Types of carburetors

The technology for flushing and adjustment after repair depends on the design. Therefore, the first thing you need to do is determine which model of device is installed on your car.

Throughout the history of the existence and production of the VAZ 2106 and VAZ 2107, 3 types of carburetors were used:

Good to know: Regardless of the model, the carburetors used on the VAZ 2106 are two-chamber and consist of 3 main parts: the device cover (protects the fuel fittings from dirt), the housing (it contains chambers, diffusers, from which the mixture is transferred to the engine), lower part (the float chamber and throttle valves are located).

It is the small parts of the carburetor that play a very important role. Thanks to them, fuel enters the cylinders in certain proportions and is correctly mixed with air to form a high-quality fuel mixture.

But during operation, due to contamination with small particles or dirt, especially with regard to the accelerator pump and jets, the operating modes of the carburetor are disrupted, which leads to malfunctions and failures when pressing the gas or “sneezing” of the carburetor. Flushing consists of removing dirt from all channels and jets, thereby ensuring their stable operation.

Which carburetor model to choose

For any VAZ car, starting from 2101 to 2107, only certain carburetor models are suitable

DAAZ carburetors

Carburetors DAAZ 2101, 2103, 2106. They were produced at the Dmitrov Automotive Unit Plant, which bought a license from the Italian company Weber, therefore these carburetors can be indicated under both names. The devices were not distinguished by the complexity of their design, but they could please their owners with the rapid acceleration of the car and good speed. One of the biggest problems in installing these models is their virtual absence on the market.

In addition to speed and simplicity, Weber carburetors also provided incredibly fast fuel consumption - these “monsters” consumed 10–14 liters per 100 km. fuel.

The powerful but resource-intensive Weber carburetor was produced by the Russian Dmitrov plant using Italian technology

Carburetors "Ozone"

More technologically advanced models, which were already installed in VAZ 2105 and 2107 cars, were also produced at the Dmitrov Automobile Unit Plant. However, they were not only more advanced and improved, but also more environmentally friendly. This is why they received the name “Ozone”. This carburetor made it possible to reduce fuel consumption to 7–10 liters. 100 km, while maintaining the dynamic characteristics of its predecessors. The downside of the device was the complexity of its assembly and constant contamination in one of the chambers, which led to the fact that the acceleration of the car noticeably deteriorated, the speed decreased and the engine began to act up.

“Ozone” is an environmentally friendly model of DAAZ carburetors

Solex

A little later, DAAZ 21053 carburetors appeared. They were produced under license from the French company Solex, hence the name of the models. These carburetors were not much similar to previous DAAZ models. The updated design with a fuel return system made it possible to save 400–500 ml of fuel per 100 km. These carburetors were distinguished by good power and low gasoline consumption. The disadvantage of the device was the narrow fuel and air channels, which very often became clogged.

The Solex carburetor successfully combines the power and environmental friendliness of its predecessors

Solex carburetors came in many variations with different auxiliary systems. In the CIS, the most popular option has become an electric idle air valve.

Custom carburetor Solex 21073

Often, inquisitive car enthusiasts resorted to replacing the carburetor on their own. One of the suitable models turned out to be Solex 21073, famous for its fairly wide jets and channels. Such a carburetor increased the car’s power, but at the same time increased fuel consumption - 9–12 liters. per 100 km.

Solex 21083

The second non-standard carburetor, which with some modifications fits the VAZ 2106 and 2107 models, is Solex 21083. After expanding the diffusers and installing jets, this device allows you to significantly increase the dynamics of the car without much fuel consumption. However, the process of upgrading a carburetor is very complex and time-consuming.

How is a carburetor repaired and flushed?

Many problems can be eliminated by flushing the carburetor, but for it to be effective, the unit must be removed from the car. After which you will need to disassemble it to the required level so that you can gain access to absolutely all elements of the mechanism.

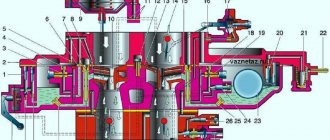

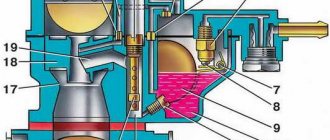

Parts of the carburetor body 2107-1107010 in the diagram: 1 - rod of the pneumatic drive of the second throttle valve; 2 — pneumatic drive housing; 3 - diaphragm; 4 — pneumatic drive cover; 5 — fuel jet of the transition system of the second chamber; 6 — fuel nozzle body; 7 — small diffuser of the second chamber; 8 — accelerator pump nozzle; 9 — screw valve of the accelerator pump; 10 — main air jet of the second chamber; 11 — emulsion tube of the second chamber; 12 — main air jet of the first chamber; 13 — emulsion tube of the first chamber; 14 — main fuel jet of the second chamber; 15 — main fuel jet of the first chamber; 16 — accelerator pump adjusting screw; 17 — fuel jet of the idle system; 18 — fuel nozzle body; 19 — return spring of the accelerator pump; 20 — accelerator pump diaphragm; 21 — accelerator pump cover; 22 — small diffuser of the first chamber; 23 — lever return spring; 24 — three-arm air damper control lever; 25 — connection rod with the throttle valve; 26 — throttle valve return spring bracket

Repair consists of the following steps:

- Dismantling the device.

