKEN COOLING FAN BELT

On vehicles with a longitudinally mounted engine, the fan can be driven by a drive belt from the crankshaft pulley. In this case, the fan works forcibly. The service life of the drive belt is from 30 to 120 thousand km. Typically, several units are driven by one belt. When a belt breaks, the internal combustion engine immediately tends to overheat, especially when the speed decreases. If you have a domestic car with a belt-driven fan, it is recommended to install an additional electric fan to avoid unpleasant incidents.

DIRTY RADIATOR

Once every 80-100 thousand kilometers it is necessary to flush the radiator along with the entire cooling system. The radiator becomes clogged for the following reasons:

- untimely replacement of antifreeze

- use of low-quality liquid

- application in water system

- application of cooling system sealant.

To wash the radiator, you should use special compounds that are added to old antifreeze; the engine runs on this “mixture” for 10-15 minutes, after which you need to remove water from the system. It is advisable to remove the radiator and wash it with water under pressure, inside and out.

Fuel pump VAZ 2110 carburetor price

Unlike electric fuel pumps, mechanical fuel pumps are generally cheaper; the price largely depends on the manufacturer. The most famous companies producing gasoline pumps:

The cost of the device ranges from 350 to 850 rubles; repair kits are also sold for used mechanical pumps; the kit contains a diaphragm, rod, and valves. The repair kit is quite cheap - from 70 to 200 rubles, but it does not always make sense to carry out repairs, since the pump assembly itself is inexpensive.

An interesting fact is that the fuel pump for carburetor engines for the VAZ “ten” is suitable for the VAZ 2108-09-099 models, as well as for the Zhiguli VAZ-classic 2101-07. The “Classic” BN differs only in a slightly different arrangement of fuel fittings, and in order to install the pump from the “Classic” on a car 2110, it is necessary to use longer fuel hoses.

Dear customers, in order to avoid errors when sending the fuel level sensor harness 21101-3827010РХ, in the “Comment” line, indicate for which engine power system 21114, 21124 or 11183i, 11194i, your car model, year of manufacture.

Electric fuel pump assembly - is an electric fuel pump module with a fuel level indicator sensor assembly. Designed to supply fuel from the gas tank to the engine injectors, as well as determine the fuel level and signal its minimum level in the gas tank with an electronic engine control system (ECM)

1- built-in fuel pressure regulator; 2- fittings for installing fuel lines with quick-release tips; 3- electrical connector; 4 — fuel level indicator sensor.

The VAZ 21126 Lada Priora electric fuel pump assembly is of a submersible type, installed in the gas tank located under the bottom of the car body, in the rear seat area behind the service hatch, which, when opened, can be detected.

The submersible fuel pump is lubricated and cooled by fuel.

The fuel level sensor 21101 - 3827010 as part of the fuel system is used to determine the fuel level and is installed directly in the fuel tank. The fuel level sensor is used in conjunction with the fuel level indicator, which in turn is located on the dashboard. The fuel level indicator sensor is based on the operating principle of changing the voltage (pulse height, frequency) at the sensor output when the fuel level in the tank changes.

The fuel level sensor wiring harness 21101-3827010РХ is intended for connection to the common wiring block, as well as to the FLS wiring block from the fuel pump in cars of the VAZ 2110-2112, VAZ 2113-2115, VAZ 2170 family.

Structurally, the fuel supply sensor is nothing more than a rheostat with nichrome resistance. The movement of the movable adjustable contact is carried out through a float lever, the console of which is equipped with an additional contact point. This additional contact, being in a specific position, closes the control circuit, thereby indicating the need to use the fuel volume of the reserve group, which includes a volume from 4 to 6.5 liters. gasoline.

The fuel level sensor is a device of low reliability. Sometimes it becomes necessary to buy a fuel sensor, because after a certain period of operation, the indicators of this device begin to “jump”, that is, produce incorrect parameters. This is due to the fact that the main disadvantage of such a device is the thinning of the track of the contact group under the influence of the friction force of the runner.

