How to check the ignition switch of a VAZ 2114

There are several ways to determine the source of the problem:

- diagnostic;

- visual.

First you need to check the car's reaction to different positions of the key in the lock. To begin with, the key must be set to position number one, which is also the ignition. If the module is in order, all the car's electrics should work. However, in the case when all or part of the electrical system does not work, we can conclude that the lock is damaged.

In position number two of the key, the engine starts, for which the starter is turned on. If, when you turn the key, you do not hear the sounds of the starter operating (rotation), as well as the sound of the relay clicking, then either the ignition switch or the starter itself is broken. In this case, you need to run a diagnostic to get other details about the problem. In this case, you will need a multimeter set to ohmmeter mode. Also, before removing or installing the lock, you need to remove the steering column cover.

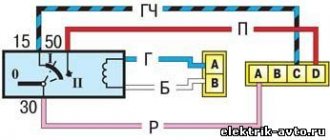

Pinout of the ignition switch VAZ-2114:

- +12V comes for the inserted key sensor microswitch;

- the mass comes when the driver's door is open;

- +12V goes to the starter (pin 50);

- +12V goes out after turning on the ignition (pin 15);

- +12V goes out when the key is inserted to pin 5 of the BSK;

- comes +12V to illuminate the lock cylinder;

- +12V comes from the battery (pin 30);

- not used.

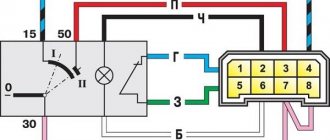

- The first thing to do is disconnect the ignition switch power connector.

- After this, connect the multimeter to wires four and seven, and then do the same with wires fifteen and thirty, respectively.

- Turn the key in the lock to position number one. If during testing the node is not damaged, the multimeter should show a zero resistance value.

- Next you need to turn the key to position number two. The resistance on the multimeter screen, as in the case described above, should have a zero value.

In a situation where, after checking the lock with a multimeter, the resistance value in at least one of the cases was not equal to zero, it needs to be replaced. Otherwise, the lock is working properly and other components of the car should be checked for malfunctions.

Signs of a malfunction of the ignition switch contact group

The ignition switch contact group is a device that, when the key is turned, closes different contacts, thereby connecting the necessary electricity consumers. Signs of its malfunction can manifest themselves in different ways, so we will analyze them all.

Different contact groups have different modes. That is, with fixed key positions in the lock, different sets of devices are connected in different cars. For example, on a “classic”, with the key in the minimum position (when it can be pulled out), all external lighting can fully work, but on a VAZ-2110, in the same position, only the dimensions can be turned on. Thus, the sets of symptoms of malfunctions in the ignition switch contact group for these vehicles are also different. But in all cars in the world, these faults still have much in common.

The most important sign of a faulty lock contact group is the simultaneous failure of an entire group of electrical devices. This happens because within the group several electricity consumers are powered through each contact. For example, low and high beams, turn signals and reversing lights turn on only when the ignition is on. If the contact through which power is supplied to these consumers, say, burns out, then current will not be able to pass through it and the above-mentioned lighting devices will “fail.”

When several devices, seemingly unrelated to each other, stop working, the problem is almost always in the contact group of the ignition switch. Another “bottleneck” point is the fuse box, where several consumers can also be “suspended” to each socket. However, the same headlights are too powerful consumers, so even in the classics they are separated into separate fuses, and their failure together with the reversing lights clearly indicates a malfunction in the contact group of the ignition switch.

Based on this main principle for diagnosing a contact group, other signs can be easily derived:

— The starter is not working , when neither the solenoid relay nor the control relay even clicks (they are simply not supplied with voltage through the contact group in the lock)

— Failure of electrical consumers, which, at first glance, are not connected in any way, but must work together in the same position of the ignition key.

— Restoring the functionality of devices when moving the key in the lock within one position (the contacts of the group are still in contact with undamaged areas and still pass current to consumers)

If there is at least one of the above symptoms, then with a high degree of probability we can talk about a malfunction of the ignition switch contact group. As a rule, the group cannot be repaired, so it is better to replace it. However, if there are some malfunctions or deviations from normal electrical parameters in your car, the new group may suffer the same fate - it will break and will have to be replaced again. To prevent this from happening, you need to know why the ignition contact group may fail .

