Car : Lada Kalina. Asks : Petrov Sergey. The essence of the issue : When driving on a rough road, a knock appeared in the steering rack!

Hello! I had this problem! When driving on an uneven road or, for example, when driving on crushed stones or just stones, a knock appears in the steering rack! I can just feel how everything is going into the steering wheel. Tell me how to fix this and is it possible to somehow fix this problem?

Malfunctions of RM Kalina and ways to eliminate them

Even the most reliable mechanisms wear out, especially if they are not protected from dust, dirt, water and aggressive environments. Although the steering rack of the Lada Kalina is located under the hood of the car and is protected from below by a pallet, during operation, especially in off-road conditions, it is exposed to all of the listed factors. The main malfunctions of the PM can be grouped into three groups:

- large free play of the steering wheel;

- knocking, noise and creaking in the mechanism;

- tight steering wheel.

Increased play, squeaks and knocking of the Kalina PM can be caused by:

- loosening the tie rod nuts,

- wear of their tips and silent blocks,

- loosening the PM fastening nuts,

- large gap between the rack and the adjusting nut.

These faults are easy to fix: you need to tighten the nuts and pin them where necessary, and replace the silent blocks with new ones.

Difficulty turning the Lada Kalina steering wheel can be caused by more serious reasons:

- wear of the bearings of the upper support of the steering column upper universal joint,

- damage to the rack support bushing,

- failure of the telescopic strut of the front suspension,

- faulty electric power steering or low tire pressure.

Many Lada Kalina owners are interested in whether it is possible to replace the standard rack with a mechanism of a different design. It's possible, but not necessary. The manufacturer does not structurally provide for the replacement of the rack and pinion steering mechanism with other types. Worm or screw PMs simply won't do. To facilitate steering wheel rotation, an electric power steering is installed on all Kalina models.

Editorial Lada Kalina: civil breakdowns

Our Lada Kalina withstands racing loads, but periodically upsets us with annoying breakdowns and shortcomings that are associated with normal everyday use. Let's refresh our memory of previous faults and add new items to the list.

Kalina managed to cover approximately 65,000 km. During this time there were many breakdowns. Let's focus on those that are in no way related to participation in amateur competitions. The long-term presence of Kalina of both generations in the world of motorsport at any level will help separate the flies from the cutlets. Servicemen with extensive experience in servicing civilian vehicles will also act as arbitrators.

Editorial Kalina adequately withstands the stress of racing tracks and often pleasantly surprises with its durability. But in everyday life it often upsets. Paradox!

Editorial Kalina adequately withstands the stress of racing tracks and often pleasantly surprises with its durability. But in everyday life it often upsets. Paradox!

In previous episodes

Causes of bearing failure

The main cause of support bearing failure is dust and water, which inevitably penetrate inside. The lack of lubrication does not have the best effect. Sharp blows to the rack will not add to the service life

It is worth taking into account the quality of roads, because they have a direct impact on the natural wear of the support bearing. That is why with us, a part can wear out faster than its manufacturer claims

Dirt and sand are some of the hardest impacts on a bearing. We remember that a journal bearing is a type of rolling bearing, and it does not have any protection mechanisms against harmful factors. Driving at high speeds and harsh brakes, especially on bad roads, also do not add to the service life of the part in question. However, not only the bearing itself suffers from this, but also all other suspension elements as a whole will soon require repair.

Basic work on adjusting the mechanism

The main type of repair work on the steering mechanism is considered to be its adjustment, while if the steering rack on Kalina can be adjusted independently, then adjusting it on a sports modification of the car is quite problematic.

Repair of the Kalina steering mechanism may be necessary for the following reasons:

- loosening of the steering rack fasteners;

- wear of steering racks or gears;

- poor pair engagement adjustment;

- high degree of wear of the bushing in the place where it connects to the rack and steering rods.

The rack is tightened in order to use this procedure to reduce or completely eliminate backlash in the mechanism for controlling the direction of movement of the car.

This allows you to significantly improve vehicle control in different road and weather conditions. In addition, it may be necessary to tighten the steering rack even if it was initially configured incorrectly. To do this, they usually loosen the tightening of the adjusting screw, which makes the steering wheel easier to move and makes it easier to control the car.

In addition to adjustments, if difficulties are identified in its operation, it makes sense to lubricate the steering mechanism. You can find out how to do this and how to adjust the steering rack from. In addition, it indicates the type of lubricant recommended by the manufacturer and describes the design of the steering rack.

In this case, there are 2 ways to carry out the operation of adjusting the steering mechanism:

- with dismantling the rack;

- directly by car.