In some cases, you can repair the device by slightly bending the so-called. “rocker arm” (bending) of the runner, thereby placing its working contact surface slightly above the wear area of the contact track. If wear exceeds permissible standards, the FLS fuel sensor must be replaced with a new product.

If the fuel tank is half full and the VAZ fuel consumption sensor shows a zero tank fill value, the following measures must be taken:

— test the technical conditions of the contact group on the rear of the instrument panel and, if necessary, tighten the electrical wiring fasteners;

— check the smooth movement of the float spoke, focusing on eliminating unauthorized stops in intermediate positions.

Due to low-quality gasoline and additives, the internal electrical mechanisms in the electric gasoline pump are corroded. When working dry, the brushes overheat and wear out. With proper operation, the service life of the fuel pump is very long.

Connectors DUT 21101-3827010РХ with assembled wiring are highly resistant to adverse environmental influences (high humidity, saline solutions, oil, gasoline and their fumes, aggressive detergents). Connectors with Cargen wires use wires with copper cores with a cross-section from 0.5 mm to 6 mm.

The wiring harness for the fuel level sensor 21101-3827010РХ, fuel pump in cars of the VAZ 2110-2112, VAZ 2113-2115, VAZ 2170 family satisfies the needs of consumers and complies with the requirements of GOST R51814.1-2004 (ISO/TU 16949:2002).

Replacing the wiring harness of the FLS 21101-3827010РХ, located in the electric fuel pump module, connecting the common wiring block, as well as the fuel pump FLS wiring block in cars of the VAZ 2110-2112, VAZ 2113-2115, VAZ 2170 family, can be done independently, without contacting specialized services service.

When replacing a VAZ fuel sensor, it is dismantled along with the electric fuel pump for supplying fuel.

Other article numbers of the product and its analogues in the catalogues: 211013827010 РХ, 211043827010 РХ.

VAZ 2110, VAZ 2112, VAZ 2113-2115, VAZ 2170.

Any breakdown is not the end of the world, but a completely solvable problem!

How to independently replace the fuel level sensor in the VAZ 21126 electric fuel pump on a VAZ family car.

With the online store Discounter AvtoAzbuka, repair costs will be minimal.

Just COMPARE and BE SURE.

Don't forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons below.

Pinout BN VAZ 2113, 2114, 2115

— block headlights; — gearmotors for headlight cleaners*; - fog lights*; — ambient temperature sensor; - sound signals; — engine compartment lamp switch; — electric motor of the engine cooling system fan; — generator; — low oil level indicator sensor; — washer fluid level sensor; — front brake pad wear sensor; — wire tips connected to the common windshield washer pump**; — windshield washer pump; — headlight washer pump*; — wire ends for connecting to the rear window washer pump on VAZ-2113 and VAZ-2114 cars; — low oil pressure indicator sensor; — engine compartment lighting lamp; — wire lug for connecting to the wiring harness of the engine control system; — gear motor for windshield wiper; — starter; — a block connected to the wiring harness of the ignition system on carburetor cars; — coolant temperature indicator sensor; — reversing light switch; — low brake fluid level indicator sensor; - accumulator battery; — low coolant level indicator sensor; — relay for turning on fog lights; - mounting block; — brake light switch; — plug socket for a portable lamp; — hydrocorrector scale illumination lamp; — switch for the parking brake indicator lamp; — block for connecting a backlight lamp; — switch for instrument lighting lamps; - Understeering's shifter; - hazard warning switch; — front seat heating element relay; — ignition switch; — rear fog light circuit fuse; - fuse for the front seat heating elements; — door lock circuit fuse; — front ashtray illumination lamp; — ignition relay; - cigarette lighter; — glove box lighting lamp; — switch for the glove compartment lighting lamp; — heater fan electric motor; — additional resistor for the heater electric motor; — heater fan switch; - heater switch illumination lamp; — lamp for illuminating the heater levers; — gear motors for electric windows of the front doors; — power window switch for the right front door (located in the right door); — gear motors for locking front door locks; — wires for connecting to the right front speaker; — gearmotors for locking rear doors; — wires for connecting to the right rear speaker; — door lock control unit; — wires for connection to radio equipment; — headlight cleaner switch*; — rear window heating element switch; — relay for turning on the rear fog lights; — block for connection to the heating element of the right front seat; — rear fog light switch; — switch for the heating element of the right front seat; — fog light switch*; — switch for external lighting lamps; — left front seat heating element switch; — block for connection to the heating element of the left front seat; — wires for connecting to the left front speaker; — power window switch for the left front door (located in the left door); — power window switch for the right front door (located in the left door); — wires for connecting to the left rear speaker; — side direction indicators; — courtesy light switches on the front door pillars; — courtesy light switches on the rear door pillars; - lampshade; — ceiling lamp for individual interior lighting; — block for connecting to the wiring harness of the electric fuel pump; — trunk light switch; — instrument cluster; — trunk lighting lamp; — display unit of the on-board control system; - trip computer*; — block for connecting the wiring harness of the engine control system; — rear exterior lights; — rear interior lights; — pads for connecting to the rear window heating element; — license plate lights; — additional brake signal located on the spoiler.

