Symptoms of a problem

If you repair the crankshaft yourself, you can save a lot on car service costs. Therefore, it is worth understanding its diagnosis, repair and installation. If repairs are not carried out in a timely manner, the engine may seize, and this can lead to more serious repairs. The following are signs that serve to identify malfunctions:

- when the engine is running, the oil level control light does not go out, which indicates a decrease in oil pressure in the system;

- at medium and high speeds a metallic knock is heard in the engine, which increases with increasing speed;

- engine jams.

Crankshaft installation process

Before installing the crankshaft on the VAZ 2106, you need to wash, clean and dry the cylinder block. And only after that read the process.

Tools

To complete the installation you will need the following tools:

- a set of keys;

- Screwdriver Set;

- micrometer;

- consumables (liners, seals, half rings);

- torque wrench.

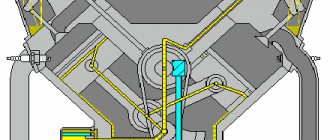

Set of repair tools

If defects in the form of scratches, burrs, or signs of wear are found on the surface of the liners, they must be replaced. The earbuds cannot be adjusted. When using the removed bearings further, you need to check the gap between them and the main and connecting rod journals of the crankshaft. For main shafts, the permissible size is 0.15 mm, for connecting rods - 0.10 mm. If the dimensions exceed the permissible limits, the liners are changed to a greater thickness after boring the necks. If the journals are properly ground and the appropriate bearings are selected, the crankshaft should rotate freely.

The oil seals that ensure the tightness of the crankshaft are replaced regardless of how long they have been standing. Half rings, like liners, cannot be adjusted. If burrs and scratches are found, the half rings are replaced. They are also changed if the axial clearance of the crankshaft is greater than the maximum permissible, which is 0.35 mm. The selection of new rings is carried out according to the nominal thickness or with a thickness increased by 0.127 so that the axial clearance is in the range of 0.06-0.26 mm.

Stages

Installation of the crankshaft on the VAZ 2106 is carried out in the following sequence:

- First, the support bearing of the input shaft is pressed in.

- Next you need to install new liners. The main liners are installed to the required repair size. The connecting rods are the same size, so they are interchangeable. When installing, you need to be careful not to mix up the bearings. The connecting rod bearings are smaller in diameter than the main bearings and do not have annular grooves.

- Then you need to install the thrust half rings into the bed of the 5th main bearing. In this case, the grooves should be directed towards the crankshaft. Half rings are selected according to tolerances.

Replacing worn parts

- The main and connecting rod journals must be lubricated with engine oil.

- Now the crankshaft should be placed in the block.

- The bearing caps are installed according to the marks. The surface of the bearings and journals should be wiped well with a clean rag. When installing the covers, you need to ensure that the arrows marked on them are directed forward along the power unit. The fastening bolts must be lubricated with engine oil and tightened to a torque of 68-84 Nm.

- Next, the connecting rod bearings are mounted and the connecting rods are attached. The tightening torque should not exceed 54 Nm.

- We check the rotation of the crankshaft; it should rotate freely, easily, without play or jamming.

- Next you need to install the rear crankshaft oil seal.

- Next, the engine sump is installed on the block.

- When grinding, in any case, it is necessary to replace the front oil seal. It must be installed on the block along with the cover.

- After tightening the front cover, you can install the crankshaft pulley.

- Then the intermediate shaft, timing parts and cylinder head are installed on the power unit.

- Then you need to adjust the chain tension.

- Next, marks are installed on the camshaft and crankshaft.

- Then the remaining engine parts and components are installed.

- After installing the alternator belt, it is necessary to adjust its tension.

- At the last stage, the ignition is installed and adjusted.

When installing gaskets, you should use a sealant to ensure reliable sealing and prevent leakage of working fluids during further operation of the vehicle.

After final assembly, you need to start the engine and check its performance.

Thus, even a driver with little experience in repair work can perform crankshaft repairs on a VAZ 2106, and you can significantly save on car service costs.

Installation of VAZ 21083 engine

Photo. Box boot VAZ 21083

You can immediately lubricate the release bearing with oil, preferably transmission oil or mixed with lithol; it can be pressed with a syringe through the slot shown in the photo below.

