Any car enthusiast may encounter such a problem as a knocking sound in the suspension on small bumps. On the Lada Kalina, there are several reasons that could result from this effect. If a problem is identified, it is necessary to solve it as soon as possible, since it can cause more significant problems in the suspension or chassis of the car.

Video about what can knock in the front suspension

The video story will tell you about knocking in the car suspension, the reasons for its occurrence, as well as recommendations for elimination.

Knock in the front suspension of Lada Kalina

Many motorists dread the day when strange knocking noises appear in the suspension, especially the front suspension, which increases with increasing speed.

Of course, there is reason to worry, but at the same time, a car’s suspension is a strong and reliable unit that will clearly withstand a few more kilometers to a service station or garage, where it can be diagnosed. There are four main reasons for the occurrence of knocks and squeaks in the front suspension of the Lada Kalina. Of the three possible causes of knocking, two of them can be eliminated independently.

So, the first reason why a knocking sound may occur in the suspension is the quality of the road surface. Yes, suspensions, even the most ideal and new ones, can squeak and knock on a bad road, even if this has not been observed before. To test this theory, you should drive onto a well-paved road and drive a few hundred meters; if there is no knocking, everything is fine with the suspension; if not, look at the second reason.

The second reason for the knocking sound, if it is accompanied by vibration in the steering wheel, is a malfunction of the steering, or rather the steering rack, or thinning of the brake discs. If the discs can be replaced independently, then in the case of steering, if you are not a level 80 mechanic, it is better not to flirt with it right away bring the car to the service station.

The third reason is the springs that have lost their tone, as a result of which the car body practically hits the suspension. You should not deal with this problem on your own - it is better to immediately take the car to a service station or service center, since self-repair may seriously damage the front suspension strut.

The fourth reason is a worn-out silent block, which is designed to dampen vibrations and knocks when driving. You can replace the silent block yourself; see the step-by-step replacement of the silent block in the Lada Kalina mono in the next paragraph.

Replacing front suspension silent blocks

Replacing the silent blocks of the Lada Kalina front suspension is necessary after 15-17,000 km, otherwise noises and knocks may be observed when driving. In most cases, the loss of its functions is observed after 15-17,000 km; knocking noises that appeared during this period of kilometers are a problem of faulty silent blocks.

Silent block

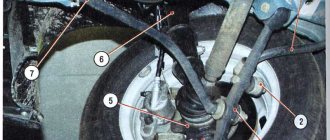

The silent block replacement diagram looks like this:

- The machine is placed above a hole or ditch in order to be able to comfortably see the entire suspension. The movers are fixed by the wheels, we put the car itself on the handbrake, then it’s worth checking again that the car is stationary.

- Use a jack to lift the car and remove the front wheel.

- After this, you should fix the bolts of the ball joint with your hands, after which its fastenings are removed.;

- The SPU nut is unscrewed, before this the ball-type support is knocked out into the lower part, after these manipulations the bolts are removed.

- After removing the bolts, the sleeve blocking the lever is pulled out. After pulling out the bushing, the lever is pulled out.

- There are marks on the lever that indicate the direction of installation of new silent blocks; this should be taken into account when installing new blocks.

- The silent blocks must be lubricated at the point of contact with the lever. Using a vice or pliers, apply pressure to the blocks until they fall off.

The diagram is approximate and is for informational purposes to understand how many manipulations need to be made to replace silent blocks.

A knock in the Kalina's front suspension requires a full diagnosis of the car's chassis. It is the suspension that is particularly negatively affected by defects in road surfaces, various holes and dents. A creaking or knocking sound from the suspension indicates any breakdown of the chassis mechanism that needs repair.

Operating principle

On the Lada Kalina, MacPherson suspension has improved ride quality. Starting with Kalina, all new AvtoVAZ models began to be equipped with MacPherson strut suspension. When driving, the level of impact of a bad road on the body is much more effectively reduced, making driving a car much more comfortable than, for example, a VAZ 2109, where a similar type of suspension is installed.

Thus, the independent MacPherson suspension consists of two axle shafts, allowing the wheels to be practically independent of each other. This means that the wheels, when one of them hits a bump, a depression or something else, do not change the level of inclination, as is the norm in semi-independent and dependent suspensions.

Differences between the front suspension of Kalina and previously produced AvtoVAZ cars

All AvtoVAZ cars had a MacPherson strut suspension at the front, but it was significantly different from those used in the 70s, 80s and 90s by Ford, Fiat, Volkswagen, etc. So, the main differences between the MacPherson strut suspension and the suspensions of Lada models until 2004 are concluded as follows:

- Instead of a bearing, a bushing is mounted in the MacPherson.

- In MacPherson, the ball bearing has a larger radius, and the design also differs. Now it is located in the upper part between the support and the spring element in a compressed state, which perfectly helps to remove knocks when moving.

- When the wheels turn, the front suspension strut, or rather its body, rotates with the spring simultaneously. When this happens, the shock absorber rod remains motionless.

Causes of extraneous noise and knocking

In order to carry out an independent inspection, and, if necessary, repairs, you will need a lift or inspection hole.

Support stand

For comparison: old and new support strut on Logan

Before you begin inspecting the suspension under the car, first assess the condition of the front strut supports. To do this, you need to open the hood and evaluate the gap on the spring stop cup.

If the gap exceeds 1 cm or it differs relative to the opposite side, this indicates that the supports have sagged and they do not absorb impacts on small bumps, therefore, they need to be replaced.

Shock absorber struts

The presence of a dull knock in parts of the front suspension may indicate defects in one of the shock absorber struts. The easiest way to diagnose is to alternately rock the car on the left and right sides. If there are working shock absorbers, the car will smoothly return to its original position, already on the first or second free play.

