Hello everyone, the mechanical pump has been out for a little less than a year and problems with it overheating and failure have started again. Having studied a large amount of information, it was decided to install a low-pressure electric fuel pump. At first I wanted to order from Aliexpress something like this ru.aliexpress.com/item/Hi…y-free-shipping-Universal and I probably would have ordered the price 2.5 times less, but then I changed my mind because I had to wait a month and the decision to purchase such a pump was reluctantly made (catalog number PFP093 price 1229 rubles) and everything ended up waiting for about a month (((

We also ordered an AUDI a100 fuel pump relay or a J271 relay (catalog number OSSCA 06455 - an analogue of the original one is 3 times cheaper) or you can order it from Aliexpress ru.aliexpress.com/item/Ne…Control-Unit-Wiring-Relay 4- x contact relay + signal (small) contact. The principle of its operation: When the ignition is turned on, the pump pumps for 3-4 seconds and if there is no signal that we take from the hall sensor, it turns off the fuel pump. ( connect 86 contact to coil contact B 86a contact to coil contact B 85 contact to ground 87 and 30 contact to the positive EBN break

)

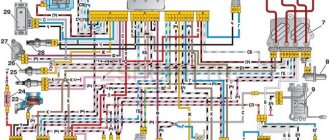

I connected the relay according to this diagram:

The relay itself looks like this.

My Solex carburetor already had a full return to the tank, which couldn’t help but please me. The only thing I did was remove the plastic check valve that was there and replace it with a solid hose. I attached the fuel pump itself next to the ignition coil on its mount, making a kind of adapter from a metal plate.

This is what it looks like under the hood. I put the plugs on the mechanical fuel pump that were included with the EBN and haven’t started removing them yet, otherwise you never know)))

Well, what can I say based on 2 weeks of experience in using this gas pump. The car drives and does not heat up even in the heat of 30+ degrees. 140 - 150 the car began to drive much better; there is enough gasoline, consumption has not increased, in general, so far everything is good,

The only downside is that starting up has become worse, I don’t know exactly what this is connected with, but we can assume that there is a voltage drop on the coil. Also along the way, there were replacements of spark plugs, high-voltage wires, and a gasoline and air filter.

UPD 2016

If it doesn't start well, turn the key, wait until the gas pumps up, and then start it. and one more necessary thing is an aluminum check valve, I haven’t seen this in my stores ru.aliexpress.com/item/1-6-8-10-12/32906030743

UPD 2022

Read the comments there is some useful information. The Audi relay that is mentioned in this article does not work as expected, if someone wants to implement competent control of the fuel pump, they will have to solder.

Electric fuel pump control circuit on a 555 timer

Quote from the site below: “I found on a foreign site a diagram for controlling the fuel pump from the ignition, maybe it will be useful to someone. I soldered this myself, it works great, when you turn on the ignition, the relay turns on for about 10 seconds, which is necessary to increase the pressure in the fuel system, then we start the relay again turns on the fuel pump while the ignition coil is working."

Let's start with the fact that the carburetor is a mechanical component of the power supply system of a gasoline engine. The main task of the carburetor is to prepare a suitable fuel-air mixture, as well as to dose the finished working mixture when supplied to the engine.

Naturally, many solutions are borrowed from more modern systems. Quite often on carburetor cars you can find electronic ignition or an electric fuel pump. Next, we will talk about what advantages an electric fuel pump provides for carburetor engines, how to connect an electric fuel pump to a carburetor engine, as well as what subtleties and nuances need to be taken into account during such an installation.

Read in this article

What exactly is HEP-02A?

The pump operates using an electromagnet and actuates a cylinder with a valve. The fuel pump is designed for use on carburetor cars of any brand, which makes it a universal element of the fuel system, regardless of the standard fuel pump. The body is sealed and riveted.

In fact, this is a disposable pump, but with the help of sandpaper you can grind off this edge and disassemble it.

Some craftsmen even repair it. There are 2 common breakdowns. This is a burnt element in the circuit, or damage to the rubber valve. But often they are not repaired, they just buy a new one.

Installation of fineness pump and chips

We install the EBN only vertically!

