After strong heating of the VAZ-2115 engine, the likelihood of its complete combustion increases. To prevent this from happening, it is necessary to constantly monitor the cooling system. Beginners believe that the injection mechanism does not require regulation, but this is not so - for the VAZ-2115 engine, the injector does not change anything.

Being able to independently maintain the cooling system, correct defects and breakdowns means saving a certain amount of money and time. What factors does the VAZ-2115 cooling system require to control?

- All components work properly.

- Degree of tightness.

If at least one of the problems listed above exists, it’s time to start repairing. There is no point in delaying repair work - the engine is too expensive to conduct experiments with it, much less wait for it to burn out.

Operating principle and design of the VAZ-2115 heating system

17.02.2017

If the heater in the car does not work, especially in the cold season, there is a possibility of being left without a means of transportation, since in the cold you can simply freeze inside the car.

In severe frosts, it is very difficult to clear the windshield of ice to ensure visibility, and with a non-working stove this becomes doubly problematic. You may not even be able to get to a service station.

But most often, if you know the operating principle, circuit and design of the VAZ-2115 stove, you can solve the problem on the spot yourself.

Construction of the VAZ-2115 heating system

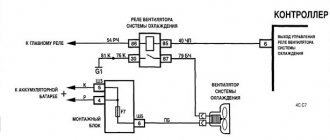

The electrical diagram of the VAZ heater operation is represented by the following elements:

- Electric motor with fan. The fan drives hot air into the car interior and onto the windshield.

- Buttons and levers for switching heat level and air flow speed. The VAZ-2115 has 3 options for heat flow rates that can be adjusted.

- Additional resistances that provide the required rotation speed of the stove fan (step-down tungsten turn coils).

- Fuses and connection wires.

The diagram of the VAZ-2115 stove presented below clearly shows its operating structure and components.

Connection diagram for the VAZ heating system

- Mounting block.

- Ignition.

- Unloading ignition relay.

- Heater motor switch.

- Additional resistor.

- Stove motor.

- Stove control button.

- Heated rear window.

K7 is a relay that turns on the heated rear window.

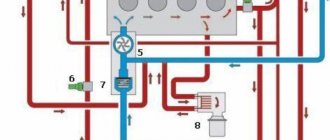

Heater operation diagram

- Fan.

- Windshield defroster.

- Damper that distributes air flow to the central and side deflectors; zones that warm the feet of the driver and passenger.

- Damper that controls the stove.

- Radiator.

- Airflow to the driver's feet.

- Internal air duct.

The operation of the stove is based on the following principle

The cooling and heating system works the same on almost all VAZ car models. The heater is turned on using a regulator located in the car itself; antifreeze is supplied to the radiator. Its temperature after warming up reaches more than 80 degrees. After which the fan starts working, operating at one of 3 speed modes.

The fan begins to create a directed air flow. It moves from the outside of the heating system into the interior of the car. Using control flaps, the driver selects heating zones, there are three in total: on the feet, on the windshield and in the car interior.

The key element of a car's heating system is the fan, and if it fails, the heating will be lost. Without it, hot air will not enter the cabin, and to heat the interior of the VAZ-2115, it will take not a couple of minutes, but a couple of hours.

Major electrical failures of the heating system of the VAZ-2115

If no changes occur in the heating system at any position of the switch knob, then most likely the system motor is faulty (the brushes are worn out) or there is no voltage at the terminals. But also in this case there may be problems with the ignition switch or mounting block (fuse F4 has blown).

It is important for the proper operation of the car's heating system that there is no more than 3 ohms at the engine ground (installed under the hood). If the heater works normally at maximum engine speeds, and problems arise only at low speeds, then the cause of the malfunction most likely lies in the speed switch button or additional resistors.

If you turn on the interior heating system and hear a noise and the heater is not blowing properly, this also indicates an engine problem.

Malfunctions may include jamming of the impeller or armature bearings. Malfunctions can be eliminated by replacing components or, if necessary, lubricating them.

But, as a rule, these actions have a short-term effect and the problem returns.

Over time, any equipment breaks down and requires repair.

Don’t forget that over time the system ages and wears out, so the older the car, the more it needs to be prepared for the heating season.

Malfunction

These components do not have a specific service life. They will last a long time if you follow the recommendations for using the vehicle and its systems provided by the manufacturer, follow assembly rules and buy spare parts made from high-quality materials. Spare parts are sensitive to high temperatures; this should be taken into account if the vehicle is used in hot weather conditions. If there are connection problems, then checking the sensor is not difficult - you just need to know where this device is located. It is located on the outlet pipe.

If the question arises of how to check the operation of the ventilation and what breakdowns may occur, then it will be difficult to answer.

