The injectors of injection engines are very sensitive to the presence of foreign impurities and contaminants in the fuel.

These parts clog much more easily than jets on carburetor engines, and cleaning or replacing injectors is much more complex and costly than repairing a carburetor. The fuel filter for the VAZ 2107 (injector) cleans the fuel from impurities that can harm the injection system. It should be replaced after at least 30 thousand km. car mileage, and taking into account the poor quality of fuel at gas stations in the country, much earlier.

When is it obvious that the fuel filter needs to be replaced?

The filtration system provides two levels of purification: coarse, removing all large particles, and fine. Fine filters are installed between the engine and the fuel tank. Experts advise replacing filters every 60 thousand kilometers. After all, their clogging leads to very serious consequences, for example, there is an additional load on the gas pump, and it can fail much faster. Clogging also causes the engine to not operate properly because fuel is not supplied to the system as it should.

Thus, the car starts to stall, stalls, and sometimes may not start at all; incorrect gear shifting also occurs (in the case of an automatic transmission, i.e., the automatic stops correctly interpreting engine commands to shift and carries them out at the wrong time or does not respond at all). But, in order not to bring the situation to such a critical moment, you can check whether the fuel filter needs to be replaced. At low speed, sharply press the gas pedal; if the car does not accelerate or there are jerks, it means that the filter needs to be replaced.

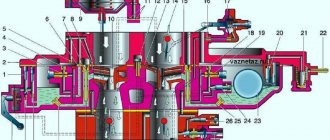

Cleaning the carburetor fuel strainer Ozone 2105, 2107

On Ozone 2105, 2107, the fuel filter is installed at the inlet to the carburetor.

If it becomes contaminated with deposits coming from the fuel tank along the fuel line, gasoline stops flowing into the carburetor float chamber in sufficient quantities. This leads to a lean fuel mixture and, as a result, disruption of the carburetor and, accordingly, the car engine. Unstable idling, dips and jerks appear when you press the gas pedal, the power and throttle response of the engine decreases. To avoid these malfunctions, or eliminate them if they already exist, you should first clean the fuel strainer at the inlet to the Ozone carburetor. This work can be done without removing the carburetor from the car engine.

Required Tools

— Key 17 for unscrewing the filter plug

— Toothbrush or brush with hard bristles, acetone (for cleaning)

— Pump for filter purge

Preparatory work

— Remove the engine air filter housing

— Clean the outer surface of the carburetor from dirt

Procedure for cleaning the carburetor fuel strainer Ozone

Unscrew the carburetor fuel filter plug

We use the key to “17”.

Unscrew the filter plug with a key to “17”, counterclockwise

Removing the mesh filter

We remove the plug; under it, in the mounting hole, a fuel filter is installed.

We remove the mesh fuel filter from the mounting hole in the “cover” of the Ozone carburetor

Clean it with a brush soaked in acetone.

The filter may look clean in appearance, but its mesh probably contains deposits that can only be removed with a brush.

Blow with compressed air

We use a pump (can be a car pump) or a compressor.

Replacing air, oil and fuel filters on VAZ 2101-2107

Filters in VAZ cars must be replaced periodically, depending on the mileage. The air filter should be changed every 10-15 thousand km, depending on the conditions in which the car is operated, the oil filter, along with an oil change, which needs to be done every 10 thousand km, the fuel filter should be changed every 30 thousand km or as it becomes dirty has a transparent body and the level of contamination of the filter element is clearly visible.

Replacing the air filter VAZ 2101-2107.

To replace the VAZ air filter, the first step is to unscrew the three bolts that hold the upper part of the air filter housing. Then we remove it and take out the old air filter. We close the air intake hole with a regular rag or rag, and then thoroughly clean the casing of dust and dirt. We install the new filter in place, removing the protective film or paper from it, close the casing and fasten it with bolts.

Replacing the oil filter VAZ 2101-2107.

The VAZ oil filter must be replaced at the same time as the oil change, at a time when the old oil has already been drained from the engine and new oil has not yet been added. Unscrewing it with bare hands is not always easy; this may require a special key or puller. After the filter is removed, wipe the landing pipe with a dry, clean cloth. Before installing a new filter, you need to moisten the rubber o-ring with oil and pour a little inside (enough so that it does not leak out during installation). Then screw the filter onto the seat and tighten it by hand. After replacing the filter, you need to start the car and let it run for 2-3 minutes to flush out the oil.

