Hello, dear friends! I propose to discuss with me today such a topic as valve knocking on a hot engine. You probably know what a timing belt is, what this abbreviation means and what purposes the gas distribution mechanism serves.

One of the key components of the timing belt is the valve. In addition to valves, the assembly contains pushers, hydraulic compensators, rocker arms, hoses, etc. Also, do not forget about the camshaft, or simply camshaft. It is he who is responsible for ensuring that each of the timing elements works correctly.

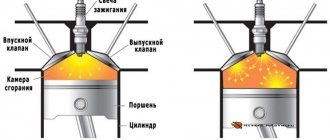

The essence of the mechanism is that the shaft rotates and actively interacts with its cams with the pushers. The latter rises along with the so-called barbell. The upper edge of the rod acts by pressing on the rocker arm. It, in turn, as it rotates, opens groups of intake and exhaust valves located in the cylinder head.

At the same time, in a car or motorcycle, motorists may notice how the valves begin to knock on a warm and hot engine. You need to know the possible causes and further actions on the part of the car owner.

Sign of severe valve wear

True, as the working resource is exhausted, this picture gradually changes for the worse. Miracles do not happen, and thoroughly worn-out metal parts begin to rumble, rumble and tinkle more clearly and frighteningly.

- Such changes in the functioning of the engine are signs of increasing valve damage.

- In this material we will talk about the reasons for the knocking of valves in the engine and what needs to be done to put an end to this alarming phenomenon.

Faulty spark plugs

If a car owner uses spark plugs other than those recommended by the manufacturer, this may cause knocking. The plug has a specific heat range, which means it draws heat from the combustion chamber.

Using the wrong part may interfere with normal operation. The engine also knocks frequently when the spark plug gap is not set correctly.

Fixing such engine problems is usually quite simple, and most car owners can do it themselves. In other cases, it may be wise to contact a professional technician.

The characteristic ringing sound of breaking valves

It can be very difficult for inexperienced car enthusiasts to identify by the nature of the sound alone the segment of the power plant that has begun to operate abnormally.

There are too many components and assemblies in a modern car, and only a driver who has covered hundreds of thousands of kilometers can study all the details of their functioning in the event of severe wear and tear.

At the same time, knocking valves stand out somewhat from the background of other failing mechanisms. The valves make a ringing sound, reminiscent of an iron rod hitting a rail. This noise comes from the timing belt area.

It is important to note that a drop or increase in engine speed does not in any way affect the intensity of this sound.

Typical causes of ringing “fingers” during normal operation of the internal combustion engine

If the “fingers” knock during acceleration in the Kalina, the mass air flow sensor may have failed. If it is not working correctly, then the ECU will receive incorrect information and issue incorrect commands. Another reason is an incorrectly set ignition timing. For this reason, the point at which the fuel will burn maximum is approaching TDC. This leads to increased pressure in the combustion chamber. If the “fingers” knock when accelerating on a Ford Focus, then the knock damping sensor may have failed. It's definitely worth checking this item. If it stops working, it should be replaced.

Difficulty identifying specific valve problems

If the car enthusiast is able to accurately recognize that the knocking noise is coming directly from the area where the valves are located, then only those who have extensive experience in engine repairs, including major ones, will be able to identify the specific cause of this malfunction.

With all this, even a novice motorist can use a clear scheme for finding the source of problems, thanks to which it is possible to almost accurately indicate the problem that caused the knocking.

Algorithm of diagnostic procedures

The sequence of operations in this case is as follows:

- You should lift the hood and unscrew the cap on the neck into which the engine oil is poured;

- Next you need to listen to the operation of the motor. Typically, an increase in the intensity of the knocking noise when the cover is removed definitely indicates that the valves are the root cause of the observed problems;

- A stethoscope, which must be placed in close proximity to the likely source of mechanical problems, will provide additional clarity in diagnosing such problems.

Izhevsk trailers for passenger cars: characteristics, owner reviews

- Renault Logan;

- Chevrolet Niva;

- VAZ 2114;

- Lada Priora;

- VAZ 2106;

- Ford Focus;

- VAZ 2109;

- Opel Astra;

- Daewoo Nexia;

- Nissan Almera;

- Renault Sandero;

- Cherry Amulet, etc.

Don’t think that solving a knocking problem is very easy. If you make a mistake, you will only increase the noise and cause the situation to worsen. Therefore, beginners are not recommended to take on such work.

Before you begin disassembling, be sure to read the instruction manual specific to your car.

If we talk about the general repair scheme, it can be described approximately as follows:

Top 5 causes of valve knocking

The most common reasons why valves begin to annoy and make strange sounds are as follows:

- The size of the technological gap that should separate the pushers from the valves changes. During assembly of the machine on the conveyor, this gap is fine-tuned. If, as a result of long-term operation of the engine, this gap goes beyond the permissible limits, a characteristic knock with metallic notes inevitably follows.