Defects

- cracking;

- oxidation of contacts;

- broken cables;

- damage to fasteners;

- contamination of components;

- short circuit;

- microprocessor melting;

- fusion of plastic elements.

Fault indication

- continuous operation of ventilation when the engine is running;

- no fan response after the temperature rises or the air conditioner is activated;

- deterioration in vehicle controllability;

- reduction in the efficiency of the air conditioner.

Causes of failure

- influence of humidity;

- using vehicles on bad roads;

- voltage instability in the electrical network;

- low quality components;

- incorrect installation;

- violation of water tightness;

- frequent overheating.

If the fan turns on, then everything is fine.

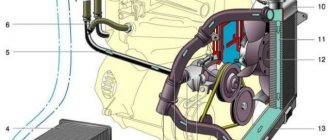

DIAGRAM AND DEVICE OF THE COOLING SYSTEM

The cooling system of the VAZ 2114 is liquid, with forced circulation. Antifreeze or antifreeze is poured into the system as a coolant. In the most extreme case, you can fill it with water, but you can’t drive it for a long time - in winter you can defrost the engine, and during the rest of the season, when the engine is used for a long time on water, the cooling jacket in the block and cylinder head is corroded, and rust accumulates in the radiator.

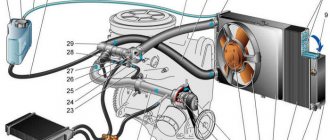

The VAZ 2114 engine cooling system (SOD) consists of the following elements:

- Radiator. It is the main cooling part in the system and performs the function of transferring heat to the liquid into the surrounding airspace;

- Water pump (pump). The pump creates forced movement of antifreeze in the system, thereby cooling the entire SOD, including the internal combustion engine (ICE). The pump rotates from the timing belt;

- Branch pipes (hoses). Antifreeze circulates through them;

- Thermostat. It regulates the passage of coolant through all pipes or only in a small circle and maintains the required operating temperature of the internal combustion engine;

- Electric fan. The fan is located on the plane of the radiator and, due to the air flow created, cools its surface when turned on. The electric motor turns on only when the temperature set by the sensor is reached (103°C);

- Expansion tank. Liquid is poured into the tank, and when the fan is activated, antifreeze flows into it through the return hose, thereby releasing excess pressure into the SOD;

- Expansion tank plugs. There are valves in the plug that relieve excess air pressure created in the system when antifreeze circulates.

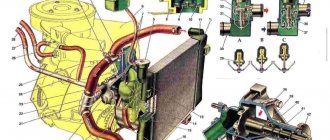

The VAZ 2114 cooling diagram is shown in the figure below:

Cooling diagram for VAZ-2114

The design of the engine cooling system on the VAZ model 2114 is simple and practically no different from the design of any other fuel-injected internal combustion engine of a passenger car. After starting the engine, the water pump is driven by the rotating crankshaft through the timing belt. The pump creates coolant circulation in the system, and the antifreeze passes through a small circle (pump, upper pipe, cylinder block). When the internal combustion engine is heated to operating temperature, the thermostat valve opens and the coolant flows through the lower pipe into the internal combustion engine in a large circle.

RADIATOR

The VAZ radiator is aluminum, consists of a double-row core and two plastic tanks on the sides. Coolant is poured into it through the expansion tank; there is a drain plug at the bottom.

PIPE

The set of cooling system pipes includes:

- Upper and lower pipes (main);

- Metal tube of water pump;

- Filler hose from the expansion tank to the radiator;

- Return hose from tank to radiator;

- Two hoses for heating the throttle valve.

Check the integrity of the pipes (very often they sell defective ones in car dealerships)

Causes of airlock

The main reason for this inconvenience is a mechanical violation of the tightness of the system or a breakdown of one of the units, leading to a violation of the tightness.

Therefore, when diagnosing it, pay attention to:

- the density of clamps on pipes and hoses, especially in winter, when materials are compressed;

- serviceability of the radiator cap and expansion tank valve;

- integrity of radiators (main and heating);

- the tightness of the pump and the integrity of its impeller;

- Thermostat serviceability;

- mechanical damage or clogging of the system of pipes and other flow channels of the SOD with foreign bodies.

Burnt engine gasket

How does the VAZ-2115 cooling system work?

The VAZ-2115 has the same cooling system built into it as other injection-type cars. The principle of operation is based on heat exchange that occurs with the help of liquid. The latter can be antifreeze, cooling antifreeze, or, in extreme cases, water, although experts do not recommend using the latter option.

The cooling system circuit built into the VAZ-2115 consists of the following key components indicated in the photo:

- electric motor;

- pump – ensures the movement of the filled liquid throughout the system;

- radiator;

- thermostat - regulates the activity of all components of the structure.