The presence of smudges and unsatisfactory condition of the bumpers will also indicate that the rack should be replaced.

Anti-roll bar link

This chassis element is checked when the vehicle is under load.

By rocking the car, you should pay attention to the movement of the cup relative to the lever itself. If this element malfunctions, it will jump and make a characteristic knock, which in turn, undoubtedly, is observed when driving on an uneven road

Inspection and replacement of the stabilizer bar link

The same goes for the anti-roll bar bushings. When they wear out, play and free movement will be felt in the places of contact with the rod itself. Diagnostics and replacement of stabilizer bushings can be carried out both on the ground and with the car suspended.

Silent blocks

The arrow marks the silent block

After the car has been raised, you should check the silent blocks in the suspension arms. In order to determine the degree of their wear, you will need a mount, with the help of which, by moving the lever on the subframe in the longitudinal and transverse directions, you can determine their play, as well as identify rubber defects.

On Renault Logan, the silent blocks are attached to the front suspension arm, so their replacement should be carried out on a removed element.

Spherical bearing

Diagnostics of a ball joint is diagnosed in the same way as silent blocks. By turning and pushing movements (left - right) you should influence the front suspension lever, and if the ball joint is faulty (there is play), moving it will not be difficult.

Ball boot diagnostics

The support on the Renault Logan is pressed into the front suspension arm. Therefore, before dismantling it, the lever must first be removed, and the replacement itself must be carried out using a press. Read more in the material: replacing and diagnosing a ball joint on a Renault Logan.

If the ball joint is sentenced to replacement, then it is important to know which ball joints are better!

Replacing silent blocks

A dull knock in the front suspension usually occurs due to problems with silent blocks and springs. If the reason is silent, then the car's handling will noticeably deteriorate. The only option is to replace the entire set. There is only one way to check whether this is true - carefully examine the front suspension arms. To do this you will need a mount. Using a pry bar as a counterweight arm, bend each front suspension arm. You need to bend in different directions. If there is a malfunction, you will find play, which is why the knocking occurs.

If you can disassemble the structure, then all that remains is to replace the silent blocks in the following sequence:

- Remove all levers.

- Next you need to pull the silents out of their seat. Using a special mandrel they can be easily pressed out.

- Clean the seat from any remaining oil and dirt.

- New silent blocks must be lubricated with machine oil before installation.

This, in fact, is all that is required of you.

The rear suspension suffers less from this problem, since the main load falls on the front suspension due to the motor assembly. Nevertheless, it is worth checking the condition of the silent blocks in both parts of the chassis.

Knocking in the suspension on bumps and uneven surfaces - what are the reasons?

The cause of knocking in a car's suspension is most often the shock absorber struts. At the same time, such a knock is characterized by the fact that it appears only on the side where the strut is faulty - this is why you can usually hear the knocking clearly either in the front suspension, or in the rear, or in the front, or in the rear.

Most often, knocking in the suspension appears only on bumps. In this case, the culprits for such a knock may be:

- worn or damaged racks, as mentioned above;

- worn or damaged leaf springs, brackets holding them together;

- worn or damaged control levers (in this case, knocking in the suspension may occur on bumps only when turning the steering wheel and only from the front);

- damaged or damaged ball joints;

- broken shock absorbers also often cause knocking;

- weakened or damaged body supports - knocking also occurs only in the front suspension.

When it comes to diagnosing a knocking noise when driving over bumps, the most obvious thing required is a road test to determine the source and nature of the sound. Before you take your car on a road test, you need to walk around the car to make sure nothing falls off while driving. Look carefully under the bottom of the car.

A quiet thud in the suspension due to the struts

Press down on the front and rear of the car. This will determine if the racks are working properly. If the racks are working correctly, the car body will rise after you stop putting pressure on the car and return the body to its original state.

Step two - start the engine. Turn the wheels from lock to lock in both directions alternately. This will determine whether the skid plates make a clicking noise or a rhythmic noise when the vehicle is stationary.

Inspect the racks themselves for fluid on them - if one of the racks is leaking, it needs to be replaced. In some cases, to inspect the racks, you will need to jack up the car and remove the wheels.

Typically, failed struts are characterized not only by a dull knock, but also by discomfort when driving - you may feel that the car has begun to handle road unevenness differently, hitting the “fifth point” hard even in small holes or bumps.

If after checking you find out that the struts are in working order, and the reason for the knocking is not in the suspension, do not rush to draw conclusions. Open the hood and locate the mounting studs and nuts with the strut support plate. Check to see if these bolts or nuts are loose - sometimes they can be the cause of a knocking sound in the suspension.

Loud thud due to damaged springs

Leaf spring clamps tend to wear out on vehicles over time, even under normal road and operating conditions. In this case, they can knock. Typically, the clamp on one end of the leaf spring will become deformed or broken, creating a characteristic loud thud.

To check the cause of knocking in the springs, first, visually inspect them for visible damage. In the case of broken clamps, you can easily find them.

You can then perform the following diagnostic procedure. Get behind the wheel and start driving slowly. Then press the brakes sharply and firmly, and then accelerate sharply and strongly. If the cause of the knocking is in the springs, then in this case it will manifest itself especially strongly. A loose leaf spring clamp may not make noise when operating normally, but may move, making a thumping noise when the center of mass is suddenly shifted by hard braking and acceleration.

In any case, check the fastening of the bolts and nuts of the clamp holding the spring leaves together.

Typically, problems with springs should be corrected as soon as possible, and driving such a car is highly undesirable.

