The pump belongs to the vehicle's cooling system. In its unit, this part is the second most likely to break down. On a VAZ-2112 with a 16-valve engine, replacing the pump is quite easy, so even a novice motorist can do it.

The pump promotes stable circulation of coolant in the vehicle system. Therefore, if it malfunctions, leaks of this substance are possible, and air often gets into the system, which is very bad. It is much less common for valves to bend and the pump to jam, which may require a complete engine repair if we are talking about the 21120 model.

How to determine if a VAZ 2112 pump is broken

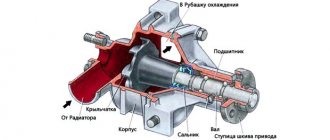

The pump is a device with blades, centrifugal type. It is driven by a timing belt via a crankshaft pulley. The device is housed in an aluminum housing, inside which the roller rotates in a double-row bearing, with a supply of grease for the entire period of operation. The outer ring of the bearing is secured with a screw. The toothed pulley is pressed in front of the roller, the impeller is mounted at the rear end. The end of the impeller is held by a thrust ring made of a graphite-containing composition. There is an oil seal underneath it. The one-piece design does not allow for high-quality repair of the unit, therefore, if a breakdown is detected, a complete replacement of the pump on the VAZ 2112 is necessary.

Factors determining the malfunction of the VAZ 2112 pump

One of the main signs of pump failure is the formation of play in the drive pulley of the structure. In this case, the pulley begins to dangle, which indicates wear of the bearings and imminent failure of the pump. Worn bearings can make a characteristic noise, and due to bad bearings, the tension roller can wear out the timing belt. You can identify such a defect by touch by removing the timing belt and turning the pump pulley by hand or rocking it from one side to the other; if there is a gap, it will be immediately visible. As a result, very soon the belt can jump off the pulleys, and this contributes to the impact of the pistons on the valves and deformation of the latter

Urgent repair of the water pump or its replacement should save the situation. If you find traces of coolant near the drain hole located at the bottom of the pump housing, you need to pay attention to the stuffing box seal. The faulty element cannot be used further; the leak will intensify, which can lead to big troubles, including the engine jamming due to overheating

In this case, the pump on the VAZ 21124 needs to be replaced as soon as possible.

Replacing the pump on a VAZ 2112 car

The procedure for replacing a VAZ 2112 pump includes removing the pump from the engine. For this:

- The wheel nuts on the right front wheel are loosened.

- The car is jacked up and the wheel is removed.

- To access the crankshaft pulley, a self-tapping screw is removed from the engine splash guard.

- The fixation to the generator bar is loosened, a thin long bolt is unscrewed that holds the tensioner to the generator belt, then the generator is pulled by the belt (see Generator repair: we do it all ourselves) almost all the way into the engine.

- The fastening bolt at the engine pulley is unscrewed.

Tip: To unscrew the bolt, you need to lock the crankshaft, otherwise it will turn along with the fasteners.

To perform this operation, you will need outside help to engage fourth or fifth gear and press firmly on the brakes. Using an extension cord and a 17mm wrench, unscrew the bolt. So:

- Having released the generator from the belt, the pulley is removed from the crankshaft.

- Support the engine sump on a wooden spacer. In this case, the standard jack must be left in place for insurance purposes.

- The gas distribution device drive is completely disassembled: the front casing cover, rollers, belt, toothed pulley on the camshaft, and rear casing cover are removed.

- The bolts securing the pump are unscrewed, as shown in the photo.

Releasing the pump from fixation with three bolts

Due to the large width of the device's toothed pulley, the spar prevents the pump from being pulled out. Therefore, using a pry bar or crowbar, the engine is moved away from the spar.

Tip: In order to avoid damage to the elements, it is necessary to place a small piece of wood between the spar and the mount.

Removing the VAZ 2112 pump

Installing a new pump

- The old gasket is removed with a scraper or knife. Care must be taken not to damage the cast iron surface of the block.

- A new gasket is installed. Made from cardboard, lubricated on both sides with sealant, placed on the pump, then the unit is installed on the block.

Advice: When installing a new gasket, it is better if it is made of paronite, the price of which is slightly higher than cardboard; you do not need to use sealant for it

It is necessary to ensure that all holes match on the gasket and flange of the new pump

Final assembly is done in reverse order.

How to correctly replace a VAZ 2112 16 valve pump can be seen in the video. If the operating instructions for the car are followed, the pump on the VAZ 2112 16 valves is replaced in a timely manner, the car will operate normally for a long time.

Instructions

A detailed and sequential process for replacing the pump will be considered for a VAZ-2112 with a 16-valve 1.6 engine:

- Using a special pit in the garage or a lift it is easier to replace the water pump. But not everyone has them, so we will consider the replacement process in a simple garage without a pit.

- Remove the front wheel on the right.

- To give yourself access to the crankshaft pulley, remove the protective plastic splash guard by unscrewing the screws securing the element to the body and removing it.

- Secure the crankshaft from turning. This is in your own interests of safety and convenience, and is also necessary in order not to disrupt the valve timing.

- Loosen the alternator and timing belt using the tension roller, which just needs to be loosened slightly.

- Unscrew the crankshaft mount.

- After loosening the fastening, remove the pulley.

- Next, it is necessary to disassemble the gas distribution mechanism, during which all elements are dismantled - casing, pulleys and rollers.

- Only now we get to the pump. Unscrew its mounting bolts - 3 pieces. Dismantle the device.

- Pull out the pump completely.

- Installation is similar, but done in reverse order.

