Knock in the front suspension

Unfortunately, it is impossible to determine by ear what is actually knocking. Therefore, when performing independent diagnostics, you need to inspect the shock absorbers, tie rod ends, anti-roll bar, front suspension arm, steering knuckle, silent blocks, ball joints. A common cause of knocking is failure of rubber seals. All rubber parts must not be cracked or damaged. If you notice a defect, you must replace them immediately.

Possible causes of knocking and their diagnosis

The cause of the knock can be any part that is part of the suspension. The most common causes of a knocking front suspension are:

Carrying out car suspension diagnostics yourself

- wear of the tie rod end;

- shock absorber malfunction;

- wear of ball joints;

- damage to rubber-metal hinges;

- deformation of shock absorber strut supports;

- wear of supports and suspension arms;

- loosening the nuts and bolts of the system components;

- wear of the cushion and rubber-metal hinges of the rod;

- production of hub bearings;

- large wheel imbalance or deformation of wheel rims;

- settling or breakage of the suspension spring.

Next, we will analyze these and other causes of knocking in more detail. You should start self-diagnosis by checking the condition of the anthers and rubber sealing parts . If they are damaged, they must be replaced. Also pay attention to signs of oil leakage from the shock absorbers.

Malfunctions in the operation of the suspension arms

A possible cause of a knocking sound from the suspension is a malfunction of its levers . This is usually accompanied by poor vehicle handling. Check the operation of silent blocks. To do this, use a pry bar as a shoulder to bend the levers. If there is a malfunction, you will see significant play . For repairs, it will be necessary to replace the silent blocks. To do this, you need to remove the levers and press the old silent blocks out of the hole. Before installing new silent blocks, lubricate the seat to reduce friction. Clean it from dust and dirt in one go.

Shock absorber malfunctions

The shock absorber may knock at the top or bottom mounting point. The reason for this may be the loosening of the fastening bolts or an increase in play in the mounting holes. Visually, wear or breakage of the springs can be determined by the vehicle's seat level. If the spring has sagged too much or is broken, this will be visible from the fit of the body. When driving, a broken spring will make a characteristic sound.

To preserve shock absorbers, it is recommended to fill them with oil of the viscosity specified by the manufacturer (provided that the shock absorbers are dismountable). In winter, never make a sudden start in a cold car. You can damage not only the engine, but also the shock absorbers, since the oil in them is also not warmed up. This will take care of the shock absorber struts and increase their service life.

Often the stand can be the cause of a knock. Especially when driving on uneven roads (knocking on bumps, uneven surfaces) or when a wheel falls into a hole. To check the strut, you need to press vertically on the fender or hood . With a proper stance, the car smoothly returns to its original position. Otherwise, you will hear creaking and sudden movement.

A possible cause of a knocking noise in the strut could be a loose lock nut. This malfunction can be identified by the car swaying while driving and decreased controllability. In this case, noise occurs randomly. The nut must be tightened, otherwise you risk losing control of the car on the road.

Steering problems

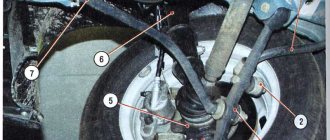

Diagnostics of steering rods on VAZ cars

The knocking noise caused by the steering is similar to that produced by faulty shock absorbers. An indirect sign confirming that the cause of the knocking is in the steering is vibration of the steering wheel and knocking on bumps and uneven surfaces.

The front knock, in this case, is the result of the interaction of the rack and the gear moving along it. During operation of the steering system, the contact gap and wear between the rack and pinion increases over time. Therefore, a knock occurs at the point of contact. To diagnose this breakdown, it is enough to jack up the car on one of the front sides and shake the steering rods. If at the same time you feel play, then most likely the dull knock comes from worn bushings. They are repairable, and in any auto store you can find repair kits for replacing bushings.

Rack support

A dull sound when driving on uneven roads may occur due to incorrect operation of the upper part of the front suspension. It has a rubber base, which is a natural shock absorber. However, rubber wears out over time and becomes woody. Because of this, its flexibility and shock-absorbing ability are lost. Unfortunately, the designs of many cars do not allow one to reach this unit and measure the gap between the limiter and the support. However, if this can be done in your car, then know that the distance should be about 10 mm. Typically, knocking in the suspension occurs only on one side, since it is unlikely that the supports will wear out on both sides at the same time.