Replacing the fuel filter VAZ 2101-2107.

Before replacing the VAZ fuel filter, for safety reasons, it is necessary to remove the negative terminal from the battery. The filter is directional and is attached using clamps to the fuel line hoses. Before removing the old filter, it is best to clamp the hoses with any available means so that any remaining gasoline does not leak out. After the hoses are clamped, you need to unscrew the clamps and remove the old fuel filter. If the clamps are new, there is no point in changing them, but if they are already worn out, then replacement is required. We put the hoses on the new fuel filter and secure them with clamps.

It should be noted that when buying a car second-hand, it is necessary to change not only the oil, but also all the filters. In addition, any clogged filter has a bad effect on engine operation, reducing its service life and reducing key performance.

Video of replacing the air and fuel filter of a VAZ 2107

An air filter, as the name suggests, is used to clean the air. The filter purifies the air that is needed to prepare the fuel-air mixture, which is supplied to the combustion chamber. In addition to its benefits, the filter also creates additional resistance. Due to this, excessive fuel consumption and a decrease in power will occur. But if the filter is not of good quality, then it will allow combustion products, sand grains and dust particles to enter the chamber. They, like a fine abrasive, will act on the surface of the combustion chamber and increase wear on rubbing parts.

Therefore, it is important that the filter is reliable; it must have a density that is necessary for good air filtration and will not affect the dynamic performance of the engine.

It is advisable to replace the air filter for the VAZ 2107 after 30 thousand kilometers. But it is advisable to check its condition from time to time, in case you need to replace the air filter ahead of time. The process of replacing the air filter for the VAZ 2107 is not a complicated procedure, and even a novice in the automotive business can cope with it. To replace the air filter you need to have: a new air filter, a vacuum cleaner and a Phillips screwdriver. The whole process will take about 20 minutes.

Signs of a clogged filter device

The filter has special filter paper, the cells of which become clogged over the course of vehicle operation. Because of this, fuel flows worse, which causes problems with the engine itself. You can detect that the filter is clogged by several obvious signs.

- Fuel consumption has increased sharply;

- Your car begins to stall frequently at idle;

- At higher speeds, failures in engine operation are observed;

- Starting the engine is carried out with certain difficulties;

- The engine falters and the power drops noticeably;

- When driving, the car brakes spontaneously, although you did not press the brake pedal;

- The car rarely jerks when going uphill.

As you can see, there are many signs, and they differ from each other in many ways. These signs do not indicate 100% that the problem lies with the filter. Similar phenomena occur when there is a malfunction of the electronic control unit, sensors, throttle valve, spark plugs, detonation, and so on.

How to check that the problem is in the filter? Easily.

- Connect a nanometer to the nipple on the fuel frame of the injectors;

- Start the engine;

- Measure the pressure;

- If the indicators are lower than those indicated in the technical documentation of the VAZ 2114, it means that the cleaner is really clogged.

Measuring pressure in the fuel rail of a VAZ 2114

Operation and repair of the device

The carburetor serves to form a combustible mixture by combining injected fuel and air, in order to ensure the operation of the internal combustion engine. In this case, the correct proportions must be observed to ensure normal combustion. If the proportions are not observed, an over-enriched mixture is formed due to an excess amount of fuel or lack of air, which leads to breakdowns.

In addition, you need to adjust the gaps on the gas distribution mechanisms and open the air damper

Special attention should be paid to the correct setting of the ignition timing. When adjusting carburetor 2105, first of all, set the crankshaft rotation frequency to 700-800.

When installing a carburetor on a classic VAZ 21053, you should remember that, unlike the VAZ 2105, 21053 20 has a somewhat poor second chamber. This is explained by the fact that the first has a fairly rich adjustment. It can be made poorer by installing 102-150 jets, but then there will be a need to enrich the second chamber by installing 115-135 jets.

The effectiveness of this method lies in the fact that when a compressor is installed, the charge of the fuel-air mixture increases. The mixture enters the cylinder due to increased air supply to the fuel system. The compressor has not only advantages, but also disadvantages, one of which is increased fuel consumption.

The compressor consists of a pulley, a drive gear, a rotor driven gear and an internal oil gear. All installation work should be carried out with the engine cool. After installation, the compressor should have minimal resistance to air movement. Typically, an installation kit is used for this, which includes all the necessary parts. A mechanical supercharger (compressor) plays an important role in the process of improving the quality of a car.