Replacement sequence on an 8-valve engine

Having all this, you can start replacing:

It is advisable to place the car on a viewing hole and jack up the front right wheel. But this is not always possible, so in extreme cases, it is enough to simply turn the steering wheel to the right all the way. After this, remove the right front wheel fender liner protection; We remove the decorative panel from the engine and unscrew the absorber so that it does not interfere. In this case, there is no need to disconnect the wiring and tubes from it; after unscrewing it, it is enough to put it aside. The coolant can be drained immediately or later; Unscrew the bolts securing the plastic protective cover of the drive belt. After this, you can diagnose the condition of the pump. To do this, just start the engine and look at it - if play is clearly noticeable when it rotates, it definitely needs to be replaced. We install TDC on the first cylinder. To do this, turn the crankshaft clockwise until the marks on the timing gear align with the protrusion on the protective screen installed behind this gear. Then we check that the TDC is installed correctly. To do this, remove the inspection window plug on the clutch housing. We make sure that the marks on the flywheel and the housing also match. In this case, the coincidence control must be carried out on the flywheel, and not on the camshaft gear (a slight mismatch of the marks on the camshaft is allowed); We loosen the mount of the generator, feed it to the engine and remove its drive belt; Remove the crankshaft pulley. To do this, you can go in several ways: lock the crankshaft using a powerful screwdriver installed in the teeth of the flywheel and resting on the housing, or ask someone to engage 4th gear in the gearbox and squeeze the brakes. Both of these methods are good, and it’s up to you to decide which one to use; After removal, we check again that the marks match and correct them if necessary. Loosen the tension roller nut to remove tension from the belt. Carefully remove the belt first from the timing gear, and then from the crankshaft, unscrew the tension roller; Remove the timing gear. To do this, through the technological hole, using a wrench, we press against the rear screen mounting bolt to fix it, after which we loosen the bolt with the wrench. Then we check again that the marks match, correct everything if necessary, unscrew the bolt completely and remove the gear

You need to tighten it carefully, since there is a key on the shaft - it is important not to lose it; We unscrew all the bolts and nuts securing the rear screen, which at the bottom are also the pump mount. If the coolant has not been drained, then before unscrewing the mounting bolts, you need to place a wide container under the engine; Having unscrewed the bolts, remove the screen and, using light tapping movements, remove the pump from its place; Before installing a new pump, be sure to thoroughly clean its seat with a knife to remove any remnants of the old gasket. This is necessary so that after assembly there is no misalignment of the pump, this will lead to constant rapid wear of the drive belt; Before installing the new pump, lubricate its gasket on both sides with sealant and give it a little time to dry (10 minutes); We put the pump in place, then the screen, and only after that tighten the bolts that secure them.

Next, assembly is performed in the reverse order. It is important to check that the labels match. After installing the belt, tension it. Next, we check that the assembly is correct - we rotate the crankshaft several times, and then align the marks again. If the marks on the timing belt with the protrusion and the flywheel coincide with the housing, then everything is assembled correctly and you can reassemble the engine and fill in coolant. If they do not match, then you will have to set the marks on the flywheel, remove the belt, adjust the marks on the timing gear and put on the belt

This is necessary so that after assembly there is no misalignment of the pump, this will lead to constant rapid wear of the drive belt; Before installing the new pump, lubricate its gasket on both sides with sealant and give it a little time to dry (10 minutes); We put the pump in place, then the screen, and only after that tighten the bolts that secure them. Next, assembly is performed in reverse order.

It is important to check that the labels match. After installing the belt, tension it. Next, we check the correctness of assembly - rotate the crankshaft several times, and then align the marks again

If the marks on the timing belt with the protrusion and the flywheel coincide with the housing, then everything is assembled correctly and you can reassemble the engine and fill in coolant. If they do not match, then you will have to set the marks on the flywheel, remove the belt, adjust the marks on the timing gear and put on the belt.

Symptoms of malfunction

There are several signs of a pump breakdown, and they can be obvious, or the fault can only be determined after diagnosis.

Signals that the water pump has become unusable are:

- Increased noise when the engine is running from the timing belt side, a squeak is possible;

- A constant and significant decrease in the coolant level in the expansion tank and traces of coolant leaks from the crankshaft drive pulley;

- Strong pump play.

As can be seen from the list, all these signs are caused by severe wear of the bearing and seals.

Some argue that a pump malfunction leads to an increase in temperature during operation of the power plant.

But this happens in very rare cases when, due to corrosion, the impeller blades are almost completely destroyed. Because of this, the pump simply physically cannot impart movement to the liquid.

But such a malfunction is an isolated case; in general, the pump cannot affect the temperature regime due to the fact that it is constantly in motion.

But ignoring the problem with the pump’s operation will also not lead to anything good.

In the best case, the bearing and seals will wear out so much that they will not prevent the coolant from flowing out at all.

And since there is a drainage hole in the pump body, the antifreeze will drain through it quickly, and this can actually lead to overheating of the engine.

It is much worse if the bearing collapses due to severe wear and leads to jamming of the pump.

The result of this is a belt rupture and possible collision of the valves with the pistons. And this is already a major expensive repair of the power plant.

Recommended.

Check the pump every time the drive belt is replaced. Well, if any of the signs of malfunction appear, you should immediately check the condition of the pump and, if necessary, replace it.

Let us note here that increased hum and squeaking can be caused not only by the pump, but also by the tension roller, so the pump is not necessarily the cause of the noise.

But if a faulty element is identified, it is worth checking both of these details. Fortunately, they are located nearby, so it is not difficult to determine whether the pump or the roller caused the increased noise.

Shaft defects

Among the signs of a malfunctioning water pump, one should note the presence of deformation on the shaft. Upon inspection, it may appear bent or completely destroyed. If it is broken, it means the overload was sudden. Also, imbalances lead to similar consequences.

If the material from which the shaft is made has changed color (most often it acquires a blue tint), this indicates the gradual destruction of the shaft. This occurs due to excessive heat. The reason for this failure is the misalignment of the drive belt. This leads to shaft deformation or even fracture. Due to insufficient quality maintenance, significant vibrations appear in the system.

In this case, the pump is changed, and the belt drive is also checked. All elements of its system need to be inspected. You also need to evaluate the condition of the fan that is located on the pump (if it is provided in the engine system). If it is bent, other deformations are visible on it, this can destroy the shaft. Wear of the fan coupling and spacer ring also lead to a similar outcome.

The process of replacing the pump (water pump)

General view of a water pump manufactured by AvtoVAZ

So, before you begin directly replacing the pump on a 16-valve VAZ 2112, you need to collect some tools. Tools you will need: a 10 and 17 wrench, a flat screwdriver, a timing belt clamping mechanism, a hammer, rags, 2 liters of coolant, a container for draining the coolant from the system.

Now that everything is available, you can proceed directly to the process. Let's look at detailed instructions for replacing the water pump:

- It is best when there is a pit or a lift, which will simplify the procedure, but in the absence of this we will change it directly in the garage.

- We dismantle the front right wheel.