- Flushing, which includes cleaning and purging of carbon deposits and adhering dirt.

- Replacement of faulty parts.

Important: You need to remove the carburetor if you are 100% sure that the problem is in the carburetor, because the problem in other components of the car’s fuel system is also possible.

Where does carburetor repair on a VAZ 2106 car begin?

Do-it-yourself repair of a VAZ 2106 carburetor begins with its removal. To do this, you will need to remove the air filter, which will still have to be replaced with a new one, and dismantle its housing.

It is recommended to first seal the openings in the chambers with rags to prevent small objects from getting into them. After this, the hose going to the brake vacuum is removed from the pneumatic valve, the choke installation cable is unscrewed and the rod is removed from the gas pedal lever that controls the throttle valve.

Cleaning the idle system of carburetors 2105, 2107 Ozone and their modifications

As a result of long-term operation of VAZ cars of the “classic” family (2101, 2102, 2103, 2104, 2105, 2107 and their modifications), the channels, holes and jets of their carburetors gradually become covered with deposits, become clogged and over time lead to disruption of the engine in different modes. If the car engine is worn out, then this process accelerates many times. The carburetor idle system is most susceptible to clogging. Unstable idle, the impossibility of adjusting it, failures when pressing the gas pedal - this is not a complete list of engine malfunctions that arise due to clogging of the idle system.

In-place method for cleaning the carburetor idle system 2105, 2107 Ozone

This method can be used to clean the carburetor idle system, as well as transition systems, both when its channels and jets are severely clogged, and periodically for preventive purposes. Its essence is to create an increased vacuum in the channels of the idle system, which will carry all deposits and blockages from them into the engine cylinders, where they will burn without a trace.

The procedure is as follows:

— remove the air filter housing (you can do without removing it, but it’s more convenient);

— start the engine and set the speed to “choke” around 3000 rpm;

— use a slotted screwdriver to unscrew the fuel nozzle holder for the idle system a couple of turns ; on carburetors with a solenoid valve, use a 13 mm open-end wrench; the resulting gap, together with the increased speed, will create a real hurricane in the CXX channels;

fuel jet holder CXX and solenoid valve for carburetors 2105, 2107 Ozone

— “advance the gas” several times by hand rotating the lever on the axis of the throttle valve of the first chamber (or moving the throttle drive rod);

— screw the holder of the fuel jet CXX (solenoid valve) back;

- repeat the operation two or three times.

carburetor cleaner aerosol

In addition, you can enhance the effect of cleaning the idle system of the carburetor 2105, 2107 Ozone by using a carburetor cleaning aerosol. Before cleaning with high vacuum, unscrew the fuel nozzle holder (solenoid valve) and pour a little cleaning aerosol into its hole for about five minutes. Screw the holder or valve back in and clean it as described above.

You can further enhance the cleaning effect if you set the idle speed even higher and completely unscrew the holder or valve. Constantly pour aerosol into the hole under it. At the same time, the engine idle speed will rise and fall, the main thing is to ensure that the engine does not stall. You can again repeat this operation several times until positive results are achieved.

Cleaning the idle system with disassembling the carburetor

It is necessary to stock up on acetone and thin wooden sticks or copper wire in advance.

— remove the air filter housing;

— remove the upper part (cover) of the carburetor and unscrew the holder of the fuel jet of the idle system or the solenoid valve (depending on the modification of the carburetor);

— disconnect the lower part of the Ozone carburetor (throttle valve block);

— we clean the fuel jet of the idle system (it is inserted into the holder or into the solenoid valve), if there is deformation, we replace it with a new one;

fuel jet CXX carburetor 2105, 2107 Ozone

— we clean the air jet of the idle system, use a wooden stick soaked in acetone or copper wire;

— we clean the emulsion channel CXX in the carburetor body , pour acetone into it (you can use a syringe) through the hole in the holder or valve; for mechanical cleaning it is better to use wire;

— we clean the air jet and the emulsion channel of the transition system of the second chamber of the carburetor;

— in the throttle valve block, remove the forced idle economizer valve or the “fuel mixture quantity” screw housing installed instead (depending on the modification of the Ozone carburetor), and also unscrew the “quality” of the fuel mixture;

— we clean the holes that opened after removing the screws and also the CXX outlet into the first chamber of the carburetor;

— we clean the outlet openings of the transition systems of both carburetor chambers;

After cleaning, we blow out all the parts and channels with compressed air and put everything back together.

