Hello, dear car enthusiasts! Without a doubt, one of the most important attributes for safe driving is the steering. Attempts to find another way to give the machine the required direction of movement do not stop.

But in the coming decades, automakers are not going to change their traditions of putting steering wheels in cars. The steering is very reliable, durable, and informative. The steering system does not have many parts, and it is not difficult to understand.

As a rule, almost no attention is paid to such a part of the steering as the steering gear, mistakenly believing that a piece of metal rod cannot create problems.

Despite its structural simplicity, the steering column also wears out and can give the driver many “surprises”. A heart-rending squeak when turning the steering wheel is the most harmless nuisance that a steering column can cause.

The rotation of the steering wheel seems much more frightening when the car does not change the direction of its movement due to such actions. Such a breakdown can cost the life of the driver, passengers and other road users. The steering column must be monitored and kept in good condition.

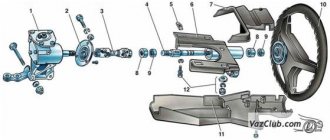

Steering column VAZ 2106 – 2107. Design and purpose of elements

Bumpy steering column VAZ 2101-07

Despite all the unity and similarity of the structure of the elements of classic VAZ models, there are still differences between them. This also applies to the steering column. Any car enthusiast knows that the steering column or steering wheel shaft is designed to transmit rotational motion from the steering wheel to the steering worm shaft.

The column itself is held on the body using a special bracket, as well as a rigid clutch to the steering mechanism. The steering column of the VAZ 2106 is an all-metal shaft, which in the upper part has an external spline connection and thread for attaching the steering wheel, as well as an internal spline connection for attaching the worm shaft to the upper part.

The steering column of the VAZ 2107 has a more complex structure: it includes two “cardanic joints” - hinges that allow the shaft to fold. Thanks to this device, the steering column is called injury-proof.

In the event of an accident and a blow to the front left side of the car, the steering shaft folds in hinges and does not injure the driver. In addition, the upper shaft of the “seven” has 2 needle bearings, which greatly facilitates control.

Typical steering column problems

Given the simple design of the steering column, there may not be many breakdowns. It is important not to ignore “signals” from the steering column itself about a malfunction and carry out repairs in a timely manner.

Among the main signs of a faulty steering column, the following should be highlighted:

- creaking in the steering column, which can be caused by wear of elements, deformation of facing panels and trim, malfunction of parts of the steering column switch unit;

- play in the steering column is a more serious symptom. Play in the plane of the steering wheel may indicate wear or weakening of the bracket elements, and axial play indicates weakening of the spline joints.

Provided that all parts are installed properly, the steering column will serve for a very long time. Loosening the bolts and nuts of spline joints leads to free play and gradual wear of the splines.

As a result, this leads to the fact that the column rotates and becomes unusable, since the connection without splines can no longer perform its function.

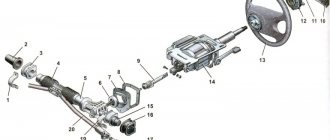

DIY steering column replacement

Considering that the spline joints in the steering column cannot be restored, provided that the steering wheel and steering mechanism are in good condition, the steering column simply needs to be replaced.

The column itself is quite easy to remove; much more time is required for the preparatory procedures.

The steering column is replaced as follows:

- the battery is turned off;

- the steering wheel and steering shaft casing are removed;

- the steering column control system (switch) and ignition switch are removed;

- the steering bracket bolts are unscrewed (some of them will have to be drilled out);

- the coupling bolt of the splined connection with the steering mechanism is unscrewed;

- the lower shaft seal is unscrewed and it is removed inside the cabin.

When starting to repair a car, you should make a rule of putting the removed parts one by one. This will make reassembly much easier. This will make your work easier, and there will be significantly fewer stupid questions on car Internet forums.

How to replace the steering shaft of a VAZ 2101, VAZ 2102, VAZ 2103, VAZ 2106?