Knock in the suspension not only when driving, but also when turning the steering wheel - ball joints

Ball joints tend to wear out in cars over time under normal driving conditions. In the case where the cause of the knocking in the suspension is the ball joints, the knocking is typical only for the front suspension.

Take a flashlight and visually inspect the ball joints and suspension of the vehicle. Raise one side of the front of the car on a jack and try to shake the lifted wheel - if it has play, then the cause is most likely the ball joint. In addition, you may also feel such play on the steering wheel.

Try turning the steering wheel from lock to lock in both directions - if the ball joints are worn out, the knock will appear not only when driving, but also when the car is stationary.

Racks, supports, springs

A strong knock in the front suspension occurs due to impacts on the car body. This happens when the shock absorption system wears out. In rare cases, the shock absorber spring can also be the culprit of the knocking, but this happens extremely rarely, since the springs are the strongest part of the assembly.

The sound occurs on small bumps when the shock absorbers take a sharp blow. The vibration damping system copes very poorly with such an active load, so rapid wear of the elements during frequent driving on uneven roads leads to such consequences. The result is wear of the rubber layer of the support.

To detect a malfunction, you will have to go through the entire rack, remove it along with the support, and for this you need to dismantle the wheel and partially disassemble the chassis. There will be a lot of work. To make sure it is the strut support that is the problem, you need to measure the distance from the support to the rubber stopper. Ideally, there should be no discrepancies, maximum 1–2 mm.

If the reading is higher, you will have to replace the rubber layer of the strut.

If you don’t want to do this yourself, then the service station will do this work much faster, albeit for a fee. Vibration and knocking should disappear immediately after replacement.

It is extremely rare that the cause of a knock is the rack itself, which has become severely worn out due to constant loads. The sound will be very loud, and the car will shake considerably on bumps.

Checking the strut is quite simple: press harder on the hood. If the rack is faulty, the car will sharply return to its original position with a characteristic loud knock, while the body will sway a little.

The source of the sound may be a loose nut inside the mechanism that can be tightened.

Well, the latest option is a complete malfunction of the shock absorber mechanism. This happens as a result of accidents and collisions. At first, no attention is paid to the knocking, but the problem is discovered much later.

Knock in the front suspension on small bumps - determine the causes and options for eliminating them

Malfunction in the lever system

Very often the problem is wear of the silent blocks of the levers. As a result of their wear, the system begins to “play” and knock. At the same time, the car’s controllability deteriorates, and accordingly, traffic safety is greatly reduced. To troubleshoot silent blocks, you will need a jack and a pry bar.

First of all, you need to jack up the wheel to hang it completely. Then use the pry bar as a lever, applying load to the suspension arms in different directions, i.e. shaking them from side to side. If play with a dull tapping sound is detected, then your diagnosis is correct. In the same way, you need to check the levers of the second wheel.

You can even replace the hinges yourself. To do this, first of all it is necessary to dismantle the levers. To remove the old joints from the arms and install new ones, you will need a special tool designed specifically for your make and model of car.

When do the supports knock?

If you hear a dull knock on the left or right when driving over potholes, bumps and other uneven surfaces, the cause may be wear on the shock absorber strut support. It is a rubber damper gasket through which the load from the shock absorber is transferred to the body. Over time, the rubber wears out and loses its elasticity, which leads to knocking noises.

To make sure that the diagnosis is correct, you need to measure the gap between the support and the stop plate. It should be within 8-10 mm. If the gap is increased, the support must be changed. It must be said that access to the support is usually difficult. To dismantle it, you need to release the upper part of the shock absorber, as, for example, on a VAZ Kalina car (below in the photo).

To visually assess the condition of the bearing and replace it, it is necessary to dismantle the shock absorber strut and support.

Balloons are no joke

The cause of knocks and squeaks is often wear and tear on the ball joints. This is a very important part in the form of a hinge that connects the wheel hub to the suspension arm. True, ball joints usually knock only on rear-wheel drive cars with a simple suspension. On front-wheel drive vehicles, the malfunction manifests itself in the form of a squeaking sound. The exception is cases when wear reaches a critical value, i.e. the hinge begins to simply dangle in the body.

To verify that the ball joint is faulty, you need to hang the wheel, press the brake pedal and try to turn the wheel left and right. If there is play and knocking, then the ball needs to be changed. It must be said that in some cars, such as the Lada Granta or VAZ 2110, the ball joint is bolted on, so replacing it is not difficult. But sometimes there are supports that are pressed into the lever (Mercedes CLS W219 or SsangYong Rexton). Accordingly, they are replaced along with the lever, even if it is still in good condition.

If no play is detected, you need to check the condition of the boot. The fact is that often the cause of noise in ball joints is dirt getting under the joint. Therefore, you need to add lubricant to the hinge and replace the boot.

What other components cause knocking?

If you have checked all the components described above, but have not found out the cause of the knocking, pay attention to the stabilizer bushings. As a rule, their wear is accompanied not only by knocking on bumps, but also by creaking

By the way, it is for this reason that the rear suspension most often creaks.

On some cars, such as the Ford Focus or Renault Duster, the engine mounts are a whole mechanism with rubber bushings. Therefore, the knocking noise may be caused by wear of the bushings. Malfunctions of the supports can only be determined visually by carefully inspecting all engine mounting components.

Do I need to depress the clutch? Do I need to put it in neutral?

Actually, where did all this come from? Coasting was invented by our grandfathers and great-grandfathers. In those days, engines were weak and unreliable, so it was necessary to regularly let them cool down - reduce the speed to idle, for which they turned on neutral. In addition, older cars saved fuel this way. It’s logical: lower engine speed means lower fuel consumption.