Photo. Release bearing of VAZ 21083 engine.

We install the engine as we removed it through the bottom without the head; this can be easily done at home with two people. To do this, pass a belt or rope under the engine, place a thick rag on the front of the car and using a pipe or crowbar you can effortlessly pull the engine onto the box, as shown in the photo below. Bolt the box, lift the engine, screw on the mount, the engine is installed, all that remains is to install the head.

Photo. Installing the VAZ 21083 engine through the bottom.

Great guys, I decided to share my creativity from the BZ. Peculiar hehe)

Once I decided to change the half rings, but there is not a lot of concrete and understandable information on the internet, so I described in detail what kind of rings they are, where they are and why they are needed)

Where and why?

The thrust half-rings are located on the sides of the support cover of the third main bearing, i.e. Simply put, half rings are installed between the block support and the crankshaft cheeks. The half rings keep the crankshaft from axial movement and play.

Why do they need to be changed?

Over time, the half rings become thinner and the play increases, but this is not the most dangerous thing; over time, the rings can wear out to such an extent that they stop holding on and one or both fall out into the oil pan... What happens in this case? When there is nothing between the crankshaft and the block cover, the crankshaft begins to grind the support cover.

The whole unpleasantness of the situation that has arisen is that the block bearing support cover is cast together with the block to increase accuracy. Simply put, if you don’t notice crankshaft play in time, you may end up having to replace the block and the crankshaft itself... In addition, increased crankshaft play leads to constant squeezing out of the crankshaft rear oil seal and oil leaks, the rear oil seal is located behind the flywheel, and to replace it you will have to do a huge amount of work . How to determine?

Yes, very simple.

We take the mounting tool in our hands, press it into the body on one side, and with the other press on the generator pulley on the crankshaft; the axial clearance of the crankshaft should not exceed the maximum permissible - 0.35 mm. Also, have someone press the clutch while you watch the crankshaft. If you notice severe play, you must urgently replace the half rings, because if the half ring falls out, the crankshaft will grind off the groove on the bearing cover and the new half ring simply will not hold. I recommend checking the play after 120,000 miles. How to replace?

Quite simple. First you need to buy: the half rings themselves, the oil pan gasket, sealant. Since it will be necessary to drain the oil from the engine, the work of replacing the half rings can be combined with changing the oil; you can also clean the pan and oil receiver. Half rings are available in three sizes: standard 2.31; first repair 2,437; the second repair 2.56, produced by ZMZ. It is noteworthy that at the factory the half rings are installed differently - a steel-aluminum half ring is installed on the front side of the bearing (On the timing drive side), and a metal-ceramic (yellow) half ring is installed on the rear side.

The semi-rings on sale are the same, both are metal-ceramic, steel on one side and with an antifriction layer on the other. There are also non-original ones, metal-ceramic on both sides.

Gasoline engine on the "eight"

The appearance of the VAZ 21083 gasoline engine is directly related to the low quality of domestic rubber products. The fact is that at the very beginning of production, the Lada Samara family of cars was equipped with a VAZ 2108 engine, the first domestic power unit designed specifically for transverse placement under the hood of a front-wheel drive car.

However, the VAZ 2108 engine had an unpleasant feature, also characteristic of foreign engines with a timing belt drive. When the timing belt breaks, the engine pistons meet the cylinder head valves, and the latter inevitably bend, which leads to expensive repairs of the VAZ 2108 engine. On foreign cars, such a breakdown occurred extremely rarely due to the high reliability of timing belts. However, in the first Samaras, the breakage of a low-quality belt was such a frequent occurrence that it was necessary to urgently modify the engine with the help of specialists from German automakers. As a result, a new engine appeared, which became the progenitor of a whole family of power units. Assembling a VAZ 21083 engine is not a difficult task; it can be completed without the help of specialists.

Symptoms of a problem

If you repair the crankshaft yourself, you can save a lot on car service costs. Therefore, it is worth understanding its diagnosis, repair and installation. If repairs are not carried out in a timely manner, the engine may seize, and this can lead to more serious repairs. The following are signs that serve to identify malfunctions:

Crankshaft installation process

Before installing the crankshaft on the VAZ 2106, you need to wash, clean and dry the cylinder block. And only after that read the process.