Removal: 1) First, de-energize the battery; to do this, remove the “Negative” terminal from it. (For information on how to remove the terminal, see the article: “Replacing the battery” in paragraph “1”)

2) Next, remove the steering wheel from the car. (For information on how to remove the steering wheel on a VAZ 2106, see the article: “Replacing the steering wheel on a VAZ”)

Note! On other cars such as VAZ 2101, VAZ 2102, etc. The steering wheel can be removed following the example of removing the steering wheel on a VAZ 2106!

3) Now remove the casing from the steering column by unscrewing all the lower screws that secure it.

Note! For more information on how to remove the casing, read the article entitled: “Replacing the instrument panel”, in paragraphs “1-2”!

4) Next, find three blocks that are connected to three wire connectors, and after finding them, disconnect them from each other.

5) Then loosen the bolt that secures the clamp of the switch (Turn, light, etc.), and after unscrewing the bolt, carefully remove the switch by sliding it toward you along the shaft.

6) Next, remove the two screws that secure the ignition switch.

7) And after that, insert the key into the lock and turn it to position “0”, and then carefully insert a thin screwdriver into the hole and press the latch, and then remove the lock by pulling it by the key that is inserted in this lock.

Now you should use a marker and thereby make marks on the wires relative to the ignition switch so that when reinstalling the wires they do not get mixed up.

9) Next, unscrew the two bolts and two nuts that secure the steering shaft bracket to the car body.

10) Next, loosen the bolt that tightens the terminal connection of the steering shaft to the steering shaft by 2-3 turns.

Note! After the bolt is loosened, loosen the terminal connection as far as you can using a screwdriver!

We recommend: Opel Astra H fuses and relays in a complete set

11) Next, without removing the screwdriver from your hands, loosen the bolt that tightens the clamp securing the tube of the upper shaft support by 2-3 turns.

Note! After loosening the bolt, slide the tube up the shaft and remove it. Following the tube, slide and thereby remove the shaft bracket indicated by the arrow!

12) Finally, pull the shaft towards you and thereby remove it from the car.

Installation: 1) Installation is carried out in the reverse order of removal.

Note! Before you start installing the new steering shaft in its place, pick up the shaft mounting bracket and loosen the two nuts that secure it!

And all the nuts and bolts need to be tightened only after the shaft and all the removed parts are finally installed in their places!

Hello, dear car enthusiasts! Without a doubt, one of the most important attributes for safe driving is the steering. Attempts to find another way to give the machine the required direction of movement do not stop.

But in the coming decades, automakers are not going to change their traditions of putting steering wheels in cars. The steering is very reliable, durable, and informative. The steering system does not have many parts, and it is not difficult to understand.

As a rule, almost no attention is paid to such a part of the steering system as the steering column, mistakenly believing that a piece of metal rod cannot create problems.

Despite its structural simplicity, the steering column also wears out and can give the driver many “surprises”. A heart-rending squeak when turning the steering wheel is the most harmless nuisance that a steering column can cause.

The rotation of the steering wheel seems much more frightening when the car does not change the direction of its movement due to such actions. Such a breakdown can cost the life of the driver, passengers and other road users. The steering column must be monitored and kept in good condition.

Steering column VAZ 2106 – 2107. Design and purpose of elements

Despite all the unity and similarity of the structure of the elements of classic VAZ models, there are still differences between them. This also applies to the steering column. Any car enthusiast knows that the steering column or steering wheel shaft is designed to transmit rotational motion from the steering wheel to the steering worm shaft.

The column itself is held on the body using a special bracket, as well as a rigid clutch to the steering mechanism. The steering column of the VAZ 2106 is an all-metal shaft, which in the upper part has an external spline connection and thread for attaching the steering wheel, as well as an internal spline connection for attaching the worm shaft to the upper part.

The steering column of the VAZ 2107 has a more complex structure: it includes two “cardanic joints” - hinges that allow the shaft to fold. Thanks to this device, the steering column is called injury-proof.

In the event of an accident and a blow to the front left side of the car, the steering shaft folds in hinges and does not injure the driver. In addition, the upper shaft of the “seven” has 2 needle bearings, which greatly facilitates control.