Support bearing

The sound that a worn support bearing makes is similar to that produced by a damper, but is louder. To detect a breakdown, it is necessary to dismantle the front strut. The peculiarity of its production is the uneven wear around the perimeter of the body. The greatest generation occurs when the car is moving straight. Therefore, knocking is possible when moving in a straight line . If you turn right or left, the knocking stops. If you have such a situation, it means that the support bearing of the car has failed.

Ball joints

On old rear-wheel drive cars (for example, VAZs), problems with ball joints are considered a classic cause of knocking in the suspension. The check must begin by hanging the car on the shock absorber above the wheel where the knock is coming from. Without rotating the disk, you need to try to shake its opposite parts toward and away from you. The procedure must be carried out in two planes , grasping the left and right parts of the wheel, then the top and bottom. If the supports are faulty, you will feel play.

Constant velocity joint (CV joint)

If the CV joint is faulty, then while driving it produces a characteristic crackling sound, especially when turning. When a CV joint breaks down, it has to be replaced because it cannot be repaired.

Uncharacteristic causes of failure

Another reason for knocking could be a loose brake caliper . This is a fairly rare reason, since, as a rule, the caliper is mounted very securely using locknuts. But if the fastening bolts do loosen, the sound of the caliper, especially when braking the car, will be very loud, so it is impossible to confuse it with anything else. Sometimes, especially if the brake pads are of poor quality, they can make a small and dull sound. In some cases, peeling of their working surface may occur. The cause of knocks in the front suspension can also be the stabilizer bar bracket . It has bushings with rubber elements in its design. It is necessary to check their integrity.

What did you decide to repair?

Together with a mechanic and a repairman, we decided that the following needed to be changed and repaired:

- Replace the rubber bands of the levers (daisies).

- Replace the stabilizer struts (in common parlance, eggs).

- Lubricate the brake caliper guides.

- Replace brake linings and pads on all 4 wheels. Although the rear ones were not too worn, I decided to change them.

- The handbrake cables were rotted at the bends near the rear wheels. The braid broke, water got in, and everything rusted. As a result, the right rear wheel was not stopped by the handbrake. Therefore, it was decided to change both cables.

- We also decided to replace the two outer CV joints. I knew this even at home, since a characteristic crunch was heard when turning.

The master calculated the cost of spare parts and labor. It turned out that for cars older than 6 years there is a 20% discount on spare parts. Therefore, we calculated 12,566 rubles for everything.

I left the car at the dealership and drove into town. They said it would take about 4 hours to get it repaired by the dealer. Later they called me and said that the rear brake drums were very scuffed. They asked whether we would change it or not, to which I agreed to replace it.

Knock in rear suspension

Diagnosis of the rear suspension is faster because its design is simpler. There can be several reasons for the knocking sound - worn torque rod bushings (if any), loose wheel bolts, loose or broken exhaust pipe fastening, broken suspension spring coil, loosening of the short torque rod mounting bracket, recoil valve in the shock absorber, rear shock absorber bushings, released axle shaft, pad spacer bar. Also, unknown sounds may be caused by reasons not directly related to the suspension. For example, objects in the trunk, an unscrewed spare tire, and so on.

It is also recommended to check the exhaust pipe mounting and its general condition. After all, a burnt-out muffler produces extraneous sounds that a car enthusiast may mistake for a knock in the rear suspension. In addition, it is necessary to check all pipe fastening elements. If it is not securely fastened, then on uneven roads it can produce a small and dull knock, which the driver may mistake for problems with the suspension.

When diagnosing yourself, you need to check the following components (some of them may be absent on some car models):

- rear suspension guide structure;

- levers (transverse, longitudinal);

- anti-roll bar;

- rear shock absorbers;

- shock-absorbing springs;

- shock absorber cups and brackets;

- rubber bushings;

- rear axle beam;

- compression buffer;

- bearings.