The steering mechanism is usually dismantled in the event of a serious breakdown, that is, when it directly occurred. Usually, some parts of the mechanism need to be replaced, and not all car owners can carry out this procedure on their own.

In the same case, when it is necessary to carry out relatively simple procedures, for example, eliminating play and knocking, as well as tightening or loosening the rack, this can be done independently, without removing the steering mechanism from the car. You can involve a more experienced car owner for consultations.

The serviceability of the steering system of any car is an important safety requirement on the road. Repair of the steering rack on Kalina must be carried out when any suspicious sounds occur. As practice shows, many car enthusiasts are calm about the fact that when turning the steering wheel there is a knocking or creaking noise, but this may indicate that the steering rack is knocking. Repairing the steering rack on Kalina is best done at a service station, but you can do it yourself.

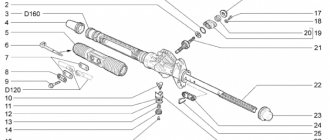

Steering mechanism: 1 – boot; 2, 20 – bolts; 3 – washer; 4 – oil seal; 5 – crankcase cover; 6, 17 – sealing rings; 7 – separator; 8 – drive gear with bearing; 9 – steering rack; 10 – left protective cap; 11 – rod support; 12 – bracket; 13 – plug; 14 – stop nut; 15 – stop spring; 16 – retaining ring; 18 – rack stop; 19 – stop liner; 21 – locking plate; 22 – cover plate; 23 – clamp; 24 – protective cover; 25 – right protective cap; 26 – steering gear housing

Diagnostics of the condition of components and troubleshooting

After carrying out a visual inspection of the suspension of the Lada Kalina, which will allow you to find out the cause of the knocking, you can proceed to dismantling the faulty elements. For example, car shock absorbers. Diagnostics are carried out by placing the car over an inspection hole or using a jack

Particular attention is paid to elements adjacent to the body or car frame

Diagnostics involves a thorough examination of the suspension elements, the presence of various damages, cracks and breaks on them. If a breakthrough is detected in the rubber protection of the steering tip, it must be repaired. Rubber seals are inspected for mechanical damage and those areas where there are breaks and cracks are identified.

As a result of a muffler breakage, a knock will be heard in the suspension. To identify the cause of such sounds, which may lie in the exhaust pipe, the muffler should be rocked in different directions. This is a quick way to diagnose the front suspension. After this is completed, you can proceed to suspension repair.

The front suspension consists of: 1 — nut for securing the upper strut support; 2 - bolt; 3 — upper support of the front suspension strut; 4 — bearing of the upper support of the strut; 5 — upper insulating gasket of the spring; 6 — front suspension spring; 7 — protective casing; 8 — telescopic stand assembly; 9, 10 — nuts securing the strut to the steering knuckle; 11 — bolt with eccentric; 12 - bolt; 13 — steering knuckle; 14 — front wheel drive shaft; 15 — stabilizer bar; 16 - stretching; 17 — lever; 18 — ball joint; 19 — hub; 20 — hub fastening nut; 21 — brake disc; 22 — front suspension compression buffer; 23 — upper spring cup; 24 — compression stroke limiter of the upper strut support; 25 — travel limiter of the upper strut support; 26 — stabilizer strut mounting nut; N - reference size

It is possible to eliminate various malfunctions that occur in the front suspension of the Lada Kalina car if their cause is known. If there are faulty front suspension struts that can knock, they should be replaced. In some cases, they can be repaired.

If during the diagnosis it was revealed that the bolts that secure the stabilizer bar that provides lateral stability to the car body are loose, then they need to be tightened. Worn rubber or rod pads are replaced.

If the fastening of the upper support of the Lada Kalina suspension strut is loose, then it is necessary to tighten the nuts securing this unit. If the front suspension exhibits destruction of the rubber support of the strut, then it must be replaced. If the rubber-metal hinges (silent blocks) are worn out, new ones should be installed.

The presence of a malfunction in the stabilizer bar struts requires replacement. If the front suspension spring settles and the front suspension spring breaks, it should be replaced. If the compression stroke buffer is destroyed, it is dismantled and a new one is installed. If there is increased wheel imbalance, you should contact a tire repair shop so that specialists can eliminate the identified malfunction.

Features of Kalina's suspension

A detailed inspection of Kalina’s suspension reveals hydraulic shock-absorbing struts, which are attached to the steering knuckle in the lower part, being the basis of the entire structure of the unit. The bolt located in the upper part of the steering knuckle allows you to adjust the camber element.