How to check the performance of the fuel pump without removing it?

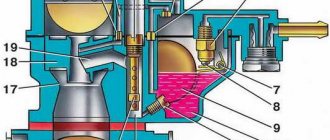

First of all, you need to carefully inspect the fuel pump. Particular attention should be paid to the fit of the cover 4 to the body 3. The skew of the cover, its weak tightening, and an incorrectly installed nylon mesh filter 2, which also serves as a sealing gasket, contribute to the leakage of gasoline in the connector of the cover and the body or in the mating of the cover and the bolt 5 of its fastening.

Fuel may also leak through the outer spacer 1. This occurs when the working diaphragms 8 are damaged. If the screws 7 securing the housing to the bottom cover are loosened, air may leak into the vacuum cavity, and therefore the fuel pump will work intermittently, supplying fuel to the mixture with air.

If you find traces of oil leakage, check first of all that the fuel pump is securely attached to the cylinder block, and then determine the condition of the sealing heat-insulating gaskets. The fact is that oil often leaks in these places when the seal is broken.

Without removing the fuel pump, you can check its functionality. To do this, simply disconnect the fuel line coming from the carburetor and, using the manual pumping lever, check the strength of the fuel supply. Remember that manual pumping is impossible if pusher 1 (Fig. below) is at the top of eccentric 2, and the diaphragm rod is correspondingly in its lowest position.

Fuel pump pusher position

In this case, you need to use the starting handle to turn the engine crankshaft just one revolution. This will allow the eccentric and the rod to take a position in which the manual fuel pumping mechanism will be operational.

A working fuel pump delivers gasoline in a full pulsating stream without noticeable air. To be more confident, you can check the operation of the fuel pump using a mechanical drive by turning the engine crankshaft with the starter. At the same time, you should not be embarrassed by the fact that a stream of gasoline will not appear from the first revolutions.

If you suspect a malfunction of the internal elements of the fuel pump, it is, of course, necessary to remove it, disassemble it and eliminate the defects.

Recommendations for selection

Service station foremen and managers of official representative offices advise purchasing consumables with original catalog numbers.

The high price of a product is not affordable for everyone, so car owners are forced to look for cheap analogues, but not always of high quality.

Check the packaging for integrity and the presence of holograms. Ask distributors to provide quality certificates for their products. Otherwise, avoid questionable purchases.

Conclusion

The design of the fuel system is quite complex, not every master can handle it, let alone an inexperienced driver. However, elements such as a filter or mesh can be replaced independently, without resorting to outside help. If you follow the recommendations, dismantling will take 10 - 15 minutes. If you doubt your abilities, or don’t have enough free time, contact the service station masters.

Zero resistance filter care

As already mentioned, the zero-resistance filter requires maintenance. The filter needs to be removed and washed; this procedure should be performed approximately once every 5,000 km, and if you drive in a particularly dusty area, then this should be done even more often. So, the procedure for caring for a zero resistance filter:

- remove the zero from the car and remove all the dust from it with a soft brush;

- Now we proceed to impregnate the filter with a special agent, usually it is purchased separately from the filter;

- then carefully wash the filter in a container of water and then rinse it under a weak stream of water;

- shake off the water from the filter and leave it to dry (you cannot dry the nulevik with a hairdryer or any other heating devices);

- After the filter has dried, inspect it; if there are light spots, the filter must be soaked with a special agent again;

- install a zero resistance filter on the car.

Replacing the air filter:

As the name suggests, the VAZ 2107 air filter (injector) is designed to clean the air supplied to the combustion chamber from dust. A clogged filter creates additional resistance to passing air. As a result, the composition of the air-fuel mixture changes, fuel consumption increases and engine power decreases. If the filter is damaged, it will allow dust particles and grains of sand to pass through, which, when entering the engine, will begin to act as an abrasive, increasing wear on the rings and cylinder surface. Therefore, the filter must have the proper density, which will not allow dust to enter the engine, but will not create unnecessary resistance to air flow.

According to the instructions, the VAZ 2107 air filter needs to be changed after 30 thousand kilometers. But its service life may be shorter due to operation in very dusty conditions or due to poor filter quality. It is advisable to periodically check its condition and change it if necessary. The replacement procedure is very simple and does not require special knowledge and experience. You only need a minimum of tools and 20 minutes of time.

Video “State of the fuel purifier after a run of 70,000 kilometers”

This video shows how dirty the fuel cleaning element of a VAZ car is after driving seventy thousand kilometers. The filter material has completely deteriorated and is no longer able to fulfill its duties.

