Probably many owners of front-wheel drive VAZ cars have at least once encountered such a thing as replacing a pump (also known as a water pump according to technical documentation).

During installation, there is such a small but very important parameter as the so-called “impeller overhang,” namely the distance from the blades to the response part of the pump. The performance of the pump is in an inverse cubic (!) dependence on this distance - the closer the blades, the higher the flow.

For Zhiguli, this parameter is described in the repair literature, but for engines that are installed on the front-wheel drive family there is no special mention in this regard.

But, if you scour the Internet, you can find the following information here: On engines of the 2108 family, which includes engines 2111, 21114, 2112, 21124, the gap between the water pump impeller and the cylinder block using the “minimum-maximum” method should be ranging from 0.62 to 1.71 mm, according to the probabilistic method - approximately from 0.9 to 1.2 mm

So, the old pump has been removed, the remains of the old gasket have been cleaned off. We try on a new pump without a gasket, install it and turn the shaft - if it catches, then you need to install it with a gasket, if, as in my case, it doesn’t stick, then to put your mind at ease, you can measure the gap.

To do this, we sculpt plasticine onto the blades in this way:

Next, we insert it into the block, press it and then carefully pull it out. After these manipulations, we got the following casts:

Next, carefully use the blade of a stationery knife to partially cut off the plasticine in this way:

And we actually measure its height; this will be the size of the gap. In my case, with a 21114 pump with straight blades, the gap was 1.1-0.9 mm when measured without a gasket, which means that for good performance it needs to be installed with a sealant.

By the way, for reference, the thickness of the cardboard spacer (on the left) is 0.5 mm and the spacer with sealant is 0.8 mm (article 21100130704200)

Also a small educational program on the types of impellers. At the moment, there are basically 3 options for impellers: 1. Cast iron with 6 blades (aka 2108) 2. Plastic (polyamide) with 7 blades (aka 2109) 3. Plastic with straight blades (21114 for regular 8 class, 21116 8 cl and all modifications of 16 cl engines)

The latter is considered the most productive, although there are cases of breakage of the plastic impeller.

Which pump is better for the VAZ-2111 engine - with a cast iron 6-blade impeller or with a plastic 7-blade impeller?

A water pump with a 7-blade plastic impeller, in our opinion, is preferable. It has higher performance and at the same time less tendency to cavitation. As has been written about more than once, the formation of cavitation gas bubbles in the liquid flow reduces the performance of the pump; In addition, when these bubbles disappear, they “collapse”—microimpacts occur, gradually destroying the surfaces of the parts.

PS: On my 8 cl engine 21114 from the factory there was a TZA 2109 pump with an impeller like this

In the Lada Kalina model, as in any other car, with an 8-valve and 16-valve engine, the pump operating in the cooling circuit of the power unit has its own resource. It is advisable to replace it together with the same procedure regarding the timing belt. For this purpose, the manufacturer regulated an interval equal to 60 thousand km of the distance traveled. This kind of approach will allow the owner to avoid the need for additional disassembly of the timing belt assembly in order to replace a cooling circuit pump that has become unusable. Replacing the pump yourself is not a difficult task, so the owner can safely take on the task even with little experience. The main thing is to decide which pump is better.

Self-check the condition of the alternator belt

Before replacing an implement belt, drivers should perform a visual inspection to determine if replacement is necessary.

To perform this, it must be placed in a stationary state. To prevent the car from rolling during inspection, clamps should be installed under the wheels. The generator belt is located in the engine compartment, and is tensioned on the pulleys of the attachment. The entire product must be checked. Having examined one area, inspect all the others sequentially, turning the belt. You can make a mark at the place where the inspection began. The following signs indicate the need for replacement:

- cracks and abrasions on the surface, both internal and external;

- frayed, sides;

- peeling of rubber from rubber;

- mechanical damage;

- traces of oil and working fluids are on the surface.

During inspection, you also need to check the belt tension. If it is loosely tensioned, the generator will not work at full capacity. Too much tension causes premature wear of the bearings and strap. To check the tension, press the belt in a place free from equipment. With a force of approximately 10 kg, the deflection should not be more than 7-8 cm.

If the tension is insufficient, then you need to know how to tighten the belt. The tensioner screw acts as a regulator; it is used to perform tension (video author – Remgar).