The location of the pump under my hood is as far as possible from the engine, since it also gets hot and it would be desirable for there to be airflow to the pump. I placed the filter in front of it; it is not advisable for debris to remain in the pump. A full return to the tank is also connected. Here, too, people write differently. The fact that it is not needed, since the pump, after filling the float chamber with fuel, begins to work on its own, and with the return line it will constantly oil. Others write that a return line is needed to make it easier for the pump to work, and the carburetor won’t overfill if the needle doesn’t hold well. Theoretically, both versions are correct, but I installed everything backwards

For installation, we need a soldering iron, a multimeter, wires, a chip for a 4-pin relay and the relay itself, as well as a chip for a fuse, respectively, and the fuse itself is needed for 15A. A fuel pipe and a couple of clamps.

The engine compartment of the M41 is not small, so the space for installing an EBN is quite sufficient.

Connection diagram

The circuit is very easy to connect.

Even if this is your first time connecting a relay, all the contacts are numbered and it is unlikely that you will make a mistake by mixing up the wires.

The pump was installed strictly vertically immediately behind the radiator fan.

Since our EBN is vibrating, it makes a loud sound if you don’t put a rubber gasket under it. Initially, I cut out a piece of strip from a bicycle tube, folded it several times, and attached it all with 2 bolts. As a result, the sound of the pump was audible even when the car was moving, very loud. Next, I cut out the gaskets from the fuel pipe and installed it all on the car.

The sound has become quieter, you can’t hear it when moving, but this is not the end result. In the future I will make a rubber cushion of 1 cm or more. For the experiment, I removed the EBN from the mounts and simply hung it behind the hose with a wire and screwed it to the body, so that the pump was not fixed, but simply hung on the fuel hose.

I was surprised by the result. The pump worked almost silently when the ignition was on; when the engine was running, you couldn’t even hear the pump running. I tried attaching springs instead of rubber tubes, after which I simply attached a pump to the springs, but the sound was even louder, so this is the only unpleasant situation with the EBN.

I laid all the wires in corrugation. We also do not forget that it is better to pull the + from the relay directly to the + terminal of the battery and put a 15A fuse there.

I didn’t know how much fuel it pumps from the tank, since everyone has a different length of the fuel line, different filters, maybe even more than one, so the result will be different. So far everything is fine regarding work. At speed and high revs, there is enough fuel and the car does not jerk, the spark plugs are clean. In fact, I didn’t notice any difference in operation between the EBN and the baker, the only thing is that it no longer stalls in the heat and, as it seemed to me, idling is better in cold weather.

Gasoline pump for carburetor VAZ 2107

One of the mechanisms of the power supply system of any engine is the fuel pump. The startup and operation of the power unit directly depends on its performance. Mechanical fuel pumps of the diaphragm type DAAZ 2101 were installed on carburetor “sevens”. Thanks to the simple design, the mechanism is repairable. However, it often causes problems for Zhiguli owners. Therefore, it is worth dwelling on the operation and malfunctions of this unit in more detail.

Main functions

The job of the fuel pump is to move fuel from the tank to the carburetor.

The design of the unit is not ideal, so it is one of the weak points in the car. This is explained by the fact that the impact of constant loads and low quality gasoline lead to natural wear and tear of the elements. This is what causes the device to fail. If a problem occurs with the pump, the engine begins to work intermittently or stops functioning altogether.

Design and operating principle

The mechanism is made of several parts connected to each other by fastening elements. There are two fittings in the upper part of the body through which fuel is supplied and pumped into the carburetor. The design includes a lever that allows you to manually pump gasoline from the tank into the fuel system, which is important after the car has been parked for a long time. The main elements of the node are:

- pusher;

- spring;

- balance;

- lid;

- cover screw;

- screw;

- mesh filter;

- membranes (working and safety);

- lower and upper plates;

- stock;

- valves (inlet and outlet);

- manual pumping lever.

The principle of operation of a classic fuel pump is based on creating the pressure necessary to maintain the required fuel level in the carburetor chamber. Thanks to the diaphragm, the flow of gasoline stops or decreases when a maximum pressure value is established in the fuel line. On carburetor “sevens” the fuel pump is located under the hood on the left side of the cylinder block. It is secured to two studs through a thermal spacer and gaskets, which are also used for adjustment. The spacer is also a guiding part for the pump rod.

