If the car's cooling system is working properly, the engine operates in a comfortable mode, and the entire internal combustion system ensures reliable operation of the car while driving. If the engine of a VAZ 2110 gets hot, it means there is a problem somewhere, everything must be ensured so that the temperature evens out. Overheating is just as bad as underheating. But in order to troubleshoot the cooling system, first of all, you should know how it functions.

Cooling system design diagram

Electric fan

It is assembled on three rubber bushings and secured with nuts on the casing studs 5. The four-blade impeller 3 is made of plastic and is secured to the electric motor shaft 4 with a nut. For better operating efficiency, the impeller is placed in a casing 5, which is mounted on the radiator brackets at four points. The impeller blades have a variable radius installation angle and, to reduce noise, a variable pitch along the hub.

The electric fan is turned on and off depending on the coolant temperature by sensor 6 of type TM-108, screwed into the lower radiator tank 1 on the left side.

On motors in variant versions, mechanical fans can be installed, the impeller of which is attached to the hub 4 of the pump drive pulley 3.

Radiator and expansion tank.

Radiator 1 is installed on two rubber supports (pillows) and secured to the front of the body with four bolts. It consists of upper and lower stamped brass tanks, two rows of brass tubes and cooling plates. The tanks have inlet and outlet pipes, the lower tank has a drain plug 7. The filler neck is closed with a radiator plug 2. The filler neck pipe is connected via a hose to a plastic expansion tank through the inlet and outlet valves of the radiator cap. The inlet valve is not pressed against the gasket (gap 0.5-1.1 mm) and allows the inlet and outlet of coolant.

With the engine running, when the temperature rises sharply or the liquid boils, the flow through the intake valve becomes insufficient and, under the influence of an increased pressure difference, the intake valve closes, disconnecting the cooling system from the expansion tank. The pressure in the system increases, providing better heat transfer through the radiator. When the pressure increases to 0.05 MPa, the exhaust valve opens and the coolant is released into the expansion tank. The temperature of the liquid will be 118-120°C. Excess steam escapes to the atmosphere through the rubber valve of the expansion tank plug, which operates at a pressure close to atmospheric pressure. The pressure at which the exhaust valve opens has been increased since 1983 to 0.08 MPa (0.8 kgf/cm2).

Replacing the pipe

I went to the store, bought a set of pipes (in reserve), clamps, and antifreeze to top up. I returned to the garage and began to disassemble. This was my first time replacing this pipe. I knew that it was going to the stove and I also knew that I would have to take a lot of disassembly, plus drain the antifreeze.

First things first. First, I unscrewed several screws and removed the left trim (aka sound insulation). Then I removed the air pipe, loosening two clamps, and also disconnecting the crankcase ventilation pipe.

Next, I proceeded to dismantle the front window trim and removed the wiper arms.

After all the operations performed, I finally saw where the damaged pipe ends. But it is blocked by the heater fan housing.

So we’ll remove it too. It is held on by three screws and two top latches. There were no problems with withdrawal. In one step I cleaned the fan of debris.

I didn’t take out the fan itself, I just moved it a little to the left. And now I had access to the clamp and pipe.

Coolant pump

Engine advantages of Lada Granta

Centrifugal pump. Housing 1 and cover 6 are made of aluminum alloy. In the double-row ball bearing 2, locked with a screw 5, a pump roller 7 is installed, which acts as the inner race of the bearing. The bearing is filled with lubricant only during assembly and is not subsequently lubricated. The hub 4 of the pump drive pulley 3 is pressed onto the front end of the roller 7, and the pump impeller 9 is pressed onto the rear end. The seal ring 8, made of a graphite composition, is pressed against the end of the impeller, hardened by high-frequency currents to a depth of 2-3 mm. The non-separable oil seal 8 is pressed into the pump cover.

How to drain antifreeze

Now all that remains is to drain the antifreeze into a container. I used a 5L bottle and only drained from the block. See how to drain antifreeze here.

A piece of garden hose (about 1.5m) worked very well for draining.

That's all. After draining the coolant, I unscrewed the two clamps of the torn pipe and replaced it with a new one. That's where the pipe broke.

I didn’t encounter any particular difficulties in my work, even though I was doing it for the first time. As a result, I gained invaluable experience and money savings. The service would charge from 600 to 800 rubles. In addition, I wiped all the hidden cavities and removed debris from them. It's unlikely that a service station would do this to you. Video to help))) (replacing the stove)

Good luck to everyone on the road and in the repairs!

