Camshaft location

Modern cars most often use a mechanism with an overhead camshaft, which has reduced the metal consumption of the structure and, as a result, increased reliability.

Since metal expands when heated, and the valves are constantly in a high-temperature zone, to prevent it from being pressed in, as a result of which it does not fit tightly into the seat, a thermal gap is provided between the valve stem and the camshaft cam.

In this case, the thermal gap has a certain value to ensure the maximum possible opening of the valve, eliminating its tightening.

Previously, on engines with an overhead camshaft, the thermal clearance was adjusted by placing shims of a certain thickness between the valve stem and the camshaft cam.

The disadvantage of using these washers was the need to periodically check the gap and adjust it by selecting washers.

Nowadays, to ensure thermal clearance, hydraulic compensators are increasingly being used, popularly known as hydraulic compensators, the use of which eliminated the need to adjust the gap, and all because the gap is adjusted by oil pressure.

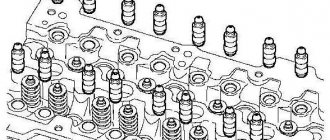

Hydraulic compensators, like shims, are located between the valve stem and the camshaft cam.

Externally, the hydraulics look like a small piston, so the head has seats for them.

What are the types of hydraulic compensators?

Manufacturers can install these products on any type of gas distribution mechanism. Based on the types of timing belts, it is customary to use the following classification:

- roller tappets;

- hydraulic support of the lever;

- hydraulic support for the rocker arm;

- hydraulic pusher.

Although a special design is used in each case, the same operating principle is repeated in all cases. They almost equally effectively compensate for the gaps between the camshaft cams and the pushers.

Design and operating principle

The design of the hydraulic compensator itself is simple. It consists of a cylindrical piston, the bottom of which receives the force from the camshaft cam.

Inside this piston, a plunger is installed in its seat, through which force is transmitted through the piston from the cam to the valve stem (see photo above).

The plunger moves freely in its seat, providing a thermal gap.

The hydraulic valve works like this: when the engine is running, the cam runs up against the bottom of the hydraulic compensator piston and moves it down. While moving, the piston presses on the valve through a plunger, and it opens.

The gap is adjusted using oil.

The oil pump supplies working fluid to the head under pressure. In the hydraulics, it enters the space below the plunger and displaces the plunger inside the seat.

The higher the oil pressure, the more it will put pressure on the plunger and the more it will come out of its seat.

When the pressure decreases, the plunger enters the seat again. Thus, the thermal gap between the plunger and the valve stem is independently regulated and depends on the pressure in the lubrication system.

To prevent oil from flowing out of the hydraulic compensator after stopping the engine, ball valves are installed in the oil supply channels in the cylinder head.

Having the advantage of no need for adjustment, the hydraulic compensator also has one significant drawback - high sensitivity to engine oil.

Debugg

Among experienced motorists, the most dangerous cases are when the tapping does not stop after the engine warms up or the sound increases noticeably when entering operating mode. Finding and troubleshooting engine problems in such a situation is more difficult, since, unlike the option with a cold internal combustion engine, the range of potential causes is much larger.

Before troubleshooting, you will need to clearly determine the location, because there are different types of noise. It is worth considering that when the engine is warmed up, possible oil deposits in the channels soften and have the ability to move, accumulating in some place and thus clogging the channel. It will be necessary to carry out preventive measures:

- hydraulic compensators are being replaced;

- the used oil is drained and new fluid is added;

- it is necessary to clean the engine after partial or complete disassembly;

- The dirty oil filter is removed.

One of the restoration measures is flushing. The motorist can carry it out independently. Before washing the hydraulic compensators, it is necessary to remove them from their seats by removing the rocker arm axles.

Next, immerse the parts in a deep container filled with kerosene or diesel fuel. Gasoline will also work. We clean the parts one by one from contaminants by pressing the valve ball and moving the plunger. We continue the movement until the move becomes as easy as possible. We repeat the operation with each part in a new container filled with a cleaner washing liquid.