Tools

To complete the installation you will need the following tools:

- a set of keys;

- Screwdriver Set;

- micrometer;

- consumables (liners, seals, half rings);

- torque wrench.

If defects in the form of scratches, burrs, or signs of wear are found on the surface of the liners, they must be replaced. The earbuds cannot be adjusted. When using the removed bearings further, you need to check the gap between them and the main and connecting rod journals of the crankshaft. For main shafts, the permissible size is 0.15 mm, for connecting rods - 0.10 mm. If the dimensions exceed the permissible limits, the liners are changed to a greater thickness after boring the necks. If the journals are properly ground and the appropriate bearings are selected, the crankshaft should rotate freely.

The oil seals that ensure the tightness of the crankshaft are replaced regardless of how long they have been standing. Half rings, like liners, cannot be adjusted. If burrs and scratches are found, the half rings are replaced. They are also changed if the axial clearance of the crankshaft is greater than the maximum permissible, which is 0.35 mm. The selection of new rings is carried out according to the nominal thickness or with a thickness increased by 0.127 so that the axial clearance is in the range of 0.06-0.26 mm.

Stages

Installation of the crankshaft on the VAZ 2106 is carried out in the following sequence:

- First, the support bearing of the input shaft is pressed in.

- Next you need to install new liners. The main liners are installed to the required repair size. The connecting rods are the same size, so they are interchangeable. When installing, you need to be careful not to mix up the bearings. The connecting rod bearings are smaller in diameter than the main bearings and do not have annular grooves.

- Then you need to install the thrust half rings into the bed of the 5th main bearing. In this case, the grooves should be directed towards the crankshaft. Half rings are selected according to tolerances.

When installing gaskets, you should use a sealant to ensure reliable sealing and prevent leakage of working fluids during further operation of the vehicle.

After final assembly, you need to start the engine and check its performance.

Thus, even a driver with little experience in repair work can perform crankshaft repairs on a VAZ 2106, and you can significantly save on car service costs.

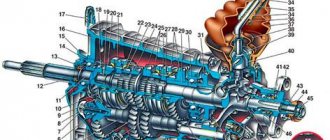

VAZ 2106 Features of engine assembly

1. Bearing shells and thrust half-rings of the crankshaft, as well as pistons and cuffs must be lubricated with engine oil.

2. Place the main bearing shells in the cylinder block housings and in the corresponding covers.

3. Place the crankshaft with the oil pump drive gear, the camshaft drive sprocket and the gearbox input shaft bearing into the main bearings and insert two thrust half-rings into the slots of the middle cover of the main bearings.

4. Allowable axial play of the crankshaft is 0.1–0.29 mm (if the axial play is 0.35 mm or more, replace the half rings with new ones).

5. Install the main bearing caps with the lower shells in accordance with the marks and evenly tighten the nuts of the main bearing studs. Perform final tightening with a torque wrench in accordance with Fig. The sequence of tightening the bolts and nuts of the main bearing cap studs. Tightening torque 90–100 N·m (9–10) kgf·m.

6. Place the cuff cover gasket on the rear flange of the cylinder block. Place the cover with the cuff on the mandrel (Fig. Installing the rear cuff cover of engines mod.331, 3317 and 3313 using a mandrel) and, moving the cover from the mandrel to the crankshaft flange, bolt it to the cylinder block. Center the cover with the cuff in relation to the crankshaft flange using three special protrusions on the cuff cover.

7. Install the flywheel on the crankshaft. Before tightening the bolts, place three locking plates under them (one for two bolts). Tighten the bolts and bend the ends of the stop plates so as to prevent the bolts from being loosened. Make final tightening of the bolts with a torque wrench. Tightening torque 70–80 N m (7–8 kgf m)

8. Insert the liners into the bores of the cylinder block and check the amount of protrusion of the end of the liner above the plane of the block (Fig. Checking the protrusion of the end of the cylinder liner above the plane of the block of engines mod.331, 3317 and 3313). The amount of protrusion should be in the range of 0.01–0.08 mm. The check is carried out with a caliber, having previously pressed the sleeve against the block with a force of 5–7 kgf. Before installing the liners, you should especially carefully clean the ends of the sockets for the liners in the block and the seating ends on the liners themselves from scale and wear products.

