Owners of early Zhiguli models remember and know what problems arose in connection with the operation of distributors with a mechanical ignition distribution system. From time to time the car began to behave strangely: it would either stall at idle, or suddenly begin to move jerkily. The reason for this in most cases was burnt contacts of the mechanical breaker. With the advent of electronic ignition and a Hall sensor on the VAZ-2106, this problem immediately faded into the background.

History of the Hall sensor

The sensor got its name from the American physicist Hall, who discovered the effect of the same name back in 1879. Its essence lies in the fact that a metal plate under direct current voltage, once in a magnetic field, receives a potential difference at its edges. The invention did not find its application for a long time until the 50s of the last century. Everything changed with the advent of the era of semiconductors, which began to be made based on rare earth elements: germanium, indium and silicon. This opened up the possibility for the production of mini-controllers that measure the characteristics of electric current in a magnetic field, including Hall sensors (HL) for the electronic ignition of the VAZ-2106.

Hall sensor VAZ 2106:

Device

When switching to a non-contact ignition system (BSI), the distributor was improved. The design of the ignition distributor itself was changed, and a switching device was added - an electronic ignition control unit. The cover and slider remained the same, but the place of the breaker was taken by a Hall sensor and a synchronization cup (screen with slots) was installed coaxial with the shaft.

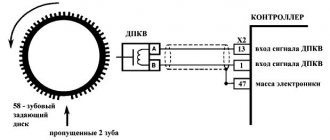

The DH is attached with two screws to the bearing holder under the distributor cover. Three wires stretch from it through the connector to the switch: two of them supply power (+ and 0), and the third transmits a control signal to the switch. The sensor consists of two parts: a meter and a magnet. Between them there is a side of a rotating cup with 4 cutouts (according to the number of engine cylinders).

Household location:

Operating principle of DH

The ignition distributor shaft is splined into a helical gear, which in turn is connected to the crankshaft sprocket. A change in the openings of the cup, falling into the “field of view” of the sensor, causes fluctuations in the electromagnetic field, which is reflected by a proportional change in the voltage in the signal wire, “notifying” the switch about this. This, in turn, synchronously supplies high voltage current to the central wire of the distributor cover, from where the current enters the spark plugs through the slider and wires.

This contactless ignition system is certainly more advanced than a distributor with a contact breaker. And yet, compared to modern electronic ignition modules, the BSG VAZ-2106 is more susceptible to breakdowns due to the presence of moving parts. It is they who most often become the cause of malfunctions in its ignition system.

BSZ VAZ 2106:

The principle of operation of the sensor and its features

In its operation, the sensor uses the physical Hall effect, discovered in the 19th century. However, they began to use it only in the 70-80s of the last century, when automakers began to switch from contact ignition systems to electronic ones.

The principle of operation of the sensor is quite simple. As the motor shaft rotates, metal blades pass through slots in the motor housing. It gives an electrical impulse to the switch, as a result of which the latter unlocks the transistor and supplies voltage to the ignition coil. It, in turn, converts the low-voltage signal into a high-voltage one and supplies it to the spark plug.

Structurally, the sensor has three contacts:

- for connection to “ground” (car body);

- to connect voltage with a “+” sign and a value of about 6 V;

- to supply a pulse signal from it to the switch.

The advantages of using a Hall sensor in electronic ignition systems are two main factors - the absence of a contact group (which constantly burns out), as well as a higher voltage on the spark plug (30 kV versus 15 kV).

Since Hall sensors are also used in braking and anti-lock braking systems and tachometer operation, the device performs the following additional functions for the car:

- increases engine performance;

- speeds up the functioning of all machine systems.

As a result, the ease of use of the car, as well as its safety, increases.

Hall sensor for VAZ 2107

Hall sensor for VAZ 2109

Hall sensor for VAZ 2110

DH malfunctions

Malfunctions of the VAZ-2106 engine can be caused not only by the failure of the diesel engine. Therefore, identifying the causes of failures is carried out in stages, checking the power supply, the condition of the coil, wires, contacts, etc. Only by eliminating other causes can we conclude that the Hall sensor is unusable.

Deterioration in the performance of the VAZ-2106 DH is characterized by the occurrence of the following malfunctions:

- fuel consumption increases sharply;

- the engine choke while the car is moving and may stall;

- the engine does not start.

After all options for the reasons for the malfunction of the internal combustion engine (ICE) have been checked, we move on to checking the functionality of the Hall sensor.

Self-check and replacement of the Hall sensor on a VAZ 2106

The Hall sensor is one of the main elements of the contactless ignition system of the VAZ 2106 engine. And this device, like all others in domestic cars, tends to break down periodically. Therefore, we will tell you how to understand that the Hall sensor of a VAZ 2106 is broken, how to check it and how to replace the device.

Tuned car VAZ 2106

Problems in the functioning of the Hall sensor on a VAZ 2106 car can manifest themselves in different ways. Sometimes even an experienced specialist will not be able to detect a breakdown. Therefore, we will look at the main symptoms that may indicate a malfunction of this element:

- the engine becomes difficult to start or does not start at all;

- the car does not work well at neutral speed: jerking may occur periodically, the car stalls;

- when the car picks up speed, the engine may twitch and stall;

- The engine occasionally stalls while driving.