When replacing a belt, it is advisable to change the tensioner pulley, which should also be inspected. It should be free of scratches, chips, play, and deformation. The roller should rotate freely without delay. You should not neglect regularly checking the condition of the belt drive.

If the belt breaks on the way, further movement is only possible using the battery. But even if it is fully charged, you can move it for no more than one hour. Therefore, it is recommended to have a spare alternator belt in the trunk in case it breaks.

Technical regulations for Lada Granta cars

In order to be sure that the car will not fail on the road, you should monitor its technical condition and comply with technical regulations. Maintenance consists of diagnosing vehicle systems and components, identifying and troubleshooting problems. But even if everything is in order with the car, it is necessary to carry out the routine operations provided for in the vehicle’s operating manual.

Experts recommend doing a technical inspection when purchasing a used car and every 15 kilometers. During a visual inspection, you should check the systems and components for leaks, check the reliability of the fastenings, the tension of the belts, and their condition. If necessary, change filters, oils, working fluids, and consumables. In order to bring the car into good working order, you need to buy all the necessary consumables in advance so that they can be replaced during inspection.

The accessory strap is a consumable item that needs to be replaced periodically. In the Lada Granta manual, the manufacturer recommends replacing the belt every 30 thousand km. Experienced drivers advise checking the condition of the belt drive at intervals of 15 thousand km.

The frequency of replacement of consumables is influenced by the following factors:

- terms of Use;

- driver's driving style;

- quality of consumables;

- serviceability of components and mechanisms;

- climatic conditions.

If the machine is operated in difficult conditions, then diagnostics should be done more often. It is recommended to do a technical inspection before a long trip so that the car does not fail along the way.

Functions and purpose of a pump in a car

Lada kalina sedan russian mercedes logbook replacing the gearbox lever ball race with bearing

Normal engine operation is impossible without a cooling system that circulates coolant through the pipeline (system components, pipes and hoses). The purpose of the pump (water pump) is to ensure constant movement of antifreeze throughout the entire system while the engine is running. If at some point the pump stops functioning, this will immediately disrupt the thermal conditions of the engine. In this case, the coolant will boil, which can lead to serious engine damage.

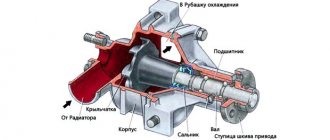

Structurally, the pump is a fairly simple structure, consisting of a metal body and a pulley and impeller located on the shaft. The pulley is driven by a belt from the engine crankshaft. An impeller is located on a shaft inside the housing, which moves the coolant with blades from one part of the cooling system to another. This is how the motor is cooled.

Read also: Dummy car keys

Let's sum it up

As you can see, replacing a pump is not such a difficult process. The main thing is to strictly follow the instructions and decide in advance which pump is better. We recommend checking the tightness of the system by warming up the LADA Kalina engine until it reaches the operating temperature. If no leaks or noises are detected, then we boldly hit the road.

To avoid being blown up by a mine, it is enough to know where it is laid. Let's play sapper and find out when you really need to change coolant pumps and timing belts on VAZ engines.

Domestic engines for Grant, Kalin, Prior, Vest and Iksreev, with the exception of VAZ-11183, belong to the “plug-in” category. What this means is that when the timing belt breaks, the pistons meet the valves. Read - it exploded and led the engine to destruction, which was expensive to repair.

Replacing the pump on Lada Kalina 8 valves

Replacing the pump on a car Kalina

Personal experience Lada Priora hatchback On an 8-valve Kalina, you can change the water pump yourself. However, if the car owner does not have minimal experience in car maintenance, many questions may arise. For example, which pump to buy, how to choose the right tool, and is it worth draining the antifreeze from the system completely?

Which pump to choose

When the time comes to change the water pump, car owners begin to look at car dealerships for a worthy replacement. But which pump to choose so that it lasts as long as possible and does not cause problems for the owner?

In contrast, it will not last long - after 10 thousand kilometers the pump will need to be changed again.

At AVTOVAZ, designers install a TZA water pump on the Kalina. It has a long service life; drivers often change the pump only after 100 thousand kilometers. As an alternative, you can install more expensive German-made Bosch pumps - they are also famous for their quality and durability.

Where is the water pump located on Kalina?