In the assembly, the upper part passes through a hole that is located in the existing bracket. The body part is equipped with a mudguard, to which the top of the rack is fixed using three nuts. Due to the existing elasticity of this unit, high-frequency vibration is excellently damped. In this case, a characteristic swaying of the Kalina suspension strut occurs during the working stroke.

The front suspension of the Lada Kalina is telescopic and has complete independence.

Kalina's suspension, which is characterized by the presence of conical or coil springs, ensures a particularly smooth ride due to the presence of a stabilizer. This allows you to avoid compromising the lateral stability of the car. This function is also performed by levers that relate to transverse braces. The bearing for turning the strut must allow the wheels to turn.

Non-standard cases

It may not be the suspension or steering parts that are knocking. Shocks and body pecks lead to the movement of units. If they “sit” loosely and there is metal-to-metal contact, clinking cannot be avoided.

- Single dull knock when starting off. See rubber-metal engine or gearbox mounts, transmission driveshaft. For example, when starting, the motor may tilt and hit the spar.

- Rattling on small bumps and in turns. Listen to see if there is a knocking sound in the steering wheel when braking; if there is, the brake caliper guides are worn out.

- Intermittent impact sound, more common when turning at low speeds. Malfunction in the differential of a front-wheel drive vehicle.

Tighten the key bolts and nuts more often, refuel only at gas stations with high-quality gasoline, and remember: a worn CV joint does not knock, but crunches, and does this with the wheels turned out.

Causes of creaking and knocking car suspension

A creaking or knocking sound indicates malfunctions in the components of the Lada Kalina. The front suspension rattles more often. This is due to the fact that it is more susceptible to breakdowns than the rear one. Among the various components of the car, the malfunction of which can cause problems with the suspension and knocking in it are the following.

- CV joints.

- Shock absorbers.

- Bearings.

- Steering rod and reaction rod.

- Exhaust pipe.

- Rubber seal, etc.

Knocking can come from parts such as ball joints, silent blocks, front suspension arms, steering knuckle, mounting bolts. Without diagnostics, it is impossible to accurately determine the causes of creaking or knocking in the suspensions in order to effectively carry out repairs.

Only visual diagnostics of the Lada Kalina in the traditional way will help to identify why a knock is heard. A creaking or knocking sound from the suspension can only be associated with a broken rubber band, so there is no need to rush to use the services of a service station; this may take too much time and money.

If an independent visual inspection of the suspension did not reveal the real cause of the creaking or knocking noise, then the car must undergo a full diagnostic and subsequent repair. This will help identify the reasons why suspension knocking occurs.

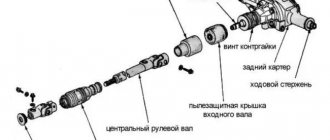

Dismantling and disassembling the electric amplifier

Before removing the amplifier, you need to remove all the steering column switches. Remove the steering rack cover and dismantle the devices, remembering to disconnect the connectors from the power supply.

How to remove the EUR with your own hands:

- After removing the switches, you will need to dismantle the lower cross member of the dashboard. To do this, you need to press the fasteners that secure the connector with wires, and then disconnect the wiring from the control module. Once these steps are completed, you can disconnect the connector from the switches.

- The system bracket is secured with nuts; you will need to unscrew them with a wrench.

- After this, the steering rack will need to be carefully lowered down. To do this, you will need to find the bolt that secures the driveshaft to the booster shaft. This bolt must be unscrewed, but when unscrewing, you will need to fix the nut, this will prevent it from turning. When the bolt is removed, the fastening will need to be loosened, after which the intermediate shaft will be carefully removed. At this stage, we recommend marking the position of the shaft and gears; you can use a marker for this. This step is very important because doing it will prevent possible installation problems in the future. If the marks on the shafts do not match, this may cause problems with the amplifier. When dismantling, be careful not to damage the wiring, as this will also lead to the inoperability of the ESD.

- When the unit is dismantled, it will need to be disassembled and the failed elements replaced. Further editing is done in reverse order (the author of the video is Murzik Bely).

Design characteristics

An important technical characteristic of the Kalina’s front suspension is the presence of shock absorber elements in the strut. In the design of the car, the lower arm and the steering knuckle in a pair are fastened simultaneously with the cross member related to the front suspension, which is carried out using a ball joint. Similarly, due to silent blocks, the brake pads are mated to the suspension.

To adjust the angle of the steering axis, the suspension uses washers that are located in the connection formed by the lever and the brace. The angular contact bearing can be fixed to the wheel drive using a nut. When repairing Kalina's front suspension, it is imperative to take into account the extent to which the process of adjusting components and structural parts is possible.