Cleaning the fuel is necessary for the normal operation of a car engine and increasing its service life. The engine must receive fuel purified from various impurities and contaminants. For this purpose, it is customary to install fuel filters. How to work with them on VAZ 2109 and 99, 2114 and 2115 will be discussed below.

Instructions for replacing the fuel filter on a VAZ 2107 with video and photos

https://youtube.com/watch?v=pZqCQjmnpKw

1. Relieve pressure;

2. Open the hood;

3. Disconnect the battery;

4. Unscrew the fuel pipe fitting, while holding the old filter itself with a wrench. In order to protect against the leakage of a small amount of gasoline, you can lay down an old rag or rags;

5. Disconnect the running pipes from the filter;

6. Unscrew the fuel filter mount using wrench 10 - the filter is secured with a coupling bolt;

6. Remove the old filter;

7. Install a new fuel filter, making sure that the arrow drawn on the body points to the fuel rail;

8. Replace the sealing rings between the tubes and the fuel filter with new ones;

9. Carry out assembly work in reverse order;

Start the engine and make sure there are no gasoline leaks. All work is not difficult even for a person who does not have special knowledge in auto mechanics.

Also watch the video on replacing the fuel filter on a VAZ 2107:

I didn’t think that there might be problems with replacing the fuel filter on a VAZ 2101-2107... It’s a matter of a couple of minutes.

First of all, you should purchase a gasoline (fuel) filter for the VAZ 2101-2107 (with a carburetor engine). You can find two types of them on sale - horizontal (2) and vertical with a sump (1). Look at the photos below.

After purchasing the filter, you can proceed to replacement. The fuel filter on Zhiguli is located in the engine compartment. Installed on the fuel hose, usually in front of the fuel pump.

Take a Phillips screwdriver and loosen the clamps. We take out the gasoline filter and install a new one in its place.

Please note that each filter has an arrow, which, when installing the filter, should point to the fuel pump (the direction of fuel movement in the system). Tighten the clamps.

All that remains is to start the car engine and check the filter itself and the fuel hoses for gasoline leaks. Insurance in case of a defective gasoline filter or loose hose clamps.

The replacement of the gasoline (fuel) filter on the Classic (as the Zhiguli is also called) is complete. As you can see, there are no problems and this activity takes 2-3 minutes))).

The fuel filter was completely clogged, as you can see it simply had no chance to “live” longer.

Determining the causes of fuel pump failure

To determine the cause of a fuel pump failure, you can use several operations related to checking its functionality without removing it from the car.

The fuel pump does not supply fuel to the vehicle systems:

- We check the presence of fuel in the gas tank. It is recommended to operate the car with at least half a tank and with the obligatory use of the entire set of filters that reduce the impact of small particles on fuel pump parts.

- We check the performance of the fuel filters and, if necessary, replace them with new ones.

- We blow out and clean the pipeline system, removing deposits of small particles.

Check fuel filters

The main reasons for fuel pump failure may be:

- Damage to the diaphragm with leaks.

- Loss of spring stiffness and performance.

- Valves clogged due to dirt accumulation.

- Loss of filter capacity due to the accumulation of contaminants.

- Violation of the tightness of the pump circuit with leakage of gasoline and oil.

- Failure to operate due to exhaustion of the pump components.

You can see how the DAAZ fuel pump works in the following diagram:

Dismantling and disassembling the fuel pump module Lada Vesta

The work is unpleasant because of what will happen inside the cabin, since the pump assembly can only be obtained in this way. A similar solution can be observed on other new AvtoVAZ models, for example, on the Lada Priora; dismantling the fuel module is similar there. Of course, the solution is somewhat strange, and many will find it impractical, but this arrangement of the fuel pump can be seen in most modern foreign cars.

- The first step is to provide access to the location of the fuel module. To do this, we dismantle the rear sofa cushion. This is done as follows: the front part is pulled out from the latches, and the rear part is removed from the hooks.

- Next, you need to remove the cover (just turn it) and clean the workplace from dust and sand. We take a vacuum cleaner and vacuum up dust and sand so that nothing gets into the fuel tank during dismantling.

The next step is mandatory! You need to relieve the pressure in the fuel system so that when you disconnect the fuel lines from the pump, you do not flood the entire cabin with gasoline.