9. The final installation of the liner is carried out after installing the piston with rings and connecting rod assembly into it.

10. After checking the protrusion, remove the liners from the block and install the pistons with rings and connecting rods in them. Before installing the piston with rings and connecting rods assembly into the liner, lubricate the piston rings, piston skirt and piston pin with engine oil. Install the piston rings so that their locks are located at an angle of 120° relative to each other (Fig. The relative position of the piston ring locks before installing the piston in the liner). Before installing the piston with rings into the sleeve, compress the rings with a special crimp.

11. Before final installation of the sleeves, lubricate their seating surfaces with nitro paint.

12. When installing the liner into the cylinder block, pay special attention to the correct location of the piston and connecting rod. The arrow on the piston bottom, the protrusion on the connecting rod rod and the groove on the connecting rod cap must face the direction of the camshaft drive chain drive.

13. Install the bearings into the connecting rods and connecting rod caps, having previously lubricated them with engine oil, and connect the connecting rods to the crankshaft journals, install the caps and tighten the connecting rod bolt nuts evenly. Make final tightening with a torque wrench. Tightening torque 55–65 N m (5.5–6.5 kgf m).

14. Check whether the crankshaft rotates easily in the bearings, having previously secured the liners with holder strips (see Fig. Securing cylinder liners for engines mod.331, 3317 and 3313).

15. Remove the liner holder strips from the cylinder head mounting studs and install the sealing gasket and the cylinder head with the intake pipe, exhaust manifold and fuel pump assembly onto the studs.

16. Replace a damaged or heavily compressed sealing gasket with a new one.

17. Lubricate the head gasket on both sides with a thin layer of graphite grease.

18. Tighten the cylinder head fastening nuts in the sequence shown in Fig. The procedure for tightening the nuts of the studs securing the cylinder head to the engine block mod. 331, 3317 and 3313. Make final tightening with a torque wrench. Tightening torque 90–100 N m (9–10 kgf m).

Video “Assembling the engine of a classic VAZ car”

This video demonstrates the procedure for assembling an engine on a VAZ classic, including installing the crankshaft.

The crankshaft is the most important part of internal combustion engines with a crank mechanism. The health of the entire engine directly depends on its condition. A power unit with a worn crankshaft does not develop full power, and the oil pressure in such an engine is low even at rated speed, not to mention idle.

The VAZ 2106 crankshaft, the wear of which exceeds the permissible level, will not be able to operate reliably. Therefore, in order to prevent the engine from jamming, this part is removed and repaired.

Crankshaft assembly

Next in line in the engine work section is a page with material describing the assembly of the crankshaft. I think there is no need to once again focus on the seriousness of this work. The crankshaft is assembled according to the sequence described below.

Install the upper main bearing shells so that the installation lug of the liner is aligned with the recess in the cylinder block bed. Install bushings that do not have a groove and are larger in width into the bed and cover of the middle bearing.

Immediately after installing the liners in place, they should be lubricated with clean engine oil. Install the crankshaft into the cylinder block, install the lower bearings that do not have grooves into the main bearing caps. Lubricate the crankshaft journals with clean engine oil.

Install the main bearing caps, except the rear cover, in their places in accordance with the marks, since they were installed before disassembly.

Read also: Tomahawk car will not start

Lubricate the thrust half-rings with clean engine oil. Install front steel-aluminum and rear metal-ceramic thrust half-rings on the rear crankshaft support.

In the image, the arrows show the recesses on the thrust half-rings. The thrust half-rings should be installed using notches

to the bearing surfaces of the crankshaft.

Install the cover on the rear main bearing and, using a torque wrench, tighten the cover bolts to the appropriate torque.

Using a flat feeler gauge, measure the axial clearance of the crankshaft; to do this, use a mounting blade to move the crankshaft until it stops. The axial clearance should be from 0.06 to 0.26 mm, the maximum allowed clearance is 0.35 mm. If the gap exceeds the values, the above thrust half-rings must be replaced with new ones, increased by 0.127 mm.