Lada Kalina hubs are characterized by the presence of fastening nuts, which are interchangeable. They can only have right-hand threads. The presence of a rod, which is a stabilizer, ensures the stability of the transverse, being responsible for it. Its knee, which has rubber hinges, must be secured to the suspension when using silent blocks with racks. Fastening the torsion bar part to the body is ensured by the presence of brackets.

It must be taken into account that the design of the suspension sometimes requires the driver to carry out certain measures that are aimed at strengthening the elements of the strut supports (cups). This allows you to increase your mileage without worrying about suspension chatter.

Improved suspension scheme

Kalina is equipped with SSAZ suspension. At the same time, installation of CC20 or KAYABA models on a car is associated with their best characteristics, while the first guarantees silent operation, which is combined with high reliability.

How to tighten the steering rack on a Priora

Lada Priora is a Russian-made car that is highly popular among our compatriots due to its low price and attractive appearance.

However, even despite this, the Lada Priora has one vulnerability associated with the poor quality of the road surface - the steering rack or, in the language of specialists, the “power steering/power steering gearbox”.

Fortunately, you can tighten it with your own hands.

When does the steering rack need to be tightened on a Priora?

The steering rack is a vulnerable point for the Lada Priora. The first sign indicating the need to adjust the rack is the appearance of a knocking sound when driving over small uneven surfaces.

The knocking will be felt especially clearly when driving on country roads. In this case, the driver will feel shocks and vibrations on the steering wheel, which will also be transmitted to the entire car body. In addition, if the steering wheel adjustment nut is loosened when driving on the highway, the car will “float” a little, and additional steering will be required from the driver, which will also immediately become noticeable.

Experts also say that a tightening is necessary if the driver begins to notice the appearance of a clearly audible crunching sound in the area of the steering column, as well as an increase in the amplitude of the steering wheel rotation.

When tightening doesn’t help and the mechanism needs to be changed

It’s worth thinking about replacing the rack when tightening it does not in any way affect the car’s behavior on the road, and also does not help get rid of the unpleasant knocking noise.

A failed steering rack will cause significant play in the steering wheel. Moreover, it may begin to jam (this happens extremely rarely, but similar cases are known).

If the rack begins to jam, then it is better to stop using the car, as this can lead to the most dire consequences.

You cannot do without a replacement even if after tightening it you managed to get rid of knocks and vibrations, but they reappeared later.

What is needed for work and how to tighten the steering

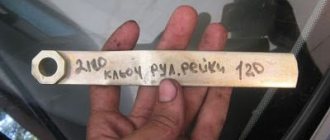

To tighten the steering rack you will need special wrenches. To carry out the tightening you will need the following tools:

To make the work more comfortable and faster, it is recommended to drive the car into a special inspection hole or overpass, and also use an assistant, whose role even a child can handle.

The lower rack fastening nut is not easy to unscrew

To get to the rail, you should perform a number of simple steps:

After this, you will have access to the nut responsible for adjusting the thermal gap in the rail.

Next, you need to put your hand under the steering rack and try to put the rack wrench on the nut.

It is necessary to tighten the nut clockwise, but since the rack itself is located upside down, from the outside it may seem that the nut must be tightened counterclockwise.

It is also necessary to listen to the sounds coming from the steering wheel - if there are no knocks when turning the steering wheel, and there are no other noises, then the rack is tightened correctly, and you can put the battery and rubber plug in their place.

The nuances of working on a car with EUR and power steering

According to experienced auto mechanics, the process of tightening the steering rack on cars with electric steering and power steering is practically no different, so this guide can be called universal.

It is worth noting that the complete replacement process is also identical in the case of electric steering and power steering, with the exception of one point - in cars with power steering, before replacing the rack, it is necessary to drain the fluid from the power steering tank, and in cars with electric steering, remove the terminals from the battery.

Tips for use

A complete replacement and repair is a series of actions, for the implementation of which you need to have not only special knowledge, but also a considerable amount of free time, so if the car owner does not have either the first or the second, it is preferable to go to the nearest service station.

It is better to entrust steering rack repair to service station specialists

At the same time, in order not to become their regular guest, you should know some secrets for operating the steering rack, which can significantly extend its service life.

From time to time you need to undergo a full maintenance, which will allow you to eliminate faults in advance, which can cause irreversible consequences, injury to yourself, your loved ones and other road users. And also, if problems are detected in the operation of the car, it is better not to take risks and go to the nearest car service center as quickly as possible.

Nuances of troubleshooting on Kalina

Sometimes applying lubricant to the shock absorber bushings does not bring positive results; a squeak accompanies the driver when driving on uneven roads. The reason is improper installation of the part, wear of rubber bushings, cushions, and oil leakage.