In most cases, changing the group is not difficult. After all, it is located in the ignition switch, and access to it is limited only by the steering column cover. The instructions for replacing the contact group are different for each car, depending on the design of its lock, so look for information about removal and installation in the repair manual for your particular car.

Source: russia-avto.ru

Installation and connection of a new lock

Now that the old ignition switch has been removed, you can begin installing the new one. In order to do this, you need:

- Take a new lock, insert the key into it and turn it to position number one. This is necessary so that the latch responsible for locking the steering shaft goes inside and does not interfere with the installation process.

Breakaway bolts to prevent the lock from being stolen

- Reinstall the lock and tighten the release bolts. There is no need to tear off the bolt heads right away, so that if something happens, you won’t have to work with a chisel again. This can be done later.

Do not immediately tear off the bolt heads

- Connect the electrics of the new lock to the mating part of the car; you should be careful when working with electricity.

Ignition switch terminal VAZ 2114

When replacement is required

Ignition switch kit

There are several basic situations when a car owner may urgently need to replace a unit. The reasons for the malfunction of the VAZ 2114 ignition switch include:

- Mechanical failure of keys;

- Lost key;

- Damage to the lock as a result of an attempted theft;

- Broken ignition contacts.

How to set the ignition yourself?

Precise ignition adjustment on the VAZ 2115 injector is performed using a special strobe light. If this is not possible, you can set the ignition on the VAZ by spark.

To do this, follow these steps:

- First of all, the engine is warmed up until it reaches operating temperature.

- The distributor does not need to be removed, but only relaxed.

- You need to remove the central wire from the distributor.

- The piston in the 1st cylinder must be at TDC (the marks are set differently on 8 and 16 valve engines).

- Now you need to hold the short-circuit wire with your left hand and turn on the ignition.

- Use your right hand to adjust the distributor counterclockwise, while keeping the high-voltage wires above the metal.

- Then similar actions are performed, turning the distributor clockwise until a spark appears.

- At this point, the alignment ends, and the distributor is fixed in its regular place.

With the ignition set correctly, the car will operate without interruption with optimal fuel consumption and maximum power.

Let's summarize

From the step-by-step instructions we can conclude that replacing the ignition switch on a VAZ 2115 and other models is not difficult. The cost of replacing a lock at a service station will cost you from 500 to 700 rubles, so if you decide to replace the part yourself, you can save this amount.

Hi all! There have been no entries for a long time, and there’s nothing else to write about yet. Someone may ask why there is no record of installing an auto-corrector? The answer is simple, everything was installed a long time ago, BUT!

During operation, a small problem occurred regarding the ECM unit; spare parts are now of “very good quality.” And in the BUK itself the operational amplifier simply burned out or burst due to frost, one of these days the mikruha will come and make a recording. And now about the lock, about a month ago the ignition switch started acting up. The tape recorder began to cut out on bumps, why the tape recorder? Yes, because I made the power supply through the ignition switch, or rather from the sensor of the inserted key. At times everything was fine and I just thought that maybe snow got into the lock with the key, and that was what caused all this trouble. But as they say, the disease progresses. And it made me so sad that I decided it was time to solve this problem! I disassembled the steering column casing, picked up a chisel and a hammer and went ahead, tearing off the bolts. In principle, everything worked out quickly, then I disconnected the block and took it home.

The lock can be disassembled quite easily; you just need to unscrew three screws on the back plate.

Next, I carefully halved the lock; whoever will occupy the same position, carefully halve it, otherwise you might lose the ball with the springs.

I studied the design and came to the conclusion that the microswitch of the lock is to blame.

I decided to take it apart, took off the cover and saw that the rocker was broken. The trouble is, the microswitch is not sold separately, and buying a new lock for 1k is a toad.

Here is the hero of the occasion. I called for disassembly to find out if there was a 10-point lock, they said it was possible, they would call me back a little later. 2 hours later he called and said yes, yes. I immediately went there and picked up an almost new lock.

But I didn’t want to install it, I just updated my lock with the missing part and went through the secrets in the cylinder, otherwise they had become a little worn out after such a long time.

In principle, that’s all, then I lubricated the cylinder with lithol and safely installed the lock in place. I also bought new shear bolts in advance; I didn’t want to install regular ones on a turnkey basis.