Typical steering column problems

Given the simple design of the steering column, there may not be many breakdowns. It is important not to ignore “signals” from the steering column itself about a malfunction and carry out repairs in a timely manner.

Among the main signs of a faulty steering column, the following should be highlighted:

- creaking in the steering column, which can be caused by wear of elements, deformation of facing panels and trim, malfunction of parts of the steering column switch unit;

- play in the steering column is a more serious symptom. Play in the plane of the steering wheel may indicate wear or weakening of the bracket elements, and axial play indicates weakening of the spline joints.

Provided that all parts are installed properly, the steering column will serve for a very long time. Loosening the bolts and nuts of spline joints leads to free play and gradual wear of the splines.

As a result, this leads to the fact that the column rotates and becomes unusable, since the connection without splines can no longer perform its function.

DIY steering column replacement

Considering that the spline joints in the steering column cannot be restored, provided that the steering wheel and steering mechanism are in good condition, the steering column simply needs to be replaced.

The column itself is quite easy to remove; much more time is required for the preparatory procedures.

The steering column is replaced as follows:

- the battery is turned off;

- the steering wheel and steering shaft casing are removed;

- the steering column control system (switch) and ignition switch are removed;

- the steering bracket bolts are unscrewed (some of them will have to be drilled out);

- the coupling bolt of the splined connection with the steering mechanism is unscrewed;

- the lower shaft seal is unscrewed and it is removed inside the cabin.

When starting to repair a car, you should make a rule of putting the removed parts one by one. This will make reassembly much easier. This will make your work easier, and there will be significantly fewer stupid questions on car Internet forums.

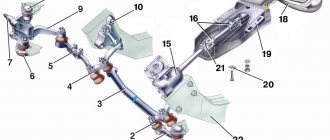

Signs of breakdown of the gearbox and other elements of the steering system

The steering gearbox on a VAZ 2106 very rarely fails alone. As a rule, a gearbox failure is preceded by the failure of several elements of the steering system, after which the gearbox itself breaks down. That is why it is better to consider the problems of this system as a whole. We list the most well-known signs of a breakdown of the control system on the “six”:

- when turning the steering wheel, a characteristic grinding or loud creaking sound is heard from under the steering column;

- the driver observes a constant leak of lubricant from the gearbox;

- turning the steering wheel began to require more effort than before.

Now let’s look at what exactly can cause the above symptoms and how to eliminate them.

Steering system noise

Here are the main causes of noise behind the steering column:

- The clearance on the bearings installed in the steering wheel hubs has increased. Solution: adjust the gap, and in case of significant wear of the bearings, replace them completely;

- The fastening nuts on the steering rod pins have become loose. It is these nuts that usually cause loud squeaking and grinding noises. Solution: tighten the nuts;

- The gap between the bushings and the pendulum arm of the steering system has increased. Solution: replacing the bushings (and sometimes you have to change the bushing brackets if they are very worn);

- The worm bearings in the gearbox are worn out. A grinding noise when turning wheels can also occur due to them. Solution: replace the bearings. And if the bearings are not worn out, it is necessary to adjust their clearances;

- loosening the fastening nuts on the swing arms. Solution: tighten the nuts after placing the car wheels straight.

Leakage of lubricant from the gearbox

A lubricant leak indicates a violation of the seal of the device.

- The seals on the bipod shaft or on the worm shaft are completely worn out. Solution: replace the seals (sets of these seals can be purchased at any spare parts store);

- The bolts holding the steering system housing cover have become loose. Solution: tighten the bolts, and they must be tightened crosswise. That is, first the right bolt is tightened, then the left, then the top bolt, then the bottom, etc. Only such a tightening pattern can guarantee the tightness of the crankcase cover;

- damage to the sealing gasket under the crankcase cover. If the above tightening pattern does not lead to anything, it means that the seal under the crankcase cover has worn out. Therefore, the cover will have to be removed and the sealing gasket replaced.