With such problems, the shock absorber will move freely. Worn bushings must be replaced, installation errors can be corrected by tightening the fastening bolts and nuts. When oil leaks, stains mixed with dirt appear on the shock absorber. It is necessary to simultaneously replace parts on the left and right.

Sometimes it is necessary to remove the crankcase guard to replace the gasket and tighten the bolts. To do this, you need to dismantle the engine splash guard, drain the residual oil, unscrew three bolts, remove the lower clutch housing cover and the engine sump. Then you should replace the gasket and bolts, while tightening them from the middle to the edges.

To eliminate the damage, the steering wheel is completely disassembled

To prevent noise from disturbing the driver, you need to know the correct tightening pattern for the wheel bolts. To ensure even tightening and to avoid figure eight, the bolts are tightened clockwise in the following order:

- 4 bolts - “hourglass”, pattern: 1-3-4-2;

- 5 bolts - “pioneer star”, scheme: 1-4-2-5-3;

- 6 bolts - “radiation”, scheme: 1-4-5-2-3-6.

You need to tighten the bolts by hand, first using a can with a short lever, then with a long one.

A dull knock when turning the steering wheel may come from the front wheels. Springs and shock absorbers are best replaced in pairs. If the driver wants to change the springs because of their age, this is not always reasonable. Ground-in old springs make the suspension soft, and they should be changed if the car owner is not satisfied with the ground clearance, which is measured in the front of the car.

When replacing a spring, trouble may arise.

- The new part will burst.

- A creaking and crunching sound will appear in the CV joint.

- You will have to do the alignment several times.

If the cause of the knocking is due to metal fatigue of the spring, it needs to be replaced. Otherwise, the racks will quickly break, the supports and balls will fail, the Kalina springs will bend sideways and will not allow the installation of other racks.

It is advisable to replace it if the stand begins to hit the rubber bumper too much.

Removing the steering rack from the car

The rear wheels are fixed by rolling back, the front wheels are lifted with a jack. Inside the car, on the driver's seat side, the column spline bolt is unscrewed. The difficulty in disconnecting is that it is located where the pedals are grouped.

After removing the front wheels, the cam nuts are removed and the space under the hood is prepared. The terminals from the battery and the battery itself are removed, along with the mounting plane and the heat reflector. The body mount of the rack is removed with a nut, it is released and placed on a flat surface for further work with it.

Diagnostics for the presence of play is carried out as follows: the rack casing is clamped in a vice and swung with force from side to side. If you feel any play, you should try to tighten the spring nut no more than 10 degrees. Check the play again, and so on until the problem is resolved. Tightening is prohibited, as the steering wheel will become very difficult to rotate, even if an electric booster is installed.

A steering rack repair kit can be purchased at any automotive store. But before you use it, you need to examine the old spare part. If this is not done, the part may need to be removed again.

Electric power steering for Kalina

Some drivers have learned to make adjustments without removing the rack. This method helps save time and effort. To perform this type of work, the car is placed in a pit and the location of the part in the front part is determined. The spare part is pulled clockwise if you can only get to it from below. If you can feel it from above, then the tightening goes counterclockwise. Actions are carried out in the sequence described above.

It must be remembered that replacement does not always solve the problem; the rack continues to make noise and squeak when turning the steering wheel. To double the service life of the steering rack of a power-assisted vehicle, constant oil monitoring, checking the technical condition of the steering rod boots and their timely replacement are important.

Replacing the ball joint

Tool for work:

- wrenches 17, 19;

- hammer;

- mount;

- puller;

- head for 12.

The ball joint is being replaced

The car is put on the handbrake, the bolts of the wheel from which the ball joint will be removed are loosened. Using a jack, the front part of the Lada Kalina car is raised, the bolts and wheel are removed. Use a 19 wrench to unscrew the ball pin nut. Insert the puller and twist to release the support pin.

The support fastening bolts are removed using a 12mm socket. The lever is pressed down, the support is released and removed. There is another way to dismantle the ball joint: the brake disc is placed on a rigged brick, the jack is lowered slightly to relieve the lever. At this moment the rack rises up, the ball is released.

A large amount of lubricant must be added to the new support. The pin is put in place, the nut is tightened with a torque of 66-82 Nm. If the holes of the steering knuckle and the support coincide, the bolts are tightened. The procedure requires patience and considerable effort.

Front suspension repair

The cost of the parts themselves when eliminating the described reasons is most often small, but the price of replacing them in car services sometimes causes bewilderment. In such cases, it is better to repair the suspension yourself. This requires special devices and tools.