Thank you all for your attention and good luck on the road! I also want to congratulate all men on February 23! Issue price: 300 ₽

The lock cylinder (lock cylinder) is a type of lock security mechanism, in the form of a cylinder, the working part of which can be rotated in the body only when a key is inserted into the cylinder hole. The uninterrupted operation of the lock cylinder protects the car from unauthorized entry and protects the owner’s property. Therefore, a malfunction of the lock cylinder is a serious concern that requires an immediate solution, and many car enthusiasts are seriously thinking about how to change the lock cylinder of a VAZ 2114 with their own hands.

Replacing the ignition module yourself

So, first of all, we are looking for a module (for those who don’t know). The PVNs from the spark plugs go to it.

- Remove the negative terminal from the battery

- Disconnect the wire block from the module

- Disconnect the PVN

- Unscrew the module itself and remove it

- Now install the new module and reassemble in reverse order.

When installing, do not confuse the position of the PVN on the reel.

Helpful note! If you are installing a new coil and old wires, pay attention to them. If there are yellow stripes at the tips of the spark plugs and wires, then the wires need to be replaced. After replacing the module, you need to check its operation

We start the engine and enjoy the work done.

After replacing the module, you need to check its operation. We start the engine and enjoy the work done.

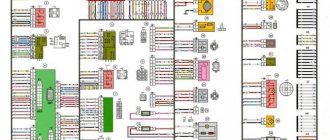

In the article brought to your attention, we will pay attention to an electronic device called the ignition module of the VAZ 2115 car. Or, more precisely, its description, circuit diagram and performance testing. This module includes two high-voltage transformers and two control units (electronic), enclosed in a durable plastic case with four high-voltage wire outputs

Electronic control units are also commonly called ignition coils, and one of them - “working” - is connected to the spark plugs of the first and fourth cylinders of the power unit, the other - “idle” - with the spark plugs of the second and third.

This module consists of two high-voltage transformers and two control units (electronic), enclosed in a durable plastic case with four outputs of high-voltage wires. Electronic control units are also commonly called ignition coils, and one of them - “working” - is connected to the spark plugs of the first and fourth cylinders of the power unit, the other - “idle” - with the spark plugs of the second and third.

The VAZ 2115 ignition module is controlled by a controller whose operating functions include processing data received from vehicle system sensors: coolant temperature, rotation speed and position of the crankshaft, air flow, presence of detonation, etc.

The circuit diagram and connection diagram of this electronic device is presented below.

The only negative point in the operation of this electronic device is its complete inability to repair. However, even a novice car enthusiast can replace it on his own.

- Unstable operation of the power plant when accelerating the vehicle.

- Decrease in engine power.

- “Intermittent” idle speed.

- Malfunction of paired (1/4 - 2/3) engine cylinders.

Purpose and principle of operation

The ignition switch is an electrical device responsible for both starting the engine and turning on the power in the on-board network. It has 3 different sector switch positions controlled by the ignition key.

Each of them is responsible for its own separate function, namely:

- Position “Off 0” - power is supplied to contacts 30 - all equipment is turned off.

- Position “Ignition 1” - power is supplied to contacts 30-15 - current goes to the ignition system, instruments, headlights, windshield wipers, stove, cigarette lighter, glass heater, turn signals.

- Position “Starter 2” - power is supplied to contacts 30-15 and 30-50 - all the same circuits are energized as in position “1”, as well as the starter.

Ignition switch pinout

In turn, the pinout of the VAZ 2114 ignition switch looks like this (the legs of the lock connector are indicated):

- 1 - +12 volts for the key sensor;

- 2 - to ground (if the driver's door is open);

- 3 - +12 volts to the starter (aka contact 50);

- 4 - +12 volts with the ignition on (aka - pin 15);

- 5 - +12 volts with the key inside the lock;

- 6 - +12 volts for lock illumination;

- 7 - +12 volts from the battery (aka - pin 30);

- 8 - not applicable.

The VAZ 2114 ignition circuit, according to which the lock is connected to the on-board network in accordance with the pinout presented above, looks like this:

This is interesting: Which generator is better to install an injector on a VAZ-2114 - photo, video

Main signs of failure

Drivers need to take into account during operation that breakdowns can occur both due to failure of the mechanical part and due to problems with the electrical system. Popular mechanical problems manifest themselves in the following factors:

- the lock is stuck in one position and there is no way to unlock it without using significant effort;

- the steering column is jammed;

- an attempt was made to gain unauthorized access to the lock using a master key or other object unsuitable for this purpose.