Diagnostics of the guide structure

During the diagnostic process, you must perform the following steps:

- Check the force and condition of the beam, as well as the levers (if any). Make sure there is no deformation on these parts.

- Check the hinges. They may develop cracks due to wear and tear. This also leads to deformation.

It is worth checking the threaded connections of the flanges at their attachment points. Depending on the make and model of the car, they can be repaired or you will have to buy and install new ones. The above work must be performed in a car service center or in a garage with an inspection pit.

Diagnostics of suspension springs

Despite the fact that the steel from which the springs are made is strong, they can fail over time. Their individual coils break, so the spring stops working normally. To diagnose it, it is enough to conduct a visual inspection. In this case, it is worth paying attention to the absence of defects on the spring coils, as well as the integrity of the rubber inserts that are located in the places where they are installed. If a spring fails, it must be replaced; it cannot be repaired.

Rear shock absorbers

Used shock absorber boots

As with the front shock absorbers, it is necessary to diagnose the anthers . If necessary, replace them. When inspecting the shock absorber, you should also pay attention to the absence of oil leakage from its housing. If the shock absorber is collapsible, it makes sense to dismantle it and disassemble it to ensure that the internal elements are in good working order. In this case, it is worth checking the rubber bushings inside, which often fail.

Additional reasons

If you have checked the parts listed above, but the rear knock still persists, you should pay attention to the following things:

- Stopping support. Here they proceed as in the case of the front suspension. When it is skewed, the caliper will make a loud sound, so diagnosing this malfunction is not difficult.

- Wheel bearing. You need to jack up the car completely or just the wheel you want to check. When rotating freely, the bearing should not make noise, knocking or creaking noises. When checking, the brake pad may rub against the disc, the sound of which is very similar to a squeak. Therefore, be careful when diagnosing.

Removing squeaks from the airbag plug.

In cars not equipped with a passenger airbag, noise often occurs from the plug of the non-existent safety element and the element located under it. The work must be comprehensive. First we need to remove the airbag cover. To do this, using plastic spatulas for working with car interiors, or a credit card, pry the trim from the upper left corner and pull it up. After removing the lining, we apply Bitoplast 5mm or Madeline to the joints of the plastic elements.

Another well-known source of noise can be the cable that regulates the intake of air from the passenger compartment or from the street into the air conditioning system. It may touch the airbag cover, right air duct and instrument panel elements. Carefully inspect the places where the cable contacts other elements and apply Bitoplast 5mm to these places. Also secure the cable itself using a tie on the body of the right air duct to completely eliminate vibrations of the cable on the road.

The last element in this part of the panel that can make extraneous sounds is the air duct itself. To reduce noise, apply sealant to the joints of the air ducts or seal them with Madeleine.

List of the most common reasons

Knocking in the suspension when driving over uneven surfaces is an extremely common problem. In most cases, the sound that appears when the body vibrates when a wheel hits an uneven surface is associated with partial performance of the chassis, but occasionally there are other reasons. The most common reasons are:

- faulty shock absorber strut mounts;

- damage to shock absorbers or their individual elements;

- wear of ball joints, silent blocks, support bearings;

- damage to the steering rack.

These are the most common causes of metallic knocking noises coming from under the car body. Defective suspensions are much less common. Sometimes the engine support components are to blame. Each individual problem is solved in its own way, but most often you simply have to replace the damaged part. The most common cause of the problem is wear of components due to poor quality roads. Since most foreign cars simply do not have any additional chassis protection systems, silent blocks, supports and other elements suffer, which bear the brunt. While reducing damage to the body and other parts of the car, these elements themselves wear out, and very intensively.

First of all, it is worth checking them and replacing them if a malfunction is detected.

You should definitely not repair damaged parts yourself; they must be replaced with factory equivalents. You shouldn’t ignore the problem either, because the longer the knocking continues, the more extensive the damage will be in the end. Try to quickly check all possible causes, and this should be done in this order.