How does the device work?

After the driver turns the key in the ignition switch, the relay begins its work. The part sends a signal to the fuel pump and it turns on for 2 - 3 seconds to achieve the required pressure in the rail. The relay turns off the pump and then it starts only when the engine is rotated by the starter or while driving. After stopping the engine, the relay turns off the fuel pump and relieves pressure. In the latest models of gasoline pumps, the device performs several additional functions:

- Acceleration. If the automatic transmission needs to increase speed, the relay can additionally turn on the pump to supply more fuel.

- Slowing down the engine speed. If the engine is running at maximum speed, the relay may temporarily turn off the fuel pump. Temporarily turning off the device allows you to normalize the number of engine revolutions.

A sign that the fuel pump is working is a slight hum. Normally, the hum lasts only a few seconds, but if the relay or other parts of the system fail, the device may not turn off for a long time or may not turn on at all.

Step-by-step installation with photo of the fuel pump

K-contact is a signal (spark-producing) B-contact is + 12V ignition

I connected the relay according to this diagram:

The relay itself looks like this.

This is what it looks like under the hood. I put the plugs on the mechanical fuel pump that were included with the EBN and haven’t started removing them yet, otherwise you never know.

Well, what can I say based on 2 weeks of experience in using this gas pump. The car drives and does not heat up even in the heat of 30+ degrees. 140 - 150 the car began to drive much better; there is enough gasoline, consumption has not increased, in general, so far everything is good.

The maximum speed at which it was driven

I found on a foreign website a diagram for controlling the fuel pump from the ignition, maybe it will be useful to someone. I soldered this myself and it works great, when you turn on the ignition the relay turns on for about 10 seconds, which is necessary to increase the pressure in the fuel system, then we start the relay again turns on the fuel pump while the ignition coil is working

Checking the fuel pump Lada Kalina/Granta

If after turning the ignition key there is no buzzing sound from the fuel pump, then the first thing to check is the fuel pump fuse and relay. In the Lada Kalina and Lada Granta mounting block, the fuel pump fuse is F21 (15A), and the fuel pump relay is K12. If the fuse is good, do the following:

- Turn on the ignition

- Remove the fuel pump relay

- Apply +12V to pin No. 11 of the diagnostic block, or place a jumper between 87 and 30 relay pins

- Check by ear that the fuel pump is turned on

If the fuel pump does not turn off, then check:

- Wiring and contacts between the fuel pump and the diagnostic block/fuel pump relay. To do this, check the voltage at the fuel pump chip using a test lamp or multimeter.

- There is no connection between the fuel pump and the vehicle ground. Apply the mixture to the fuel pump (located under the rear seat).

- The fuel pump is faulty. To check it, apply +12V directly to the contacts of the fuel pump (Attention! Remaining gasoline may ignite from a spark!).