To make replacement easier, remove the front right wheel from the car.

- Now, to gain access to the crankshaft pulley, you need to remove the plastic protective splash guard. We unscrew the fastening screws and remove it.

Unscrew the crankshaft pulley nut, which will later be removed

- We fix the crankshaft from turning.

At the same time, in order not to disrupt the valve timing, it is necessary to secure the camshafts. Fixing the camshafts from turning so as not to disturb the valve timing - Loosen the generator and timing belt.

This can be done using a tension roller, which must be lowered. Unscrew the timing belt pulley and loosen the belt. - Unscrew the crankshaft mounting nut.

- When the fastening is loosened, it is necessary to dismantle the pulley.

Dismantling the crankshaft pulley - The next step is disassembling the gas distribution mechanism. It is necessary to completely dismantle all casing elements, rollers and camshaft pulleys.

General diagram of timing belt disassembly

- Now, having unscrewed the 3 bolts securing the water pump, we dismantle the pump.

- We take out the pump.

Unscrew the mounting bolts and dismantle the pump - We carry out the installation in reverse order. Don't forget that the pump gasket needs to be replaced. The factory manuals say that it needs to be lubricated with sealant. But, if the gasket is made from paronite, then sealant will not be needed.

The car pump has been replaced and for the next 40-50 thousand km this unit should not bother the car owner.

Reasons for replacement

Now, let's look at the causes of the malfunction, as well as the signs by which you can understand that the unit is not suitable for use.

So, signs of a faulty water pump:

- Bearing noise or “clatter” in the pump area.

- An increase in coolant temperature (a non-functional automatic transmission may be to blame, diagnostics and replacement).

- Leaks that come from the side of the water pump. Gasket failure or bearing wear.

Now, let's look at the reasons for pump failure:

- Worn water pump bearing or shaft , which leads to poor fluid circulation or leaks.

- Gasket failure due to wear.

- Shaft wear can also cause it to turn and therefore not have enough circulation, which will lead to a lot of heat.

- Pulley wear , which will be visible from belt wear.

The causes and symptoms are named, so any motorist will be able to diagnose this system on their own.

Choice, price and some recommendations

So, you should be careful when choosing a water pump for a VAZ 2112, since the normal functioning of the cooling system depends on this unit. So, if you do not replace the pump in time, you can not only boil on the way, but also be left without circulation, but also get deflection and deformation of the cylinder head .

The modern spare parts market has a fairly large number of counterfeits, especially for spare parts for the chassis and cooling system elements. So, when choosing a pump, you need to look at the availability of relevant documents, holograms and certificates.

Original

2112-1307010 is the original catalog number of the water pump manufactured by AvtoVAZ. This part is directly designed for this 16 valve vehicle. The cost of the part is 1500 rubles .

Analogs

Now, let’s look at analogues of the original part, which is recommended for installation on the VAZ 2112. All of them have received the highest reviews from consumers, have the appropriate certificates, and also fit perfectly in terms of mounting fasteners.

| Manufacturer's name | Catalog number | Price in rubles |

| Weber | WP 2110 | 1000 |

| Master-sport | 622-N-PR-PCS-MS | 1100 |

| Fenox | HB1003L1 | 1200 |

| Dolz | L-125 | 1300 |

| SCT | SQ 006 | 1350 |

| Finwhale | WP110 | 1400 |

| Magneti marelli | WPQ 0580 | 1500 |

| Starline | VP LA103 | 1500 |

| Pilenga | WP-P 2112 | 1600 |

| Coram | WP2112 | 1700 |

| Kroner | K202012 | 2000 |

| Ruville | 67212 | 2200 |

| Bugatti | PA 6402 | 3000 |

Water pump manufactured by Fenox

Tuning

To increase engine performance and increase service life, you can install tuning spare parts. As practice and experience show, modernized spare parts have a longer service life than standard ones.

So, for the VAZ 2112 they produce tuning parts, such as ProSport and Brembo.

Of course, their cost is about 3,000 rubles, which is twice as expensive as a standard part, but they have a smaller pulley, which allows the engine to circulate fluid faster. This, in turn, contributes to better cooling of the system.

Tuning version of the pump produced by Luzar

The engine of any car will never be able to operate stably without optimal functioning of the cooling system. The circulation of coolant inside the engine is ensured by a special pump or (pump - approx.), which is located in the gas distribution mechanism (timing) drive unit. It happens that an element fails and needs to be replaced. In this article we will talk about this in detail.

The video shows the process of replacing the pump on a VAZ-2112; usually the pump is replaced along with the timing belt during scheduled maintenance:

Step-by-step instructions for replacing the pump on a Lada-Priora car yourself

It should be noted that it is impossible to replace the water pump on a Lada-Priora car without dismantling the engine generator drive.

Required Tools

When replacing the water pump on a Lada Priora car, you will need the following tools:

- open-end wrenches No. o10, No. o15, No. o17;

- spanners No. o15, No. o17;

- Allen key No. o5;

- two screwdrivers of different sizes;

- a specially designed wrench for installing the tension roller or a puller for retaining rings;

- Torx T-30 wrench used to remove the five screws that secure the front upper timing cover;

- mounting blade.

Photo gallery: a set of tools for replacing the water pump on a Priora

The procedure consists of performing the following operations:

- The wire is disconnected from the negative terminal of the battery.

- The used coolant is drained from the vehicle's liquid coolant.

- For convenient operation, you can dismantle the adsorber (not necessarily disconnecting all its communication connections).

- At the next stage, the protective plastic engine cover is removed, as well as the belt protection cover, which drives the gas distribution mechanism (abbreviation - timing).

- Using a jack, the right front part of the car is raised, and the front right wheel is hung in the direction of travel.

- It must be removed to provide access to the timing belt housing mounting bolts.

- The position of the timing mechanism is determined by the marks (additionally, for convenient subsequent work, you can make your own marks using white paint).

- The rollers, drive pulleys of both camshafts, and the timing belt protective cover are also removed, for which it is necessary to slightly loosen the tension roller clamp.

- The timing belt is removed.

- The gears of both camshafts are unscrewed after first locking them with some flat tool (this must be done carefully so as not to damage their teeth).

- To dismantle the car's water pump, unscrew the mounting bolts, which are made for a hex key with size No. o5.