Replacing silent blocks

A dull knock in the front suspension usually occurs due to problems with silent blocks and springs. If the reason is silent, then the car's handling will noticeably deteriorate. The only option is to replace the entire set. There is only one way to check whether this is true - carefully examine the front suspension arms. To do this you will need a mount. Using a pry bar as a counterweight arm, bend each front suspension arm. You need to bend in different directions. If there is a malfunction, you will find play, which is why the knocking occurs.

If you can disassemble the structure, then all that remains is to replace the silent blocks in the following sequence:

- Remove all levers.

- Next you need to pull the silents out of their seat. Using a special mandrel they can be easily pressed out.

- Clean the seat from any remaining oil and dirt.

- New silent blocks must be lubricated with machine oil before installation.

This, in fact, is all that is required of you.

Steering rack

A knock in the suspension when turning can occur due to problems with the steering rack. Typically, it is the turning of the steering wheel that causes the sound, which occurs due to play inside the structure. A characteristic feature is that the sound comes from one side and is also accompanied by a noticeable vibration of the steering wheel. The malfunction is especially pronounced on a gravel placer, then vibration is very frequent, although there should not be any at all.

The sound occurs when the steering gear and the rack itself rub against each other.

Occasionally, a similar defect is observed immediately after replacing the bearing in the hubs of VAZ 2109. As a result of the defect, the backlash will increase, which will lead to damage to the elements of the steering structure. To verify the reason, you will need a jack to raise the car:

- Raise the car.

- Take a pry bar and carefully move the tie rods from side to side.

- If significant play occurs (it should be visible to the naked eye), then the problem is worn out bushings that will need to be replaced.

- It is also necessary to tighten the rack nuts to seat it on the gear.

It is rare, but it still happens that the steering wheel and its components are in order, but vibration and knocking are still present. In such cases, attention should be paid to inspecting the steering joints.

How to glue plastic in a car to prevent squeaks

Among the many disadvantages of budget cars is the low quality of materials (upholstery, plastic, rubber products, etc.). The unpleasant creaking of plastic, which is found almost everywhere (panel, door cards, etc.), while driving due to vibrations and friction, produces an unpleasant irritating creaking noise, which constantly reminds you that when buying a car you decided to save money...

Car owners come up with everything they can to eliminate the squeaking of plastic panels, some “chemically” do something with their own hands, others put their car in the hands of professionals, others “don’t worry” and just turn up the music louder so as not to hear how the plastic is held together.

Racks, supports, springs

A strong knock in the front suspension occurs due to impacts on the car body. This happens when the shock absorption system wears out. In rare cases, the shock absorber spring can also be the culprit of the knocking, but this happens extremely rarely, since the springs are the strongest part of the assembly.

The sound occurs on small bumps when the shock absorbers take a sharp blow. The vibration damping system copes very poorly with such an active load, so rapid wear of the elements during frequent driving on uneven roads leads to such consequences. The result is wear of the rubber layer of the support.

To detect a malfunction, you will have to go through the entire rack, remove it along with the support, and for this you need to dismantle the wheel and partially disassemble the chassis. There will be a lot of work. To make sure it is the strut support that is the problem, you need to measure the distance from the support to the rubber stopper. Ideally, there should be no discrepancies, maximum 1–2 mm.

If the reading is higher, you will have to replace the rubber layer of the strut.

If you don’t want to do this yourself, then the service station will do this work much faster, albeit for a fee. Vibration and knocking should disappear immediately after replacement.

It is extremely rare that the cause of a knock is the rack itself, which has become severely worn out due to constant loads. The sound will be very loud, and the car will shake considerably on bumps.

Checking the strut is quite simple: press harder on the hood. If the rack is faulty, the car will sharply return to its original position with a characteristic loud knock, while the body will sway a little.

The source of the sound may be a loose nut inside the mechanism that can be tightened.

Well, the latest option is a complete malfunction of the shock absorber mechanism. This happens as a result of accidents and collisions. At first, no attention is paid to the knocking, but the problem is discovered much later.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

Other reasons

In addition to all the options described above, the suspension also knocks for other reasons. One of these is brake pads that produce a metallic knock. In such cases, the sound disappears as soon as the brake pedal is pressed. Often this problem occurs after installing new elements or severe wear of old pads.