Due to the fact that the pump is driven by the timing belt, it is part of the gas distribution mechanism. That is, you need to look for the water pump on the Lada Kalina from the side of the engine itself. Visually, before removing the belt, you can only see the pump pulley, which is involved in the gas distribution system.

The pump on the VAZ is located in the timing device

Preparing tools

It is recommended to prepare a standard set of tools for removing bolts and unscrewing nuts. You will also need a 6-point hex key. To drain the antifreeze without contamination and inconvenience, it is better to immediately find a container for draining and a rag to blot up any drops that have fallen on the engine elements. To ensure reliable installation of the pump, you can use a sealant with good thermal conductivity properties.

How much coolant to drain/fill when replacing the pump

In any case, before dismantling the old pump, you will need to drain the antifreeze from the system. This is necessary in order to reduce the pressure in the hoses and not be injured during sudden releases of liquid.

If the water pump has not been changed for a long time, then it is advisable to immediately drain the entire volume of antifreeze from the system and replace it with a new one. If the car owner has recently filled in new coolant, then there is no point in completely draining it: just disconnect the hoses from the expansion tank and wait until the antifreeze comes out.

To make it easier to fill a large volume of coolant, drivers usually use funnels

Operating procedure

First of all, you will need to install the machine on a flat surface. You can drive the Kalina into the inspection hole, you can simply lift the front right part on a jack. It is recommended to make sure that the car is securely secured; it is better to place additional supports under the body beam.

When dismantling the pump, you will need to remove the timing belts.

The work of replacing the pump on the Lada Kalina is carried out according to the following instructions:

- Remove the engine splash guard.

- Disconnect the negative terminal from the battery.

- Unscrew the cap from the expansion tank and immediately remove the plug located on the cylinder block. Wait until the coolant drains out.

- If all the antifreeze is drained, then unscrew the cap from the radiator and place a container under the drainage area.

- After the antifreeze has been drained, screw all the plugs back on.

- Remove the protective cover from the timing belt.

- Loosen the belt by slightly tightening the timing pulley.

- Remove the drive belt.

- Remove the four bolts that secure the pump pulley to the cylinder block.

- After removing the pulley, unscrew the last screws securing the pump.

- Pull the water pump out of its socket along with the gasket.

- Clean the planting site from adhering dirt and antifreeze drips.

- Apply heat-resistant sealant to the edges of the hole and install a new gasket on it.

- Place a new pump on the gasket and then proceed in the reverse order of removal.

Preparatory activities

Before changing the pump on Kalina, you will have to partially empty the cooling system. Antifreeze should only be drained from the cylinder block; there is no need to touch the radiator. Unless you notice fluid leaking on the pipes, then you can change the hoses at the same time. The procedure is performed according to the following algorithm:

- Remove the mudguard that protects the engine from below from dirt. It is held on by bolts with 10 mm socket heads.

- Disconnect the positive terminal from the battery and the high-voltage wires from the ignition coil. Unscrew the coil mount with a 5 mm hexagon and move it to the side, freeing access to the drain plug.

- Empty the cylinder block by placing a special container and unscrewing the drain plug with a 13 mm wrench. In this case, it is necessary to open the cap of the expansion tank.

- If you need to empty the radiator, you should move the container under its drain neck and also unscrew the plug.

To carry out work on replacing the pump, no special pullers or devices are required. It is enough to have a set of regular and ring wrenches, a screwdriver and thin pliers. It is also quite possible to do without an inspection ditch by placing the car on a flat area and securing it with anti-roll bars.

2. Installing a pump on the Lada Kalina engine

Lada Kalina

By visiting the plastic expansion tank, you can visually control the amount of antifreeze and antifreeze. There are special marks for the highest and lowest levels of liquids in the tank. Outside the tank, there is a pipe at the top for connecting to the heat exchanger sleeve, and at the bottom - with a filling tube.