To remove the tips and ball joints of the steering wheel, pullers are needed that, during dismantling, preserve the integrity of these parts.

Silent blocks are replaced using a long threaded rod or bolt with a corresponding nut and a set of bushings and washers. The bushings should rest on the lever cage, and the washer should match the diameter of the rubber seal. Tightening the nut squeezes the silent blocks out of the lever, and then presses a new one in its place.

Dismantling the shock absorber strut is done with two ties that compress the spring. This makes it possible to unscrew the mounting bolts, remove the support bearing and remove the shock absorber and spring. The new spring is also completely compressed by the ties, then the entire assembly is assembled.

A knock when turning the steering wheel should not make the driver nervous. However, as soon as you have time, you should immediately start troubleshooting the problem. Today on the Internet you can find videos from professional craftsmen and amateurs about repairing suspensions of different car models and for various malfunctions. It is better to spend time studying their experience and then repair everything efficiently and quickly.

The steering, along with the car's braking system, are the most important elements that ensure safe driving at any speed and on any road. Therefore, when knocks, clicks and other extraneous noises begin when turning the steering wheel, in any case, you need to sound the alarm and immediately look for the cause of the problem in order to eliminate it. Now we will tell you why a knocking sound may appear when turning the steering wheel while standing still or in motion, and what problems does it indicate?

First of all, you need to clearly localize the place where the knocking is heard, as well as determine the conditions under which it occurs, this will greatly help you in finding the breakdown, the symptom of which is the knocking. In addition, different steering systems may knock in different situations and such a knock will indicate different breakdowns. We list the main causes of knocking when turning the steering wheel:

- wear of the constant velocity joint;

- wear of the ball joint;

- wear of the support bearing of the stabilizer link;

- wear of steering tips;

- the appearance of play in the steering rack and leakage of working fluid from it;

- loose steering wheel nut;

In principle, these are the most common causes of knocking and other noises when turning the steering wheel. But there are also less common breakdowns that cause similar sounds. But we can talk about such special cases only using the example of a specific car model in which such knocks began.

A knocking sound, or rather a crunching sound, when turning the steering wheel, as a rule. This indicates that it is time to change the CV joint or constant velocity joint. Although, it is not always necessary to replace this unit. Often, it is enough to replace the boot on the CV joint and replenish the lubricant. By the way, a special lubricant is needed; ordinary grease is not suitable here. CV joints can be external, which is what usually needs to be changed, as well as internal. The inner CV joint fails in serious traffic accidents, or in the event of a sudden failure of other components, for example, the ball joint of the wheel. The constant velocity joint can knock for quite a long time, but still, it is better to replace it as quickly as possible so as not to worry about every trip.

If you hear a noticeable knocking noise when you move the steering wheel left to right: diagnosis

Probable Causes

If an audible knocking sound in the front suspension when turning the steering wheel indicates wear in its constituent parts, then an extraneous clicking sound when the steering wheel rocks requires inspection of other structural elements. As a rule, the problem lies in the vehicle control system.

Statistics show that there is something to knock in the “steering wheel”. Any pairing may come under suspicion:

- Gap in the fit between the steering tip and the strut.

- Excessive play in the steering rack.

- There is a problem with the steering shaft driveshaft.

- Free movement of the steering wheel on the shaft.

- Gap in steering rod joints.

These parts are present in the design of any car. Knowing the location of all the landings, it remains to identify the defective pair.

For your information. Some old foreign cars have a folding steering column assembly, which breaks under the influence of a critical load that occurs during an accident. He can knock too.

How to identify knocking: expert methods

The classic approach to identifying a faulty unit will be explained in any garage. Its essence is trivial: just ask the assistant to shake the steering wheel and at this time put his hand on the mentioned connections.

Steering rack

However, in some situations this technology loses its relevance. In particular, it will not be possible to identify a defect in the mechanism using this method. To identify a problem in the gear-rack engagement, it is necessary to carry out the following experiment:

- If there is power steering (hydraulic booster): a knocking sound appears when the steering wheel is rotated on a car with the engine turned off, but when the engine is running, there is no knocking at the place.

- There is no power steering: drive along a road section with a changeable direction - when you swing the steering wheel left to right, a knock is heard, but when turning, the rack does not knock due to the small wear of the working surfaces of the gearing in the extreme positions.

For your information. It is not recommended to tighten a worn rack. One of the owners of Hyundai Solaris performed this procedure and after 10,000-12,000 km the steering wheel began to bite. An autopsy showed that the mechanism was beyond repair.

Emergency system

It is also possible to determine experimentally whether the steering column folding assembly is the cause of the knocking. It is enough to swing the “steering wheel” to the sides, while simultaneously pressing it to the bottom. The sound disappeared - the problem is in the emergency system.