The steering wheel turns hard

If the driver feels that it has become very difficult to turn the steering wheel, this can happen for the following reasons:

- Incorrect alignment of the steering wheels. The solution is obvious: install the car on a stand and set the correct toe and camber angles;

- one or more parts of the steering system are deformed. Steering rods are usually deformed. And this happens due to external mechanical influences (flying stones, regular driving on uneven roads). Deformed rods will have to be removed and replaced with new ones;

- the gap between the worm and the roller in the steering gear has increased (or vice versa, decreased). Over time, any mechanical connection can become loose. And worm joints are no exception. To eliminate the problem, the roller gap is adjusted using a special bolt, then the gap size is checked using a feeler gauge. The resulting figure is checked against the figure specified in the operating instructions for the machine;

- The nut on the swing arm is too tight. The peculiarity of this nut is that over time it does not weaken, like other fasteners, but rather tightens. This occurs due to the specific operating conditions of the pendulum arm. The solution is obvious: the nut should be slightly loosened.

Steering column device

In the VAZ sixth model, the steering column arrangement is similar to many other vehicles. The purpose of this vehicle control unit is to transmit the muscular efforts of the driver turning the steering wheel to the worm-type steering column shaft with subsequent transmission of the rotational force to the wheelset. The steering column itself is attached to the car body with three powerful bolted connections using a special fastener element and has a rigid connection with the steering mechanism.

There is an installation bolt in the top of the cover, which is used to adjust the steering column if necessary. This need arises if increased play is detected in the steering column, which in its projection represents a shaft made of a solid metal pipe, equipped at the top with splines and an external threaded connection for fastening the steering wheel, as well as splines on the inside for fastening the worm shaft in the upper position.

Taking into account the simplified design of the steering column of the VAZ 2106, the defects of such a unit are few. In such a situation, the main thing is to literally listen to the operation of the steering column, to the sounds that it makes during operation. Timely diagnosis and adjustment of the steering column is of great importance, which can be carried out without the involvement of specialist car repair specialists.

Typical steering column defects include:

- creaking in the steering column caused by increased wear of components, temporary changes in the lining, defects in the elements of the switch system located under the steering wheel;

- play in the steering column, which is regarded as a more serious sign of a malfunction of the steering mechanism. Such play in the steering column ultimately leads to increased wear of components or their sagging. At the same time, the play of the steering column along the projection of the axis of the product indicates a weakening of the spline connections, which can provoke a situation where the splines begin to wear out.

We recommend: How to change the battery in Volkswagen keys

To eliminate deficiencies in the functionality of the steering column during repairs, it is necessary to use a steering column repair kit, which can be used to eliminate any malfunctions that have arisen.

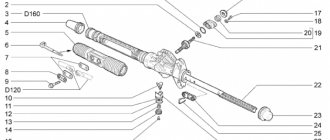

Filling oil into the steering gear

As mentioned above, the steering gear housing is sealed. Oil is poured inside, which can significantly reduce friction of parts. Any GL5 or GL4 class oil is suitable for a VAZ gearbox. The viscosity class should be SAE80-W90. Many owners of “sixes” fill in the old Soviet TAD17 oil, which also has an acceptable viscosity and is cheaper. To fill the gearbox completely, you will need 0.22 liters of gear oil.

How to check the oil level in the steering gear

In order for the steering gear parts to last as long as possible, the driver must periodically monitor the oil level in this device and, if necessary, add lubricant.

- The gearbox cover has a hole for filling oil, closed with a plug. The plug is unscrewed using an 8-mm open-end wrench.

Oil filling sequence

If the driver needs to add a little oil to the gearbox or change the oil completely, he will need an empty plastic bottle, a piece of plastic tube and a medical syringe of the largest volume. It should be noted here that the operating instructions for the machine say: the oil in the steering gear should be changed once a year.

- The oil plug on the gearbox cover is unscrewed. A plastic tube is placed over the syringe. The other end of the tube is inserted into the drain hole of the gearbox, the oil is drawn out into a syringe and poured into an empty plastic bottle.