What about today? Today's engines are as reliable as nails and as healthy as oxen. They do not require additional cooling, especially such as turning on neutral, and are even designed for intensive work at high speeds.

Fuel economy

As for fuel consumption, there has been a forced idling mode for about 30 years now. Its essence is that when you release the gas pedal while the gear is in gear, fuel stops flowing into the engine, and consumption during deceleration is zero. Hard to believe? If the trip computer in your car can calculate instant fuel consumption, try it yourself and look at the fuel consumption readings during braking. You will see there nothing more than a zero without a stick. And when driving in neutral, the engine idles and consumes 1-2 liters of fuel per hour. It turns out that braking in gear with the gas released is more economical than in neutral or with the clutch pedal depressed. I cover the entire topic of economical driving in our school’s exclusive course “MBA course for drivers: Mastery of Car Driving.”

Design characteristics

An important technical characteristic of the Kalina’s front suspension is the presence of shock absorber elements in the strut. In the design of the car, the lower arm and the steering knuckle in a pair are fastened simultaneously with the cross member related to the front suspension, which is carried out using a ball joint. Similarly, due to silent blocks, the brake pads are mated to the suspension.

To adjust the angle of the steering axis, the suspension uses washers that are located in the connection formed by the lever and the brace. The angular contact bearing can be fixed to the wheel drive using a nut. When repairing Kalina's front suspension, it is imperative to take into account the extent to which the process of adjusting components and structural parts is possible.

Lada Kalina hubs are characterized by the presence of fastening nuts, which are interchangeable. They can only have right-hand threads. The presence of a rod, which is a stabilizer, ensures the stability of the transverse, being responsible for it. Its knee, which has rubber hinges, must be secured to the suspension when using silent blocks with racks. Fastening the torsion bar part to the body is ensured by the presence of brackets.

It must be taken into account that the design of the suspension sometimes requires the driver to carry out certain measures that are aimed at strengthening the elements of the strut supports (cups). This allows you to increase your mileage without worrying about suspension knocking.

Improved suspension scheme

Kalina is equipped with SSAZ suspension. At the same time, installation of CC20 or KAYABA models on a car is associated with their best characteristics, while the first guarantees silent operation, which is combined with high reliability.

Posts 1 to 25 of 63

1 Topic by anatolii 01/31/2015 18:01:39

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Topic: Knock in supports

I have the first one with a larger hole, there is a metallic knock, as they say, “the stand is falling”? On a speed bump too, if you drive a little faster, then with such a blow the wheel falls off. How do you fight this?

2 Reply from .gsm 01/31/2015 18:25:33

- .gsm

- Newest Member

- Inactive

- Messages: 2

- Thank you: 0

Re: Knock in supports

I have a mileage of 1000 km on bumps, the rear strut seems to be knocking, I'm waiting for 2000 km

3 Reply from anatolii 01/31/2015 18:29:43

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Re: Knock in supports

I have a mileage of 1000 km on bumps, the rear strut seems to be knocking, I'm waiting for 2000 km

4 Reply from 7TT 01/31/2015 18:55:02

- 7TT

- Participant

- Inactive

- From: Orenburg

- Messages: 690

- Thank you: 58

Re: Knock in supports

I have a mileage of 1000 km on bumps, the rear strut seems to be knocking, I'm waiting for 2000 km

Check the top nut first.

5 Reply from max-xx 01/31/2015 20:04:45

- max-xx

- Moderator

- Inactive

- From: Moscow

- Messages: 2,886

- Thank you: 375

Re: Knock in supports

Pull the pendant to start. I didn’t notice any iron in myself in the indicated situations. Yes, the suspension worked. but without unnecessary overtones. Mileage 7.5 t.km.

6 Reply from Vadyai 01/31/2015 23:26:22

- Vadyai

- Participant

- Inactive

- From: Ulyanovsk

- Messages: 77

- Thank you: 4

Re: Knock in supports

I have the first one with a larger hole, there is a metallic knock, as they say, “the stand is falling”? On a speed bump too, if you drive a little faster, then with such a blow the wheel falls off. How do you fight this?

This is normal, the struts hit the return line - you need to drive more carefully.

7 Reply from 7TT 01/31/2015 23:46:33

- 7TT

- Participant

- Inactive

- From: Orenburg

- Messages: 690

- Thank you: 58

Re: Knock in supports

This is normal, the struts hit the return line - you need to drive more carefully.

This is not normal!, - the racks should not be hit either forward or backward, - ammas for replacement.

8 Reply from .gsm 01-02-2015 13:24:41

- .gsm

- Newest Member

- Inactive

- Messages: 2

- Thank you: 0

Re: Knock in supports

yes rear right. fastening nut inspected and tightened

9 Reply from denisl56 01-02-2015 14:11:31

- denisl56

- Participant

- Inactive

- From: Orenburg

- Messages: 637

- Thank you: 46

Re: Knock in supports

On Kaliny, this is everywhere, the design highlight of SAAZs.

10 Reply from vl116rus 01-02-2015 14:41:04

- vl116rus

- Participant

- Inactive

- From: Tatarstan Nizhnekamsk

- Messages: 802

- Thank you: 129

Re: Knock in supports

On Kaliny, this is everywhere, the design highlight of SAAZs.

I confirm that the sound is the same on the DOSH.

11 Reply from anatolii 01-02-2015 15:06:35

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Re: Knock in supports

I have the first one with a larger hole, there is a metallic knock, as they say, “the stand is falling”? On a speed bump too, if you drive a little faster, then with such a blow the wheel falls off. How do you fight this?