- It is necessary to unscrew them and, by tapping on the pump body, and also using a screwdriver inserted into the groove, try to pull out the water pump.

- It is possible that residual coolant will be drained, so some kind of container is provided to collect it (you need to be careful when performing this step).

- If the pump gasket remains glued to the engine body, it must be removed (this part is replaced with a new one during subsequent installation).

Assembly is carried out in reverse order.

Installation of the water pump is as follows:

- The tightening of the screw that locks the bearing installed in the VN housing is checked.

- The screw is tightened if necessary.

- The new pump is installed so that the product number is at the top.

- The mounting bolts are tightened.

- A plastic casing is installed.

- Both camshaft pulleys are secured, as well as the timing rollers.

- The engine timing belt is put on according to the pre-marked marks.

- The wheel turns the engine crankshaft.

- The tension specified by the manufacturer is adjusted, as well as the position of the belt in the pulley grooves and on the rollers.

- Top up the used coolant.

- All removed wires and hoses are connected.

- The generator drive is connected.

- The engine starts to perform the test.

Preparing to replace your pump

First of all, you need to make sure that all the necessary tools are available to replace the water pump.

You will need:

- key for 10 and 17;

- Screwdriver Set;

- hammer;

- timing clamping mechanism;

- rags;

- container for draining old coolant;

- new coolant – 2 l.

You should immediately decide on the time, since the process may take a little longer if you are performing this manipulation for the first time.

Replacement

Having purchased a new coolant pump, you can begin the replacement procedure.

The VAZ 2110 works in conjunction with 8 valve and 16 valve power units. Despite there being a certain difference between them, the pump replacement procedure is identical.

Dismantling works

The instructions below are relevant for dozens with two types of motors.

- Place the car on a level area above a hole or on an overpass.

- Lift the hood, remove the negative terminal from the battery, which will turn off the power to the car.

- Unscrew the cap of the coolant expansion tank. This will relieve excess pressure in the system.

- Now get down under the car.

- Place a clean container with a volume of at least 5 liters under the cylinder block.

- Unscrew the coolant drain plug using a 13mm wrench, which will allow you to drain the coolant. Be careful, unlike oil, you need to drain the coolant when the engine is cool.

- When all the coolant is out, screw the plug back into place.

- Using a 10mm wrench, unscrew the three mounting bolts that hold the timing case in place.

- Remove the casing.

- Place the crankshaft at TDC of the first cylinder - top dead center. To do this, you need to turn off the gear and turn the special bolt that holds the generator pulley to 19 with a key. Turn until the marks on the camshaft gear align with the mark on the rear timing case.

- Make sure that the marks on the flywheel and clutch housing match. To do this, you will have to remove the plug on the crankcase. It is made of rubber and is located to the right of the cylinder block.

- Lock the crankshaft in this position. You can use a simple slotted screwdriver that fits into the teeth of the flywheel.

- Slightly loosen the tension roller locking nut using a 17mm wrench.

- Turn the roller using a special wrench in a counterclockwise direction. This way you can loosen the tension level of the timing belt.

- Now you can quite easily dismantle the tension roller and belt.

- The next step is to remove the five mounting bolts that hold the lower timing case in place. These include 3 bolts that hold the pump. You will need a socket wrench or a 10mm socket.

- The casing can then be removed.

- The VAZ 2110 provides for installation of a pump using three hexagon bolts. Once you unscrew them, you can simply carefully remove the pump by tapping on the body.

- If that doesn't work, then use a flathead screwdriver to pry up the coolant pump housing, which will allow you to remove the pump.

- Remove traces of the old gasket that should remain on the surfaces of the seats.

Changing the gasket

- The gasket is lubricated on both sides using a special automotive sealant. The prepared and processed new gasket is placed on the body of the new pump.

- The new pump is installed in its rightful place, taking the baton from the old coolant supercharger.

Before installing a new coolant pump, make sure that it rotates normally and does not jam anywhere.

Reassembly nuances

- Reinstall the new coolant pump;

- Replace the casing;

- Fix the camshaft pulleys;

- Return the timing belt to its rightful place;

- The belt must be put on, focusing on the marks on the camshaft and crankshaft;

- Pull the belt using the tension roller and eccentric to the desired level;

- Turn the engine over several times to check that the marks match;

- Adjust the position and tension of the belt in accordance with the standards;

- Install the outer casing of the device;

- Replace the terminal from the adsorber;

- Add coolant to the required level.

Replacing the pump is an excellent reason to change the coolant at the same time. If you plan to do this in advance, you don’t have to pay special attention to the cleanliness of the container for draining the coolant.

If the pump fails some time after the coolant was changed, it is better to fill it back after the repair is completed. Still, buying a new coolant is not the cheapest thing. Learn to save wisely on repairs.

By properly organizing the replacement of the pump on your VAZ 2110, you can save a decent amount of money, plus improve your skills. On average, the work takes about 3 hours. If you follow the instructions, no pitfalls should arise during the repair process.

Loading …

Replacing the rear

It should be noted that the clutch discs may become oily due to a leak through the gearbox input shaft oil seal, or due to the rear crankshaft oil seal.

The smells of oil from the engine and transmission are different, so many experienced specialists can use the smell to determine which element is causing problems.

There is also a visual method of determination. To do this, take any container, pour some water into it, or simply use a puddle near your garage. Drop oil leaking on the clutch discs into the water and monitor its behavior. If the oil spreads and turns into a rainbow film, it is gearbox oil. And if the oil remains in the water in the form of a grain-like drop, we are talking about motor lubricating fluid.

Changing the rear oil seal is actually somewhat more difficult than changing the front oil seal. But this does not take away the fact that it is still more than possible to do the work with your own hands.

Disassembled

Following the instructions step by step, replacing the crankshaft oil seal on a VAZ 2114 will become a fairly simple task for you, which will add to your experience in repairing a car yourself.

- Disconnect the negative terminal from the battery of your VAZ 2114.

- Make notes on the location of the flywheel relative to the crankshaft, and then remove it.

- Next, the rear shield of the clutch housing is removed from the guide bushings.

- The next step is to remove the eight bolts that are responsible for securing the oil seal.

- This will allow you to remove the holder.

- The oil seal is pressed out of its holder.