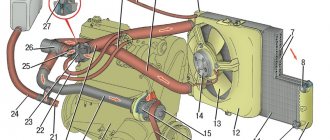

VAZ-2111 engine cooling system with fuel injection system

Cooling fan does not work

1 – expansion tank; 2 – plug; 3 – steam removal hose; 4 – hose from the expansion tank to the thermostat; 5 – coolant temperature sensor in the outlet pipe; 6 – throttle unit; 7 – radiator supply hose; 8 – radiator outlet hose; 9 – left radiator tank; 10 – right radiator tank; 11 – drain plug; 12 – radiator core; 13 – electric fan casing; 14 – electric fan impeller; 15 – electric motor; 16 – pump gear pulley; 17 – pump impeller; 18 – camshaft drive toothed belt; 19 – heater radiator outlet pipe; 20 – pump supply pipe; 21 – tap; 22 – heater radiator; 23 – coolant drain hose from the throttle pipe; 24 – coolant supply hose to the throttle pipe; 25 – coolant temperature indicator sensor; 26 – exhaust pipe; 27 – heater supply pipe; 28 – thermostat; 29 – coolant level sensor.

Prevention

Based on the above, make it a habit:

- Check the coolant level regularly;

- use only high-quality coolant;

- never use water, since it has a lower boiling point than antifreeze, and water also contributes to rapid corrosion of cooling system parts;

- pay attention to the antifreeze temperature sensor and do not let the arrow “visit” the red sector.

Sources

- vazweb.ru/desyatka/dvigatel/sistema-ohlazhdeniya-dvigatelya.html

- drive2.ru/l/5143636/

- luxvaz.ru/vaz-2110/93-sistema-ohlazhdeniya.html

Car engine cooling system repair

How does an engine cooling fan work?

I think there is no need to say that the SOD is intended to cool engine parts that are heated as a result of its operation. To identify problems with the engine cooling system yourself, you need to understand how this system works:

Operating principle of the engine cooling system

The SOD contains:

- Engine cooling radiator, which is designed to cool heated coolant with air flow.

- A radiator fan that increases the cooling intensity of the coolant in the radiator.

- The heater radiator, which is the source of heat for the car interior.

- An expansion tank, which serves to compensate for changes in the volume of coolant due to temperature. You won't be able to add antifreeze without it either.

- A pump or centrifugal pump that circulates coolant in the system.

- A thermostat, which is designed to regulate the amount of coolant passing through the radiator, thereby ensuring optimal temperature conditions in the system.

- The coolant temperature sensor is one of the cooling system control elements.

The coolant in the SOD circulates constantly, that is, it has forced circulation, which is provided by the pump.

Depending on the temperature, the liquid circulates in a small or large circle. To speed up engine warm-up, the coolant moves in a small circle, bypassing the radiator. The thermostat is closed. When the coolant (coolant) heats up to a certain temperature, the thermostat opens and the coolant begins to circulate in a large circle (through the radiator). In the radiator, the coolant is cooled by a counter flow of air, or by an air flow from a fan, which turns on when the coolant reaches a certain temperature. After cooling, the liquid again enters the small circle and so the cycle of movement of the coolant is repeated many times, maintaining the operating temperature of the engine (98-103°C).

Diagnose the engine cooling system and identify problems

The first step is to check the coolant level in the system. In cars of the tenth family, this is done either visually (the expansion tank must be half full) or using the coolant level indicator (installation instructions). If there is an antifreeze leak, then inspect the engine compartment for smudges. Usually the causes of antifreeze leakage are: old clamps on the pipes, a broken engine cooling radiator (radiator repair) or an old heater radiator (heater radiator replacement).

- Check the thermostat. With the engine warm, touch the upper and lower radiator pipes with your hand. If the top one is hot and the bottom one is cold, and the radiator is barely warm, then the thermostat is stuck and the coolant circulates only in a small circle. By the way, the thermostat can also get stuck in the open position, then the engine does not warm up to operating temperatures. The thermostat needs to be replaced.

- Another reason for engine overheating may be air in the engine cooling system (how to remove an air lock is described here).

- If the radiator fan does not turn on, then check the coolant temperature sensor, wiring to the fan and relay.

- It is not uncommon for the radiator honeycombs to become clogged due to dirt and dust and it is not able to cool the antifreeze properly. The result is overheating of the engine, and the solution may be to clean the radiator.