The electrical part may also fail. This can be determined by the following factors:

- the starter does not rotate after turning the key to the desired position;

- The dashboard indicator lights do not light up or go out after a short time;

- the operation of devices activated through the lock positions is unstable or absent.

Other factors that are less common among motorists may also occur. They are resolved according to the identified breakdowns.

Signs of a malfunction of the ignition switch contact group

A malfunction in the ignition switch contact group can be recognized by a number of characteristic signs:

- the tape recorder did not start when turned on;

- in addition to the sound signal, the car is completely de-energized;

- periodically resetting the speedometer data on daily mileage, after which it was restored again and began to work properly;

- normal functioning of the car is possible only if you hold the key;

- restarting the engine after a short-term stop;

- the key or ignition switch heats up;

- no backlight on the dashboard until the car is started;

- absence of a characteristic click of the main sub-panel relay.

Any of these symptoms may indicate a serious malfunction of the ignition switch contact group.

In order not to be caught off guard by such problems, you need to determine in advance where to order a replacement contact group. For example, if you are in Kharkov, an excellent option would be the Duplicator workshop on Moskovsky Prospekt 46. Specialists can perform tasks of any complexity, make duplicate keys, repair the ignition lock cylinder, fix a faulty contact group, etc.

Source: dublikator.com

Checking the Lada Samara ignition module

The correct functioning of the ignition module not only has a significant impact on the start of the vehicle’s power plant, but also ensures the stability of its operation in all modes. To carry out a complete diagnosis of this electronic device, you need quite complex equipment, available only in large specialized workshops. However, you can check the functionality of the ignition module yourself in an amateur garage. The only logistical support for this test will be a multimeter, or tester.

Attention! When using a donor car for testing, do not forget that only the first Lada Samara models were equipped with the ignition module, as a separate device. Cars of later releases are equipped with separate type devices (the switch is included in the electronic control unit). The procedure for replacing the ignition module includes the following measures:

The procedure for replacing the ignition module includes the following steps:

Another method involves measuring the resistance of individual module elements using a multimeter (tester). Using the tester probes, we close the “paired” terminals of the module, which provide connection to high voltage wires, and measure the resistance value.

There is another, so-called “folk” method, or the “shake-up” method. With the power plant running, lightly tap the module. Despite all the “technical non-scientific” nature of such manipulations, they are capable of producing results. True, only in the case when the contact of the elements inside the housing is broken.

Sources

- https://avtozam.com/vaz/2115/zazhiganie-remont-zamena-i-nastrojka/

- https://remontautomobilya.ru/modul-zazhiganiya-vaz-2114-princip-raboty-vozmozhnye-neispravnosti-i-zamena.html

- https://vipwash.ru/sistema-zazhiganiya/modul-zazhiganiya-vaz-2115

Characteristics Features

For the “fourteen” model range, VAZ designers chose the right-hand location of the lock. This option distinguishes the model range from the first “classic” cars of the plant. In this case, the switching zone remains under the steering column. The working part is hidden by plastic decor, so only the end of the cylinder is accessible to the driver.

This unit consists of several components. The main ones are the following components:

- durable metal case;

- unique locking mechanism;

- locking block;

- electrical part in the form of a contact group.

The presence of a steel case is designed to protect against unauthorized access to internal components. The locking mechanism borrows its characteristics from a conventional door lock with a “secret”.

Thanks to the built-in locking mechanism, it is possible to fix the steering wheel, preventing it from turning, with a free “secret”. The contact group is connected from the back and is responsible for the timely connection of contacts at a certain position of the key in the keyhole.

What can happen to the ignition switch

Depending on the type of contact group, its modes will differ. For each car model, at a certain key position, the connection of a given set of devices will be characteristic.

Actually, this causes a number of certain inconveniences, since the differences relate not only to the operation of the ignition switch contact group, but also to its characteristic failure symptoms. However, there is a certain list of what can happen to the ignition switch.

Mostly, failure occurs due to oxidation or burning of contact groups. The latter occurs due to frequent and severe voltage drops when starting a car engine.