- The new element is installed in place of the old one until it stops. Here you will need a mandrel again. Its outer diameter is 99 millimeters. Press in the element so that its working edge points inward.

- To make pressing easier, a chamfer is made on the seating edge of the element using a needle file. An alternative tool for bevelling is a small sanding wheel.

- Now we change the gasket, which is probably torn on the holder. Even if the old gasket looks fine, we strongly recommend replacing it with a new one.

- The gasket is glued with a special thick lubricant. This will ensure the strength of its retention, as well as additional tightness of the connection.

- The working edge of the pressed-in oil seal is treated with regular engine oil, as is the case with the front one.

- The crankshaft flange is subjected to similar processing.

- The fasteners of the engine oil sump to the cylinder block will need to be loosened slightly. To do this, it is enough to make 2-3 turns on each of the 14 bolts that hold the crankcase.

- When installing the holder, the working edge of the new oil seal is carefully tucked onto the crankshaft flange. Arm yourself with a wooden stick for this purpose, but do not use metal objects.

- Retighten the holder bolts.

- Screw back the engine crankcase mounting bolts.

- Place the clutch housing rear shield back onto the guide bushings.

- According to the previously marked places, mount the flywheel, gearbox and clutch in their place. To ensure that the flywheel mounting bolts have high quality adhesion and reliability, first apply sealant to their threaded part.

Obviously, it is quite possible to replace the crankshaft oil seals on a VAZ 2114 car with your own hands. The procedure requires accuracy and consistency of actions. Plus, do not forget to use new high-quality auto parts, so that after a short period of time you do not have to carry out the entire procedure again.

What is a pump?

Without an ideal cooling system, the engine cannot function properly for a long time and may boil at the most inopportune moment. The engine for the ten has a complex design. During operation, the pistons constantly rub against each other, greatly heating the surfaces.

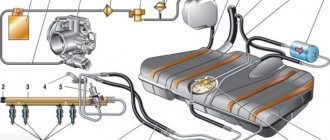

Liquids can enter directly into the vehicle's expansion tank. The pump pumps coolant, moving it through the system while the engine is running.

To check how this unit functions, you do not need to remove the pump from the vehicle; the whole procedure will take no more than ten minutes:

- you should warm up the engine to 91 degrees;

- Be sure to protect your hands;

- securely clamp the pipe;

- if everything is normal, pressure is felt in the pipe;

- if the hose is soft, then the antifreeze circulation is slowed down, which means the pump is not working properly;

- check the quality of pump operation;

- The coolant supply pipe is pinched to determine the pressure level.

You need to be careful because the coolant is hot.

How to test your pump for malfunction

In order to ensure that the pump is damaged, you need to perform a number of simple measures. First you need to warm up the engine to operating temperature, then compress the upper radiator hose. If you can feel fluid circulating in the system, then the water pump is working.

It is also worth listening to the operation of the compression unit. If you hear a hum, the bearing is probably damaged. It is necessary to urgently replace the “tens” pump, without expecting major breakdowns.

Tips for choosing

Now a little about choosing a pump. Now the automotive spare parts market offers the widest selection of this unit from a variety of manufacturers. But, unfortunately, there are also a lot of fakes.

When choosing a water pump, it is advisable to give preference to the manufacturer who supplies its products to the automobile plant.

Before purchasing, you need to inspect the pump packaging - it should be made of hard cardboard, with printed information indicating the characteristics of the unit, as well as the manufacturer’s data. There must be a holographic sticker.

Inside, in addition to the assembly, there should be a gasket for it and fastening bolts (but not always), as well as a warranty card.

Attention must also be paid to the pump itself - when checking, there should be no play, and when rotating, there should be no wedging or jamming. Many manufacturers are upgrading pumps, especially the blades.

Many manufacturers are upgrading pumps, especially the blades.

In this case, look for driver reviews on forums about this device model; in most cases you will receive true information.

Breakdown and signs

There are several characteristic signs based on which you can recognize the failure of the coolant pump:

- A hum or a rustling sound appears near the timing drive;

- There are traces of coolant leakage from the pump seat;

- Mechanical damage occurred to the belt - cracked, delaminated, teeth broke;

- The engine began to overheat excessively;

- The coolant level drops below normal, even when topping up;

- Liquid does not circulate well through the system.

Most often the pump fails due to bearing failure. It, in turn, breaks due to wear or incorrect installation of the timing belt tension. If such problems are found, the pump must be completely replaced.

Consequences of ignoring

If you ignore a pump breakdown and do not take any action to repair or replace it, this can lead to dire consequences. Namely:

- The timing belt is damaged or broken. It will then have to be repaired, the cylinder head, gas distribution mechanism, and piston group must be replaced;

- The motor is overheating. Because of this, all rubber connection elements of the engine cooling system, cylinder head gasket, valve cover, and rubber components of the piston group can be destroyed.

According to the operating manual, the pump with belt and tension rollers should be replaced every 50 thousand kilometers, or when signs of element wear appear.

The current cost of a new pump is up to 1000 rubles. And the price for replacement services at a service station is another 1,000 rubles. If you don’t want to spend that kind of money on a car service, then you can easily do the replacement yourself.

Purchase rules

If you are going to change the pump, then first you have to purchase a new part. To choose it, follow a few simple rules.

| Rule | Explanation |

| Choose a good manufacturer | Today there are a lot of pumps on the market produced by a variety of companies. Trust only proven brands. Avoid Chinese counterfeits |

| Refer to the catalog number | For standard pump VAZ 2110 catalog number 21081307010 |

| Factory packaging | After studying the manual and samples, you can discover several distinctive features of the factory packaging. They have learned to fake them, so be careful |

| Gasket included | Responsible and conscientious manufacturers must provide gaskets with the new pump. If they are not there, then it is a spare part of questionable quality, or the seller removed it to sell separately. Check online to see if the manufacturer of the pump you are purchasing includes gaskets. If yes, then all claims to the seller |

| Warranty card | Be sure to make sure there is a warranty card in the box. It will allow you to exchange the unit for a new one or get your money back if the device turns out to be defective |

Replacing the engine pump VAZ 2110, 2111, 2112 16 cl. without removing the generator drive

I had a little trouble. The pump is leaking. This creates several troubles - antifreeze runs out, the engine makes noise. And, the most dangerous thing, if the pump bearing becomes skewed or jams, the timing belt will be affected. And then, you yourself understand what the consequences are. I read a lot before the replacement: that, they say, there will be a lot of removal there. It was decided to disassemble and navigate the work independently. For convenience, I removed the adsorber without disconnecting the wires and hoses and pulled it to the side. Then I removed the plastic cover from the engine and the timing belt cover.