Notes and additions

— If desired, you can completely clean the carburetor by soaking it in acetone for several hours.

— You can also clean the transition system of the second carburetor chamber using an in-place method. To do this, at increased engine speeds, unscrew and turn the fuel nozzle holder of the transition system of the second chamber on the back side of the carburetor a couple of turns.

holder of the fuel jet of the transition system of the second chamber of the carburetor 2105, 2107 Ozone

— On carburetors 2105, 2107 Ozone with a solenoid valve, before cleaning the idle system, check the functionality of this valve itself. At idle, remove the wire from the valve terminal - the engine should stall. If this does not happen, you should look for the reason for the inoperability of the EHR. An article on this topic on our website is “Checking the solenoid valve of carburetor 2105, 2107 Ozone.”

Five more articles on the Ozone carburetor website

How to clean a VAZ 2106 carburetor without removing it

The first cleaning method is to do it without disassembling the mechanism. The fact is that not every car enthusiast is able to disassemble and reassemble the unit. A special technique was developed for its washing. For this purpose, a special aerosol product in cans is used. Common cleaners include “ABRO”, “Mannol”, here I made an overview table of carburetor cleaners, perhaps it will be useful to you when choosing.

To clean, you will need to perform the following steps sequentially:

- Warm up the engine and turn it off.

- Remove the filter and its housing.

- To effectively flush, remove the solenoid valve by unscrewing it from the housing.

- Special nozzles are sold with the cans, which effectively distribute a powerful stream of product. All visible parts are treated with the substance.

- Afterwards, process the external parts of the device.

- Next, you need to wait from 5 to 8 minutes, which depends on the manufacturer. During this time, the product dissolves carbon deposits, after which it is easily washed out with gasoline and the dirt burns in the cylinders along with the fuel.

Cleaning a VAZ 2106 carburetor is usually accompanied by replacing the gasket, which is located between the carburetor body and the manifold. The manufacturer produced several types of gaskets made of paronite, metal and heat-resistant special cardboard. If you are not sure about modifying your carburetor, then take it to the market with a real material example.

To replace the gasket, the seating area should be thoroughly cleaned of dirt and wiped with a rag. Lay the new one in the same way as the old one was laid, install the mechanism on it and tighten the fastening nuts.

How to clean the carburetor on a VAZ 2106 using a solvent

One of the most accessible ways to flush the carburetor on a VAZ 2106 is to flush the carburetor with a solvent. The washing process is clearly shown in this video:

How to quickly blow out a carburetor with your own hands

If you do not have a compressor or any other specialized equipment for purging, you will need a regular car compressor, which can be bought in a store for pennies. How to blow through a carburetor on a VAZ 2106 with a car compressor in this video:

How to install the unit in place

You can assemble and reinstall the carburetor in the same way as you disassembled it, performing all the steps in reverse order.

- The carburetor is installed in its place, the mounting bolts are tightened.

- The pipes through which fuel is supplied are attached. The gas cable is connected to the throttle lever.

- The wiring is attached.

- A vacuum hose is connected to the ignition distributor, and the EPHH limit switches are combined.

- After installing the carburetor, it is adjusted.

Video: installing a carburetor on a VAZ

It is not so difficult to independently remove, disassemble, clean and reinstall the carburetor in the VAZ 2107 and 2106. The main thing is not to be intimidated by the huge number of hoses, valves, parts and dirt and strictly follow the instructions.

Didn't find the information you are looking for? on our forum.

Carburetor settings

After flushing and disassembling the VAZ 2106 carburetor, you will need to adjust the engine performance characteristics.

There are several points for this:

- Float mechanism tongue - when the float stroke is less than 8 mm, consumption and toxicity increase, power decreases.

- Quality screw – allows you to adjust the amount of incoming air to prepare the mixture.

- Quantity screw – adjusts the amount of the finished mixture.

These two screws adjust the idle speed according to the manual. But initially they are both screwed all the way and unscrewed 3 turns.

To adjust the thrust, you will need to set the thrust; there should be a distance of 80 mm between the guides. With these settings, the throttle should open fully when the gas pedal is pressed to the floor. If this does not happen, then the throttle assembly must be cleaned.