The structure of a car ignition switch

- Locking rod

- Frame

- Roller

- Contact disc

- Contact sleeve

- Block

- Protrusion of the contact part.

The lock mechanism is connected to many wires. They continue from the battery, connecting all the electrical devices of the car into a single chain. When you turn the ignition key, the electrical circuit is closed from the “-” terminal of the battery to the ignition coil. As a result, the current passes through the wires to the ignition switch, through its contacts it is directed to the induction coil, after which it returns back to the “+” terminal. As electricity passes through the coil, it generates high voltage, which it transmits to the spark plug. Therefore, the key closes the contacts of the ignition circuit, thereby starting the car engine.

Steering lock testing

Testing the steering wheel

If you do not check the operation of the steering wheel lock, you may encounter certain problems in the future. Therefore, do not waste your time on this event. It consists of removing the key from the ignition and turning the steering wheel at a slight angle.

- If there is no lock, you will need to slightly adjust the position of the lock. Make sure it fits into the groove located on the steering shaft.

- If the locking is effective, you will only need to tighten the four installed breakaway bolts until they stop. Twist until the heads break.

It is worth noting one very important nuance. Some people don't find it necessary to use breakaway bolts. Instead, the most common fixing bolts with a length of 20 millimeters and an M6 thread are used. On the one hand, this will make it easier to remove the device in the future, if such an event is required again. On the other hand, in the absence of a reliable anti-theft system, voluntarily giving attackers access to your car is not the best idea.

When the lock installation is completed and the test has passed, do not forget to connect the device to power and start the engine. If it starts, all systems dependent on the ignition switch are working, you can fully begin reassembly. Follow the reverse instructions for removing the casing and steering column switches. It would not be amiss to check the condition of certain nodes along the way. It is quite possible that some of them also need replacement or a little preventive maintenance.

Loading …

Reasons for replacement

Many problems associated with the ignition switch can be eliminated by replacing only individual parts, and not the entire switch as a whole. You can buy a contact group or a lock cylinder separately. That is why repairs should begin with high-quality diagnostics. Main malfunctions and their symptoms:

- The starter does not respond to turning the key. The reason is most likely in the contact group. To verify this, check whether power is supplied to the starter relay after turning the key to the On position (starter activation mode). If the relay clicks, it means that the system “sees” the key being turned and there can be no complaints about the components of the electrical circuit of the lock. On vehicles that are not designed to have a starter relay, the power should be checked at the corresponding terminal of the solenoid relay. For diagnostics, you can use a multimeter or a tester (one lead to ground, the other to the retractor contact coming from the ignition switch). If the retractor and wiring are in good condition, then the contact group has failed;

- the key moves with a wedge. The problem is in the lock cylinder, as over time the mechanism wears out and becomes clogged. In this case, aerosol lubricants can only temporarily eliminate the malfunction;

- The key does not turn to all positions. The reason is mechanical damage to the lock cylinder. It may also be due to jamming of the anti-theft locking mechanism of the steering shaft;

- the key turns, but power does not come to the corresponding groups of contacts. The reason is in the contact group. The pinout of your vehicle's ignition switch can be found in the repair and maintenance manual.

Tips for replacing the door lock cylinder on a VAZ 2114

Often, when repairing a door handle lock, it turns out that severe wear of the part leads to the need to replace several elements of the device. You can try to restore the lock, but such repairs will not help for long and after a while you will have to start solving this problem again.

When using the car for a long time, it is recommended to inspect the door locks from time to time and replace the part if necessary. Before removing the lock cylinder from the package or from the door handle, be sure to insert the key into the lock hole. Otherwise, this threatens the pins falling out of the lock grooves, which will be problematic to put in place.

On a VAZ 2114, replacing the door lock cylinder is a job that you can do yourself, if you have free time and the necessary tools. To change the lock cylinder you will need:

- open-end wrenches “8” and “10”;

- pliers;

- WD-40 lubricant;

- flat and Phillips screwdriver;

- new lock cylinders and springs for VAZ 2114.

The price for a set of door lock cylinders with a trunk lock for a VAZ 2114 manufactured by VAZ with article number 21140610004520 is 400 rubles, and its analogue with article number 21140-610004520 from the manufacturer DAAZ is 450 rubles. The cost is indicated for spring 2022 in Moscow and the region.