Expansion cap with breathers. Device means inlet and outlet breathers. They are capable of providing systemic impermeability. Inlet valve

maintains elevated pressure in a hot engine. As the temperature increases, steam leakage decreases. The reduced pressure facilitates the opening of the released breather as the car engine cools evenly. The pump pumping antifreeze is a quick discharge blade. The crankshaft wheel drives the pump by means of a toothed belt on the camshaft rod. Its body consists of aluminum. The rotation of the shaft occurs in a double-row ball bearing, in which there is enough fuel oil for the period of warranty operation. The outer ring is tightened with a screw. A gear is pressed in front, an impeller, a retaining ring, and an oil seal are in the back. Antifreeze or antifreeze leakage is monitored through a hole in the pump shell. This method will help identify unit malfunctions. If the pump cannot be repaired, it is replaced with a similar assembly device. The redistribution of antifreeze is corrected by the coolant. Systemic cooling of paired cycles occurs as follows: in a larger circulation circle, the antifreeze seeps through the motor shell to the radiator battery; when moving in a small circle, antifreeze or antifreeze passes only through the cooling shell, without getting into the heat sink.

The cooling system consists of a radiator battery and a throttle heating unit. The circulation of antifreeze or antifreeze here occurs continuously, regardless of the location of the coolant valve.

Thermostat. The thermal unit and two breathers are components. There is a redistribution of the flow of antifreeze, also called antifreeze. When the engine is cool, the node valve redistributes the direction of water movement. It circulates along the smallest radius without entering the radiator. High temperatures of 85°C allow the valves to open and allow fluid to flow into the radiator. At temperatures above 100° C, the main valve is completely open, the spare valve is closed. Water circulation occurs over a larger radius. Antifreeze or antifreeze temperature meter. This device is screwed into the cylinder head for automatic antifreeze control. The sensor is connected to the temperature indicator on the machine's device panel. This information is sent to the controller. Heating heat sink. Built into the engine cooling system, it heats the car interior by circulating hot antifreeze. The radiator is a 3.2 plastic tank in a vertical position. Some of them have a partition. There are also 4 rows of round aluminum tubes, aligned horizontally, which are passed through cooling plates. The pipes are connected to the tanks through a rubber key. Antifreeze enters through the upper pipe and comes out through the lower pipe. The inlet pipe is located next to the narrow steam exhaust hose. The radiator has a casing with an electric motor. Drain plug at the bottom. The fan maintains the temperature inside the car. When the controller receives a signal, the fan is turned on by means of a relay.

How to change license plate lights

Lada Kalina Hatchback UltraViolet Logbook -062- How to drain antifreeze

Replacing the license plate light bulbs on the Lada Kalina is a simple task, so you can easily handle it yourself. By changing the lights yourself, you will not only save money on the services of workshop specialists, but you will also be confident in the excellent quality of the work.

Open the trunk of the car and pry the lamp on the left side with a flat-blade screwdriver. This will free him from the latch;

Step #1

Push the light on the right side and move it to the left. After some pressing, it should come out easily;

Step #2

Pull out the lamp along with the power wires. This will make it easier to replace the license plate lamps of the Lada Kalina;

Slightly lift the plastic clip up and remove the power plug;

Step #3

Carefully turn the white housing of the Lada Kalina license plate light bulb counterclockwise and completely pull out the base;

Step #4

Pull out the lamp itself. To do this, simply pull it to the side. After this, remove the lampshade from the base.

Step #5

Install a new lampshade in place of the burnt out bulb. The job is done in the same way as removing a light bulb, but in reverse order. Make sure the new light is lit.

Determining the performance of a part

In some ways, the water pump is a pretty tricky part. Without disassembling the timing belt assembly, it is not so easy to determine its performance.

But there are some signs of a pump malfunction that require you to pay close attention to it:

- At an early stage of wear, bearing noise appears. Not every auto mechanic, let alone an ordinary car enthusiast, will be able to distinguish it. But if you managed to catch this noise, then there is a reason to look under the plastic cover of the gas distribution mechanism.

- Wet marks under the timing cover and a belt shiny with moisture indicate that antifreeze is gradually penetrating into the compartment. Naturally, through the pump.

- The belt is not in the center of the camshaft gear, but is shifted to the very edge. This happens when, due to play in the pump bearing, the gear warps and the belt slides to the side.

- The coolant in the expansion tank of the Lada Kalina gradually decreases, and wet spots are constantly observed under the car directly under the timing mechanism.

Some tips on how to check your pump. If you observe one of these signs, then it is worth taking the time to remove the timing belt from the camshaft gear by releasing the tension roller. Now you can manually check the bearing play and, if any is found, immediately replace the part.