In rare cases, the fuel pump does not work due to:

- ECU (controller) malfunction

- alarm malfunctions

Lada Kalina dashboard diagram

1,2,3,4 — blocks of the instrument panel wiring harness to the blocks of the rear wiring harness; 5,6 — blocks of the instrument panel wiring harness to the blocks of the front wiring harness; 7 — block of the instrument panel wiring harness to the block of the wiring harness 8 — block of the instrument panel wiring harness to the block of the front wiring harness; 9 — lighting control module; 10 — ignition switch; 11 — on-board computer mode switch; 12 — windshield wiper switch; 13 — sound signal switch; 14 — light signaling switch; 15 — instrument cluster; 16 — evaporator temperature sensor; 17 — interior air temperature sensor; 18 — air conditioner switch; 19 — controller of the automatic climate control system; 20 — heater damper gearmotor; 21 — rear window heating switch; 22 — alarm switch; 23 — brake signal switch; 24 — cigarette lighter; 25 — electric amplifier control unit; 26,27 — blocks of the instrument panel wiring harness to the radio; 28 — backlight lamp for the heater control panel; 29 — illuminator; 30 — mounting block: 31 — heater electric motor switch; 32 — heater electric motor; 33 — additional resistance of the heater electric motor; 34 — glove box lighting; 35 — glove box lighting switch; 36 — control unit of the APS-6 automobile anti-theft system; 37 — driver airbag module; 38 — passenger airbag module; 39.40 — blocks of the instrument panel wiring harness to the blocks of the ignition system wiring harness.

KZ - additional starter relay; K4 - additional relay; K5 - relay-interrupter for direction indicators and hazard warning lights; K6 - windshield wiper relay; K7 - headlight high beam relay; K8 - sound signal relay; K9 - relay for turning on fog lights; K10 — relay for turning on the heated rear window; K11 — electric seat heating relay; K12 - air conditioning compressor clutch activation relay;

Instrument panel wiring harness - 11186-3724030-20.

General diagram of electrical equipment of VAZ 1118

1 — block headlight; 2 — windshield wiper gear motor; 3 - generator; 4 - battery; 5 - starter; 6 — sound signal; 7 — hood open sensor; 8 — power window switch for the right front door; 9 — motor-reducer for window lifter of the right front door; 10 — electric pump for windshield washer; 11 — connecting blocks of wires for connecting the right (front) speaker of the audio system; 12 — electric drive for locking the lock of the right front door with an open door sensor; 13 — ambient air temperature sensor; 14 — connecting block of the wiring harness for connection to the engine control system harness; 15 — electric drive for locking the left front door lock (with an open door sensor and a central locking switch); 16 — sensor of insufficient brake fluid level; 17 — connecting blocks of wires for connecting the left (front) speaker of the audio system; 18 — right front door power window switch (installed on the driver’s door); 19 — left front door power window switch; 20 — central locking switch; 21 — motor-reducer for window lifter of the right front door; 22 — remote control unit; 23 — immobilizer control unit (APS-6); 24 — mounting block; 25 — instrument panel; 26 — right side turn signal; 27 — glove box lighting lamp; 28 — switch for the glove compartment lighting lamp; 29 — brake signal switch; 30 — ignition switch (lock); 31 — lighting control unit; 32 — steering column switches; 33 — left side direction indicator; 34 — connecting blocks of wires for connecting the left (rear) speaker of the audio system; 35 — electric drive for locking the left (rear) door with an open door sensor; 36 — electric heater fan; 37 — additional heater resistor; 38 — heater switch; 39 — alarm switch; 40 — reverse lock solenoid switch; 41 — rear window heating switch; 42 — connecting blocks of wires for connecting the right (rear) speaker of the audio system; 43 — electric drive for locking the right rear door lock (with a door open sensor); 44 — fuel module of the engine control system; 45 — reverse light switch; 46 — parking brake warning lamp switch; 47 — cigarette lighter; 48 — reverse lock solenoid; 49 — connecting blocks of wires for connecting the head unit of the audio system; 50 — backlight lamps on the trim of the center console of the instrument panel; 51 — electric power steering control unit; 52 — interior lamp; 53 — rear light; 54 — block for connecting the electric drive for locking the trunk lid lock*; 55 — luggage compartment lid open sensor; 56 — license plate lights; 57 — additional brake light; 58 — rear window heating element; 59 — luggage compartment lighting lamp.

