The issue of ensuring safe and quick engine starting worries every motorist. And the leading role in this matter is played by the car’s starting system, which is essentially a kind of start when operating the car. For this reason, in order to avoid unpleasant situations, this system must always be in good condition. And special attention should be paid to such an element of the ignition system as the distributor. Such a mechanism can be called indispensable in the overall design, and therefore, it is very important to understand the signs of its malfunctions and have a good understanding of how they can be eliminated in the future.

What are the signs of distributor malfunctions?

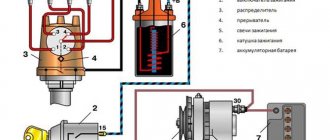

The distributor-breaker, and in fact this is what the distributor actually sounds like, is a unique mechanism that is designed to determine the moment of formation of high-voltage pulses in the system. The distributor is used to distribute the generated electric ignition among the cylinders of injection and carburetor engines. The functions of the distributor are reduced to interrupting the primary ignition circuit and distributing a certain amount of energy between the cylinder spark plugs. In the first case, the distributor also provides oscillations in the primary winding of the coil, due to which high voltage appears. As for the signs of a malfunction with such an element, they may be as follows:

- The engine jerks unusually and abnormally;

- The power unit does not start;

- There is a knocking sound from the piston rings while accelerating;

- Slow acceleration;

- Increased fuel consumption.

But the main thing in this matter is that even if any of this factor is present, you cannot be completely sure that the problem is hidden in the ignition distributor. But nevertheless, if they arise, something must be done. And it’s best to start preparing in advance for the fact that most likely the distributor will have to be repaired.

Signs and causes of distributor cap malfunction

Using the example of the ignition distributor cap (distributor) of VAZ 2108, 2109, 21099 cars, we will look at what signs can be used to determine its malfunction and what is their cause.

Signs and causes of distributor cap malfunction

Signs of a faulty distributor cap

— The car engine does not start. Especially in wet weather.

— The car engine starts and stalls.

— The engine “troubles” at idle (either one cylinder does not work, or they are switched off one by one).

— An unheated engine “troits” at idle, but as it warms up the speed stabilizes.

— Popping sounds are heard in the exhaust pipe of the muffler.

Failure when pressing the gas pedal when starting from a stop or trying to accelerate in motion.

— The engine jerks while driving.

Causes of distributor cap malfunction

1. The distributor cover is broken.

“Broken” - the distributor cover has burned out due to constant current leakage to the “ground” along its surface. Through the crack, the high voltage current goes entirely or partially to the “ground” and not to the spark plug. As a result, the spark between the electrodes of the spark plugs weakens or disappears altogether. And these are interruptions in engine operation in all operating modes, disruption of the combustion of the fuel mixture, etc. The location of the “breakdown” can sometimes be seen visually, sometimes the crack has to be looked for through a thorough inspection.

A similar situation can arise if the cover is damp or dirty, since dampness and dirt conduct current well. In this case, it is enough to wipe it with a dry cloth to eliminate the problem.

2. The contact spring-loaded angle is faulty.

It is part of the central contact of the cover to which the armored wire from the ignition coil is connected and through it the high voltage current is supplied to the distributor runner.

The ember in the distributor cap may collapse, become stuck, or wear off due to prolonged use. In this case, the supply of high voltage current from the coil to the ignition distributor is disrupted. The spark power at the spark plug electrodes decreases or disappears altogether.

Ember in the cover of the distributor of the contactless ignition system of the VAZ 2108, 2109, 21099 carburetor engine

See “Contact ember in the distributor cover, what is it for?”.

3. Wear or oxidation of contacts.

During operation, both external and internal contacts of the distributor cover are destroyed by constant exposure to high voltage current. In addition, their strong oxidation is possible. As a result, the current supply is disrupted or the resistance in the electrical circuit increases. The spark on the candles either disappears or appears or is too weak. The fuel mixture burns inefficiently or does not burn at all.

As a result, the signs listed at the beginning of the article appear.

Distributor cover elements

To eliminate all of the above problems, the best thing is to buy and install a new cover. As a temporary measure, cleaning the contacts and replacing the carbon may help. In the event of a breakdown, the cover will definitely have to be changed.

It should also be taken into account that similar signs of malfunction may occur when high-voltage wires, coils and spark plugs fail.

Notes and additions

— How does the distributor cap work? High voltage electric current from the central terminal of the ignition coil is supplied through an armored wire to the central terminal of the distributor cover, then through a spring-loaded contact (charcoal) to the distributor (slider). Rotating, the slider transfers it to one of the side contacts, depending on the order of operation of the engine. From the side contact, current flows through the high-voltage wire to the spark plug.

— Indirectly, faults in the distributor cover can be attributed to incorrectly connected wires.

More information on the topic in our VKontakte group -

Twokarburators VK , on Facebook Twokarburators FB , as well as in Odnoklassniki - Twokarburators OK

More articles on the ignition system of VAZ 2108, 2109, 21099 cars

— Why is one spark plug in the engine black and the rest are not?

