The operation of an internal combustion engine is necessarily associated with the release of heat. As you know from a physics course, when heat interacts with a metal, it expands. Motor designers take this fact into account when designing them and provide thermal clearances. When calculating thermal clearances, special attention is paid to the valve mechanism of the car, where an error can lead to valve burnout or knocking in the engine.

So that car workshops and drivers can control the clearance, the engine valve mechanism has the ability to adjust it. It must be performed as the machine operates, since worn parts lead to a change in the gap.

Initially, adjusting the gap was done using washers and levers, which was extremely inconvenient and also too difficult for the end driver. Over time, designers proposed a more modern solution - the use of hydraulic compensators. These mechanisms independently select the required gap and do not require additional settings. But problems can also arise with them, and the most well-known of them is the appearance of a knock during engine operation.

What are hydraulic compensators?

An automobile hydraulic compensator is a piston, with the bottom of which the camshaft cam interacts. The piston contains a ball valve, the task of which is to open the valve to allow oil to enter the piston cavity. The plunger is responsible for transmitting force from the camshaft cam to the valve stem.

During operation, oil enters the piston. It fills the free space, after which it begins to press on the plunger. This causes it to move upward along with the piston until the mechanism rests against the camshaft cam. Thus, it is possible to achieve automatic selection of the optimal gap due to the hydraulic compensator mechanism. When the camshaft cam presses on the hydraulic compensator piston, some of the oil pours out of it, after which the ball valve blocks the path of the oil, the piston moves down and a gap is created.

The hydraulic compensator, unlike washers and levers, does not require additional adjustment when engine parts wear out. In any case, the gap is adjusted due to the flow of more oil into the hydraulic compensator.

Why is the hydraulic compensator knocking?

A faulty hydraulic compensator is easy to determine. If there are problems with this element, it begins to knock during operation. The consequence of knocking of the hydraulic compensator is incorrect or untimely adjustment of the valve clearance, which can lead to problems with the engine.

The reasons why the engine hydraulic compensator knocks can be classified according to the conditions under which they occur. Depending on whether the hydraulic lifters are knocking on a cold or warm engine, the faults that can cause the problem differ.

Hydraulic lifters knock on a cold engine

Problems with the operation of hydraulic compensators can arise in two cases: if the mechanism itself malfunctions or due to problems in the oil supply system. On a cold engine, the following are the main reasons why hydraulic compensators knock:

If the hydraulic compensator is dirty, the plunger of the mechanism may jam in the seat. There is also an increased risk of the ball valve sticking in the open position;

Element contamination.- Oil contamination. Dirty operating fluid, contaminated with friction products, will cause the hydraulic compensator to knock on a cold engine. Because of it, the oil supply channel may become clogged, but this problem will disappear when the engine warms up, due to the washing out of the “garbage” with the flowing heated operating fluid;

- Mechanical wear of the hydraulic compensator. If damage occurs on the plunger or its seat, the oil will not be retained in the sub-plunger space, maintaining the required pressure, and accordingly, the mechanism will not be able to work properly, providing the required clearance;

- High oil viscosity. When a car uses high-viscosity oil, before the engine is completely warmed up, it does not have time to reach the hydraulic compensators, which is why knocking occurs in them;

- Severely dirty oil filter. If obstacles arise through the oil filter, cold oil will not be able to fully flow into the cylinder head.

Important: It is necessary to distinguish between the knocking of hydraulic compensators on a cold engine and when the engine starts. Many drivers are mistaken in believing that if a characteristic sound is heard when starting the engine, there are problems with the hydraulic compensators. The knocking noise may occur and subside quickly because some of the valves remain open (due to the location of the camshaft) after the engine is stopped.

Camshaft location

Modern cars most often use a mechanism with an overhead camshaft, which has reduced the metal consumption of the structure and, as a result, increased reliability.

Since metal expands when heated, and the valves are constantly in a high-temperature zone, to prevent it from being pressed in, as a result of which it does not fit tightly into the seat, a thermal gap is provided between the valve stem and the camshaft cam.

In this case, the thermal gap has a certain value to ensure the maximum possible opening of the valve, eliminating its tightening.

Previously, on engines with an overhead camshaft, the thermal clearance was adjusted by placing shims of a certain thickness between the valve stem and the camshaft cam.

The disadvantage of using these washers was the need to periodically check the gap and adjust it by selecting washers.

Nowadays, to ensure thermal clearance, hydraulic compensators are increasingly being used, popularly known as hydraulic compensators, the use of which eliminated the need to adjust the gap, and all because the gap is adjusted by oil pressure.

Hydraulic compensators, like shims, are located between the valve stem and the camshaft cam.

Externally, the hydraulics look like a small piston, so the head has seats for them.