Signs and Symptoms of a Malfunctioning Fuel Pressure Regulator

- the engine stalls at idle;

- engine power is greatly reduced;

- when accelerating, it is not possible to achieve normal dynamics;

- the car reacts poorly to pressing the gas pedal;

- fuel consumption suddenly increases greatly;

- the amount of carbon dioxide emissions increases;

- the crankshaft rotation speed changes.

All these problems arise due to the fact that the regulator becomes clogged or completely clogged over time. Another common cause of failure is weakening of the spring, leading to a strong decrease in pressure. In the absence of normal pressure, fuel supply decreases, power decreases and controllability deteriorates. Such problems are especially common on Ladas - Kalina and Priora, as well as on cars of the 2110, 2112, 2114, 2115 series.

To check the part, you need to carefully inspect it itself, the vacuum hose and all connections. Any leaks found must be corrected. It is also recommended to check the membrane. Disconnect the tube that goes from the RTD to the receiver and shake it. If no gasoline comes out from inside and there is no strong odor, then the membrane is in order.

RTD in diesel engines

Diesel vehicles running on the Common Rail system are also equipped with a pressure regulator. It fits into the fuel rail or is located on the high pressure fuel pump housing. The principle of operation is approximately the same. A special valve diverts unused fuel into the return line, preventing excessive loading.

In diesel engines, the regulator has a slightly different structure than in gasoline engines. It consists of a solenoid and a rod, which rests against a ball to shut off the return line. The design protects the engine from hydraulic vibrations and, as a result, from rapid wear.

Changing the fuel pump yourself

If the fuel pump in the VAZ does not pump, and all of the above system components are normal, it is necessary to clean the filters, and, if necessary, completely replace the unit.

Before starting work, you must completely drain the fuel from the gas tank. To do everything with our own hands, we need a screwdriver and a set of keys. Replacing the VAZ 2114 fuel pump is carried out according to the following algorithm:

- We de-energize the car by removing the “-” terminal from the battery;

- We take out the rear row of passenger seats;

- Unscrew the plastic cap that covers the pump;

- Remove the power wires from the device and disconnect the fuel supply hoses;

- We dismantle the main fastenings of the fuel pump; for this we need the 7th key;

- Now you can remove the fuel pump on the VAZ 2114 and remove the device.

It must be removed carefully, since the float sensor for determining the fuel level is a very delicate structure that is easy to damage. Inspect the fuel pump - if necessary, clean or replace the strainer, however, it may be necessary to completely replace the unit.

Ignition system diagram Lada Kalina Lux

1 — oil pressure warning lamp sensor; 2 — coolant temperature indicator sensor; 3 — additional fuse block; 4 — fuses for the electric fan of the engine cooling system; 5 — electric fuel pump relay; 6 — relay for the electric fan of the engine cooling system; 7 - ignition relay; 8 — relay 2 of the electric fan of the engine cooling system; 9 — relay 3 of the electric fan of the engine cooling system; 10 — electric fan of the engine cooling system; 11 — throttle position sensor; 12 — idle speed regulator; 13 — coolant temperature sensor; 14 — diagnostic block; 15 — ignition system harness block to the instrument panel harness block; 16 — solenoid valve for purge of the adsorber; 17 — speed sensor; 18 — ignition system harness block to instrument panel harness block 2; 19 — mass air flow sensor; 20 — crankshaft position sensor; 21 — oxygen sensor; 22 - controller; 23 — rough road sensor; 24 — diagnostic oxygen sensor; 25 — ignition coil harness block to the ignition system harness block; 26 — ignition coils: 27 — ignition system harness block to the ignition coil harness block; 28 — spark plugs; 29 — nozzles; 30 - resistor; 31 — air conditioning system pressure sensor; 32 — blocks of the ignition system harness and injector wiring harness; 33 - phase sensor; 34 - knock sensor.

Ignition system wiring harness -11184-3724026-10. Ignition coil wiring harness -1118-3724148-00. Injector wiring harness -11184-3724036. A - to the “plus” terminal of the battery.