Do-it-yourself carburetor cleaning

Most new gasoline cars are equipped with fuel injection systems. However, on our roads there are a sufficient number of cars with carburetor engines. They often have weaker performance characteristics, but remain popular due to their high self-repairability.

Most systems in carburetor cars can be put in order in a garage with a minimum set of auxiliary tools. The list of available operations also includes carburetor cleaning.

- 1 Why do this

- 2 Preparatory activities

- 3 Cleaning

- 4 Conclusion

Preliminary work

In order to properly maintain the carburetor, you will need to rinse the strainer, which is located in the float chamber at its inlet. Clean all carburetor parts, including air jets, from dirt. Clean the float chamber itself from deposits. And only after that can the VAZ 2107 carburetor be adjusted, which includes adjustments:

- idle systems;

- float mechanism;

- starting device;

- the level of fuel located in the float chamber;

- adjusting the air damper opening gap.

Adjusting the float system of the carburetor of the VAZ-2107 car

Adjusting the float system involves the following steps.

1. Check the position of the float. If the position of the float is incorrect, it is necessary to align the holder (bracket).

2. Adjustment with the valve closed. Remove the chamber cover and carefully move the float to the side, then pull the tab located on the bracket. Thus, you must adjust the gap between the float and the rubber gasket of the cover. The gap should be within 6 - 7 millimeters. If your gap is greater than the required range, then the needle of such a mechanism is considered faulty.

3. Measuring the distance between the float and the needle when the valve is operating in the open position. This value should be about 15 millimeters.

Adjusting the carburetor starting system on a VAZ-2107

1. Remove the air filter and start the engine, first pulling the choke towards you.

2. Forcefully open the choke (about 1/3 of its maximum opening angle) and set the engine speed to 3200 - 3600 rpm.

3. Release the air damper and adjust the crankshaft speed to three hundred units less than the initial value.

Adjusting the idle speed of a car carburetor

To properly adjust the idle speed, it is necessary to warm up the engine to operating temperature. Next, using the quality screw on the carburetor, you need to set the maximum number of revolutions. Then you must start the engine and use the same quality screw to adjust the speed.

After setting XX, the carburetor adjustment of the VAZ-2107 can be considered complete.

Plaque on carburetor parts

If you disassemble the carburetor to service it, you may notice a dark brown tarry coating on its internal parts, do not be alarmed. This plaque is a natural formation. It is formed as a result of the operation of forced crankcase ventilation.

And the older the engine, it has more wear, and as a result, the amount of these gases that rise in the cavity of the air filter increases, while more contamination of carburetor parts occurs. This is the relationship.

Plaque on carburetor parts and the walls that are located near them must be cleaned. But it is not necessary to clean the deposits on the walls of the neck, the walls of the dampers, and diffusers, since this deposit does not significantly affect the overall operation of the carburetor.

So don't waste your time. Although if you are a pedantic person and you have time, you can clean the carburetor to perfect cleanliness, in any case it won’t make it worse and in the future it will have a better effect on the adjustment of the VAZ 2107 carburetor.

Due to the fact that the secondary chamber of the carburetor is in operation for a short time, its secondary jet and the main air jet do not become very dirty. However, it is still necessary to check the degree of contamination.

It is recommended to do this every time you remove the carburetor cover.

It is recommended to clean the jets with either gasoline or solvent. You can use a thin wire for this.

To ensure that you do not encounter any troubles related to the operation of the carburetor along the way, every 50 - 80 thousand kilometers, check the condition of the mesh filter, which is located in the float chamber of the carburetor at the inlet.

The fact is that thanks to the effective operation of the fuel purification system of the VAZ 2107, this filter rarely becomes clogged. However, if you do not change the fine fuel filter in a timely manner, then there may be problems along the way, since this mesh filter will quickly become clogged.

All parts and cavities of the carburetor must be washed carefully. Let's say the float chamber, where there are resin deposits, it is advisable to wash it with a solvent or other effective means.

But, for example, you should only wash the diaphragms themselves and gaskets with pure gasoline, since all solvents can seriously damage them, and for this they must be washed separately.

How to wash the strainer

Washing the strainer is a recommendation.

- Before you start washing the strainer, pump fuel into the carburetor using a fuel pump; naturally, this is done manually. This is done so that the required amount of fuel enters the float chamber and the closing valve closes.

- Next, unscrew the plug that holds the mesh filter, remove it, wash it (you can wash it with a solvent) and be sure to clean it with compressed air, to be sure.

- Also note that it is not recommended to clean the float chamber with a rag, since fibers from the rag can remain inside unnoticed by you and clog the fuel jets, including the idle jet.