After cleaning, we return the HA to its place. Assembly is carried out in the reverse order of disassembly.

Causes of knocking hydraulic compensators

The hydraulic compensator is still not an adjusting washer, which can only decrease in thickness due to constant friction; it may well fail.

Problems with the operation of the hydraulics manifest themselves in the form of a clearly audible knocking sound during operation of the power plant. Moreover, the knocking may occur in some engine operating modes, but in others it disappears.

Also, the knocking of hydraulic compensators can appear when the engine is not warmed up and disappear after reaching the optimal temperature, or vice versa.

The most common cause of hydraulic knocking is engine oil, although there are quite a few other causes.

If, when starting the power plant, a knocking sound is heard from the hydraulic compensators, but it quickly subsides, this is not the reason for their failure.

It’s just that after the next stop of the power unit, some of the valves remain squeezed out due to the location of the camshaft, the oil supply channels also remain open and the working fluid from the hydraulic fluid flows through them.

When starting, the amount of oil in the channels is quickly replenished.

But if knocking on a cold engine continues for a long time or until the engine is completely warmed up, this indicates a malfunction.

The hydraulic compensator knocks when cold.

Knocking when cold may indicate:

- Mechanical wear of the plunger and its seat. In this case, the working fluid does not maintain its pressure and constantly flows out of the sub-plunger space;

- Jamming of the plunger in the seat due to contamination;

- Ball valve jamming in the open position due to contamination;

- Oil supply channel clogged. When warmed up, the blockage is washed out by flowing oil and the hydraulic compensator works normally;

- Use of high viscosity oil in cars. When the engine is running cold, viscous oil simply does not have time to enter the hydraulic compensator;

- Exhausted oil life, as well as significant contamination with friction products;

- Significant clogging of the oil filter, as a result of which its throughput drops, and cold oil is not supplied in full to the cylinder head.

The reasons for the knocking of hydraulic valves on a cold engine are in many ways similar to the reasons for their knocking on a hot one.

Knock of the hydraulic compensator on a hot engine.

The appearance of a knock may be due to mechanical wear, jamming of the plunger or valve.

Regarding the oil, it is worth noting that knocking when hot can be due to highly fluid oil, then the oil pump cannot provide the proper pressure.

Another reason for knocking, both cold and hot, may be wear of the oil pump with a subsequent drop in its performance.

What to do if hydraulic lifters are knocking

If hydraulic compensators start knocking, what should you do in this case? There are two ways to solve the problem - complete replacement of the kit or repair of defective units. Let's consider each of them separately.

Replacement

The advantage of replacement is a guarantee of a good result. There are two disadvantages. A set of original catalog parts will be expensive. It is unlikely that you will be able to install it correctly yourself, so the car will have to be sent to a service center. Here you will also have to wait two or three days.

It must be taken into account that some foreign-made machines are subject to a shortage of parts. You have to wait for the complete set to arrive, spend money on postage, and make an appointment for repairs at a service center. For proper installation, you will also have to allocate some money for disposable parts - sealant and gaskets.

If the case is neglected and the driver does not try to take action to restore normal operation of the engine, the consequences can be dire. At first, when starting up, the knocking noise gets stronger over time. Then the smooth idle speed disappears. Since the thermal gap is not adjusted properly, it becomes more difficult to gain momentum each time. Ultimately, the entire valve mechanism wears out, and engine repair becomes inevitable.

Repair

To quickly troubleshoot the problem, you must first find out which compensator is starting to knock. Repair is possible if the malfunction begins to manifest itself when cold. With regular use of high-quality lubricant, with timely replacement, you just need to buy original oil, change the filter and check the result again. Most likely, the owner, without realizing it, bought a fake canister.