If one of these symptoms is typical for your car, then this, of course, may indicate other malfunctions. However, first of all it is necessary to check the Hall sensor of the VAZ 2106.

How to check?

There are several methods that will help determine the functionality of the Hall sensor on your car. Let's look at these methods in more detail:

- The simplest method is to diagnose the operation of a VAZ 2106 engine with a new, known working Hall sensor. If you have one, install it in place of the old one and try to operate the car. If the problem has disappeared, then the answer is obvious.

- Try checking for spark in the engine. This is done when the ignition is turned on. To do this, it is necessary to dismantle the block installed on the distributor, which is called the distributor. Now turn on the ignition. After this, you will need to take a small piece of wire and connect its ends to the third and sixth outputs of the switch. If a spark appears while connecting the wire, this means that the Hall sensor of the VAZ 2106 has failed and needs to be replaced.

- You can also check the functionality using a voltmeter. You need to connect the device to the sensor output. If the Hall mechanism is working, then the voltmeter will respond to it. In this case, the device arrow will fluctuate from 0.4 V to 3 V.

New mechanism for VAZ 2106

Replacement process

So, if you encounter problems with the mechanism, you will need to replace it. It's not that difficult. What will you need for this?

Preparing the tools

- wrench set to “13”;

- screwdriver;

- pliers;

- hammer.

Wrench 13 3. Long screwdriver Pliers Construction hammer for work

Phased replacement

- First, turn off the engine and open the hood of the car. The supply pipe must be disconnected from the vacuum corrector.

- After this, you should unclip the ignition distributor cap and remove it.

- You will then need to unplug the connector of the device you want to replace. Using a wrench set to “13”, you next need to unscrew the nut that secures the holder plate.

- Now remove the distributor.

- Using a hammer, knock out the clutch spring screw from the ignition distributor.

- Then, using a screwdriver, unscrew the screws that secure the vacuum corrector. The corrector needs to be pulled out. This gives you access to your engine's Hall sensor. Using the same screwdriver, unscrew the screws that secure it and remove the mechanism.

- Replace the device with a new one. All subsequent assembly should be done in reverse order. After replacement, take a test drive to ensure that the device is working properly.

1. Disconnect the pipe leading to the vacuum corrector 2. Dismantle the distributor cover 3. Using a 13 key, unscrew the plate nut 4. Now you can dismantle the distributor itself 5. Use a screwdriver to unscrew the pins of the vacuum corrector 6. Then dismantle the mechanism itself and replace it with a new one

In general, the procedure is not particularly complicated, but, as in any other matter, there are some nuances. For example, you should knock out the clutch spring screw with force, but carefully. Deformation of parts will subsequently lead to worse results.

Video “Installing the device yourself”

We invite you to find out how to replace the mechanism.

Household check

There are different ways to check the Hall sensor on a VAZ-2106. One of them is the simplest and will require the participation of two people, however, if you have extraordinary dexterity, you can get by with two hands. The method consists of the following steps:

- Remove the plug from the DH connector.

- Remove the central wire from the distributor cover and expose its tip by sliding the protective cap.

- Contacts 3 and 2 of the sensor connector are closed with wiring.

- The tip of the central wire is brought to any part of the internal combustion engine or body at a distance of 3–5 mm.

- Turn on the ignition. At this moment, a spark should jump between the tip and the ground.

If a spark does not occur, this means that the DC must be replaced.

Find out more about removing the old meter and installing a new device.

Replacing the hall sensor on a VAZ 2101-VAZ 2107

Welcome! The hall sensor is a very important sensor, if it completely fails, you will not be able to start the car, but in injection systems this sensor is not there, there is a crankshaft position sensor, in fact these are the same sensors working on the same principle and if they fail , then the car will no longer start (If any other sensor fails, the car can still be started, but the engine will operate in emergency mode), since a spark will not be given to more than one spark plug and the engine will simply spin at idle (With the help of a starter, we have in view).

Replacement of DH

Replacing the Hall sensor can be done by any car owner who has minimal experience in handling simple tools such as a screwdriver and pliers. To install a new sensor, proceed as follows:

- Remove the negative terminal from the battery and put the car on the handbrake.

- Folding back the two spring brackets, remove the distributor cover.

- Remove the cotter pin from the vacuum regulator rod mounting axis.

- By unscrewing two screws, remove the regulator itself, freeing up the side opening in the ignition distributor bowl.

- Unscrew the screws securing the Hall sensor and its connector.

- The sensor with wires is pulled out through the opening.

- A new sensor with wires and a connector are installed on the seats.

- All the above steps are repeated in reverse order.

HH dismantling:

When purchasing a new Hall sensor, pay attention to the fact that the device belongs to the VAZ-2106 because the sensors of other VAZ models will not be suitable for mounting. Avoid households from unknown manufacturers. A cheap purchase can cause trouble in the form of an unexpected car stop on the road.