Turn the crankshaft a certain number of revolutions, if the shaft rotates smoothly without getting stuck, the shaft is assembled correctly. Having aligned the installation tab of the liner with the notch on the connecting rod, insert the liners and connecting rods, connecting rod bolts.

ONCE AGAIN ABOUT THE THRUST HALF RINGS

ONCE AGAIN ABOUT THE THRUST HALF RINGS

The article “Don't mix up the details” in the September issue of the magazine aroused great interest among readers. In addition to what was published, its author A. NIKOLAEV from Ufa clarifies information about the interchangeability of crankshaft thrust half-rings of VAZ engines.

There are six half rings in the photo. Of these: a and b - 2101–1005183, steel-aluminium, nominal size, shown from the working and non-working sides, respectively; c — repair half-ring 2101-1005183-20 of the old model (the marking “0.127” is stamped on the non-working surface - the size of the repair thickening); d - the modern repair half-ring 2101-1005183-20 differs from the half-ring “c” in that the marking has become shorter (“P” - “repair”); d and f - metal-ceramic (bronze-graphite) half-ring 2106–1005183, shown from the working and non-working sides, respectively. The repair cermet half-ring 2106-1005183-20 looks exactly the same and has no additional markings. It can be distinguished from the nominal one only by measuring the thickness with a caliper - it should be 2.437–2.487 mm (0.127 mm more).

By the way, in recent years, a yellow bronze-graphite ring has been installed in the engines of all VAZ cars, including Samara, 2110 and Oka - it secures the crankshaft from the flywheel side.

If the pressure in the lubrication system decreases or dull noises appear when the VAZ 2106 engine is running, the reason may be a faulty crankshaft. The article discusses the causes of malfunctions, as well as how to change the crankshaft of a VAZ 2106. In addition, a video is attached that demonstrates the partial assembly of a VAZ engine with the installation of the crankshaft.

Signs of a bad crankshaft

There are several signs that can directly or indirectly indicate a crankshaft malfunction:

- when the engine is running at low speeds, the oil pressure indicator light comes on;

- when operating at medium and high speeds, a metallic knock can be clearly heard, the frequency of which increases with increasing speed;

- engine jamming.

In the first two cases, the cause of the malfunction is the wear of the connecting rod or main journals of the crank. The increased gap between the surface of the journal and the liner is what causes a drop in oil pressure. With a critically large gap, the shaft may run out, which causes knocking (the engine “knocks”). The third case is the most difficult. Only a small portion of crankshafts from seized engines can be repaired. In most cases, the crankshaft will need to be replaced.

Fault diagnosis

Diagnosis of thrust parts is usually carried out after the 120,000th mileage of the engine. It consists of three steps.

- Visually inspect the internal combustion engine for oil leaks. If they are present, this is already an indirect sign. A poorly fixed crankshaft squeezes out the oil seal responsible for sealing. And the lubricant begins to flow out.

- Loosen the generator pulley with a mounting blade, resting one end of the tool against the body. The permissible axial play should not exceed 0.35 mm.

- Press the clutch pedal from inside the car. The crankshaft should not move forward. Otherwise, this is the surest sign of breakage of the thrust half-rings.

Axial movements of the crankshaft cause a loud, irregular knock, which experienced mechanics can distinguish.

Crankshaft repair

The crankshaft removed from the vehicle is thoroughly cleaned and inspected. The presence of cracks on the main and connecting rod journals, as well as on the cheeks, is not allowed. If they are found, the crankshaft can be submitted for welding, but it would be better to replace it. Typically, restored crankshafts do not last more than 50 thousand km. They also check for the presence of deep grooves, burrs, scratches and nicks at the contact point of the VAZ 2106 crankshaft oil seal.

To determine the runout, as well as the displacement of the axes of the connecting rod journals, the crank is mounted on prisms. The values of radial runout, axial displacement and non-perpendicularity of the flange end to the crankshaft axis are measured. If the permissible parameters are exceeded, a decision is made to replace the part or edit it using a hydraulic press. Let us immediately note that the VAZ 2106 crankshafts are made of cast iron, so attempts to correct its geometry with a press often end in part failure.