1Use a Phillips screwdriver to unscrew the three screws at the bottom of the trim.

2Remove the cover. We take the front shutter glass position switch out of the pocket along with the wiring harness block, disconnecting it from the wire switch.

3Using a screwdriver, remove the armrest handle cap.

4Use a Phillips screwdriver to unscrew the 2 screws securing the armrest handle to the inner door panel.

5Press the fasteners securing the inner lock handle trim to the door panel...

7 Carefully, using a screwdriver, remove the six pins from the holes in the door panel and remove the door card.

8Using an 8 wrench, unscrew the two nuts securing the outer lock handle. First one...

10 Disconnect the outer handle rods and the lock switch from the internal lock.

11Remove the outer lock door handle with rods.

12Then remove the pin from the end of the rods.

14Remove the plastic rod end from the door lock cylinder.

15Remove the locking spring by removing its ends from the slots on the cylinder and on the lock handle.

16 We take out the old lock cylinder along with the key.

17Unpack the new set of larvae. Having previously lubricated all the rubbing parts with grease, we insert the lock into the door handle.

18Install a new cylinder return spring.

19When turning the key, the key should return back from any position.

20Install the pin on the tip of the rotary rod. The handle is assembled. We carry out further assembly in reverse order.

The larva has a cylindrical shape, which is activated when the key is turned in the well. If the mechanism jams and makes it difficult to open/close, then one day the driver simply will not be able to get behind the wheel of his car. Therefore, if the device does not operate correctly, it is recommended to replace the door lock cylinder with a VAZ 2114.

Preparation

At the preparation stage, you will need to collect the necessary tools near you, which will be useful in the process of dismantling and installing a new ignition switch. You will also have to remove the steering cover and steering column shifters. Doing this is quite difficult, but we will tell you step by step about all the nuances of these preparatory activities. So you can easily figure out for yourself how to remove the ignition switch on a VAZ 2114.

Replacement process

Tools you will need:

- Phillips strong screwdriver;

- Open-end wrench 10 millimeters;

- Chisel;

- Hammer;

- Pliers or pliers;

- New ignition switch assembly;

- Lock mounting screws (4 pieces).

Now let's move on to the casing and switches. For more convenient work, many advise removing the steering column switches and the steering wheel itself. Dismantling the casing is performed in the following sequence:

- Disconnect the negative cable from the battery. Nobody has yet canceled the requirements for personal safety and protection against electric shocks;

- Unscrew the three screws securing the two parts of the casing. A screwdriver is useful for this;

- Unscrew the screw that connects the housing to the connector of the steering column switches;

- Remove the two screws that hold the lower housing to the steering column;

- The lever that fixes the column at the corner leads down;

- The steering wheel also goes down;

- The lower casing is then removed;

- The power supply from the emergency lights must be disconnected;

- Now you can remove the top casing;

- To dismantle the steering column switches, you need to act one by one;

- Simultaneously press both latches and thereby remove the elements from their seats;

- Disconnect them from the power supply.

Installing a new part

The removal and assembly algorithm is the same, although the instructions for installing the cylinder mechanism have its own nuances. Before inserting a new cylinder into the core, the part is lubricated with a silicone substance and only then inserted into the handle. Further algorithm of actions:

- The return spring is inserted next to the cylinder.

- The functionality of the key is checked. It should turn easily in all positions.

- A pin is installed on the tip of the rotary rod. Connection is being made.

- The inner and outer panels are screwed on, the handles are fixed, and the plug is returned to its place.

- The main three screws are tightened from the inside.

- autorn.ru

- www.drive2.ru

- etlib.ru

- infokuzov.ru

Troubleshooting Methods

There are two methods for detecting faults:

- Visual;

- Diagnostic.

Ignition switch circuit

We suggest studying a visual method for determining a malfunction or breakdown of the contact elements of the ignition switch using the table.

| Action | The device is working properly | The device is faulty |

| Turn the key to the right position (ignition) | All electrical equipment turns on | All or part of the electrical equipment does not work |

| Turn the key to the second position | The starter is spinning | The starter does not work, the traction relay does not click under the hood |

But diagnostics allows you to get a more detailed answer. In addition, a visual inspection will not give you the opportunity to find all the reasons that could cause the ignition switch to break down.