Malfunctions of the water pump are fraught with consequences, including major engine overhauls. A non-functioning unit leads to overheating of the power unit, which entails failure of the piston rings and jamming of the pistons themselves in the liners.

Some Kalina owners, in order to improve the performance of the cooling system, practice installing an additional pump. This is a very effective remedy for airing the system.

As a rule, the additional pump is a standard water pump from the Gazelle, equipped with its own electric motor. The device crashes into the small circle of coolant circulation, or rather, it is placed on the return pipe of the stove. The electric motor is connected through an additional relay and a button inside the cabin so that the pump can be turned on if necessary.

Korean-made coolant pump for VAZ-21179 engine

The owner of any elderly foreign car with a timing belt will confirm that repairmen insist that during a scheduled belt change, they replace both the pump and the pressure rollers with bearing assemblies. And these parts are often sold as a set. Moreover, at a discount - the whole set is cheaper than the belt, rollers, and pump separately.

I don’t want to once again convince you that the stingy pays twice, but over the years I have come to the conclusion that Western manufacturers include in the regulations changing the belt not because of the belt as such, but because of the pump and tensioner bearings. They just needed a reason to reliably replace the entire set of parts associated with the camshaft drive, and they found it.

I propose to do the same with our engines. Why? Formally, at each maintenance it would be necessary to remove the cover and inspect the timing belt and water pump. You can see a tear in the belt, as well as a leak on the pump. In both cases, the part is changed without delay. But this is a malfunction. And if everything is outwardly normal, the ideal option is to include preventive replacement in the regulations.

Signs of pump failure

You can talk about a pump malfunction if you have the following malfunctions:

- The coolant level in the reservoir drops to a minimum. This reason is the most common, since this is how you can understand that the coolant is constantly leaving due to leaks. They can be in the tank itself, the pipes, or at their connections, as well as directly in the radiator. Only by checking the entire system can you be sure that this is not the reason.

Coolant level is at minimum.

A clear example of a new and old pump.

Note! Remember that with a stably functioning, working pump, the arrow on the dashboard very rarely climbs to the red mark. This can only happen in the summer, in the heat, when the car is idling or at high speeds.

Examination

It’s easy to check the operation of the pump on the go; you need to move the control levers to blow warm air into the cabin and wait to see what the effect will be. If the air is cold, this means that there is no coolant circulation and the pump is faulty.

Above, all the reasons were described, if they occur, you will, one way or another, need to replace the water pump. And you may have a reasonable question about which one is better to choose and how to protect yourself from buying a obviously low-quality, and sometimes counterfeit, product.

Symptoms of damaged water pump

- Motor overheating - the pump

is faulty, the drive belt is not working, the impeller is damaged. - The temperature arrow indicator is located closer to the middle. It is necessary to brake to check the radiator. For which the inoperability design is intended, the unit and the pump drive will heat up.

- Noisy, smell of antifreeze in the cabin.

- Low antifreeze circulation is the result of pump destruction. Diagnosis is carried out with the engine idling; you must immediately clamp and lower the outer radiator hose. During normal operation of the pump, a push of antifreeze in the hose will be felt.

- Large free play of the ball bearing of the pump - damage to the ball bearings.

It is necessary to change the water pump if the car's mileage is 90 thousand km.

How to determine the performance of the pump?

To come to the conclusion that the pump needs to be replaced, you can conduct an inspection. It is very difficult to identify the presence of a malfunction in the pump without removing the belt. However, in practice there are some signs that make it possible to sufficiently identify the occurrence of deviations in the operation of the pump with the Lada Kalina engine running or turned off.

Among these symptoms are the following.

- The appearance of noise produced by the exhausted bearing of the Lada Kalina pump. Not every mechanic can identify this factor, not to mention an inexperienced car enthusiast. If you are “lucky enough” to detect noise, then there is a reason to inspect the gas distribution mechanism, located under the protective plastic cover. In this case, the pump needs to be replaced.

- The appearance of traces of antifreeze leakage. This may be indicated by a wet surface of the belt drive or pockets of moisture accumulating on the end surface of the motor unit. If the leak is quite intense, then over a short period of time a wet spot accumulates under a stationary car, and the level of antifreeze in the expansion tank gradually decreases. This phenomenon can occur due to wear of the oil seal present on the pump shaft.