At the initial stage, it is worth buying flushing oil. Along with it you will have to acquire two filters. One is used when pouring flushing material, the other must be screwed on when the technical fluid has had time to circulate through the system in 15-20 minutes of idle operation. For special cases, you will need an aggressive composition. For example, pharmaceutical dimexide. Its chemical structure contains hard elements that are capable of removing soot and other deposits, regardless of their thickness.

Note!

Repair by flushing with pharmaceutical dimexide does not always help. Much depends on the initial state of the engine. There should be no fragile plastic parts or painted elements inside.

Consequences of the knocking sound

It is interesting that the breakdown of hydraulic compensators does not lead to any damage to other mechanisms of the power plant.

For knocking hydraulic compensators, the thermal clearance is simply disrupted, which only leads to a decrease in the power and throttle response of the power plant and an increase in fuel consumption.

But a knocking sound may indicate a malfunction in the lubrication system, so it is important to find out why they are knocking and fix the problem.

As for the use of SOHC and DOHC gas distribution systems on cars, the only difference is in the number of installed hydraulic compensators.

Thus, modern cars, including domestic ones, for example, VAZ 2112 and Lada Priora, already use a DOHC gas distribution system, with 4 valves per cylinder, and therefore with 4 hydraulic valves, the total number of which is 16.

The reasons for the knocking sound for all cars, including those mentioned, are the same.

The presence of such a number of hydraulic valves only makes it more difficult to identify a knocking hydraulic compensator if only one or several of the total number is knocking.

How to remove knocking

A knocking hydraulic compensator does not always need to be replaced with a new one. If a characteristic knocking noise appears, first of all, you need to change the oil and oil filter. Sometimes this procedure is enough and the noise disappears.

You can use special flushes of the lubrication system. With the help of modern developments from leading brands, it is possible to wash not only contaminated, but also coked oil channels.

Oil channels must be periodically flushed with special liquids.

The most effective is mechanical cleaning of hydraulic compensators. The hydraulics are removed, disassembled, cleaned and washed.

Identifying faulty hydraulic compensators

In principle, it is not difficult to identify a knocking hydraulic compensator. It is enough to remove the valve cover from the car to gain partial access to them, which will be enough for checking.

To check the hydraulics, it is enough to use a thin wooden block.

The check is carried out by pressing on the bottom of the hydraulic valve. When force is created, it will begin to sink into its seat. When checking, it is important that the camshaft cam does not act on the bottom of the hydraulic valve.

A jammed hydraulic compensator will simply not be recessed into the seat by the created force; human impact will not be enough to overcome the forces of the valve spring.

If there is no oil in it for any of the listed reasons, the hydraulic valve will be recessed into the seat with significantly less force than when working normally.

Using this method, you can calculate broken hydraulic compensators.

The role of hydraulic compensators in engine operation

Hydraulic compensators are necessary to compensate for the thermal gap in the valve drive mechanism. The need for a thermal gap arises due to the different coefficient of thermal expansion of the cylinder head parts. The design of many internal combustion engines does not include hydraulic compensators. Instead, adjusting cups are installed, with the help of which the thermal gap is adjusted. This technology is more reliable, but requires periodic maintenance.

Hydraulic compensators allow you to ensure minimal valve drive clearances throughout the entire temperature range of engine operation and do not require regular adjustment.

Is it possible to drive with knocking hydraulic lifters?

Many drivers are interested in the question of whether it is possible to drive with knocking hydraulic compensators and what consequences this can lead to. Let's answer it right away - it is possible, but it is not advisable, since the car will be plagued by a number of problems . In particular:

- loss of power;

- loss of control elasticity (the car will respond worse to steering);

- unenvironmental friendliness (unhealthy exhaust plume from the rear);

- excessive fuel consumption may occur;

- increased vibration;

- additional noise under the hood.

Accordingly, during the operation of a faulty engine there is a chance to “finish off” it completely. Therefore, it is strictly not recommended to drive with faulty engine components. After all, sooner or later it will fail. And the sooner you start repair work, the cheaper and easier it will cost you.