Replacing crankshaft half rings

The crank support of the connecting rods, which creates torque, is not a flat or single piece, but several individual elements connected together. Due to this design, strong axial play appears inside the block, which can disrupt the operation of the motor. To eliminate it and stabilize the rotation, the designers came up with the idea of locking the device with special sliding bearings. The crankshaft half rings , as they are called, take on heavy loads, so they wear out soon.

Installing the crankshaft

The crankshaft is installed on a pre-washed, dry and clean block. Assembly is carried out in the following sequence:

- Press in the support bearing of the input shaft.

- Install new crankshaft main bearings.

- Crankshaft half rings are selected according to the tolerance parameters.

- The connecting rod and main journals are lubricated with engine oil, after which the crankshaft is placed in the block.

- Place the bearing caps according to the marks and tighten the fastening bolts with a force of 68-84 Nm.

- Next, the connecting rod bearings are installed and the connecting rods are secured. The bolts must be tightened to a force of no more than 54 Nm.

- Install the rear crankshaft oil seal.

- The unit's oil pan is attached to the block.

- The front oil seal is installed on the block together with the cover (replacing the crankshaft oil seal is necessary after grinding in any case).

- The crankshaft pulley is installed after tightening the front cover.

- Next, the intermediate shaft is mounted on the engine, the cylinder head and gas distribution mechanism parts are installed.

- Adjust the chain tension.

- Place marks on the crankshaft and marks on the camshaft.

- The remaining parts and components are installed.

- Adjust the tension of the generator belt.

- Install and regulate the ignition.

During assembly, all gaskets must be sealed with automotive sealant. This way you can avoid oil leakage during operation of the unit.

You can't decide whether to repair or change the crankshaft? The price for a new one is currently at least 3,000 rubles. If you grind and repair an old VAZ 2106 crankshaft, the price of the work will be 5 times less than this amount, so the benefit is obvious.

The crankshaft and photos of the stages of its repair, reading specialized literature - all this will help you approach the work with confidence, breathe new life into the engine with your own hands, and grow in the eyes of friends and acquaintances.

The VAZ 2106 crankshaft is a part of the crank mechanism that plays a very significant role in the car. In order to install the crankshaft as efficiently as possible, you will need a wide variety of tools, most of which are sold at any specialized automotive store. Please note that when assembling the piston of VAZ 2106 connecting rod engines there are some peculiarities.

Crankshaft pulley

The generator and water pump on the VAZ 2106 are driven by a belt from the crankshaft pulley. When carrying out repair work on the engine, attention should also be paid to the condition of the pulley: is there any visible damage (cracks, scuffs, dents). If defects are found, the part should be replaced.

During the installation process, the pulley should sit smoothly on the crankshaft, without distortion. Despite the fact that the pulley fits quite tightly on the shaft, a key is used to prevent rotation, which can also be damaged. A defective part must be replaced.

Neck sizes

The main and connecting rod journals wear out as the engine operates, which leads to disruption of the proper operation of the power unit. In addition, wear can be associated with various types of engine problems. These include:

- low pressure in the lubrication system;

- low oil level in the crankcase;

- overheating of the engine, which leads to oil dilution;

- low quality lubricant;

- severely clogged oil filter.

The listed nuances lead to damage to the surface of the shaft journals, which indicates the need for repair or replacement of the unit. To assess the wear of the journals, you need to know their dimensions, which are shown in the table.

Crankshaft selection

The need to select a crankshaft for a VAZ 2106

, like any other car, occurs in case of engine repair or to improve engine performance. Regardless of the task at hand, it must be remembered that the crankshaft must be heavy, with large counterweights. If the part is selected correctly, mechanical losses will be significantly reduced, as well as other loads on the mechanisms.

In the process of selecting a unit, even if it is new, close attention is paid to its surface: there should be no visible flaws, such as scratches, chips, or burrs. In addition, attention is paid to a number of crankshaft characteristics, namely coaxiality, ovality, taper and journal diameter. During engine assembly, the crankshaft is balanced to balance all rotating elements. A special stand is used for this procedure. Once balancing is completed, secure the flywheel and continue the process again. Afterwards, the clutch basket and other elements (pulleys) are mounted. There is no need for balancing with the clutch driven disc.