The temperature regime available in the VAZ-2115 is also important. If the readings exceed the established 87 degrees, the following happens:

- the thermostat valve comes into action and opens;

- the cooling liquid enters a large circulation circle, which involves passing through pipes through the engine and cooling the latter;

- the fan comes into operation, it begins to supply air flow to the radiator grille, and this helps to reduce the temperature.

Among all the components of the cooling system, experts call the most important one, without which the entire mechanism could not work properly - this is the valve coming from the thermostat. The part consists of technical wax, which is deformed under certain temperatures. This is how the volume of coolant supply is ensured and the cooling intensity is regulated.

Checking the main relay in a Lada Samara car

The prices for such devices in car dealerships are minimal, but their importance cannot be denied, since they largely affect the performance of electrical equipment. F8 7.5 A.

The cost of these elements in stores is minimal, but they play a very important role and must always be in working order. The box is designed for three relays and three 15A fuses, and is covered with a plastic shield on top.

The exterior decoration was decorated with plastic elements, since metal ones were corroded by corrosion. In the instrument panel wiring harness, the second ends of the white wires are brought together into one point, which is connected to the instrument lighting switch except for the white wire, from plug “4” of block “X2” of the mounting block 28 to the display block 83 of the on-board control system. However, in general, the VAZ model remains the same - it is equipped with front-wheel drive and five doors. Give preference to new models. Despite the modernization, many car enthusiasts who are far from the domestic automobile industry are still confused and the fuses do not protect only: the ignition circuit; electrical circuit for powering the generator and starter. How to check the ignition module, ignition coil and armored wires?!

Find out the radiator pipes from VAZ 2108 to VAZ 2115

Radiator pipes VAZ 2108, 2109, 21099, 2113, 2114, 2115…

Hello dear reader of the RtiIvaz.ru blog. Let's find out today and talk to you about which radiator pipes are installed on Lada VAZ 2108, 2109, 21099, 2113, 2114, 2115 cars.

Many car owners do not know what rubber radiator hoses for the cooling system are needed for and how they work. Here I’m trying to explain in simple language about RTI auto repair kits for vases, and also show on video what goes where.

Forgive me if I'm wrong somewhere, since the rubber pipes of the cooling system are very difficult to understand. As a car enthusiast, I will try to explain to you about the radiator pipes for the cooling system, which ones fit where.

Look at the photo and also at the video of the inlet, outlet, and bypass pipes. In general, you need to at least somehow understand the hoses on your Lada VAZ cars for a fulcrum under the hood.

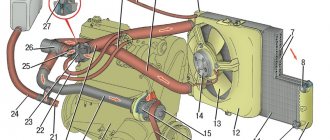

Next, see a photo of the pipes of the Lada VAZ 2108, 2109, 21099, 2113 for cars with a carburetor engine:

For VAZ cars with carburetor engines

Number 1 is the “upper” pipe that “supplies” coolant from the engine to the radiator, the so-called “wave”, has the shape of a wave.

And number 2 is the lower “angular” rubber pipe, which drains coolant from the radiator to the engine.

At numbers 3 and 4, there is one “short” one, a bypass connects the engine head to the thermostat, and the second connects the thermostat to the water pump. Expansion barrel pipe for carburetor engines number 5. Design numbers:

- 2108-1303025 radiator supply hose number -1

- 2108-1303010 outlet hose -2

- 2108 -1303092Р thermostat coupling numbered -3; 4

- 2108-1303080 cooling system filling hose with extension number -5

You are a car enthusiast, you probably know that the upper supply hose supplies hot liquid from the engine for cooling in the radiator. And the lower outlet hose carries the already cooled liquid to the engine. This is the unusual role played by the rubber hoses of the cooling system. Next, see a photo of the pipes of the Lada VAZ 2108, 2109, 21099, 2113, 2114, 2115 for cars with an injection engine:

For VAZ cars with injection engines

Number 1 is the “upper” pipe “supplying” coolant from the engine to the radiator, “angular wave”, has the shape of an angular wave. And number 2 is the “lower” coolant discharge pipe.

At number 3 is the “angle” bypass connected from the engine head to the thermostat and further to the water pump through the “short” coupling 4. At number 5 in the photo is the hose of the expansion barrel for injection engines.

Design numbers:

- 21082-1303025 radiator hose, supply number -1

- 21082-1303010 outlet hose - 2

- 2109-1303093-01 connecting hose for thermostat and water pump -3

- 2108 -1303092Р thermostat connecting coupling -4

- 21082-1303080 cooling system filling hose number -5

Video:

That an injection engine and a carburetor engine also have a “antifreeze” hose of the same length and thickness for removing steam from the radiator to the expansion tank (see video).