Preparatory actions, dismantling unnecessary parts

To remove the crankcase protection, you need to unscrew 4 screws located in one row near the bumper. Also, unscrew two screws having a standard size of M6x16. In some configurations, the protection consists of two parts, but in this case they are attached only with self-tapping screws. These words are illustrated by the following photo:

First, unscrew the “10” screws, and then the two “18” screws. In the second case, there will be more screws (eight).

Now let's look at how to remove the battery. First of all, disconnect its terminals. Then, you need to move the additional fuse box to the side. In general, actions are performed according to the photo:

You also need to remove the mounting platform itself, for which you unscrew 4 screws. You will need a 13mm wrench, as well as a 10mm spanner. We will repeat the entire sequence again:

- Unscrew the nuts holding the battery terminals using a 10 mm wrench;

- Remove both terminals;

- Move the fuse box to the side by unscrewing 2 fastening screws;

- Unscrew the nuts with a 10mm wrench and remove the battery;

- Unscrew the screws with a 13mm wrench and remove the metal plate.

Just in case, here is a look at the fuse box mountings:

Mounting screws are located under the casing

Pressure spring

As you can see, the steering rack (“Kalina 2117”) has a very simple design. Therefore, adjusting and replacing it should not pose any difficulties. In general, this is true, but the Kalinovskaya rack has one small part in its design - a pressure spring, which regulates the force of contact between the device and the gear. This spare part is a kind of cone, but during operation it quickly loses its elastic properties, and the functionality of the spring is significantly reduced. Therefore, there is a need to periodically tighten this mechanism in order to restore the necessary forces. By the way, this spring can only be seen from the inspection hole, which greatly complicates the work of adjusting it.

The tightening itself is done using a special key, but due to the design features of the model, this is very difficult to do, since it becomes necessary to dismantle the steering rack. Below we will look at how this is done.

We adjust the Kalina-2 steering rack to eliminate knocking

Cars of the Kalina-2 family are equipped with a steering rack similar in design to the Granta rack. This part transmits force from the steering wheel to the front suspension links. If you feel a knocking sound from the rack while driving, it needs to be adjusted (tightened) correctly. The effect described here can be observed after 10-15 thousand kilometers, and more often it makes itself felt on uneven roads. Next we consider how this problem is solved in practice. And the solution comes down to turning one nut.

- A little theory: front suspension design

- Lyrical digression

- Making adjustments yourself

- Preparatory actions, dismantling unnecessary parts

- It turns out that the steering rack can be repaired (video example)

A little theory: front suspension design

Before attempting to fix any problem, there is a tendency to look at the blueprints or repair manual. It is known that the VAZ-2192 parts catalog contains the following object:

Whether the knock will remain in the steering rack of Kalina-2 depends on the following: how accurately element “14” is adjusted. The adjusting nut, marked “14”, looks almost invisible here. But first impressions are deceiving. In the catalog, by the way, the element is called “Stop Nut”.

Now let's move on to practice and see what the node in question looks like in reality:

The nut has a non-standard notch, and it can only be rotated with a special tool. By the way, the recess will be closed with a cap. In the catalog it is designated by the number “15”, and now, let’s look at the appearance of the special key:

The thrust nut is turned at small angles. We are talking about values of 10-15 degrees. What happens if you overdo it with tightening the rack? The knocking noise will disappear, but the steering wheel will turn with difficulty. Therefore, if necessary, the nut can be pulled back.

Lyrical digression

In Lada Kalina, the steering rack never makes a knock when we are talking about a new car. This is also true for the break-in period. Let's say in your case this is not done. Then, do not try to repair anything, but go straight to the dealer. According to reviews, the defect in question is covered under warranty, and most car dealers do this: the steering rack assembly is replaced with a new one.

There is a logic here. At the factory, adjustments are made correctly (this is true in 99.9% of cases). If a defect appears, the dealer replaces the assembly without expecting that adjustment will solve the problem. The owner does not need to hope for this either. The choice is yours.

Making adjustments yourself

You can access the adjusting nut from the engine compartment, but to do this you will need to remove the battery, as well as the battery mounting pad. It is better to drive the car into a pit and then remove the crankcase protection (engine mudguard). If you look from under the bottom, the required element is immediately visible:

And when you open the hood, you can feel the nut, but not see it. Its location is marked in the figure:

Before adjustment, remove the rubber cap from the recess. Its appearance is shown in the photo:

If it is not entirely clear what exactly needs to be done, it is better to contact the service. The key is installed in the recess and then rotated 10-15 degrees.