- The belt is not located evenly on the camshaft drive gear, but rather offset from the center of its longitudinal axis. Its slippage can be caused by the appearance of play in the pump bearing.

Below are a few recommendations that will allow the owner of a Lada Kalina to facilitate the process of identifying pump faults. If one of the above factors is detected, then you should not be lazy and remove the belt from the camshaft gear. To do this, you will need to first loosen the tension on the belt drive by unscrewing the eccentric roller fasteners. Now it is enough to apply a manual rocking force to the pump shaft, which will reveal the play. When such a situation occurs, the water pump is immediately replaced. Even if there are no antifreeze leaks, further operation of the pump is prohibited, since a jammed bearing will cause the belt to break. Here we will not remind you about the risk of engine failure, because everyone already knows this.

A failed water pump on a Lada Kalina car can cause engine overheating, which in turn can cause irreparable damage to the cylinder-piston group. Some “advanced” owners resort to installing an additional pump, which is a very effective action in preventing the risk of airing the cooling circuit. As an additional pump, a part from the Gazelle is often used, the rotation of which is carried out by an independent electric motor. The component is cut into a pipe designed for the return flow of coolant, that is, into a small circulation circle. Power to the electric motor of this component is supplied through an additional relay, which is activated by a button located inside the cabin. This allows you to increase the mobility of the pump and turn it on at the right time.

Procedure for servicing the fuel pump, possible malfunctions

The easiest way to replace the timing belt, pulley and pump on a Lada Granta with an 87 hp 8-valve engine

For this device, two parameters are usually monitored: operating pressure and operating performance. After removing the device, you can check the current consumption at rated and full load. But for such measurements you will need a specialized stand.

The disadvantage of this control method is the inability to detect unreliable contact in the electrical circuit on the way to the connector. Any loose connection in the fuse box, fuel pump relay, will result in the 12 V received at the terminals upstream of the pump showing the same 12 V. But a working pump will receive only a few volts and will not be able to work normally.

All control relays are located inside the car and, when malfunctioning, distinguish themselves with characteristic clicks. Replacing the fuel pump relay yourself is not difficult; it is enough to recognize the location of its installation by the special printed symbols.

Checking the pressure created consists of monitoring this parameter in the pump pumping mode, when it turns on after turning the key for 1.5-2 seconds to add fuel to the pipeline system. For Lada Kalina this figure is 0.8-1.2 kgf/cm2. If the pressure turns out to be underestimated, then you should look for the cause of this phenomenon, checking each link in turn: filter, mesh, fuel pump. Ultimately, the part that prevents the pressure from quickly building up to normal will be replaced.

Rapidly falling pressure will cause uncertain or long engine starting, which is especially important at sub-zero temperatures. Despite a generally serviceable power supply and ignition system, starting the engine in cold weather may simply discharge your battery or prevent the engine from starting at all.

Relieve pressure in the fuel line. To do this, simply let the car sit for 30 minutes after the last start. To be more sure, after turning off the power to the fuel pump, you need to briefly start the engine to exhaust the gasoline in the fuel line.

Be sure to turn off the power to the car by disconnecting the negative terminal on the battery.

Provide access to the gas tank hatch

To do this, recline the rear seats and, having unscrewed 4 self-tapping screws with a Phillips screwdriver, carefully open the hatch, preventing possible contaminants from entering the tank. Disconnect the electrical connector from the plastic fuel module cover and

Disconnect the electrical connector from the plastic fuel module cover and

fuel pipes from the cover. Work should be carried out without applying unnecessary force to avoid breaking the plastic parts of the cover.

Remove the retaining ring, which will require a special puller. If you use a handy tool, you need to be patient.

You can begin dismantling the pump block by carefully lifting the structure up. Care must be taken as the float can easily be damaged. When removing, you need to tilt the entire block slightly, pulling it diagonally.

If the fuel pump does not work and needs to be replaced, installing the new mechanism should be done in the reverse order. Before installing a new pump, it is advisable to fill it with fuel, since a dry fluid supercharger may not be able to pump fuel to start the pump. The fuel pump is not a suction device, but only a pressure device.

Disassembly and installation of a new part

First of all, you need to gain access to the timing mechanism, for which, using a No. 10 key, unscrew the 3 bolts securing the protective plastic cover. If you are disassembling a 16-valve Kalina model, you will have to remove 2 covers by unscrewing 5 bolts with a No. 5 hexagon.