0:953

1:1458

Next, let's jack up... We hang up the right front wheel. This is necessary in order to put everything on the marks. By the way, for convenience, I made one mark... with white paint, which is very helpful in the future. Photo below. In the end, you will have to remove the wheel exactly, because only from below you can get to the lower bolt securing the inside of the plastic casing

And now ATTENTION))) The condition of the timing belt was excellent... Therefore, it was decided not to remove either the timing belt, or the generator drive belt, or the generator drive pulley. Which saved us a lot of time

But you still need to remove the plastic casing, which means you need to remove the camshaft pulleys and rollers. Actually, this is not difficult, we loosen the tension rollers and remove them and the timing belt. Then we use something flat to place a spacer between the camshaft gears... and unscrew them

Be careful, the teeth themselves are very soft, so only push into the teeth, not lateral pressure

1:3102

2:504

We removed the pulleys... now we unscrew the plastic casing itself (one fastening bolt will have to be unscrewed from below, from the cavity of the wheel) and finally we get to the pump.

2:789

3:1294

The pump itself is screwed on with three hexagons. We unscrew them... and gently tapping on it, we begin to pull it out... antifreeze will begin to flow... we substitute the vessel along the way so as not to make dirt. As it turned out, I got home by miracle))) The pump bearing was so damaged... there was both axial and lateral play... about 4 - 5 mm. In short, it was hanging unrealistically))) Now we take a new pump (check for the presence of lubricant in it), if the gasket is paper, then lubricate it with sealant, a thin layer... and let it dry for 5 - 10 minutes. Yes yes... the sealant should always dry out a little.

3:2315

4:504

Now we put everything back together in reverse order. We install the pump... We install the plastic casing... We install the camshaft pulleys... And now we need to put on the timing belt. In the photo you can see the mark that I made on the crankshaft pulley (circled in red)... there are marks on the camshafts. We combine everything and put on a belt, nothing complicated.

4:1063

5:1568

We turn the engine by the wheel a couple of times, adjust the position and tension of the belt if necessary, and assemble further. At this stage, you can check the operation of the engine.

5:1868

6:2373

Then we put on the cover, the adsorber... we put the wheel in place... that's all)) This work took about 3 hours.

6:203

7:708

Many people write on the Internet that you can remove the pump without removing the plastic casing - this is not true! Be sure to remove it... here's the pump mount in the photo... you can unscrew it, but you won't be able to pull it out.

7:1047

8:1552

I'm happy with the work!

8:1586

https://www.drive2.ru/l/444340/

8:1621 next article:

Engine repair VAZ 2110, 2111, 2112

Actually, it all started with the fact that the engine began to absorb too much oil, I had to constantly top it up,

9:2429

Rating 0.00 15704

Purpose

The purpose of the oil pump is to circulate oil through all engine components to lubricate them evenly and increase their service life. It is driven by an internal combustion engine (internal combustion engine) and is structurally divided into two different types, based on the principle of coupling with the crankshaft. In our case, it connects directly to the crankshaft, that is, it rotates with it. This is the operating scheme of the unit for front-wheel drive VAZ cars. Cars with all-wheel drive, as well as classics, have a more complex system installed. There, the drive contains additional links: an intermediate shaft, a timing chain (gas distribution mechanism), and toothed gears, through which torque is transmitted from the crankshaft to this device.

Common faults

So:

- Most often, the pump of the VAZ 2112 and other VAZ models with front-wheel drive leaks through the seal, which has to be changed.

- The oil receiver also often fails, especially if you use low-quality oil, or missed replacing it in a timely manner, or the oil does not meet specifications (too thick).

- Too liquid simply will not be pumped and the pressure sensor will immediately light up.

- In this case, the oil receiver mesh becomes clogged, the circulation of oil through the engine becomes difficult, causes oil starvation, and as a result, the service life of the engine is significantly reduced.

- This includes a malfunction of the pressure reducing (bypass) valve: either it is stuck in the open position, and then the oil pressure drops. Either it does not bypass, and then the oil will squeeze out through the oil seal

What oil to fill and at what frequency?

The manufacturer recommends changing the engine oil after 10 thousand kilometers, however, it is recommended to shorten this period if possible, and at the same time change the oil filter. You should only buy oil from well-known companies and, when choosing it, beware of counterfeits. The ideal option is to pour oil recommended by the manufacturer and not be fooled by cheapness or high cost (expensive does not mean high quality).

Recommendations for choosing spare parts

So:

- The oil pump usually does not cause car owners much trouble, since it has a service life of at least 120 thousand kilometers. However, no one is immune from breakdowns

- If suddenly you still need to replace the oil pump on a VAZ 2112, it is better to take original spare parts and not save

- Among the well-known suppliers of parts for VAZ cars, the official one is the Tolyatti Automobile Assemblies Plant (TZA for short).

- It also produces oil pumps for the VAZ 2112

- This is one of four varieties of such units in the VAZ line, which fits all front-wheel drive fuel-injected cars

Helpful advice: To avoid serious consequences for the car and major engine repairs, it is important to monitor the indicators on the dashboard. If the oil pressure lamp flashes at idle speed, and replacing it does not solve the problem, the lamp lights up again - this means there is a breakdown

When the warning light suddenly comes on and the performance of your car’s engine is alarming, it is recommended to turn off the ignition and call a tow truck to a repair station. This will save money on subsequent engine repairs (continuing to drive the car under its own power in such a situation, you risk serious damage to the engine).

- Typically, removing the oil pump on any car occurs when disassembling the engine.

- Only if necessary, this work is carried out on the car without removing the engine from it.

- Before starting this procedure, first drive the car into the inspection hole.

- And immediately purchase everything you need to carry out a full replacement, as shown in Photo No. 2.

Designations in the photo:

- 1 - oil pump

- 2—pan gasket

- 3 - pump gasket

- 4 - sealing ring

- 5 - sensor mounting bracket

Attention: The pumps of the VAZ 2108-1011010 and 2111, 2112-1011010 engines are almost the same, with the exception of point No. 5 - the sensor mounting bracket is different, do not miss this point!