How to reduce backlash?

The gearbox does not require special care during operation; the main thing is to prevent oil leakage and maintain its level at normal levels. If play appears in the gearbox, the wheels turn only after the steering wheel reaches a certain angle of rotation. This creates inconvenience in driving a VAZ 2106.

You can reduce the backlash yourself; for this you will need an assistant, a 19-mm wrench and a flat-head screwdriver:

- Unscrew the nut on the adjusting bolt;

- Have an assistant turn the steering wheel a quarter turn in both directions;

- At the same time, screw in the screw until you are sure that the play has disappeared;

- Tighten the nut firmly.

After these manipulations, the steering movement will become tighter.

Replacing the upper arm

Removing the upper arm

To replace the upper arm of the VAZ 2106 front suspension yourself, you will need keys 13 and 22, a jack, a support, and a wheel wrench for removing the wheel. To dismantle the upper front suspension arm, you must follow the instructions:

- Raise the car on a jack and remove the wheel, then place a support under the lower arm and lower the car. This is necessary to load the suspension to the point that the car is standing under its own weight. The levers will then be aligned.

- Secure the upper arm axle with a wrench and loosen the axle nut by unscrewing it until it aligns with the end of the axle.

- Unscrew the bolts that hold the upper ball joint in place, and then move the lever up a little and completely unscrew the axle nut, pulling the axle out of the lever.

- Remove the lever together with the silent blocks without dismantling them.

Next, carry out all the work that required you to remove the front suspension arm of the VAZ 2106, and install it in place or replace it with a new one. The assembly process is the same as disassembly, but in reverse order.

Replacing the steering column of a VAZ 2106

It is no secret that not only the controllability and stability of the car, but also the safety of the people in it depends on the serviceability of the steering system. When you first suspect a breakdown, you must quickly diagnose and fix the problem. But what is the right way to proceed? In fact, everything is simple - just know the design features of the unit, possible faults and methods for eliminating them. And in this article we will focus on one of the most important elements of the system - the steering column.

Purpose, device and features

The steering column is the connecting link between the steering wheel in the cabin and the wheels of the car. Its task is to transmit commands from the driver turning the steering wheel to the worm of the steering mechanism. Many car enthusiasts underestimate the importance of this unit. But in vain. Ignoring seemingly insignificant problems can lead to the destruction of mechanical elements and, as a result, loss of vehicle controllability. It's scary to imagine how this could end when driving on the highway.

Among the structural elements of the column, it is worth highlighting the shaft itself (essentially the same steering column), the bracket on which the steering wheel is attached, the bearing, the crosspiece (some models have it) and the steering wheel. Please note that even in classic models of AvtoVAZ products, the design of the steering columns may vary. For example, in the “six” it is a solid shaft made entirely of metal. On top there is a spline connection and a special thread for mounting the steering wheel. On the other side of the column there is an internal connection intended for fastening to the worm gear. In the same “seven” the design of the mechanism is more sophisticated. It includes a pair of small hinges that allow the steering column to fold in the event of a powerful frontal impact. Thanks to this property, this type of design is called “injury-proof”.

Signs and causes of failure

Signs of a faulty steering column are as follows: 1. A knocking sound appears in the rack. If nothing is done, the sound will increase (especially with frequent trips on uneven roads). Over time, strong feedback will appear in the steering wheel, which in itself is very dangerous. The longer you ignore the problem, the worse the controllability will be, and the greater the likelihood of complete failure of the unit. 2. The occurrence of backlash. The appearance of play in the axle is often caused by loose spline connections, and in the plane - by problems with the bracket elements (wear or weakening of the structure is also possible here). 3. Creaking in the steering column is often caused by bending of facing panels or trim, or failure of the steering column switch unit. With high-quality installation and timely care, the steering column can last a very long time. But most car enthusiasts don’t even look under the car. With such operation, after just a few thousand kilometers, nuts and bolts may become loose, play may appear, and the splines may wear out. Over time, the unit becomes completely unusable.