The device operates in the following order:

- the pump pusher is driven by a drive cam operating from the gas distribution mechanism;

- the membranes located inside the gas pump move and alternately create pressure and vacuum in the chamber;

- if the pressure decreases, the outlet valve closes and fuel flows through the inlet valve;

- when the pressure increases, the valve at the pump inlet closes, and gasoline is supplied through a hose to the carburetor.

Which fuel pump is better

When there are problems with the fuel pump, the question of choosing a new device often arises. Owners of Zhiguli cars mainly prefer products of two. If problems arise with the factory mechanism, for example, when it overheats, many change it to the second option, explaining that Pekar pumps do not have a tendency to form a vapor lock, which causes defects in the operation of the device in hot weather. In fact, this opinion is wrong, since they also have this problem, as evidenced by numerous reviews from car owners. It is also worth considering that Pekar costs 1.5–2 more than DAAZ. Therefore, a standard fuel pump is the best choice based on criteria such as reliability, price and quality. The cost of a factory pump is 500–600 rubles.

Table: parameters of different fuel pumps

| Test results | "Baker" | DAAZ | QH | OTA |

| Zero supply pressure (at a crankshaft speed of 2 thousand rpm), kgf/cm² | 0,26 | 0,28 | 0,3 | 0,36 |

| Capacity for free drainage (at a crankshaft speed of 2 thousand rpm), l/h | 80 | 76 | 92 | 74 |

| Suction period at a crankshaft speed of 2 thousand rpm, s | 4 | 13 | 9 | 6 |

| Valve tightness at a pressure of 0.3 kgf/cm² (fuel leakage within 10 minutes), cm³ | 8 | 12 | 8 | 8 |

| Place | 3 | 4 | 1–2 | 1–2 |

QH petrol pumps are manufactured in the UK, while OTA petrol pumps are manufactured in Italy. However, these devices have some features: the QH pump does not have a lever for manual pumping of fuel, and the housing is non-separable. The Italian mechanism has excellent parameters compared to others, but its price is almost 3 times higher than Russian products.

Why is an electric pump better than a mechanical one?

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more". The efficiency of an electric pump is clearly visible on diesel cars, where diesel fuel is supplied under high pressure, and on gasoline cars with a direct injection system.

Fuel is injected directly into the cylinders of the power unit. And in this case, a conventional mechanical pump simply will not be able to provide the required level of pressure

The efficiency of an electric pump is clearly visible on diesel cars, where diesel fuel is supplied under high pressure, and on gasoline cars with a direct injection system. Fuel is injected directly into the cylinders of the power unit. And in this case, a conventional mechanical pump simply will not be able to provide the required level of pressure.

Direct injection injectors use two pumps. The electric one is installed in the fuel tank, from where it pumps gasoline, and the second pump is the injection pump. The latter’s task is to increase the pressure of gasoline before it is directly supplied to the injectors.

The electric pump is capable of pumping an average of 1-2 l/min. Crazy efficiency, which is only possible at a pressure of 3-4 atm. To equalize the operating pressure to the desired performance level, a special regulator is used in the fuel rail. It's called RDD.

Signs of a fuel pump malfunction

An experienced car enthusiast can determine the malfunction of his car by its behavior or by extraneous sounds. This also applies to the fuel pump. If knowledge is not enough, it is worth considering the following characteristic signs indicating problems with the fuel pump:

- the engine does not start;

- the engine stalls almost all the time;

- the power and dynamics of the car decreases.

However, it is worth considering that power may decrease for a number of other reasons: problems with piston rings, valves, etc. If the fuel pump is completely faulty, the engine will not be able to start.

The fuel pump does not pump

There may be several reasons why the device does not supply fuel. Before you start troubleshooting, you need to make sure that there is gasoline in the tank. It happens that the level sensor shows incorrectly and the problem simply comes down to a lack of fuel. You also need to make sure that the filter elements are not clogged, but it is better to replace them, because they are inexpensive. After these steps, you can begin diagnostics.