Any knocking noise in the rear suspension can repeat the problems described above, but this happens extremely rarely due to the fact that most modern car models are front-engined. Since the engine is one of the heaviest parts of the car, the front part of the body bears much more load, and even shock absorbers do not protect against this. The rear of the car is unloaded, and therefore is not subject to such problems.

By the way, knocking noises in the front end may be the result of a worn engine mount.

The rubber inserts of the unit wear out over time, this happens after about 100–120 thousand kilometers of a new car. As a result, when the rubber parts are worn out, any trip on an uneven road will be accompanied by a metallic knock. Additional sound can be produced by the motor itself, the unit of which will be slightly displaced. If the reason is in the support, then you will find carbon deposits on the spark plugs, and when you inspect the support itself, you will find tears.

A trip to the dealer

The struts weren't leaking yet, but I was getting pretty tired of the knocking noise, so I decided to go to a car dealership. I made an appointment for repairs a week in advance; I live in another city 300 km from the salon. At the same time, I decided to diagnose the entire suspension and replace what was needed.

I arrived a little earlier than expected and approached the repairman. I thought they would accept the car earlier, but there was no free space, so I had to wait.

I've had repairs done at a dealer before and I liked the attitude. Polite service, conscientious craftsmen. Worn parts are returned. During renovations, you can come in and see how the work is progressing.

Front suspension installed with defects

A possible reason for the appearance of knocking on bumps may be the occurrence of defects in the lever system. At the same time, you will notice changes for the worse in the car's handling. The only culprit in this situation is a set of silent blocks.

To check for problems, you need to diagnose the levers. You can do it yourself using a regular mount. To do this, use the pry bar as an extended arm to create a counterweight and bend each of the arms in different directions. If you find significant play in the structure (discrepancy of more than 5-7 cm), then it is worth carrying out maintenance on the suspension.

If the machine has a collapsible structure, then you only need to replace the old set of silent blocks with a new one. The replacement process is as follows:

- First you need to dismantle the levers;

- Then the stage of pressing out the set of silent blocks from the fixed holes occurs. To do this, use a special mandrel;

- Install a new set of silent blocks, having previously generously lubricated each of them to reduce friction during operation. Also, do not forget to clean the mounting surface of the suspension from all dust and dirt before installation.

Tip: If the suspension was supplied with defects from the manufacturer, then in case of an unexpired warranty, you can contact the dealer, and he will be obliged to replace the defective parts free of charge. Also be sure to check the rear axle of the VAZ-2107.

The appearance of malfunctions in the steering

According to experts, the occurrence of knocking on small bumps in the suspension in 70% of cases is associated with the presence of obvious problems in the vehicle components. However, many drivers believe that the problem is related to the shock absorber struts, although the fault lies in defects in the steering.

An external examination and diagnosis of the steering rack will help to find out whether this is true or not. When checking this unit, you will also hear a similar knocking sound as the shock absorber. In this case, you will hear a knock only on one side. Also, an additional symptom that indicates problems in this element is the presence of slight vibration in the steering wheel. Vibration is usually noticeable when driving on gravel roads.

Tip: the sound occurs when the rotating gear rubs against the steering rack structure. This may be a side effect of replacing the wheel bearing on a VAZ-2109.

The problem with the steering rack is the following - the gap between the gear and the rack gradually increases, and the intensity of the element’s operation increases. As a result, during long-term operation of the vehicle, significant wear is formed on the body of the mating surfaces of each pair.

Problems with the rack supports

The upper parts of the supports suffer the most when driving on uneven roads. In this case, most often it is necessary to replace the rubber base, which is necessary to dampen vibration and the resulting excess noise. The sound occurs as a result of loss of flexibility and severe wear of the base.

Often, when sounds appear, the driver begins to manually sort out the entire front suspension, spending a lot of time and money on new spare parts, but the cause of the noise does not disappear. You can identify the presence of a problem in the rubber base by simply measuring the gap distance between the support structure and the plastic stop. On average, the value of this parameter should be 8-10 mm.

To replace the rubberized base, contact a car service center - here they will carefully remove the support and install a new layer of rubber. In this case, noise and vibration will go away immediately, and the new “layer” will last another 20-40 thousand km.