Replacement features

I would like to note that replacing the steering column is a very complex process that will require some patience and knowledge from you. But armed with the necessary tools and tips from the article, you will definitely cope with the task. As an “experimental” we use one of the most popular domestic cars - VAZ-2106.

So, let's get started: 1. Drive the car onto a pit or overpass. If this is not possible, raise one of the sides with a jack and secure it with a wooden stand. 2. Prepare the necessary tools. You will need a wrench with a head at “30” and at “17”, a wrench (it is important that it is long and powerful), a hammer, a pry bar, a handle with a ratchet and one open-end wrench at “17”. 3. Immediately find the steering column - for the “six” it is located in the lower left corner. 4. Remove the steering shaft (without this, further work will be impossible). 5. Unscrew the nut holding the column to the steering rods. This is where big problems can arise. To make your task easier, treat the threads thoroughly with WD-40 and stock up on a long lever (two powerful wrenches will be just right). Be prepared to use a lot of force.

Some car enthusiasts do not unscrew this nut at all - they simply dismantle the column and steering ends assemblies (here it all depends on your tasks). If you still decide to unscrew the nut, then be prepared for another very unpleasant job - knocking the column off the splines. 6. Unscrew the bolts securing the column and spar. Getting access to them is a very difficult task, so remove the front left wheel (the work will be much easier). 7. Take the knob at “17” and unscrew the three fixing bolts one by one. To prevent turning on the other side, hold the nut with an open-end wrench. Please note that there is very little space there, so the key will have to be inserted and held from the end. 8. Once you have managed to remove all the bolts from their “established” positions, finish the job using a more convenient ratchet. 9. After removing all bolts, remove the column. And here the nuance that we discussed in point 5 “pops up”. If the tips are disconnected, you can safely remove the assembly. Have you decided to unscrew the big nut? “Then you’ll have to work extra hard to knock it off the slots.”

10. Now install the new steering rack and reassemble the unit in reverse order.

We recommend: Tuning the VAZ 2105 carburetor

In principle, if you have the necessary tools at hand and minimal technical talent, this work can be completed in 1-2 hours at a leisurely pace and with smoke breaks.

Conclusion

A good driver will never cause a fault and will detect the defect at an early stage. Follow this principle too. When you first suspect that the pad is failing, inspect it and, if necessary, replace the unit. Why put yourself and your loved ones in danger if you can spend only 1-2 hours of personal time, solve the problem and calmly go on a trip. Good luck.

How to disassemble the steering gear of the “six”

If the driver decides not to change the gearbox on his “six”, but only replace the seals or bearings in it, then the gearbox will have to be almost completely disassembled. To do this, you need the following things:

- large socket head 30;

- puller for gearbox bipods;

- flat screwdriver;

- hammer;

- vice.

Sequence of work

It should be said right away that a puller and a vice are the main tools when disassembling the gearbox. It is better not to start disassembling without them, since it will not be possible to replace these tools with anything.

- There is a fastening nut on the gearbox bipod. It is unscrewed with an open-end wrench. After this, the gearbox is installed in a vice, a puller is put on the bipod as shown in the photo, and the rod is carefully moved from the shaft with the puller.

Video: disassembling the steering gear of a “classic”

Replacing the steering column

The need to replace the steering column arises if the splines in the connecting pair are worn out, and this connection cannot be restored. To do this, you need to dismantle this mechanism. For this purpose, it is necessary to disassemble the “Shohi” steering column, which even novice motorists can do. The procedure for removing the steering column is not particularly difficult technologically, but preventive measures take a lot of time.

Information for car enthusiasts: when replacing the steering column of the “six”, a slight modernization of this unit is allowed. It is possible to install a steering column from a VAZ 2107, the design of which is complicated by two small cardan shafts, increasing the degree of safety of the mechanism. In addition, additional equipment of the system with needle-type bearings will allow significantly less effort to be applied to the rotation of the steering wheel.

The required replacement of the steering column is carried out in the following sequence:

- We de-energize the battery and carefully remove it from the car and put it aside so that it does not interfere with work.