Tip: It is recommended to install only a factory-produced gasket under the pump, since a non-standard gasket may have a thickness that does not meet the specifications and cause problems with the operation of the pump.

Necessary tool

- A set of wrenches (open-end - spanner preferably)

- Socket set and ratchet

- Two strong flathead screwdrivers

- Hexagon set

Checking the pump's health

It should be noted right away that in order to identify many problems with the water pump, this device will have to be removed from the engine and disassembled. This is the only way to see dirt, corrosion and traces of cavitation.

But there are a number of signs by which you can determine if the pump is faulty without removing it. Here they are:

- a thin continuous whistle coming from under the engine camshaft pulley. This whistle indicates a faulty bearing.

- coolant leaks, which are visible both on the engine itself and on the asphalt under the car;

- play in the pump, which can be detected by simply holding the pulley and moving the pump up and down with your hand.

Let's look at these faults in more detail.

Pump whistle

The reason for the pump whistling is a partially or completely destroyed ball bearing on the main shaft of the device. Moreover, the pump bearing, as a rule, produces a very high-pitched, piercing whistle, while the whistle of a faulty generator is significantly lower and sometimes turns into a grinding sound. This is affected by the difference in the size of the bearings: the ball bearing on the pump is small, so it whistles very thinly. The generator bearing is twice as large, so the sound comes from it accordingly. So it is almost impossible to confuse the sound of a broken pump and a broken generator.

The problem is solved by replacing the central bearing of the pump. However, there is one caveat: these bearings are practically not sold separately anywhere. And they can only be purchased in conjunction with a new pump. Therefore, the driver, having heard a characteristic thin whistle coming from under the hood, must be prepared to fork out the cash: a new water pump can cost from 2 to 10 thousand rubles (depending on the make of the car).

Coolant leak

Liquid begins to flow from under the pump in two cases:

- the mounting bolts have become loose;

- The sealing gasket under the pump is damaged.

The first problem can be solved by simply tightening the bolts. But a damaged sealing gasket will have to be replaced. Fortunately, it is easier to find a gasket for a pump on sale than a central bearing (and in especially difficult cases, car enthusiasts even order seals via the Internet, from the Chinese on Aliexpress, for example).

It should be noted here that even a new gasket can easily be cut by a pump if the mounting bolts are not tightened correctly

The pump is one of those devices where it is very important not to over tighten it. The bolts must be tightened in a cross pattern: first tighten the upper right one, then the lower left one, then the upper left one, the lower left one, etc.

Only such a tightening scheme can guarantee maximum tightness and tightness of the connection.

d. Only such a tightening scheme can guarantee maximum tightness and tightness of the connection.

Finally, we must not forget about sealants. There are situations when neither a new gasket nor the correct tightening pattern helps get rid of a leak. Then there is only one option left: to use a sealant, and its composition must be very resistant to high temperatures.

The best option here is a professional sealant from ABRO, which has proven itself on all brands of cars.

Coolant leak after replacing heat exchanger

In the vast majority of cases, after replacing the heat exchanger, antifreeze begins to flow not from under the pump, but from under the clamps of the pipe connected to the pump. On most modern cars, pump pipes are made of plastic, and very fragile plastic at that.

Any careless movement when replacing the heat exchanger, if it does not break such a pipe, will at least break the tightness of its connection to the pump. After this, the antifreeze will definitely begin to leak. There are two options to solve this problem:

There are two options to solve this problem:

- if there are no cracks in the pipe, then you can simply tighten its clamps with a flat screwdriver, then let the engine idle for a few minutes, and then check the connection for leaks;

- If the pipe is broken after replacing the heat exchanger, there is only one way out: going to the nearest auto store and replacing it. This part cannot be restored.

The pipes on water pumps are made of very fragile plastic.

conclusions

Summing up our rating, it is very important to note that truly high-quality models of coolant pumps were presented here, which have proven themselves to be the best among a large number of VAZ-2112 owners, otherwise what choice you make depends only on you

The pump is a simple assembly that consists of a housing, a bearing and an impeller. This cooling system pump circulates the coolant. If the pump does not work, then the engine will overheat. What is the pump's lifespan?

which pump to choose for VAZ

Reasons for a dying pump: Poor circulation of coolant, extraneous sounds from the timing belt casing.

VAZ pump malfunctions

The causes of breakdowns can be various, for example, the formation of play or jamming of the bearing. It is not uncommon for the impeller to start spinning freely, but separately from the shaft. If the pump is leaking or making noise, then it also needs to be replaced.

The service life of the pump depends a lot on the quality of the pump. For example, a defective or low-quality pump can work for only 10 thousand km. If the pump lasted more than 100 thousand km, then it is generally accepted that it was a high-quality pump. From the factory, VAZs are equipped with TZA pumps, which have a long service life.

How to distinguish a fake? The pump must be in a high-quality box, inside it is a warranty card with the date of manufacture and stamps and a gasket. There is a holographic sticker on the pump.

How to change the pump on a VAZ 2110?

None Which pump is better to choose?

So, let's vote and leave.

pump reviews

- Which pump did you choose?

- How long did the old pump last?

ps All off-topic comments will be deleted.

| Which is the best pump to buy for VAZ? | How long did your pump last? |

Keywords:

modification of the engine cooling system

The thorny path to replacing the timing belt and rollers has been completed, along with the water pump (coolant pump). It became thorny, firstly, due to the fact that for two years or 25 thousand kilometers I drove with a belt installed by the previous owner, which involuntarily destroyed the stereotype that you can’t trust car salesmen. He was a normal guy, he said to replace it in the spring, I replaced it two days later... The old belt, by the way, proudly demonstrated by the master (“Christina”), at the time of replacement, turned out to be cracked at least one of the teeth.

The pump has also suffered over the past years - the play was no less proudly demonstrated, and upon leaving the service center I personally noted a decrease in the noise level from under the hood. The replacement of the latter was dictated more by the expediency of combining work than by real suspicions of an imminent end. The 124th engine does not bend the valves when the belt breaks, it was possible not to worry, but... perfectionism is a serious disease.