This is normal, the struts hit the return line - you need to drive more carefully.

Where else can you be more careful? Speed on recumbents 15 mph maximum. And it turns out that the roads in our town are not particularly bad, and you need to drive 10 km/h? It seems like I haven’t seen any such riders. Why such a car with such a suspension, on which I can only drive as quietly as a turtle without knocking.

12 Reply from anatolii 01-02-2015 15:12:42

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Re: Knock in supports

yes rear right. fastening nut inspected and tightened

I also confirm this knock, from the rear right! On TO-0, “not detected” was noted everywhere. They didn’t seem to find a knock in front, a knock in the back, a howling transmission, or a gap in the hood where a finger slipped through with a whistle. So don’t put too much hope that MOT will get rid of it for you.

13 Reply from max-xx 01-02-2015 16:18:22

- max-xx

- Moderator

- Inactive

- From: Moscow

- Messages: 2,886

- Thank you: 375

Re: Knock in supports

I pass the police without worrying about 20 and a little higher. Pits earlier, after Matiz, with caution. Now how will it work out. Almost all cars have questions for the rear amams, I won’t write about Matiz. there is slag coming from the factory. It seems to me that we are escalating this issue. For me, the pendant came out quite decent.

14 Reply from anatolii 01-02-2015 16:39:38

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Re: Knock in supports

I pass the police without worrying about 20 and a little higher. Pits earlier, after Matiz, with caution. Now how will it work out. Almost all cars have questions for the rear amams, I won’t write about Matiz. there is slag coming from the factory. It seems to me that we are escalating this issue. For me, the pendant came out quite decent.

Duck here on police stations and pits the knocking is hard in front, but in the back when driving there is such a small knocking noise that is unpleasant

15 Reply from max-xx 01-02-2015 16:59:26

- max-xx

- Moderator

- Inactive

- From: Moscow

- Messages: 2,886

- Thank you: 375

Re: Knock in supports

I hear work ahead as I drive by. I don't consider this a crime. No clang, no knock. Keep in mind that we have gas and meat. And this is tougher.

16 Reply from anatolii 01-02-2015 17:22:38

- anatolii

- Participant

- Inactive

- From: Degtyarsk (Ekaterinburg)

- Messages: 38

- Thank you: 2

Re: Knock in supports

I hear work ahead as I drive by. I don't consider this a crime. No clang, no knock. Keep in mind that we have gas and meat. And this is tougher.

Those. nevertheless, this is the case for everyone and this knock is called “rack work”?)))

Source: datsun-do.ru

Knocking in the suspension when driving on bumps and uneven surfaces: Causes and consequences

A knock in the front suspension usually appears suddenly and can alarm anyone, even the most experienced driver. This problem almost never occurs in new cars, but the older the “iron horse”, the greater the likelihood of such troubles occurring. This review is about the most common sources of sound in the suspension.

The first place to start inspecting a car is with the levers. As soon as some defect occurs in the latter, the suspension begins to knock. Among the most common defects is wear of rubber-metal hinges (silent blocks). If the steering wheel begins to oscillate while driving, this can lead to deterioration in the car’s controllability, and at high speeds such a problem can even lead to a run off the road, so there is no point in wasting time checking and repairing it. In order to identify the wear of the rubber-metal hinges, you just need to shake the ends of the rods with a mounting tool. The problem in silent blocks can be eliminated by replacing them.

When checking the car, attention should also be paid to the tie rod ends. The knocking noise may be caused by large play of the finger in the socket

Play in this area can be detected in another way, simply by shaking the steering wheel from side to side.

A knock in the front suspension can also occur due to ball joints that may have worn out a long time ago. You can get rid of such a knock only by completely replacing the worn part. The main task assigned to the ball joints is to turn the steered wheels. This part takes on the maximum load that appears on a poor-quality road surface. You cannot delay replacing ball joints - the longer you delay, the greater the likelihood that they will tear out and the vehicle will immediately lose control.

When inspecting the front suspension, look at the condition of the steering wheel caps and supports. The purpose of such covers is to protect the hinge from contamination. If the protection is defective and dirt gets on it, this will greatly reduce the service life of the part.

Often the cause of a knock can be a failed shock absorber, which often becomes unusable due to improper use, as well as in cases where the car is operated in difficult conditions. You can understand the condition of the shock absorbers on uneven roads. If after a bump the car rocks in all directions, then there is a problem with the shock absorbers.

You can also check the condition of the shock absorber after removing it from the car. After dismantling, the part is installed in a vertical position, and then the rod is pulled out/lowered several times. If, when moving the rod upward, less resistance is felt than when the same manipulations are performed in the opposite direction, this indicates a malfunction of the shock absorber. If the rod moves too freely, then there is a lack of working fluid.

If you notice a knocking sound in the suspension of your car, do not hesitate and take the necessary measures immediately. If you cannot carry out repairs yourself or doubt your abilities, contact professionals. By the way, even if the suspension does not bother you, experts strongly recommend checking its condition about twice a year.

When did they start installing the cable box?

In 2013, AvtoVAZ decided to abandon the 5-speed manual transmission with index 1118, which was installed only on the Lada Kalina since 2004, in favor of a newer transmission, also with 5 gears. Thus, the cable box on the Kalina received serial number 2181.

Why did they abandon the rocker box?

There are several reasons why the manufacturer abandoned the rocker box. Firstly, to reduce the vibrations that occur on the lever connected to the transmission through a rigid rod, as a result of which they switched to a cable gear shift drive. Secondly, when installing multi-cone synchronizers, the force applied to shift first and second gears also decreased. Thirdly, to make gear shifting easier, the bevel angle of the synchronizer teeth was reduced.