Refinement of the engine cooling system

- To make maintaining the coolant temperature more stable, you can install a 6-hole thermostat. In addition, it can still be modified!

- You can warm up the antifreeze more quickly in winter and reduce the pressure in the system if you convert the dozens of SODs to the Kalina system.

- You can improve coolant circulation in the SOD by installing an alternative, more efficient pump (Luzar). An additional pump in the SOD is also not a bad idea.

- The standard radiator fan on the VAZ 2110 (Carlson) has only one speed. You can easily modify the fan start-up, or replace the fan with a more efficient and silent one.

- It is possible to change the car's firmware, then you can set a lower temperature for the radiator fan.

| What malfunction of the cooling system on a VAZ have you encountered most often? |

CO design

The cooling system of the VAZ 2110 - 8 valves works due to the forced movement of a special liquid, which is caused by high pressure. The CO 16-valve “ten” has an optimal operating temperature, which varies between 90-95°C.

When the high pressure disappears, the engine temperature returns to normal and the intake valve begins to operate, this process is repeated cycle after cycle. If the balance is upset, overheating occurs, which leads to various breakdowns and expensive engine repairs, and sometimes to its complete replacement.

The design of the VAZ 2110 carburetor power system

The fuel supply is located in the tank located under the bottom in the area of the rear seats. The VAZ 2110 tank is made of steel and consists of two stamped halves welded together. Through drainage tubes it is connected to a non-separable separator that traps gasoline vapors. The latter communicates with the atmosphere through a double check valve, which prevents excessive increase or decrease in pressure in the fuel tank. The filler neck is connected to the tank with a gas-resistant rubber hose secured with clamps. The plug is sealed.

Through a fuel intake with a mesh filter, gasoline is supplied from the tank through steel fuel lines and rubber gas-resistant hoses to a fine fuel filter, a fuel pump and then to the carburetor. Gasoline is sucked from the tank due to the vacuum created by the gasoline pump.

Fine filter VAZ 2110 - with a paper filter element in a plastic housing, non-separable design. There is an arrow on the filter housing that must coincide with the direction of fuel movement.

The VAZ 2110 fuel pump is of a diaphragm type, mechanically driven by the camshaft eccentric, with a manual pumping lever. It consists of a lower housing with drive levers, an upper housing with valves and pipes, a diaphragm assembly and a cover. The diaphragm assembly is installed between the upper and lower housings. Two diaphragms are installed on top (working ones), and one (safety) on the bottom: it prevents gasoline from entering the engine crankcase if the working diaphragms rupture. In this case, leaked gasoline is discharged through holes in the external spacer located between the safety and working diaphragms.

The diaphragms, together with the internal gasket and plates (from the outside), are assembled on the rod and secured with a nut. The rod is inserted into the cavity of the balancer using a T-shaped shank. A spring is installed between the diaphragm assembly and the lower housing. The upper housing is closed with a lid secured with a bolt. Underneath there is a mesh fuel filter.

The pump is attached to the engine on two studs through a heat-insulating spacer, sealed on both sides with cardboard gaskets. Gaskets are available in thicknesses of 0.30, 0.75 and 1.25 mm. A 0.30 mm gasket is installed between the heat-insulating spacer and the engine, and a 0.75 mm gasket is installed on the outer side of the spacer (facing the fuel pump) and the minimum protrusion of the pusher from the spacer is checked, which should be 0.8-1.3 mm. To do this, slowly turn the engine crankshaft, pressing the pusher with your finger and periodically checking its protrusion above the plane of the gasket. If the minimum protrusion is less than specified, the outer gasket is replaced with a thinner one, if more, with a thicker one.

Part of the gasoline supplied to the carburetor is drained back into the tank through a system of pipelines and hoses - this improves the cooling of the gasoline pump and prevents the formation of vapor locks in the power system. A check valve is embedded in the drain line, allowing fuel to flow in only one direction - from the carburetor to the tank.

The VAZ 2110 air filter housing can receive cold air through an intake near the radiator or hot air from an intake mounted on the exhaust manifold. The flow is switched by a damper controlled by a thermostat. The built-in thermal power element opens the hot air damper when the incoming air temperature is below 25°C and completely closes it if the air is heated above 35°C. Thus, the temperature of the incoming air is automatically maintained within 25-35°C.

The VAZ 2110 air filter is dry, with a replaceable paper filter element, mounted on the carburetor studs through a rubber gasket and secured with four self-locking nuts through a metal plate.