After all, thorniness is also due to the specifics of the choice of spare parts. I mean it's hard. And this is what was replaced (price + delivery cost): - INA timing drive kit

(Slovakia) - 1390+600=2000 rub.

// alsport.ruAccording to the assurances on the website “ Used in motorsport.

Improved timing belt design from INA. Instead of neoprene, enriched nitrile is used, because When heated, neoprene becomes rigid and loses its elasticity. “

The kit from Priora, sent earlier by mistake, turned out to be equipped with INA rollers with a Contitech belt.

And here is pure INA.

— coolant pump TZA Sport (Tolyatti) — 503+325=828 rub. //nbklada.

Design features:— New 8-blade impeller 21118 with a modified profile and direction of the blades, productivity above 170 l/min for use in internal combustion engines operating with increased loads;— Cassette-type oil seal from MTU, made in Italy;— Bearing from KINEX ” manufactured in Slovakia. This allowed: - to increase the pump performance by 20-40%; - to improve the operation of the internal combustion engine cooling system; - to improve the operation of the vehicle interior heating system;

— increase the working life of the pump by 40%.

The pump change was also marked by a replacement of the coolant - there is no need to skimp on antifreeze after last year's problems with antifreeze - AGA Z42 antifreeze

(10 liters of potion);

SCT fuel filter

(unfortunately there was no Knecht Mahle);

10W40 MotorGold oil

(5 liter canister, manufactured in 2012 - not only can this oil be bought in only two stores in the city, but also their 12th year can be considered a fresh batch...)

with a Knecht Mahle filter

;

oil seal

closest to the headlights due to detected fogging (Balakovo, FPM tires). Total: 960+130+(1100+130)+100=2420 rub. The total cost of the work was 1900 rubles. Some expensive update came out (Price: 7,200 ₽ Mileage: 126,960 km

- carfrance.ru

- xn--2111-43da1a8c.xn--p1ai

- www.drive2.ru

How to change pipes on a pump

Replacing the pipe on the water pump is advisable in cases where the hose is swollen or has small cracks through which antifreeze leaks out. A significant disadvantage of changing the pipes is that they are located below the pump - that is, you will have to jack up the body and crawl underneath.

The old pipes are removed after the antifreeze has been drained and the pump itself has been dismantled

It is important to clean the landing site from dust, dirt and coolant leaks. Then connect new pipes to the new pump, installing a new gasket at the junction

It is recommended to use heat-resistant sealant to ensure reliable connections.

Before installing new pipes, it is necessary to drain the antifreeze from the cooling system.

Signs of a faulty pump VAZ 2113 2114

The main symptoms of a malfunction of the VAZ 2113 and 2114 pumps are:

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

Article Author's Note: Often a decrease in performance is noticed after using a sealant to repair a radiator leak. The poured mixture clogs the cooling system channels and sticks to the pump impeller.

Leaking pump seal VAZ 2113 VAZ 2114

One of the most common signs of a malfunction of the VAZ 2113 and VAZ 2114 pump is its leakage. A pump leak can occur due to wear of the seals or cuff. That is, it will be necessary to remove the pump, disassemble it and replace the worn element. The procedures for removing and installing the pump will be described below.

The appearance of pump noise VAZ 2113 VAZ 2114

If during operation of the VAZ 2113 and VAZ 2114 engine you hear extraneous noise from the pump area, this indicates an imminent breakdown of the unit. The most likely cause of noise is failure of the bearings or weak fastening of the impeller. In any case, the part needs to be dismantled, subsequently damaged, repaired or replaced.

Increased vibration of the pump VAZ 2113 VAZ 2114

Another common malfunction of the VAZ 2113 and VAZ 2114 pump is its increased vibration. This sign indicates wear on the shaft bearing or pump belt tension roller.

Replacing the pump on a VAZ 2110/11/12

VAZ cars of the tenth family are produced with 8- and 16-valve engines. The pump replacement algorithm does not depend on the number of valves.

Pump selection

When purchasing a new pump, you should adhere to the following rules:

You should choose a reliable manufacturer, giving preference to well-known brands and avoiding cheap counterfeits. You need to pay attention to the product catalog number - 21081307010 for VAZ 2110/11/12. The product must have original packaging with trademarks and holograms characteristic of each manufacturer. A gasket should always be supplied with the pump. The package must contain a warranty card that allows you to exchange or return the pump if defects are found.

A high-quality pump should include not only the original packaging, but also a warranty card with a gasket

The cost of a new pump for an 8-valve engine starts from 800 rubles, and for a 16-valve engine - from 1 thousand rubles. In a car service center, the work of replacing a pump is estimated at approximately 1 thousand rubles. The most popular are water pumps produced by TZA and HEPU.

Pump location

On the VAZ 2110/11/12 the water pump is located on the cylinder block on the right side. This is due to the design features of the gas distribution mechanism, since the impeller begins to rotate only after the engine and timing belt are started. That is, the design of the gas distribution mechanism initially involves the use of a pump.

The water pump is part of the timing mechanism and is installed on the right side of the cylinder block

Required Tools

To replace the pump you will need a minimum set of standard tools:

- open-end wrench 17;

- head at 10;

- extension;

- collar

To replace the pump you will need a minimum set of standard tools

Signs that your water pump is bad

There are several signs of problematic functioning of a car pump:

- timing noises when driving;

- pump leakage as a result of depressurization;

- belt damage, for example, asymmetrical cracks, peeling.

Drops of liquid can be found on the assembly and on the asphalt surface after the car has been parked there. The pump for this model will have to be changed every 50,000 kilometers.

If you do not replace the pump, the timing belt may break, valve mechanisms may bend, moving parts may jam, or the engine may overheat. When purchasing components, you should clarify:

- branding of the manufacturer;

- number;

- cleanliness of packaging;

- Are gaskets included?

- Is there a quality guarantee from the factory?

A high-quality pump for tens is equipped with a pump that is mounted on the right side of the cylinder block.

Changing the unit to a VAZ 2110-2112 does not require additional equipment or knowledge, and the design itself involves the purchase of wrenches and open-end wrenches.

You will need to remove any remaining fluid before most work on the cooling system is done, as this will help relieve pressure or risk of injury.

If the antifreeze has recently been completely replaced, then you can drain not all the liquid, three liters to eliminate excess pressure. After replacing the old pump with a new one, you need to add fluid to the previous level.