What to do when necks wear out

What are the steps to take if the crankshaft journals are worn out on a VAZ 2106? First, the defectiveness is carried out, measurements are taken using a micrometer, after which the crankshaft journals are polished using special equipment to the repair size. This procedure cannot be done in a garage environment. The necks are ground to the closest size (based on the tables provided). After processing, thickened liners (repair) are installed in accordance with the new size of the necks.

If a major overhaul of the engine is being carried out, it would not be superfluous to inspect the oil pump, blow out the oil passages of the cylinder block, as well as the crankshaft itself. Attention should be paid to the cooling system. If there are signs of wear or damage on the engine elements or its systems, the parts and mechanisms need to be repaired or replaced.

Replacing the crankshaft oil seal

In particular, a signal that an urgent replacement of the front oil seal liners is necessary is the direct contact of oil on the pulley and its further splashing in the front part of the engine. If oil leaks in the rear oil seal, splashing occurs on the flywheel in the clutch housing. Reasons for replacement:

You can replace crankshaft oil seals yourself; this will not only significantly save time and money spent on repairs in the workshop, but also gain invaluable experience. Replacing the crankshaft oil seal is a standard procedure to ensure optimal engine performance.

According to statistics, the installation of a new oil seal should be done at least once every 3 years. However, oil seal bearings may need to be replaced much sooner. It all depends on the general condition of the parts and the conditions under which the car is used.

Which half rings are better, types

Parts of different materials are usually installed standardly - on the timing side there is a steel-aluminum or bronze ring, and on the flywheel side - metal-ceramic (yellow), bronze, copper. As a rule, the metal-ceramic version is more common on sale. If the product is original production, then one thrust washer is covered with an anti-friction layer.

Experts recommend installing bronze products. But the choice depends solely on the preferences of the owner himself. The main thing is to pay attention to the slots that should be on the parts. They are designed to allow free flow of oil to the crankshaft.

And here is some more information on the material of manufacture:

- solid bronze ones - do not need a protective coating;

- steel-aluminium, coated with aluminum alloy;

- metal-ceramic with bronze-graphite coating.

The choice of product should also imply an obligatory nuance - not only the thrust element, but also the surface of the crankshaft is subject to wear during engine operation. Therefore, it is extremely important to be able to select the correct stopper size, type and serial number. It is imperative that the parts fully meet the standard requirements and are covered with a special protective layer.

As a rule, the exact size is determined before the actual replacement process. However, this can only be done by a specialist who has been able, based on indirect evidence, to create a picture of what reigns inside the block. In other words, how worn are the mounting sockets, and what size washers should be installed. Therefore, under normal conditions, when the installation is done by hand, you have to determine this during the work. If, after installing the half-rings, a measurement with a flat feeler gauge shows a play value higher than the standard - 0.06-0.26 mm or 0.35 mm, the locking elements must be changed one size higher.

Preparation for replacing bearings and direct installation of the crankshaft

In addition, disconnect parts such as the generator, starter, coolant pump, upper nuts that secure the engine mount, and bolts that secure the clutch housing to the engine. The order in which disconnection is made must be strictly observed. During operation, the lifting device cables must be secured to the block and carefully lifted.

Using a 10mm wrench, you need to unscrew all the bolts that secure the oil pan to the cylinder block and remove it along with the seal gasket. Disconnect the oil pump. Using a 14mm socket, unscrew the nuts that secure the connecting rod cover, and then remove it. Then take a hammer, press the handle against the connecting rod, and push the pistons out of the cylinders. Next, take a 17mm socket and unscrew the bolts that attach the crankshaft to the cover. Counting from the crankshaft toe, according to the number marks, we disconnect all subsequent covers. Keep in mind that on cover 5 there are two marks on both sides.

The final stage

To secure, apply light blows with the handle of a hammer to the bottom of the piston, thereby pushing it into the cylinder. Screw on the second to fifth main bearing caps so as not to create a significant tightening. After this, purchase an odorless sealant from the store and apply a thin layer of it to the surface of the cylinder block in the place where it will come into contact with the first bearing cap.

After this, install a new sealing ring on the crankshaft and, after checking the location of the chain on the crankshaft sprocket, install the oil pump and pan. Also screw the removed cylinder head back into place, because only after this the structure can be completely assembled and the crankshaft considered replaced.