Diagnostics

The Lada Granta was driven into the repair bay and raised on a lift. I explained the problems and said that something was knocking in front.

I forgot to say that before the lift the car was checked at a stand. The front end was subjected to vibration and the operation of the struts was checked. It turned out that they were normal.

The mechanic advised not to change the racks, since by all indications they were in good working order. I checked the chassis and suspension, tapped the front brake calipers - they made a metallic ringing sound. I said the knocking noise when driving was similar.

The appearance of faults in the support bearing

The sound from a malfunction in this element is similar to the sound from the development of a damper, but it seems much louder. To detect a breakdown in the bearing, you simply need to remove the strut and inspect the integrity of the element. You will find that it is heavily worn on only one side, because the wear cannot be the same across the entire area of the bearing. The greatest wear is visible when the vehicle is moving smoothly, without any turning.

While driving, it is quite easy to detect problems with the bearing - the knocking noise appears when the car is driving straight, and disappears when the car turns right/left. Also, when the bearing wears out, high vibration is felt when turning the steering column.

The appearance of malfunctions in ball joints

Experts call this suspension unit the most common source of “classic” knocking in the front suspension of a car. However, this type of “disease” has its own specifics, since it mostly affects rear-wheel drive vehicles.

The main problem lies in the fact that the appearance of wear on the hinge structure causes a beating when the car moves over uneven roads. You can check this as follows:

- First, the wheels on the problem side are suspended;

- Next, with the disk locked, you need to make several sharp turns to the right/left from the vertical support;

Advice: in order to exclude any influence from the set of bearings located in the hub, ask your partner to press the brake pedal all the way when diagnosing the unit.

- When knocking occurs, faulty areas will be immediately found.

It is also necessary to check the set of boots attached to the ball joints. If the boot is significantly damaged, the service life of the hinge system is reduced by 2-3 years.

Troubleshooting Techniques

The rubber creaking of the suspension while driving indicates damage to various oil seals, anthers and protective covers. These parts are not repairable, so only replacing them can save the situation.

When inspecting the vehicle's chassis, it is necessary to pay attention to the presence of mechanical damage and the degree of natural wear of all rubber elements.

Diagnostics of shock absorbers

The problematic components of the suspension are shock absorbers, which quickly fail due to the unsatisfactory condition of the roads. A properly functioning part should not have any oil leaks, and when the vehicle rocks, the shock absorber should dampen vibrations. Note that these signs appear first, in contrast to third-party noises when the car rocks, and are direct evidence of the failure of the shock absorbers. In this condition, the mechanism can still work for some time, but it is better to replace it immediately.

You can check the shock absorber like this:

- Remove the part from the car and inspect the condition of its upper and lower fasteners.

- Place the shock absorber in a vertical position.

- The performance of a shock absorber can be assessed by acting on its rod. If the resistance when moving the rod down is significantly less than when it moves up, then the mechanism is working properly.

- Free movement of the rod can be caused either by the penetration of air into the part or by a loss of liquid or gas level. In this case, oil leaks are clearly visible on the shock absorber body.

You can slightly extend the life of the shock absorber by replenishing the level of working fluid in it. However, such a measure will only have an effect if its body is intact. In addition, you can replace worn out parts of the mechanism.

Checking the condition of the springs

Sagging springs also negatively affects the performance of the suspension. This is caused by their natural wear due to the aging of the metal. To verify this, you do not need to carry out complex diagnostics.

You just need to walk around the car and pay attention to its position. If the springs do not perform their function, the vehicle's ground clearance will be significantly reduced.

Please note that camber adjustment cannot be performed on a vehicle with sagging springs.

Diagnostics of ball joints

Checking the lower suspension arms will show the condition of the ball joints. It is most advisable to carry it out by lifting the car on a lift, or using a pit. Using a pry bar, you should carefully press the silent blocks located on the lower arms. If they are in good working order, there should not be even the slightest play. And their rubber parts do not have any damage (cracks, abrasions, dented places).