The causes of problems may be:

- wear due to long mileage;

- diaphragm damage;

- insufficient spring stiffness as a result of stretching;

- valve contamination;

- violation of the tightness of the unit.

If the gas pump on the “seven” does not supply fuel, then there are two ways out of this situation: install a new device or disassemble the old one, carry out diagnostics and replace damaged parts.

On my car, a situation once arose that indicated a lack of fuel for the engine: there was no normal dynamics, the engine periodically stalled and would not start. There was enough gasoline in the tank, the filters were in good condition, but the car did not drive. After lengthy investigations and clarification of the reasons for this phenomenon, the problem was found: the fuel supply hose from the pump to the carburetor was swollen inside, which indicated the poor quality of the product. The internal cross-section has become very small and insufficient to pass the required amount of fuel. After replacing the hose the problem disappeared. In addition, I change fuel filters at least every 5 thousand km. mileage (preferably more often). I have them before and after the fuel pump. As practice shows, even with the installation of two filters, as well as with a mesh in the fuel pump itself and at the carburetor inlet, debris still penetrates into the float chamber. This results in the carburetor having to be cleaned periodically.

Video: VAZ fuel pump does not pump

Stops pumping when hot

One of the problems of classic Zhiguli cars is overheating of the fuel pump, which leads to a disruption in its performance - it simply stops pumping. The problem is caused by the formation of a vapor lock, which blocks the supply of gasoline. There are several ways to solve the problem: water the cooling pump with water or ride with a wet rag on it. These methods are applicable in a critical situation, but not for everyday use. The problem can be eliminated by adjusting the fuel pump using gaskets, replacing the rod, replacing the unit itself, or using higher quality fuel.

Checking the fuel pump

If there are suspicions or characteristic signs of fuel pump problems, the mechanism should be checked. To do this, perform the following steps:

- Loosen the clamp of the hose that supplies gasoline to the carburetor, and then pull the hose off the fitting. Gasoline will leak out of the pipe, so it is better to lower its edge into an empty container.

Types of fuel pumps

Today there are various types of electric pumps, but the most common are:

- roller;

- gear;

- centrifugal;

Roller

The basis of such a pump is a rotor and rollers, which provide suction and fuel supply. The operation of the entire structure is based on increasing the volume of space between the rotor and the roller during operation. At such a moment of increase in volume, a difference in pressure is formed, fuel fills the resulting space. Further supply of fuel stops when this space is completely filled. The next step is to rotate the rotor and reduce the volume of space. This provides the required pressure, which causes the outlet opening to open, and the pumped dose of fuel enters the system.

Gear

Fuel suction in a gear pump is based on the movement of the internal gear relative to the external one. The internal gear is the rotor, while the second gear is external and is called the stator. The rotor rotates, and in its lateral teeth, when rotating, peculiar chambers are obtained. With their help, suction occurs and fuel is pumped.

The gear and roller pumps discussed above have such design features that they can only be placed in the fuel line. The most popular and widespread type of fuel pumps in modern cars are centrifugal pumps. They are characterized by low noise levels and provide the greatest uniformity of fuel supply.

Centrifugal

These pumps are located inside the fuel tank. The main element of this type of pump is an impeller with a large number of blades. Said impeller rotates inside the chamber. This chamber contains a suction and discharge valve. The rotation of the impeller blades results in fuel turbulence, which ensures its active suction, growth and maintenance of operating pressure in the fuel system.

Fuel pump drive

The VAZ 2107 fuel pump operates from a pusher (rod) and an eccentric located on the shaft of auxiliary devices (“piglet”, intermediate shaft), which is driven by the timing mechanism through a gear. Auxiliary devices include distributor, oil and fuel pumps.

Operating principle

The drive works as follows:

- the intermediate shaft rotates via a timing chain;

- the eccentric acts on the rod and pushes it;

- the rod presses the fuel pump lever, ensuring its operation.

Fuel pump drive malfunctions

As the fuel supply unit wears out, problems may occur that affect the performance of the latter.

Rod wear

The main sign of a worn-out rod is that the car does not reach the required speed. If the car accelerates, but, having gained speed to a certain value, does not develop it anymore, the reason is precisely the wear of the rod. Recently, the pusher has been made from such low-quality metal that it leads to wear out literally after 500–1000 km. The edge of the rod on the eccentric side is simply flattened, which indicates the need to replace the part.