This is very important, so I do not advise you to neglect this point. There are two ways to relieve pressure in the fuel line

- First: remove the fuel pump fuse, then start the engine and wait until it stalls.

- Second: Turn off the power to the fuel pump, then start the engine, etc.

Decide for yourself which option suits you best...

- Now that the pressure has been released and everything is ready to begin dismantling, it is necessary to take care of fire safety. Make sure there are no open sources of fire near you, remove anything that could lead to a fire. Remember that gasoline vapors ignite very quickly even from a small spark. I also recommend removing the negative terminal from the battery, “just in case,” as they say.

- Disconnect the fuel hoses. We press the latches and move them aside.

- Using a wooden adapter and a hammer, remove the retaining ring by striking counterclockwise. Sometimes you can remove it without any problems, but in most cases everyone complains that it is difficult to remove.

Next you can get the fuel pump module assembly

We remove it carefully, do not forget about the float, which complicates the entire extraction process

Disassembling the fuel pump module (cleaning, replacing, etc.)

- We do disassembly. To do this, disconnect the lower part of the module along with the coarse fuel filter. Depending on the degree of contamination, the mesh should either be washed (solvent or Carb) or replaced.

- We also disconnect the fuel pressure regulator wire

- Following this, we take out the spring filter along with the fuel pressure regulator.

- We disconnect the intake hose, hold the clamps and take out the fine filter along with the fuel pump. Almost everyone has problems with the hose, since when trying to remove it, it is often damaged. Putting this hose on is also a problem; to do this you will have to heat it with a hairdryer, but under no circumstances with an open fire!!! I recommend buying a spare hose just in case.

- Now you can remove the pump from the filter housing, do not forget to turn off the power to the pump.

Further work depends on the reason for disassembly. If you need to replace the Vesta fine filter, we do it without any problems. As it turns out, it is possible! Replacing the Lada Vesta fuel pump is also possible, both with and without filters. But I would strongly recommend that when replacing the pump, you also immediately change the fine filter. As for the mesh, in most cases it is enough to simply wash it.

That's all I have, thanks for your attention. Write in the comments whether you succeeded and what difficulties you encountered during work

Bye everyone, take care of yourselves!

Photo sources: , , 3

Safety precautions during replacement

- Smoking is strictly prohibited when working on the fuel system.

- There should be a fire extinguisher nearby.

- Be careful not to get fuel in your eyes.

- The room in which work takes place must be ventilated.

- Do not replace if it is too hot outside.

- Proceed with replacement only when the engine has completely cooled down.

As you can see, replacing a fuel filter is a fairly simple process that does not require special skills, and even an inexperienced driver can handle it after carefully studying the instructions.

Carburetor calibration data

The main dosing systems include the diameter of the mixing chamber: the size of the first chamber is 28 mm, and the second is 32 mm, the diameter of the narrow part of the large diffuser with the size of the first chamber is 21 mm and the second is 25. This also includes the marking of the small diffuser with the corresponding chamber size 3 .5 and 4.5 mm, the diameter of the main fuel jet of the GDS with chamber sizes of 1.07 and 1.62 mm.

The acceleration pump has a diametral nozzle opening of 0.4 mm and a capacity with 10 presses equal to 7 ± 1.75 cm3. Econostats have fuel jets with a diameter of 1.5 mm, air jets with a diameter of 1.2 mm, and emulsion jets with a diameter of 1.5 mm. Characteristics of the pneumatic drive of the second chamber.

Carburetor 2105-1107010 has a remote pneumatic valve, but 2105-1107010-20 does not. In addition, carburetors 2105-1107010 and 2105-1107010-20 have a vacuum tap to the vacuum ignition timing regulator. Carburetor 21053 has slightly different parameters.

Relieving pressure in the fuel system

Before any operations concerning the fuel system, it is necessary to relieve the pressure in the fuel line. To do this, put the vehicle on the handbrake and turn on neutral; remove or move back the rear seat; open the hatch located under the seat on the bottom of the car; turn off the power to the fuel line by disconnecting the connector. Next, we start the engine and wait a while until all the gasoline in the engine is used up and it stalls. After this, we try to start the car again to make sure that the fuel pressure has disappeared.

There is a second way to release fuel pressure. To do this, you need to remove the negative cable from the battery and remove fuse F3 in the mounting block, which is responsible for powering the fuel pump. Next, we also bleed off all the fuel in the engine by starting it. After releasing the pressure, install the fuse in its original place.