LiveInternetLiveInternet

-Music

—Categories

- Psychology (1)

- children (748)

- men (28)

- socks (141)

- ANIMATION (74)

- astrology, calendars (28)

- Pregnant (29)

- beads (47)

- our little brothers (21)

- bouquet of sweets (95)

- felting (14)

- everything made of paper (172)

- everything from traffic jams (7)

- KNITTING (412)

- Fortune Telling (19)

- getting ready for the holiday (207)

- AQUAGRIME (7)

- Design ideas. (67)

- interesting and beautiful (15)

- carving (15)

- computer, useful programs (83)

- suits (49)

- beauty and health (383)

- kitchen (71)

- LifeHack (14)

- Master Class (85)

- DIY FURNITURE (117)

- music (12)

- Soap making (25)

- soft toy (90)

- NEW LIFE TO OLD THINGS (90)

- tutorials (142)

- diary design (3)

- very good skillful hands (182)

- gifts (84)

- CUSHIONS (65)

- help (10)

- Parables, aphorisms (2)

- hairstyles (92)

- REPAIR WITH YOUR HANDS (23)

- RECIPES (468)

- Baking (79)

- winter preparations (95)

- salads, canapés, sandwiches (131)

- draw (81)

- HANDCRAFTS (206)

- garden design and just a summer house (243)

- wedding (23)

- Tips for housewives (156)

- cakes (147)

- Stencils (60)

- patterns (37)

- photoshop (45)

- cold porcelain, modeling (134)

- flowers (49)

- SEWING (230)

- curtains (17)

- humor (11)

—Search by diary

—Subscription by e-mail

-Statistics

Engine cooling system VAZ 2114

Engine cooling system VAZ 2114

The VAZ 2114 engine cooling system is of interest to many owners of this car. Unfortunately, domestic cars are not distinguished by good build quality and reliable operation of their various systems, including the VAZ 2114 engine cooling system.

But before you find and fix a malfunction in the VAZ 2114 engine cooling system, you need to know its structure and operating principle. We'll talk about this next.

Internal heat exchange

The operating principle of the VAZ 2114 engine cooling system is based on internal heat exchange, which occurs using liquid. I won’t reveal anything new to you here, since the operation of the cooling systems of 99% of all cars in the world is based on this principle.

The reason for this was that this principle is much more efficient and reliable than the air cooling system.

We are all familiar with the legend of the domestic automobile industry, the Zaporozhets car, on which the engine stood at the rear and was cooled using directed air flows.

And how the owners of this car suffered, coming up with various tricks to increase the efficiency of this system so that the engine does not overheat.

Important drawback

However, the engine cooling system of the VAZ 2114 and all other similar cars has one important drawback: constant monitoring of its condition, periodic mandatory maintenance and repair.

The operation of such a cooling system is based on forced circulation of coolant through a closed circuit. The only thing that connects it to the external vir is the expansion tank.

Design of the VAZ 2114 engine cooling system

The VAZ 2114 engine cooling system consists of:

- Electric motor;

- Pump;

- Left and right radiator barrels;

- Necks;

- Filler and drain plugs;

- Drain pipe.

Of course, the radiator, expansion tank, tubes and hoses through which the coolant circulates, thermostat, electric fan and its activation sensor, pipes for the heater radiator, carburetor heating unit.

Also included in the cooling system of the VAZ 2114 engine is the camshaft drive belt, which drives a centrifugal pump or simply a pump.

Principle of operation

The circulation of liquid in the car's cooling system occurs forcibly under the influence of a centrifugal pump, which, in turn, is driven by the timing belt.

The electric fan has four built-in plastic blades. It is mounted on the motor shaft. The electric motor, in turn, constantly reacts to the readings of a special sensor and, depending on its readings, turns on and off.

As you know, the VAZ 2114 engine cooling system is not as such without a thermostat valve, which has two channels, main and additional. The thermostat has a special filler that is sensitive to changes in ambient temperature.

In general, the thermostat valve is one of the most important elements of the cooling system of any car. When the coolant temperature reaches approximately 87 degrees (plus or minus 2 degrees), the main valve opens and allows coolant to flow through the large circuit.

When the coolant temperature reaches 102 degrees, the stroke of the main valve stops at 8 mm (for VAZ 2114).

Typical faults

If the cooling system of the “tens” begins to function differently than it should, this indicates a malfunction.

They can be identified by their characteristic features.