Before further disassembly, you need to align all the marks on the crankshaft flywheel and the camshaft gear.

Otherwise, during the work you can disrupt gas distribution and create a new problem for yourself.

To align the marks, it is best to jack up the 1st front wheel, engage 4th gear and turn the crankshaft by turning the wheel manually. Before doing this, do not forget to remove the plug from the gearbox side that covers the marks on the flywheel. The mark on it should coincide with the groove on the body, and the camshaft gear mark should be vertical at the top opposite the slot. Further disassembly is carried out in this order:

- using wrench No. 17, loosen the roller and remove the timing belt from the camshaft gear (in a 16-valve engine with 2 gears);

- Using the same key, unscrew the bolt holding the gear, wedging it through the holes;

- remove the gear (both in the 16V model) without losing the key;

- dismantle the internal protective plate, in an 8V engine it is held on by 2 bolts, 16V by 5;

- unscrew the 3 bolts securing the pump and pull it out of the socket;

- remove the remains of the old gasket from the cylinder block.

If a cork gasket is supplied with the new pump, then it does not need to be lubricated with anything, but it is better to place a cardboard gasket on the sealant. The new pump must be inserted into the socket in the same position as the old one and secured with bolts. After this, you can put all the parts back, put on and tighten the belt. Double-check that the marks match before replacing the covers.

To prevent air pockets from forming when filling antifreeze, you need to remove the small pipe from the throttle valve heating unit. Filling is carried out until liquid flows out of it. Upon completion of assembly, it is recommended to check the system by starting the engine and warming it up to operating temperature.

Drive 16kl. Kalina is like riding a powder keg, you never know when it will explode! I'm talking about the meeting of valves and pistons...

This can happen for several reasons - the main one is the destruction of the timing belt support (Polish) roller. The pump may also jam and, in very rare cases, the tension (Chinese) roller may fail. The belt is very reliable and can only break if hit by a foreign object.

In general, the plant declares the service life of the entire timing assembly is 200 thousand km. and does not imply replacement and inspection of rollers or timing belt during the warranty period. However, I don’t think that there will be such brave souls who will want to check the declared resource) I periodically looked through the relevant topics on the forums and wondered how to protect myself and avoid expensive engine repairs... And after all, I encountered valves with pistons for everyone at completely different mileages. Some people have 20 thousand km. Some people drive 70, others drive more than 100 and have no problems.

And since no one has any doubts about the belt, everyone is mainly thinking about what to replace the rollers with, there are many options - some fit without modifications, with some you have to put washers in and use special bolts. I didn’t bother to understand all this variety and decided to replace the set with exactly the same one at 60 thousand mileage. At the same time, I decided to replace the pump and the belt and pulley of the generator in order to forget about this problem of belts and rollers for a long time.

I ordered everything from Exist except the pump; I bought it at the Lada retail store, which is now plentiful all over the country.

The kit itself turned out like this:

Manufacturer - Article - Name

— price

1. Gates - K015631XS - Timing belt with rollers, kit

— 2940 rub.2.

Gates - 6PK1018 - V-ribbed belt (alternator)

- 293 rub.3.

Ina - 531 0760 10 - Tensioner roller (generator)

- 510 rub.4.

TZA - 21126-1307010-20 - Water pump VAZ (1.6 l., 16 cells)

- 750 rub.

Original (factory) Gates rollers and belt are sold only as a set, and the main thing here is not to run into a fake, of which there are apparently quite a few. How to distinguish a fake from an original can be found HERE:

Gates kit - K015631XS consists of:

— timing belt — 5631XS (137 teeth)— Timing belt tensioner roller “Powergripr” (T43147)— Parasitic/drive roller, timing belt “PowerGripR” (T42150)

The Lada Kalina pump is a pump responsible for circulating water by cooling it. The unit is located in the front part of the cylinder block. If the pump is deficient, the motor overheats, which leads to boiling and breakdowns.