Gearbox slide

Next, in order to stop oil leaks, it was necessary to move the gear selection mechanism from bottom to top, which was done. A selector plate was also installed, which resulted in clearer gear shifting. Well, to prevent the driver from accidentally engaging reverse gear, an electric lock was installed instead of a mechanical one, as on the previous gearbox.

Due to the fact that the gearbox gears are not sufficiently processed and have a tolerance of 0.2 mm, many Kalin owners complain about the “howl” of the transmission.

Another reason for abandoning the 1118 manual transmission is unclear gear shifting, especially on a warm engine, which is why owners have to adjust the gear control drive. The process is certainly not complicated, and even “two schoolchildren” can cope with it, but it’s still not pleasant.

As with all other AvtoVAZ transmissions, transmission seals are also famous for their low reliability; due to the manufacturer’s savings on seal material, oil leaks from the box. Replacing oil seals is not an expensive procedure, but if you miss the moment, the lack of lubrication in the manual transmission can lead to serious consequences. Fortunately, to check the oil level in the gearbox there is a special dipstick, which is located near the battery.

Left drive oil seal

AvtoVAZ determines the service life of this manual transmission at 160-180 thousand kilometers until it is completely replaced. But in practice, for a comfortable ride, Kalin owners change or upgrade most of the transmission components already within the first 100 thousand mileage.

How is a cable gearbox better than a rocker gearbox and why?

Having taken into account all the negative reviews from Kalina owners about the rocker transmission, AvtoVAZ decided to install a cable box on Kalina since 2013. For the first time, they began installing a cable gearbox on Kalina, Granta, and Priora, which were equipped with 16-valve engines

For the first time, they began installing a cable transmission on the Kalina, Grant, and Priora, which were equipped with 16-valve engines.

As a result of replacing the rigid gearbox control drive with cables, some of the shortcomings associated with the rocker manual transmission were eliminated. In particular, the travel of the gear lever has been significantly reduced, and the gear shifts themselves have become clearer. The vibration on the gearshift lever has almost disappeared, but still not completely, and car owners also slightly modified this mechanism. This suggests that problems with the cable drive of the Lada Kalina gearbox were also present, but were not as noticeable as with the previous transmission.

AvtoVAZ recommends filling this manual transmission not with mineral oil, as was the case before, but with synthetic oil. Thanks to this, even at sub-zero air temperatures, the gears are switched on “cold” with ease, and there is no need to wait for the oil in the transmission to warm up, because synthetics retain their operating properties at a much greater minus, unlike mineral oil. Also, the volume of oil poured into the box has decreased, since the gearbox itself has become more compact.

Lada Kalina knocking on the right side

front struts need to be looked at

front struts need to be looked at

What does large longitudinal play of the drive mean? Do the grenade bodies play longitudinally or does the axle shaft itself move in the outer grenade? I had a problem, the grenade began to crunch periodically, I didn’t look hard for the reason, I bought a new one, when replacing it, it turned out that the retaining ring, which from the inside of the axle shaft limits the depth of the CV joint on the axle shaft, jumped out of the slot and slid a little towards the box, so the axle shaft started move freely along the splines and go a little deeper into the grenade, longitudinal play of the axle shaft appeared, therefore the axle shaft began to cling to the outer CV joint body and a characteristic crunch appeared under sudden loads during straight-line movement, it does not sound like a knock

What does large longitudinal play of the drive mean? Do the grenade bodies play longitudinally or does the axle shaft itself move in the outer grenade? I had a problem, the grenade began to crunch periodically, I didn’t look hard for the reason, I bought a new one, when replacing it, it turned out that the retaining ring, which from the inside of the axle shaft limits the depth of the CV joint on the axle shaft, jumped out of the slot and slid a little towards the box, so the axle shaft started move freely along the splines and go a little deeper into the grenade, longitudinal play of the axle shaft appeared, therefore the axle shaft began to cling to the outer CV joint body and a characteristic crunch appeared under sudden loads during straight-line movement, it does not sound like a knock

- Replacing an additional brake light for a Volkswagen Polo sedan

- How to get rid of a grant

- VAZ 2108 installation of idle air plug

- Suzuki Grand Vitara 2008 front control arms which are better

- VAZ 2112 does not drive

Brake pads

On uneven roads, the brake pads may knock or rattle over bumps.

On VAZ 2101 - 2107 cars, pressure springs are provided (popularly called “gulls”), which are designed to hold the pads and press them against the caliper and guide pins so that they do not rattle when driving over bumps and holes.

Over time, these springs lose their properties, as a result of which knocking noises can be heard in front of the suspension.

To check this while driving, press the brakes; if the drumming disappears when rolling, it means the brake pads are knocking.

On other cars you also need to look at either the pressure springs or the petals; they can either fly off or lose their properties over time. Only replacing them can save the situation.

Dangers of coasting

Trying to save on a drop of fuel often creates additional difficulties for other drivers while driving. On a slippery surface, rolling up is all the more dangerous - the driver will not be able to get the car out of a skid, and frantic attempts to regain control often lead to erroneous actions. Before descending, especially in winter, lack of control over gear shifting and engine braking can lead to irreparable consequences.

Turning off the engine, which is often accompanied by coasting, is especially dangerous. This completely removes control from the driver. If this is a modern car brand, it is probably equipped with power steering and power brakes, which only work when the engine is running. Turning the key in the lock can cause the steering wheel to lock. And all this while the car is moving!