- We dismantle the steering wheel and the protective coating of the steering column shaft.

- We turn off the steering column control complex and the ignition switch.

- We dismantle the bracket fasteners, and it is possible that individual fastener components will have to be removed using a drill.

- Unscrew the tie bolt connecting the splines to the steering mechanism.

- We dismantle the sealing mount of the steering column shaft, and it is pulled out into the interior room.

Additional information: after completing the repair of the steering column, it is necessary to adjust the wheel alignment of the wheel pair to restore the required conditions of the chassis. It is almost impossible to install the wheelset at the optimal angle yourself without special adjustment equipment and stands.

Important: long-term operation of the “six” with splined joints, subject to increased wear, can ultimately create an emergency situation that is dangerous to the health and life of the driver and passengers. The steering wheel may turn completely uncontrollably, and this can happen at high speed. This is very life-threatening!

Substitutes

| vendor code | Price, rub.) | vendor code | Price, rub.) |

| Delphi 65140 | 850 | Finwhale 23593 | 800 |

| LS1219/S | 850 | VR311 | 800 |

| Bosch 17888 | 950 | TRW 26401 | 800 |

| 986487217 | 850 | GS8164 | 850 |

| HZTS 79927 | 800 | 2101-3502090 | 800 |

| Start 63275 | 800 | 21010-3502092 | 850 |

| MASTER SPORT 2103-3502093 | 850 | 030137-02332 | 800 |

The lists are presented for informational purposes. Before purchasing, be sure to consult with a specialist from a service center or auto store to determine the compatibility of the catalog article with the make/model of your car.

Step-by-step replacement of the steering column

Having decided to replace the steering column on a VAZ-2106 yourself, you need to stock up on free time and patience, and experts recommend performing this step in stages:

- The steering shaft, which is clamped in the column, should be carefully removed.

- Using a size 30 wrench and a long wrench, you should try to rip off the connecting nut that secures the steering column. It is not always possible to remove the fasteners the first time, but since this stage is mandatory, you have to return to it several times.

- The three fasteners that connect the column to the car body are unscrewed. It is most convenient to use a so-called ratchet for this process, since the bolts are not so easy to get to with a regular wrench.

- After unscrewing all the fasteners, you need to free the column from the tie rod splines, which continue to hold the assembly. To do this, you should pry the structure with a pry bar and try to knock it down with sharp jerks.

- After dismantling the unit, it is necessary to check the condition of the boot and oil seal; if even minor damage is detected during a visual inspection, these components must be replaced. By installing a new boot, the life of the bearing and shaft will be extended, and the new oil seal will not allow automotive lubricant to leak out of the steering column.

If all components are installed correctly, the car owner will replace the failed elements with high-quality and reliable ones, and the steering column will have a long service life.

The final stage of the replacement is to install a new steering column and assemble all components in the reverse order.

To simplify the assembly process, experts recommend putting all the removed elements from the car in strict sequence, so that when assembling the structure, you don’t confuse anything and repeat the whole process again.

↑ Adjusting the gearbox engagement

- Remove the protective cap from the adjusting screw. Using a 17mm wrench, loosen the nut so that you can lift the lock washer.

- We quickly turn the steering wheel left and right several times at an angle of about 10° and at the same time use a slotted screwdriver to tighten (unscrew) the adjusting screw until the free play and forces on the steering wheel are within acceptable limits. It is not recommended to over-tighten the screw.

After adjustment, tighten the nut, holding the adjusting screw with a screwdriver from turning.

↑ How to remove steering play on a VAZ 2106

If axial play of the pendulum arm axis is detected, then tighten the nut on the top of the axle. To do this, in the engine compartment, remove the cotter pin from the castle nut, use a 19-point socket wrench to turn it 60° (one edge) and check the play again.

If the play does not disappear, then tighten the nut again and install the cotter pin. If, after tightening the nut, the force required to turn the steering wheel increases significantly, then we repair the pendulum arm.