To work, you will need a mini-tester and a multimeter in ohmmeter mode:

- Disconnect the power supply from the ignition switch. To do this, you need to remove the skin from the steering column;

- Switch your multimeter to an ohmmeter;

- On the block coming from the lock you need to find pins 7 and 4, which correspond to pins 15 and 30;

- Connect the multimeter probes to them;

- Turn the key to the “Ignition” position;

- On the block, find pins 7 and 3, corresponding to 50 and 30. Also connect a multimeter to them;

- Turn the key to the second position - Start the engine;

- If serviceability is present, the device will show zero resistance in both test cases.

Electrical fault

The main causes of this type of breakdown include overload of the contact system, when high-power equipment is installed with a current level not provided for by it.

As a result, carbon deposits form that cannot be removed. To avoid this situation, install auxiliary elements via a relay. The second, no less compelling reason for an electrical type malfunction is a short circuit. Here you also cannot do without replacing the burnt elements of the group.

Replacing the ignition switch on a VAZ 2115, 2114

Replacing the ignition switch of a VAZ 2114, VAZ 2115 may be necessary in the event of a malfunction of the contact group, jamming of the mechanism, or simply wear.

The procedure is not complicated, so let's get started.

Before the replacement itself, it is necessary to purchase bolts with break-away heads. It is not recommended to replace them with regular ones with M6 thread, because... In addition to you, car thieves can easily remove the lock.

Before replacing the lock, turn the key to the “I” position so that the latch locking the steering shaft mechanism can enter the lock body.

- It is necessary to disconnect the battery by removing the wire from the “—” terminal

- Next, remove the steering wheel. To do this, remove the decorative trim on the steering wheel and unscrew the horn cover.

- Then, having unscrewed the steering wheel fastening nut not completely, we knock the steering wheel off the splines. After this, finally unscrew the nut.

- Remove the plastic covers from the steering column.

- Disconnect the block with the ignition switch wires.

- Use a chisel to knock the heads off the old bolts holding the ignition switch in place.

- Remove the old lock and install a new one in its place. Before installation, press the locking tab into the new ignition switch.

- Check that the steering shaft is locked correctly.

- Once you have completed adjusting the position and checking the functionality of the locking mechanism, tighten the bolts until the heads are completely free. Do this using the 10 key.

- Connect the wiring harness of the new ignition switch.

- Start the engine, make sure that the ignition switch is working correctly and that there are no problems with starting. If everything is in order, then we can conclude: the replacement of the ignition switch of the VAZ 2114, 2115 was carried out successfully!

Previous posts from the category: VAZ 2114

If engine oil or coolant appears around the perimeter of the connection of the cylinder head with the cylinder block itself, it is necessary to replace the cylinder head gasket of the VAZ 2114, VAZ 2115. A leak can also occur due to a change in the shape of the cylinder head after the engine overheats.

After prolonged use of a VAZ-2114, VAZ 2115, for no particular reason, an extraneous sound may arise from the front axle area in the form of a whistle.

Typical malfunctions of VAZ 2114, 2115 injectors: -difficulty starting the engine; — unstable engine operation; — the engine stalls at idle; — increased crankshaft rotation speed at idle; — the engine does not develop full power; — jerks and dips in engine operation when the car is moving; — increased fuel consumption; - increased content of CO and CH

The clutch briefly disconnects the engine and transmission and then smoothly connects it to start moving and change gears.

Replacing the stove fan of a VAZ 2114, 2115 may be necessary if it completely fails, or if it constantly operates only at 3rd speed.

*Add article to bookmarks:

Source

https://remontysvoimirukami.ru/remont-vaz-svoimi-rukami/remont-zamka-zazhiganija-vaz-2115-svoimi-rukami.html

Instructions for replacing the ZZ

Replacing the ignition switch on a VAZ 2114 injector takes place in stages. At each stage certain actions are performed.

Preparation

First of all, you should prepare for the replacement procedure by preparing an electrical circuit diagram and the necessary materials and tools:

- new node;

- 4 assembly mounting screws;

- chisel;

- a set of keys;

- Phillips screwdriver;

- hammer;

- pliers.

The VAZ 2114 ignition switch should be purchased assembled.

ZZ for a VAZ car

For ease of operation, remove the cover from the steering column and switches.