The steam exhaust hose “antifreeze” VAZ 2108-2115 differs from the steam exhaust hose VAZ 2110-2112 only in length.

What is the difference between auto repair kits for radiator pipes of injection and carburetor engines, I will not describe in this auto article, look friends, you can clearly see it in the photo and video.

- You might also be interested in:

- Adjusting valve clearances 2101

- Radiator pipes used on Lada

- Maintenance of the cooling system on a car

When do you need to change antifreeze or antifreeze?

Antifreeze is perfect for AvtoVAZ model 14. The manufacturer does not give clear recommendations on this matter. But practice shows that good quality antifreeze guarantees high performance and, in the opinion of many motorists, is the best remedy.

So, the coolant needs to be changed in the following cases:

- if we are talking about a new vehicle, then it is recommended to change the antifreeze after 60,000 km;

- The cooler is designed for operation for 24 months. Therefore, regardless of the “traveled” kilometers, it must be changed at least once every 2 years;

- if, as a result of a leak in the pipes, the driver was forced to add water, it is necessary to repair the breakdown and replace the coolant;

- appearance of rust color.

The cooler also needs to be changed if the power unit has been repaired or dismantled. Replacement must be carried out even if the fluid is in perfect condition.

Many car owners are interested in how many liters are provided by the manufacturer in the cooling system of the VAZ 2114?

On model 14, the system volume is 7.8 liters, regardless of the type of liquid. Let's look at several types of antifreeze designed to cool the VAZ power unit. Below are the most common types of liquids, as well as their features.

Any of the listed compositions is suitable for efficient operation of the vehicle. But the car owner must decide for himself which fluid to use, taking into account quality and price. Don't forget about high-quality antifreezes, which last on average 12-18 months longer.

Cooling System Maintenance

In order for the cooling system to function properly, it must be maintained and its condition periodically checked. The most important of these operations is the timely replacement of coolant. It is due to the fact that during circulation through the coolant system it undergoes repeated heating and cooling, as a result of which its chemical composition changes and the cooling properties sharply decrease.

In order to replace the coolant on time, you need to focus on the following important rules:

- Antifreeze should be completely changed every 2 years, and antifreeze - every 5 years;

- with high mileage, replacing antifreeze is required after approximately 15,000 km, and antifreeze after 40,000 km (these figures may be slightly more or less, depending on external conditions);

- If there is a significant change in the color of the coolant, it must be replaced, regardless of the time of use and mileage.

As you can see from the above rules, the use of antifreeze is more profitable, and preference should be given to it.

Coolant replacement

In order to avoid serious mistakes, correct coolant replacement should be done as follows:

- Completely drain all old coolant from the system.

- Tighten all plugs tightly.

- Fill the system with purified (distilled) water up to the maximum mark.

- Start the engine and let the system warm up well (overheating of the engine should be avoided, and the idle speed should be maintained around 3000).

- Turn off the engine and leave the car to stand for about 7-10 minutes.

- Drain all distilled water from the system.

- If the water flows out dirty, repeat the entire operation again.

- After clean water begins to flow out, pour coolant into the system.

If during the operation of the car the coolant level drops, then it can be periodically topped up, but after the allotted time (the timing was indicated above), it is still necessary to completely replace it.

Possible breakdowns

As for breakdowns in the cooling system, the most common occurrences are:

- problems with the radiator (leakage or blockage);

- thermostat failure;

- destruction of the water pump (most often the bearings fail or the impeller breaks off);

- fan failure;

- leakage in the pipe system.

Cooling system pipes

While problems with the radiator and other components of the system cannot be solved in one minute, problems with pipes can be quite easily eliminated - if they have lost their elasticity and began to crack, then they should simply be replaced with new ones. And in most cases, simply tightening the clamps will be enough to solve the problem of coolant leaks from the cooling system.

Thermostat repair

The thermostat sensor also serves to maintain the set temperature norm. It blocks the movement of the cooling mixture into the radiator until the engine heats up to the desired temperature of approximately 90 degrees. Liquid begins to flow through the thermostat when Celsius reaches 95 degrees. Using a thermostat, the engine takes minimal time to warm up. The thermostat is located between the engine and the cooling radiator.

Common problems:

- The valve is closed - the engine, when not warmed up, holds speed very poorly and may stall.

- With the valve open, you can drive during frosts, or turn on the heater to maximum mode, otherwise the engine will overheat.

When carrying out repair work on the thermostat, it is allowed to lightly tap the housing with a screwdriver to move the valve.

If it is necessary to completely disassemble the thermostat, it is important to tightly close the pipes to avoid antifreeze leakage, only then disassemble the thermostat. At the end of the repair, it is better to replace the antifreeze.