- For cleaning, use a rubber bulb, which sucks out all the contaminants that are located at the bottom of the float chamber. Try to act carefully so as not to lift dirt from the bottom.

- After you have washed all the carburetor parts and jets, blow out all the holes and the float chamber itself with pressurized air.

- Next, check the tightness of the locking needle. To do this, connect an ordinary bulb to the inlet fitting and, pressing it, check the tightness of the shut-off valve. In this case, a pressure of 0.2 to 0.4 kgf will be created, which corresponds to the pressure created by the fuel pump.

- We create pressure and listen to whether the shut-off valve allows air to pass through. If air passes through, the valve body and needle should be replaced.

Also, do not forget to check the sizes of the jets using special gauges. For such a check, you can use drills of the required sizes.

The specifics of servicing the VAZ 2107 carburetor are very similar to the specifics of servicing carburetors of other brands of VAZ cars. We also recommend reading the article about adjusting valves on the VAZ 2106.

Nail Poroshin presents.

Cleaners have become the most popular

| Name of carburetor cleaner | Pros + | Minuses - | Price at the time of writing |

| MANNOL 9970 Carburetor Cleaner | Cleans very well and is convenient to use. Read the reviews: 1 → 2 → 3 → 4 → 5 → 6 → 7 → 8 | When stored, the tube taped to the cylinder constantly tends to get lost. | 150 rub. for a volume of 400 ml. |

| XADO JET100 ULTRA | Probably one of the best penetrating lubricants and its lubricating properties are excellent, and it also has a pleasant smell. Read the reviews: 1 → 2 → 3 → 4 → 5 → 6 → 7 | It ends quickly. Small volume. | 342 rub. for a volume of 250 ml. |

| Hi-Gear Carburetor Cleaner | Cleans perfectly. Effectively restores carburetor characteristics without disassembly. Read the reviews: 1 → 2 → 3 → 4 → 5 | The bottle is enough for 2 times. Bad smell. Toxic. | 522 rub. for a volume of 510 ml. |

| Liqui Moly Vergaser-Aussen-Reiniger | Gently cleans the fuel system. Using this composition, you can remove not only carbon deposits and tar deposits from the surface, but also clean channels and throttle valves. Read reviews: 1 | A little expensive. | 527 rub. for a volume of 400 ml. |

| Carburetor cleaner 3ton | Quality, price, carburetor cleaning 5+ Read reviews: 1 | Not found. | 114 rub. for volume 354 ml |

It's quite a difficult choice

You should pay attention to the reputation of each manufacturer. At the same time, it is possible to study reviews of each product

It is necessary to find additional information based on the experience of friends or other people. In the age of computer technology, this process will be the simplest and fastest. In addition, on the Internet you can search for tests of the most popular brands.

To help you choose, let’s look at cleaners from popular companies in more detail:

Based on the tests, the Liqui Moly product takes the leading place. It effectively cleans various heavy contaminants, cleans channels, jets and valves. Removes even stubborn paints. Sold in aerosol cans. This allows you to clean even the most difficult places. One of the popular brands is Mannol. The cleaner effectively removes carbon deposits and washes away dirt well from the carburetor, dampers and jets. Experienced people advise using this cleaner at regular intervals.

In this case, the performance of the fuel system will improve. If car enthusiasts are looking for a manufacturer who has developed a modern formula, then they should pay attention to the Hi-Gear brand. The composition helps remove any carbon deposits

The company offers various types of cleaners. Each differs in the method of use and exposure to pollution. The product of the ZM brand has collected numerous reviews. It was loved because it can be used not only as a cleaner, but also to lubricate mechanical components. The cleaner consists of organic compounds that are harmless to the environment. The product is universal, as it is used not only for the carburetor, but also for cleaning other elements. Among the large selection, the Jet 100 Ultra cleaner is not inferior to the championship. The product is used to clean all surfaces of the carburetor. Jet is an active product, so it quickly and efficiently removes all possible contaminants. At the same time, it has a lubricating effect, which can be useful in any emergency situations.

It should be remembered that often flushing the carburetor with cleaner does not help. In this case, you need to contact a car service.

To avoid this, you should use some simple rules:

• clean the carburetor every 5-10 thousand kilometers; • disassemble and clean the carburetor every 20-30 thousand kilometers; • periodically check the fuel system; • refuel with high-quality fuel; change filters.

From the above, we can conclude that you should not get hung up on one price of the cleaner.

It is necessary to pay attention to the properties of the product, features of use, degree of efficiency and contamination of elements, degree of purification and many other factors

Author of the article: Yuri Veselov