The fuel pump rod should be 82.5 mm long.

Tips and tricks

It should be noted that before purchasing a gasoline pump, you must carefully study its characteristics in terms of performance and pressure, current consumption, etc. In some cases, a situation may arise when the device is not able to work normally with a particular carburetor.

The fact is that clogged filters increase the load on the pump, as a result of which the device may overheat or fail. As a rule, in case of problems with filters, first the pump’s performance drops, then the engine may begin to work unstably, power is lost and traction deteriorates. Ignoring these symptoms not only makes it difficult to operate the car, but also significantly reduces the service life of the electric fuel pump.

Mechanical and electric fuel pump, design and principle of operation of the device, types of pumps and main malfunctions, operating features

How to determine why the fuel pump does not pump or works poorly. Fuel rail pressure, pump diagnostics. Wiring, relays, fuel pump fuses.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

Why is it necessary to clean the fuel pump mesh? When is it better to change and how to clean the fuel pump mesh? How to properly remove the fuel pump, subtleties and nuances.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

Why does the fuel pump grid need to be changed? How to remove the fuel pump yourself to replace the filter. Features of reassembly after replacing the fuel pump mesh.

The fuel pump of classic Zhiguli cars is one of the weak points of these cars. The mechanism causes a lot of problems for car owners, which is especially evident in hot weather. If problems arise with the fuel pump, you need to know both the reasons for their occurrence and how to fix them.

Fuel pump repair

To replace or repair the pump, it will need to be removed from the engine. Tools you will need:

- 13 mm wrench;

- crosshead screwdriver.

Removing the fuel pump

We dismantle the unit in the following order:

- Wipe the pump with a rag.

- Disconnect both hoses (inlet and outlet) by loosening the clamps with a screwdriver.

- We pull the hoses from the fittings.

If you need to replace the rod, then simply remove it from the heat-insulating spacer and replace it with a new one.

Once a situation arose on my car when engine oil was leaking from the installation site of the fuel pump (in the area of the gaskets). It was not immediately possible to identify the cause. At first I made mistakes on the gaskets between the engine block and the spacer, as well as between it and the fuel pump. I replaced them, but did not achieve a positive result. After dismantling the mechanism again, I examined all the elements more carefully and discovered that the heat-insulating spacer had a crack through which oil was leaking. I had to replace it, after which the problem disappeared. In addition to the described case, there was a similar situation when oil was leaking at the location of the fuel pump. This time the pump itself turned out to be the culprit: oil was oozing from under the axis of the manual fuel pumping lever. There were two options to get out of the situation: accept it or buy a new product. I bought and installed a new pump (DAAZ), which to this day works properly and does not leak.

Disassembly

To disassemble the fuel pump you need to prepare:

- 8 and 10 mm wrench;

- Phillips screwdriver.

The disassembly procedure is as follows:

- Unscrew the bolt holding the top cover.

During assembly, the strainer must be installed so that its hole is above the valve.

Replacing valves

The VAZ 2107 fuel pump valves are included in the repair kit. To replace them, you will need a needle file and suitable attachments for dismantling.

The disassembly sequence is as follows:

- We remove the cores using a needle file.

Installing and adjusting the fuel pump

Installation of the fuel pump on the “seven” is carried out in the reverse order of removal. The process itself does not cause any difficulties. However, attention should be paid to the gaskets, since their thickness has a direct impact on the operation of the mechanism.

Adjustment of the position of the unit must be carried out if, after its removal, the gaskets were replaced or the old seals were strongly pressed in.

The fuel pump is sealed with several gaskets:

- adjustable (thickness 0.7–0.8 mm or 1.1–1.3 mm);

- thermal insulation;

- sealing (0.27–0.33 mm).

The adjusting and sealing gaskets differ only in thickness. There must always be a sealing gasket between the engine block and the heat-insulating element.

The fuel pump is adjusted as follows:

- Install the sealing gasket.