Adjusting the carburetor VAZ 2105

During operation, all DAAZ carburetors will need adjustment. Some drivers adjust the device when the seasons change, some when certain defects appear.

In any case, adjusting the VAZ 2105 carburetor is a process that will optimize engine performance and extend its life. In addition, even a standard carburetor setting significantly improves the basic performance indicators of the engine: for example, it increases speed data and reduces fuel consumption.

It is recommended to adjust the carburetor setting at a car service center. Carrying out the procedure independently is only recommended for those car enthusiasts who are well versed in car systems.

For high-quality, full adjustment you will need:

- Prepare your workplace. To adjust the device’s systems, it will need to be removed from the machine, washed, blown out and installed in a flat and clean place.

- Prepare the tool. In the case of the VAZ 2105, this is a set of wrenches, a Phillips and flat-head screwdriver. A rag will also be a good idea, as fuel leaks are possible.

- Find a service book for the VAZ 2105. In this manual, the manufacturer indicated all the operating parameters of a particular model; it is these parameters that will need to be checked during the work process.

Main adjustment steps

Once the carburetor has been fully prepared for operation, you can begin adjusting it:

- First of all, specialists usually adjust the amount by turning the crankshaft. The optimal number is between 750 and 800 rpm. To set this parameter, you will need to tighten the adjusting screw all the way, and then carefully open it three turns back.

- Next, you will need to adjust the volume of CO2 gas in the vehicle exhaust. To do this, you need to tighten the quality screw all the way and unscrew it back 4 or 5 turns.

- The idle speed is adjusted using the idle speed screw. To do this, you need to slightly tighten the screw in the opposite direction from the carburetor.

- The float in the float chamber must be strictly in the center, so to achieve the desired value, you can lightly press the latches.

Photo gallery: do-it-yourself adjustment

It is recommended to dismantle the device on a cold engine to avoid injury.

The quality screw adjusts the amount of exhaust

It is only important to tighten this screw slightly, otherwise the engine will not start.

Particular care must be taken when handling float chamber components.

Cleaning the jets

Car owners have many questions about cleaning jets. Does it make sense to clean these devices or is it better to immediately replace them with new ones? In fact, it all depends on the driver’s financial condition - of course, it’s faster and easier to remove the old jets and install new ones in their place.

However, if the holes in the tubes are not blown apart, you can simply wash the nozzles in acetone or a special liquid, then blow them out with compressed air from a can and install them back. They will work exactly as long as new ones.

The jets must have no signs of wear on the body or broken holes.

Table: numbers and sizes of VAZ 2105 jets

| Options | First camera | Second camera | ||

| Type | K-151 | K-151D | K-151 | K-151 |

| Main fuel jet, cm 3 /min | 220±3,0 | 220+3,0 | 380±5,0 | 380±5,0 |

| Main air jet, cm 3 /min | 330±4,5 | 330±4,5 | 330±4,5 | 330±4,5 |

| Idle jet block, cm 3/min: | ||||

| idle tube | 95±1,5 | 95±1,5 | ─ | ─ |

| emulsion tube | 85±1,5 | 85±1,5 | ─ | ─ |

| Idle air jet | 330±4,5 | 330±4,5 | ─ | ─ |

| Idling emulsion jet | 280±3,5 | 280±3,5 | ─ | ─ |

| Transition system fuel jet, cm 3 /min | ─ | ─ | 150+2,0 | 150+2,0 |

| Air jet of transition system, cm 3 /min | ─ | ─ | 270±3,5 | 270±3,5 |

| Diameter of the accelerator pump nozzle hole, mm | 0,4 +0,03 | 0,4 +0,03 | ─ | 0,4 +0,03 |

| Diameter of the hole in the econostat screw, mm | 1,1 +0,06 | 1,1 +0,06 | ─ | 2 +0,06 |

| Diameter of the fuel bypass hole into the tank, mm | 1,1 +0,06 | 1,1 +0,06 | ─ | ─ |

| Fuel valve seat diameter, mm | 2,2 +0,06 | 2,2 +0,06 | ─ | ─ |

| Diffuser diameters, mm: | ||||

| small | 10,5 +0,1 | 10,5 +0,1 | 10,5 +0,11 | 10,5 +0,11 |

| large | 23 +0,045 | 23 +0,045 | 26 +0,045 | 26 +0,045 |

| The mass of the float assembly is no more than 12.5 g. | ||||