Dismantling the casing is carried out step by step:

- First of all, the car is de-energized by disconnecting the negative terminal from the battery.

- Use a Phillips screwdriver to unscrew the screws securing the casing.

- Then the self-tapping screw is unscrewed, with which the housing is secured.

- Now you need to remove the screws holding the lower part of the housing to the steering column.

- At the next stage, the lever is lowered down, with the help of which the steering column is fixed at the angle, and the steering wheel.

- Next, the lower casing is dismantled.

- After disconnecting the power supply, you can remove the upper part of the casing.

- To remove the steering column switches, press the locking elements and remove the elements from their standard places.

- The switches should also be disconnected from the power supply.

Removing a faulty device

Having opened access to the protection zone, you can dismantle it. The difficulty of dismantling is that there are no heads on the 4 bolts that secure the ignition switch to the steering column on the VAZ 2114. The absence of heads prevents criminals from stealing a car without a key.

Dismantling with hammer and chisel

Dismantling of the protection zone is carried out as follows:

- you need to loosen the bolts using a hammer and chisel;

- then the loosened bolts are removed with pliers;

- then the bracket is removed from the steering column;

- the power supply is turned off;

- Now you can dismantle the unit.

The node connection diagram is simple. If it is purchased assembled, then it is not difficult to understand the diagram in order to connect the wires correctly.

Recommendations

Reassembling and lubricating individual parts will not work if the fragments are heavily worn. It is better to remove the cylinder from the core and install a new one. Recommendations for replacing the VAZ 2114 door lock:

- Partial repairs or lubrication will only temporarily restore life to the closing mechanism. If problems arise, it is better to replace the entire cylinder.

- After installation, it is necessary to periodically lubricate the mechanism. Experienced motorists use silicone substances for this.

- The repair procedure is carried out in a well-lit room at a comfortable temperature.

- To change the element, you will need a set of screwdrivers, pliers and lubricant.

- Sometimes the springs have to be replaced along with the cylinder. They are purchased separately.

The cylinder fragment is sold as a set. The price depends on the manufacturer. If you buy a cheap Chinese version, it will cost about 150 rubles. It is better to give preference to VAZ spare parts. The cost of such a kit is 400-500 rubles.

How to determine the malfunction?

Lock failures can be mechanical or electrical.

In the event of a mechanical breakdown, the key rotates with force in the lock and in the future may break off or jam. You can extend the life of the lock a little by lubricating the cylinder with WD-40 penetrating lubricant. Of course, this is a temporary measure and will not save you from replacing the lock in the near future.

In the event of an electrical breakdown, a group of contacts breaks or burns out. The most common problem is burnout of the contacts that supply power to the starter solenoid relay. You turn the key to start the engine, but the starter is silent. If the contact group breaks down, you should not replace the entire lock. There is a separate group of contacts for sale and below we have described the replacement procedure step by step.

In what cases is replacement required?

There are several situations when replacement of the seal is necessary:

- malfunction of the unit itself;

- loss of keys;

- mechanical damage to the protection during theft;

- contact group malfunction.

3Z device diagram

A unit malfunction can be detected when the engine starts. When the starter does not spin, the solenoid relay does not click, and electrical equipment does not work. Failures can be mechanical or electrical.

Replacing the contact group

To replace the contact group of the ignition switch of a VAZ 2107, do the following:

- Disconnect the battery terminal with the minus sign.

- We put the key in the lock in position “0”.

- We unscrew the screws securing the steering column housings and dismantle them.

- Disconnect the wires from the ignition switch. We advise you to remember or take a photo of how the wires were connected. If you forgot to do this, see the diagram below.

- Using a small slotted screwdriver, we pry up the spring ring that holds the contact group in the lock body.

- We dismantle the contact group.

- We mount a new group of contacts and secure it with a spring ring.

- We connect the wires and mount the steering column covers.

- Connect the negative terminal.

What are the signs to recognize a bad contact in the ignition switch?

To understand the causes and recognize the symptoms of a faulty ignition switch contact group, you need to have a general understanding of what it is, the features of its operation and possible causes that could lead to a malfunction.

The ignition switch contact group itself is the central link in the system responsible for starting the car. The moment you turn the key, the group helps close the corresponding contacts, as a result of which certain electrical consumers receive the necessary connection to the system.