- Knocking in the valve area is a consequence of purchasing cheap, low-quality fuel. The price for such savings is engine problems. In order to prevent them, you should strictly follow the instructions for selecting fuel given in the vehicle documentation. In the worst case scenario, so-called engine detonation may well occur. This destructive process will inevitably affect the performance of the valve system.

- It often happens that the valves start knocking only when accelerating or when driving very fast. This is a consequence of a decrease in oil pressure in the lubricating motor units.

- When a knocking noise makes itself felt after updating the timing belt, it means that the pulley was installed incorrectly. As a result, it works abnormally, which leads to misadjustment of the valve mechanism.

- The most common causes of knocking include banal wear of valves after the car has traveled a certain mileage. In this case, the factory resource is exhausted, and the only effective way to solve this issue is to completely update the worn parts.

Engine breakdown after gap expansion

Practice shows that the main reason for valve knocking is misadjustment of the gap, which separates the cams on the camshaft and the levers.

- If the gap exceeds the normal parameters, it results in the knock of the cam on the rocker.

- This sound is somewhat reminiscent of the iron clanking made by a hammer and chisel.

Due to the expansion of the gap, rapid depreciation of the power plant occurs, which is fraught with destructive phenomena for the engine.

For a number of models, this gap has the same dimensions, but in some cases engineers set a unique parameter.

Clamping and incomplete closure of the valve

It is important to note that narrowing the gap also adversely affects the functioning of the valve mechanism. With this development of events, there is a risk of clamping the valve, and later incomplete closure will become the order of things.

Continued use of the engine with insufficiently closed valves will lead to a drop in compression and excessive heating of the engine.

The need to periodically adjust the gap

If in such a situation you do not take timely measures to maintain and restore the valve system, then you should expect one hundred percent failure of the cylinders.

- Moreover, it is not at all a fact that only some of them will stop functioning, since failure often occurs in the entire cylinder block at once.

- In order not to find yourself in such a deplorable situation, the way out of which will be an expensive call to a tow truck and ruinous major repairs, you need to regularly check the width of the gaps and, if necessary, correct it.

A car usually needs such a service after every fifteen thousand kilometers.

How to Replace a Worn Rod Seal

It is often possible to replace worn rod seals without removing the cylinder head.

Some shops fill the combustion chamber with compressed air to hold the valve in place while replacing seals. You may not have compressed air at home, but you can use a flex cable or similar soft, thick cord instead.

- Place the transmission in Park (automatic) or Neutral (manual), and set the emergency brakes (Handbrake).

- Remove the spark plug from the cylinder you need to work on.

- Rotate the piston you will be working on to BDC (bottom dead center). Rotate the crankshaft using the socket and jumper on the front crankshaft bolt. If necessary, remove all spark plugs to make it easier to turn the crankshaft.

- Fill the cylinder with about 5 feet of cord. Use a large screwdriver to push the wire through the spark plug hole. The end of the cord should hang in the spark plug hole after filling the cylinder so that it can be pulled out later.

- Raise the piston to TDC (top dead center) by turning the crankshaft by hand. This allows the cord to press against the valve and hold it in place.

- You can now use a spring compressor to replace the valve seal.

- Install a new seal.

- Reinstall the remaining components.

- Turn the piston towards bottom dead center and remove the cable.

If necessary, consult your vehicle's repair manual.

A dirty spark plug due to oil leaks can cause a misfire.

Photo instructions for adjusting valves in the engine

Let's sum it up

The appearance of valve knocking indicates the need to quickly solve this problem. In addition to increasing the gap, the causes of increased noise may be:

- worn camshaft cams;

- broken valve spring;

- there is a defect in the valve guide;

- the timing belt/chain has become loose;

- there is a decrease in the efficiency of lubricant supply through the camshaft channels to the valve stems;

- there were problems with fixing the camshaft;

For high-quality repairs, you will need to disassemble the engine (remove the valve cover or cylinder head), after which the camshaft and other timing elements are repaired. Let us add that timely professional adjustment of valves can significantly increase the life of the gas distribution mechanism and the internal combustion engine itself.

I adjusted the valves according to the manual and set the gap to 0.4 mm. But the car is now unrecognizable. If before there was a light tapping, now there is a specific knocking. It knocks so loudly that it's even kind of scary to drive. In short, the engine works like hell. Here you can watch the video:

Need advice! What can be done about this? How dangerous is it to drive like this?

What's wrong with them

Now we will describe common reasons explaining why valves knock. In modern engines, the camshaft is located on top, its cams push the valves through rods - a simple, best mechanism. The rods are called pushers.

- There is always a minimum gap between the tip of the pusher and the cam, regulated by the manufacturer. An increase in the gap is one of the reasons why the valves began to knock. As the gap decreases, knocking will also appear, and the valve may eventually stop closing tightly.

- Another possible cause of monotonous valve song could be a knocking engine, for example, due to bad gasoline.

- If valves knock only during acceleration, this is most likely due to increased engine speed and insufficient oil pressure.

- The malfunction may occur due to a poorly tensioned timing belt.

- Finally, it is simply wear of parts or shaft cams.