Video: how to adjust the fuel pump on a “classic”

Disassembling the pump housing

To carry out all the work on disassembling the mechanism, you will need a pair of screwdrivers, a small hammer, a needle file, and a scraper. The disassembly looks like this:

- Unscrew all the bolts that secure the housing halves.

- Remove the diaphragms by pressing them and turning them 90 degrees.

- Carefully remove the diaphragms and remove the spring.

If you want to experiment, try removing two valves and installing new ones in their place, which are included in the repair kit. Please note that if there is even minor damage or cracks on the housing, the entire assembly must be replaced. Don't even try to restore it. Repairing the fuel pump in this case is not cost-effective.

Electric fuel pump for VAZ 2107

Increasingly, owners of “classics”, including the VAZ 2107, are installing modern devices on their cars. So, the mechanical fuel pump is replaced with an electric one. The main goal of introducing an electric fuel pump is to get rid of the problems that arise with standard pumps. However, you need to understand that if on injection “sevens” such a mechanism is installed directly in the gas tank, then on carburetor cars it is placed under the hood.

Which one can be installed

As an electric fuel pump, you can install any device designed to work on fuel-injected cars on the “classic”. Based on reviews from Zhiguli car owners, Chinese-made pumps, as well as Magneti Marelli and Bosch, are often used. It is important to know that the product must provide low pressure . A standard mechanical pump produces about 0.05 atm. If the indicator is higher, then the needle valve in the carburetor will simply let fuel through, which will lead to it leaking out.

Installation of an electric fuel pump

To install an electric fuel supply pump on a carburetor “seven”, you will need a certain list of materials:

- tee 8x6x8 mm;

- fuel line for VAZ 2107;

- check valve from the "eight";

- 8 mm threaded fitting;

- clamps, blocks from Kalina for a four-pin relay (3 pcs.) with a fuse holder;

- the four-pin relay itself (3 pcs.);

- fuel jet (150);

- fuel return hose from the V8;

- wires;

- non-latching button.

We carry out the work in the following sequence:

- We lay the fuel pipe (return) parallel to the standard fuel line, securing it in the factory locations.

Video: installing an electric fuel pump on a VAZ 2107

Once the installation of the mechanism is complete, it will function according to the following algorithm:

- after turning on the ignition and pressing the pumping button, the pump is activated and pumps up gasoline;

- when the starter starts, the fuel pump turns on;

- while the engine is running, the pump is powered by a generator;

- after the engine stops, the operation of the unit stops.

Installation benefits

Owners of Zhiguli cars who have installed an electric fuel pump on their cars note the following advantages:

- an engine with such a device operates more stable at idle speed;

- when accelerating sharply, the car responds well to the pedal, there are no dips, which is not the case with a mechanical pump;

- when switching gears there is a smooth ride, and when the gas is abruptly released there is no twitching;

- at high speeds the engine spins better;

- there are no jerks at low speeds when starting the car after a long trip.

The VAZ 2107 fuel pump sometimes has to be repaired or replaced. Doing this is not as difficult as it might first seem. Repair and adjustment work is carried out with a minimum set of tools in accordance with step-by-step instructions.

Source of the article: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/benzonasos-vaz-2107-karbyurator.html

Electric fuel pump filter.

It is important to note that the electric fuel pump is the “heart” of the fuel system of all modern cars. Since not all motorists have injectors, this unit has also become available for carburetors. The design of an electric fuel pump has many seemingly unnecessary elements and parts, the absence of which would in no way affect the operation of the entire device. However, this is not the case. The absence or improper operation of one small part can lead to the collapse of the entire system.

Thus, the main component of this device is the filter, which is fully responsible for the successful operation of the entire device. The presence of even minor mechanical impurities will lead to clogging of the fuel pump inlet filter. The safest nuisance will be the usual increase in the noise of the device. However, if this malfunction is not eliminated, the clogged filter will lead to the fuel pump operating at the limit, with increased loads to the maximum, which will first lead to overheating of the device, and then to a total breakdown of the entire unit. It is important to note that if the electric fuel pump overheats, the engine power may decrease, fuel consumption may increase, and the device itself may burn out, as a result of which this will cost the motorist quite a penny, since the gas pump is an integral part of the car’s fuel system.