Preparatory actions, dismantling unnecessary parts

To remove the crankcase protection, you need to unscrew 4 screws located in one row near the bumper. Also, unscrew two screws having a standard size of M6x16. In some configurations, the protection consists of two parts, but in this case they are attached only with self-tapping screws. These words are illustrated by the following photo:

First, unscrew the “10” screws, and then the two “18” screws. In the second case, there will be more screws (eight).

Now let's look at how to remove the battery. First of all, disconnect its terminals. Then, you need to move the additional fuse box to the side. In general, actions are performed according to the photo:

You also need to remove the mounting platform itself, for which you unscrew 4 screws. You will need a 13mm wrench, as well as a 10mm spanner. We will repeat the entire sequence again:

- Unscrew the nuts holding the battery terminals using a 10 mm wrench;

- Remove both terminals;

- Move the fuse box to the side by unscrewing 2 fastening screws;

- Unscrew the nuts with a 10mm wrench and remove the battery;

- Unscrew the screws with a 13mm wrench and remove the metal plate.

Just in case, here is a look at the fuse box mountings:

Vehicle control system design

On the technical side, the Lada Kalina steering rack is a mechanism that has a gear mounted on a shaft, which is connected to a rack and special rods. It is thanks to them that the process of turning the car occurs, by converting the movement of the steering wheel into a horizontal deviation of the front wheels in the direction desired by the driver.

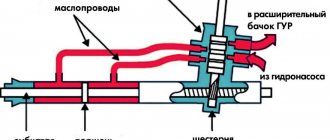

Currently, automobile manufacturers use 3 variants of the rack and pinion mechanism in the production of cars:

- mechanical;

- hydraulic;

- electric.

The mechanical rack is the simplest in terms of design and is therefore installed on most modern cars. Here, the rotation of special rods is carried out solely due to the physical strength of the driver. Naturally, driving a car equipped with such a control device is quite difficult.

The second option for equipping vehicles is a hydraulic mechanism. The Lada Kalina and Kalina 2 models are equipped with it. As a result, their owner receives not only sharpness, but also lightness of the steering wheel. Most modern cars are equipped with a hydraulic steering wheel.

Another option for a car control system that can reduce the load on the driver is an electric drive for the steering mechanism. In it, the turning force is increased due to the operation of an electric motor built into the column. This device is used only on luxury and premium cars; for example, it can be found as an additional option on the top-spec Lada Kalina.

In addition, there is a mixed version of power steering - electrohydromechanical. It combines all the positive qualities of hydraulic and electric power steering. You can see it, for example, in a car.

Each type of control system has both its advantages and disadvantages, but they break down with approximately the same frequency. At the same time, if a breakdown of the mechanical system for controlling the direction of movement of the car leads to relatively small costs for its repair, faults in hydraulics and electrical systems can lead to very serious expenses on the part of the car owner.

Steering wheel sticks when turning with ignition on

That is, it does not return back, but remains, as it were, bitten in the extreme left or right position. And this, even at a very low speed! Moreover, if the ignition is turned off, this situation is natural for any car. But when turned on... Agree, this can lead to irreparable consequences.

In this case, the problem of why the steering wheel sticks when turning is to blame for the faulty switch block, the steering column. You may have to deal with the ignition switch itself. Therefore, if you are not an automotive electrician, it is best not to take risks, since it is very difficult to carry out this work yourself without appropriate training. So, we turn on the emergency lights and slowly and carefully crawl to the nearest service station, where there is an appropriate specialist. And be careful when turning: enter them smoothly, without twisting the steering wheel to extreme positions, so as not to bite again.

How to avoid

To avoid the appearance of new knocks after repair, you must follow a few simple rules:

- Do not reach high speeds on uneven and gravel-covered roads, as well as when driving over potholes and potholes. And if you still can’t avoid this, be sure to ensure that the steering wheel is not in the extreme position at the moment the front wheels come into contact with the obstacle.

- Do not make sudden acceleration or braking when the steering wheel is in the extreme position.

- Do not drive onto curbs or high curbs.

Thanks to following these simple rules, knocks will not bother you for a long time, and the steering rack will last even longer.

We change other details

We also pay attention to how the steering rack looks externally. “Kalina” can keep many secrets regarding maintenance, so if there is the slightest doubt about the serviceability of the rack elements, we replace them with new ones. Otherwise, you will have to remove this part again. The components themselves can be purchased in a repair kit. This will not pose much difficulty for the modern car enthusiast. Having replaced and adjusted all the necessary components, we assemble the rack in the reverse order. That's it, the repair has been successfully completed.