— Why are holes needed in the distributor cover?

— Why is the distributor capacitor needed?

— What is the difference between spark plugs for injection and carburetor engines?

— Malfunctions of the distributor of VAZ 2108, 2109, 21099 cars

How to repair a distributor?

When problems have been identified in the operation of the distributor, it is necessary to begin preparing to repair the element. And the first thing that needs to be done in this case is to properly dismantle the distributor. To do this, first you need to check if there are any sparks on the running power unit. If there are sparks, then this indicates an insulation failure. After performing this check, you need to remove the negative wire from the battery terminal. Disconnect the high-voltage wires and the vacuum hose from the distributor itself. Remove the cable from the throttle valve drive and remove the bracket. Apply marks to the distributor cover and auxiliary device drives to maintain the starting ignition timing. Using a screwdriver, press the connector lock and pull out the wires. Then pull out the rubber plug and rotate the crankshaft so that the piston of the first cylinder is at the dead center. Make sure the flywheel marks match the middle division on the housing scale. At the last stage, the car owner must unscrew the nuts along with the element cover and remove the element itself. Installation of the device must be done in the same way. but in reverse order.

Learn more about replacing the distributor cap in this video:

Published: February 15, 2022

Cover and signs of its malfunction

Separately, there are symptoms that clearly indicate problems with the lid. Experienced motorists immediately distinguish them.

- “Trippling” of the power plant while the vehicle is moving, especially in damp, rainy weather.

- The speed does not increase while driving.

- An increase in the symptoms described above after driving a car through puddles.

In any case, self-repair and adjustment of automotive components is much better than completely overhauling the car or replacing expensive spare parts. It is advisable to inspect the distributor cover yourself under good lighting.

Traces of punctures, plaque, mediocre condition of the coating, the presence of moisture or condensation inside the distributor - all this may indicate a malfunction of the cover.

Cover malfunctions

The microcracks themselves may not be visible at first, but their presence is already enough for the car to not function correctly.

Eliminating defects is a responsible process. In the case of the distributor cap, you can occasionally coat the surface with silicone-based sealant or remove deposits from the contacts. But if the malfunction is more complex, only a complete replacement of the cover will help.

Replacing the cover

Replacing it is not a painstaking operation, but it is worth showing careful attention. It is worth remembering that sometimes the nuances make all the difference for a beginner who decides to do auto repair on his own. For example, if the armor wires are incorrectly connected to the cylinders, the latter simply will not work.

The sequence of connecting the armored wires is, as usual, marked on the internal combustion engine itself or can be found in the car’s operating book. All the same, whatever one may say, it is easier to make marks on the elements themselves during the process of replacing them. The masters themselves recommend doing this.

As a rule, the documentation of some car models indicates the location of only one armored wire going to the 1st cylinder. The remaining wires are installed by the car owner himself against the rotation of the emergency.

The entire operation takes no more than 30 minutes. The price of a new cover ranges from 5 thousand rubles, which is quite inexpensive. After the cover is replaced, it will not be superfluous to treat all armored wires and the surface of the cover with a special composition, which significantly minimizes the likelihood of moisture getting inside.

During the process of updating the cover or slider, removal of the distributor will not be necessary. The cover is dismantled after disconnecting all armor wires.

Features of operation of the ignition distributor cap

The “sore spot” of the ignition distributor cap and rotor is the electrodes pressed into it. Due to the fact that there is no direct contact between them and the central electrode of the slider, and the spark passes through the air as they approach, the electrodes become charred quite quickly.

A used distributor cap for a Ferrari 458 with a V12 engine can be purchased for $608

To ensure reliable operation of the distributor cap, it must be kept clean both inside and out. It is necessary to regularly check the condition of the electrodes. When carbon deposits or oxide form on them, the contacts are cleaned with a flat file. It is not advisable to use sandpaper due to the likelihood of abrasive particles getting into the distributor mechanism. It is also worth monitoring the general condition and mobility of the contact (“carbon”) of the central electrode of the cover.

Design and principle of operation of the ignition distributor cap

The distributor cover is a molded part made of non-conducting material into which metal contacts are pressed - central and side electrodes. The number of side electrodes corresponds to the number of spark plugs (not cylinders - after all, there are engines in which there is more than one spark plug for each cylinder). On the outside of the cover, a high-voltage wire from the ignition coil is connected to the central electrode, and high-voltage wires leading to the spark plugs are connected to the side electrodes. Inside the cover, the central contact is equipped with a terminal with a spring-loaded contact element (“coal”) that transmits voltage to the central contact of the ignition distributor rotor.

When installing the distributor cap, not only the order in which the spark plug wires are connected is important, but also the orientation of the cap relative to the “nose” of the slider

The ignition distributor cover is attached to the distributor body using latches and/or screws. To prevent the formation of condensation, there is a ventilation hole under the cover.