The steering rack is a quiet, separate element with sophisticated diagnostics

It often happens that after reassembling the entire chassis, it is time to check the steering rack. By moving the steering wheel left and right, you will hear small knocks if the rack has already begun to wear out. But this does not mean at all that it knocks during operation. It is difficult to give general recommendations here; there are different recommendations for owners of different cars:

- It’s worth visiting specialized forums and reading information about how and when the steering rack fails, how you can check and fix it;

- tightening the steering rack is a solution for a few days; soon it will start knocking again if a problem is identified with this particular element of the car;

- the knock of the rack is often a distinct feedback on the steering wheel, as well as on the body in the area where the control pedals are attached, so diagnosis will not be difficult;

- Sometimes steering tips or rods knock, which is more difficult to check, but you can perform a full diagnosis in a pit without any problems or inaccuracies.

The steering system likes to knock in domestic cars, as well as in cars older than 10 years. Changing the steering rack is very difficult due to the high cost of spare parts and the rather inconvenient location in many cars. Therefore, they prefer to perform this process on a service. Professionals will complete all tasks quite simply and quickly.

Struts and strut supports are a problem for every car

Even high-quality and reliable racks begin to struggle with unevenness and knock after prolonged use. For a Chinese spare part, a long service life of 1000 kilometers is considered, for an original Japanese or European one - 15-20 thousand. Struts and upper supports regularly fail on cars in Russia, and the reasons for this can be very different:

- the strut itself rarely fails completely; when the car is rocking, creaking and extraneous sounds will be heard, and the knock will be heard throughout the entire suspension at once;

- the support in most cases fails at the moment when the support bearing breaks, this happens in the event of a sudden collision with large uneven roads;

- Perhaps a simple tightening of the support or shock absorber fastening at the top point will help you; you need to check all fastening elements;

- If the struts break down, they may leak, which will be visible on the body, but this is not a prerequisite, but simply a recommendation for additional diagnostics of the suspension element.

Unpopular reasons for knocking

It would be a good idea to check the anti-roll bar bracket. This part consists of bushings based on metal and rubber, which are turned in different directions and connected by a thin isthmus. Most often it is he who breaks down. On rough roads, on small bumps and on turns, you can hear a knocking sound.

For a correct diagnosis, you need to pull the end of the stabilizer with one hand. This will work better if the wheels are turned to the right.

It happens that the motor mounts wear out. The engine moves actively at increasing speeds and on uneven surfaces. At certain moments, he reaches the body with the generator and oil pan. The result is a knock. This source of knocking is rarely guessed at. Many people change the suspension, but replacing the front suspension does nothing in this case.

Anything can knock in cars. For example, washer barrels. If it is poorly secured in place, the race will knock. There are also many other mysterious culprits behind such sounds.

How to check a support bearing

There are three methods for checking the support bearing at home: Remove the protective caps and press the upper element of the front strut rod with your fingers. Now we begin to rock the car from side to side by the wing. We do this both longitudinally and transversely. If the bearing fails, you will hear the same knocking noise as when driving. At the same time, the car body will swing, but the pillars will either stand still or swing with less amplitude.

You can place your hand on the front shock absorber spring coil. Then you need to turn the steering wheel in different directions. For this you will need an assistant. If your hand feels a recoil and a metallic knock sounds, things are bad with the bearing. You can also drive first on a flat road, and then on a rough one, and listen to what sounds the car makes. If you hear metal knocking from the front arches under extreme loads, then the problem is most likely in the support bearing.

It is worth understanding that partial or even complete failure of the support bearing is not a critical failure for the car. However, this does not mean that you can safely drive such a car. In addition, in domestic realities it is better to carry out diagnostics every 10-20 thousand km.

And it doesn't matter whether there are signs of malfunction or not

You need to maintain your car regularly, otherwise you can become an example of careless and dangerous “care” for your car. And that's not very fun.

https://www.youtube.com/watch?v=VLNGuUsv4DM

To avoid serious damage to car systems, you should pay attention to the slightest knock or creaking noise under the hood. If you stubbornly ignore seemingly minor signs of malfunction, then serious problems cannot be avoided.

In particular, this is a knocking sound when turning the steering wheel. It may indicate a faulty front strut upper support bearing.

The front strut support bearing is an important part of a car's suspension. Unfortunately, most drivers pay minimal attention to the health of their suspension systems. But in vain, given the state of domestic roads and, sometimes, the low quality of parts that are installed on modern cars. But it is the suspension that is responsible for car handling and road safety.

Its maintenance is complicated by the variety of parts, and they all perform their functions: brackets, springs, shock absorbers, and so on. In this article we will talk specifically about the support bearings of the front strut, since these parts are subject to increased wear and often fail.

Causes of shock absorber knocking

So, if everything is in order with the bushings, why might the shock absorber be knocking?

Oil leaked.

Yes, can you imagine there is oil in the shock absorber!!! (joke).

Carefully inspect the shock absorber that is knocking. If there are oil leaks on its outer side, then immediately buy a new shock absorber, or better yet two, to replace them on one side of the car.

There is a knock, but there are no external signs of oil leakage.

In this case, there may be several reasons for the shock absorber knocking.

The first thing to do is simply rock the car by pressing on the surface of the car in the place that is located above the suspicious shock absorber.

The swinging should immediately stop smoothly.

If smooth vibrations occur for a few seconds, then that’s it, the shock absorber is in trouble.

Internal damage.

This means that the shock absorber knocking occurs due to some internal damage. This could be a broken thread or even a slightly bent rod, or the shock absorber pipes are disconnected. In general, mechanical damage and breakdowns.

It is not recommended to repair the shock absorber in these cases; it is better to replace it.