Engine valves VAZ-21116

The average consumer has access to only those that come with the car from official documents. What follows from them? Open the Grants service book. Replacing the timing belt - at 75 thousand kilometers for an 8-valve engine, not a word about the 16-valve belt! The same situation is with Kalina - I came across a book where there is nothing to say about one engine, but on the other we only check the condition of the belt, but there is no talk of a planned replacement. It’s even more fun with the Priora - there are service books where there is not a word at all about the gas distribution mechanism, but the air conditioning compressor belt is mentioned in almost every maintenance coupon.

With Vesta and Xray, progress is obvious - at 45, 75, 105, 135 and 165 thousand we adjust the gaps in the gas distribution mechanism. And for the first time we plan to remember the timing belt along with the rollers for 180 thousand kilometers! This is for 16-valve engines VAZ-21129, 21179 and 8-valve Vesta VAZ-11189. I can’t do without the quote: “2.11. Replace the timing belt along with the rollers. 2.12. Replace the crankshaft and camshaft sprockets. Replace the toothed belt, tensioner and support roller (for the VAZ-11189 8-cl. engine, only the tensioner) of the engine gas distribution mechanism drive. Adjust the tension of the toothed belt." Not only is the oil oil (we change the same belt twice), but of all the parts, they didn’t remember the most vulnerable one - the pump!

Fuel pump: design features

Carburetor cars had mechanical pumps. The drive or dam pushed the diaphragm, in the process a vacuum was created and fuel entered the carburetor. Nowadays, almost all cars have an injection engine and an electric pump. It delivers hot food at high speed and maintains stable pressure in the system. The electric motor, together with the working rotor, pushes the fuel. The pump is located in the gasoline tank itself. During operation, fuel becomes coolant and lubricant. There are car models that have two pumps: the main one is under the hood, the worker is located in the fuel tank.

- special motor shell;

- heat exchanger with electric fan;

- device for maintaining a constant temperature;

- suction device;

- expansion tank;

- contact tubes.

By looking into the plastic expansion tank, you can visually check the amount of antifreeze and antifreeze. There are special marks for high and low levels of liquids in the tank. Outside the tank, there is a pipe at the top for connecting to the heat exchanger sleeve, at the bottom - to the filling tube.

Expansion cap with breathers. The device includes inlet and outlet breathers. They are capable of providing systemic impermeability. The intake valve maintains elevated pressure in the hot engine. As the temperature rises, steam leakage decreases. The reduced pressure promotes the opening of the released breather as the car engine gradually cools. The pump pumping antifreeze is a blade of rapid discharge. The crankshaft wheel drives the pump through a toothed belt on the timing rod. Its body consists of aluminum. The shaft rotates in a double-row ball bearing, which contains enough fuel oil for the entire warranty period. The outer ring is tightened with a self-tapping screw. The gear is pressed in at the front, the impeller, retaining ring, and oil seal are at the rear. Antifreeze or antifreeze leakage is monitored through a hole in the pump shell. This method will help identify unit malfunctions. If the pump cannot be repaired, it is replaced with an identical assembly device. The coolant corrects the redistribution of antifreeze. System cooling of paired cycles occurs as follows: in a larger circulation circle, the antifreeze penetrates through the motor shell to the radiator battery; when moving in a small circle, antifreeze or antifreeze passes only through the cooling shell, without getting into the heat sink.

Replacing antifreeze or antifreeze

Coolant reservoir

To perform fluid replacement work, you need to have special tools on hand to remove nuts and bolts. The Kalina car must be installed on a horizontal, level surface. If this is not possible, you should try to position the car so that its front parts are clearly visible. Work is performed in a certain sequence.

- Remove the engine splash guard.

- Reset the negative terminal of the battery.

- Unscrew the plug from the expansion tank.

- Remove the drain plug located on the cylinder block. Place a container under the drain.

- Remove the ignition module along with the holder, because it interferes with access to the drain.

- Remove the drain plug from the radiator battery and wait for the coolant to drain.

- Tighten the drain plugs of the radiator and cylinder block.

- Remove the hose from the throttle heating fitting to drain the fluid by loosening the clamps.

- Pour antifreeze or antifreeze into the conservator until liquid flows from the removed hose. Now you can put the hose in place. After this, continue to fill the system with antifreeze or antifreeze. The liquid should fill the expander so that its level is a maximum of 3 cm below the specified level. Tighten the expander lock.

You need to start the engine and warm it up until the electric fan is in normal operating condition. After turning off the car engine, add coolant to the top line.