Hydraulic compensators knock on a hot engine

The reasons for the knocking of hydraulic compensators on a hot engine partially repeat the malfunctions that cause this problem to occur on a cold engine. Here are some problems that are typical only for a hot engine:

, and as the engine warms up, it becomes even more spacious due to the expansion of warm metal;

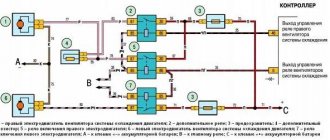

The seating area for the hydraulic compensator has increased- Problems with the oil pump. Most often, the malfunction is due to the fact that the oil pump does not produce the required pressure;

- Little or too much oil in the system. Because of this, the oil may become enriched with air, which critically affects the operation of the hydraulic compensator. A high air content in the oil leads to its compression during operation of the hydraulic compensator, and it begins to knock. This problem occurs only on a hot engine, since only as the engine warms up does the oil become enriched with air.

The situation when hydraulic compensators knock only on a hot engine rarely occurs. Most often, the problem occurs both on a cold and warm engine, and it is associated with bad oil, a dirty oil filter, or damage to the hydraulic compensator.

Choosing the right oil

As we have already figured out, hydraulic tappets can make knocking noises due to poor quality oil. Choosing one that is only suitable for your car is quite difficult. When selecting, it is recommended to read its instructions. It is quite possible that it has the same thickness, but different lubrication properties. This directly depends on the amount of different additives in the oil. You should definitely check the certification of the oil you purchased for your car’s engine brand.

An important point is to select the right brand of oil, otherwise you will have to replace other engine elements, not just hydraulic compensators. Before changing the oil, it is recommended to consult an engine specialist.

How to identify a knocking hydraulic compensator

Since there are several hydraulic compensators installed in the engine, it is necessary to determine which of them is knocking during operation before replacing or performing detailed diagnostics. In service centers, the search for a faulty mechanism is carried out using a special device for measuring noise levels. Acoustic diagnostics is an effective method for finding a problematic hydraulic compensator.

You can also diagnose the hydraulic compensator on a disassembled engine. To check them, you will need to remove the valve cover, and then make an effort to push through each element individually. Hydraulic compensators, which can be easily recessed under external influence, have insufficient oil pressure, which indicates their malfunction. A jammed hydraulic compensator cannot be drowned using human power.

Important: Pay attention that during the diagnostic process the hydraulic compensators are not pressed by the camshaft cam.

Recommendations from experts

Of course, the best option would be cleaning with flushing oil and preliminary preparation of the power unit. If this does not help, it is better to disassemble the cylinder head and identify faulty cylinder head through manual diagnostics. Next, remove them and clean or replace them.

In extreme cases, special additives come to the rescue. They temporarily fix the problem by debugging the inevitable opening of the valve cover. Additive compounds from Liqui Moly and XADO showed their best performance.

Sources

- https://AutoTopik.ru/remont/799-stuchit-gidrokompensator.html

- https://etlib.ru/blog/1233-stuchat-gidrokompensatory-na-goryachuyu

- https://nahybride.ru/dvigatel/stuchat-gidrokompensatory

- https://mashinapro.ru/1786-stuk-gidrokompensatorov-pochemu-voznikaet-i-chto-delat.html

- https://autostuk.ru/pochemu-stuchat-gidrokompensatory.html

- https://autostadt.su/stuk-gidrokompensatorov/

[collapse]

What causes a malfunction of hydraulic compensators?

Problems with hydraulic compensators do not have a strong impact on the wear of other engine components, but the solution to the problem should not be delayed. Troubleshooting of the hydraulic compensator should be carried out, since problems that arise may indicate a malfunction of the lubrication system.

Faulty hydraulic compensators themselves will lead to a decrease in engine power, deterioration in vehicle acceleration dynamics and an increase in gasoline consumption.

What to do if hydraulic lifters are knocking

In most cases, knocking of hydraulic compensators is associated with problems in the lubrication system, which are caused by poor oil. Therefore, if extraneous sounds appear from the hydraulic compensators on a cold or hot engine, the first step is to change the oil and oil filter.

Please note: The first start of the engine after changing the oil will again be accompanied by knocking noises from the hydraulic compensators. This is due to the fact that after draining the old oil, the hydraulic compensators become “empty”.

If changing the oil did not help fix the problem, you need to determine which hydraulic compensator is knocking during operation. Having identified a faulty element, you can remove it from the engine and try to wash it in gasoline or kerosene, and then put it in place. This will help if the cause of the knocking lies in contamination of the hydraulic compensator.

Important: After washing, hydraulic compensators must be installed in the position where they were before removal.

When flushing the hydraulic compensators does not help solve the problem of knocking in them, the elements will need to be replaced.

( 397 votes, average: 4.53 out of 5)

Which oil filter is better to choose?

Mud flaps for a car: installation, how to choose, why they are needed

Related Posts

Noise appears after replacing expansion joints

Another reason for the knocking of compensators is their malfunction, since they need to be changed periodically. Most often this becomes the main reason. If you are replacing a hydraulic compensator, it is recommended to replace the entire set. There is no guarantee that all expansion joints are in good working order and do not create a lot of noise. If the knocking does not disappear after replacement, then you need to find the cause in other external factors.

Most often, new expansion joints do not knock. However, if the knocking continues, then the parts may be defective, or they were not the cause. To make sure that the matter is completely different, you need to check their fastening. Perhaps the parts could not give the necessary shrinkage and create a similar sound. To eliminate the knocking, you need to tighten them, and the knocking should stop. If the knocking does not go away, then you need to go to a car repair shop.