Internal oil leak.

In addition to external oil leaks, there is also an internal leak, which is when oil from one cylinder, the internal one, flows into another, the external one.

POPULAR WITH READERS: The CV joint is crunching, how to check and fix the problem

As they say, a holy place is never empty, the oil has gone, the air has come. The airy area of the shock absorber can be eliminated and the knocking noise will stop.

You can do this either yourself or at a car service center. It all depends on the shock absorber model, i.e. This problem can be solved and there is no need to buy a new shock absorber.

Advantages of manual transmissions

Twenty years ago, the most popular were manual gearboxes, which were universal and practical to use. Even today, when functional automatic transmissions have appeared, time-tested mechanics are also relevant and in demand among buyers of new cars.

The main advantages of such mechanical transmissions are excellent reliability, vehicle practicality, simplicity of design, ease of maintenance and repair. If automatic transmissions require high-quality maintenance and frequent repairs, then the mechanics can last for many years without causing any trouble to their owners. You just need to remember certain rules for using such a car, which will allow you to avoid increased fuel consumption and the occurrence of characteristic malfunctions.

Causes

There are many reasons why a knocking sound appears while driving, even on small bumps or when turning, so you need to check everything at once.

First of all, you need to check the silent blocks. To check, you need to use a pry bar or crowbar. The pry bar will be useful as an extension, with which we will press on the levers. During such a check, significant play can be identified. Often, dismountable structures are installed on machines; in this case, to replace the silent blocks, you will need to remove the lever and remove the silent block from it. After the broken silent block is removed, you need to clean the shrinkage area for the new one and lubricate the new silent block. This is necessary to prevent it from squeaking even on small bumps. If they were the reason, then the knocking in the front suspension will disappear even when driving on a rough road.

But other troubles also happen, the elimination of which will require a little more effort and time. Such troubles usually include problems with the steering rack. The problem is that many drivers, regardless of experience, blame the shock absorber struts or even the support bearing in this case. But there are a couple of reasons why you can definitely determine a breakdown in the steering rack and eliminate the knocking sound in the front suspension.

- The first reason why you can determine that the breakdown is in the steering rack is a dull knock in the front suspension on one side, precisely on the side where the steering wheel of the car is located.

- The second reason for this is that vibration appears in the steering wheel while driving, even on small bumps or on a road covered with crushed stone or gravel. The fact is that when the steering wheel is turned, the rack interacts with the gear, as a result of which the gap between them increases. To accurately determine a breakdown in this device, you will need to shake the steering rods in different directions. If play has formed, then this is the reason why a dull knock is heard in the suspension. This problem can be fixed by simply tightening the racks and gears, and the bushings in which wear has formed can be repaired using a special repair kit, which can be purchased at any car store.

- In addition, the problem may also be in the hinge. You can check the play in this device only if someone turns the steering wheel and you observe his behavior. In this case, the play will be noticeable immediately, and it can be eliminated by simply replacing the hinge. In this case, repairing the suspension will cost much less than it would be done at a service station.

- Another reason why your suspension may be making a loud clunking sound when driving on rough roads or even while turning is a problem with the strut mount. During this problem, a dull knock will occur in the front suspension area. The problem is that many drivers, who take their car to a service station, change the entire front and rear suspension, which costs a lot of money, but still do not get rid of the knocking noises. In this case, a strong knock is produced due to the fact that the rubber damper of all knocks becomes hard over time and does not dampen all vibrations, but on the contrary gives more knocking.

Let's sum it up

It is worth using various methods to test equipment before replacing. Otherwise, because of one knock, you can change half of the suspension without eliminating the cause of the problem. Therefore, you should always approach diagnostics from different angles and use the services of testing suspension parts at several service stations. You can change parts only if you are sure that certain mechanisms are faulty. You should approach the issue of repair with full understanding so as not to spend too much money on this process. Many novice drivers simply buy every part that they are guilty of, and as a result, repairs are very expensive.

There are certain difficulties in diagnosing the chassis of a modern car. It is not at all clear which element may be causing the knocking. There are a number of possible options, they are all interconnected, and even analysis does not answer the question. Therefore, it is very difficult to use the full picture of the breakdown to purchase the spare parts necessary for repair. Sometimes you have to change parts just at random, not getting the result on the first try. There are various repair options available, but to do so you need to pinpoint the problem. How do you usually diagnose and repair the chassis of your car?

A knock in the front suspension on small bumps is one of the signs that some of the chassis parts are damaged or almost completely worn out. Novice motorists, without much hesitation, take their car to a service station for diagnostics and shell out considerable sums for repairs. However, there is no guarantee that the knocking will disappear and its source will be found. You can not only identify but also eliminate most of the causes that cause knocking on your own.

Features of Kalina's suspension

A detailed inspection of Kalina’s suspension reveals hydraulic shock-absorbing struts, which are attached to the steering knuckle in the lower part, being the basis of the entire structure of the unit. The bolt located in the upper part of the steering knuckle allows you to adjust the camber element.

In the assembly, the upper part passes through a hole that is located in the existing bracket. The body part is equipped with a mudguard, to which the top of the rack is fixed using three nuts. Due to the existing elasticity of this unit, high-frequency vibration is excellently damped. In this case, a characteristic swaying of the Kalina suspension strut occurs during the working stroke.

Kalina's suspension, which is characterized by the presence of conical or coil springs, ensures a particularly smooth ride due to the presence of a stabilizer. This allows you to avoid compromising the lateral stability of the car. This function is also performed by levers that relate to transverse braces. The bearing for turning the strut must allow the wheels to turn.