Ideally, check the silent blocks and ball joints on a lift, or by jacking up the front of the car. After this, you need to unscrew the support mount from the lower arm. Next, we rotate its body to assess the condition of the ball. Evidence of its serviceability is the complete absence of play and the free, effortless movement of the body. Due to the elasticity of the rubber parts of the silent blocks, the lower arm should always be in a horizontal position.

Inspection of silent blocks

Determining the presence of production of these elements is quite simple. To do this, you need to swing the opposite rods from side to side. The presence of play in them is a harbinger of component failure. In this case, it is better to replace them immediately, since further operation of the vehicle with damaged silent blocks has an extremely negative impact on the performance of the suspension.

Troubleshooting in the rack

Basically, the strut can make a knock and transmit impacts from uneven roads only when the entire structure is severely worn. Moreover, this element of the car suffers the most when the front pair of wheels falls into a deep hole - the rebound strut does not work, but the spring undergoes a sharp straightening. As a result, the wheel will go sharply down, stretching the spring to the maximum possible length. Thus, it turns out to be 2 hits - the racks against the support and the racks with the bottom of the pit.

Checking the functionality of the support pillar is carried out in a standard way - the vehicle is swung vertically or a partner presses forcefully on the central part of the hood. If the rack is in good condition, the body of the machine should return to its original state once without sharp straightening.

If the case falls sharply, you will hear a dull thud. This indicates a malfunction of the element due to a loose lock nut, which makes noise inside the support post itself. Repair of the rack should only be carried out at a car service center, since special equipment will be used to secure all elements in a high-quality manner.

If a knock occurs on small bumps due to the strut, the car sways strongly when moving and loses control. This may result in an accident on uneven roads.

Also, problems may lie not in the strut itself, but in the shock absorbers. A malfunction of the shock absorber system is primarily due to improper treatment with oil. Drivers often pour an oil solution with incorrect viscosity characteristics inside. This value is affected not only by the purchased oil, but also by the ambient temperature at which the solution is poured. Too low a temperature does not allow the oil fluidity to increase to the required value.

Why does a wheel make a sound when turning?

When turning the steering wheel, a knock in the wheel area on a Lada Grant, as well as other extraneous sounds that are not characteristic of a working car, are usually caused by several reasons. Let's take a closer look at them.

Incorrect alignment

If the toe is set incorrectly, the car pulls to the side when driving. The greater the deviation from the norm, the louder the tire squeak both when turning and during straight-line movement. It occurs due to the clinging of the fender liner or body to the wheel.

Incorrect camber

This is the angle of mounting the wheels relative to the road surface. The ideal option on Grant is a perpendicular installation. If the camber is negative, this will lead to increased wear on the inner edge of the tire during straight-line movement or instability during maneuvers.

Wrong castor

Castor is a longitudinally inclined axial rotation angle. In other words, a line drawn through both points of fixation of the rack. If, when viewed from the side, the steering axis of the wheel is turned toward the rear of the car, we are talking about positive castor. The more the castor is shifted here, the more stable the Grant will behave on the road, but this will increase the force on the steering wheel when turning. The car can even lift up, creating a completely unwanted lateral roll. Naturally, such a moment is accompanied by a creak.

Worn outer CV joint

If you hear a crunching sound in the area of the Grant wheels when you turn the steering wheel , it could be a grenade. You can check this by placing the car on a level surface and turning the wheels to one side until they stop. Then you need to try to move off smoothly. A crunch when turning the steering wheel will indicate damage to the outer joint.

The appearance of malfunctions in the engine mount

In order to detect problems in the condition of the motor support, it will be enough to conduct only a visual external inspection. At a high level of wear of this element, you will find the appearance of significant tears, as indicated in the photo below.

The broken support is shown on the left, and the new support is shown on the right. As a rule, problems with the engine mount can occur after 100 thousand km of the vehicle. In addition, noise in the supports may be accompanied by vibration of the engine itself. In this case, you may find black carbon deposits on the spark plugs. To determine the specific cause of knocking and shaking, conduct a detailed diagnosis of all vehicle systems.

Advice: remember - timely repairs (even if there is slight noise on small bumps, holes and uneven surfaces) will guarantee the durability of the car's front suspension in the future.