The cooling system of the internal combustion engine appeared almost simultaneously with it and has not undergone any significant changes since then. This primarily applies to long-lived domestic cars that will outlive you and me. Therefore, we need to know their design by heart if we do not plan to change to something more modern. The VAZ 2109, like the eight, is also considered one of the domestic eternal cars, for which there is no alternative. Today we will dive into the uncontested, ancient, like the trachea of the first amphibians, cooling system of the first front-wheel drive vehicles. Nines, and identical engines with an injector.

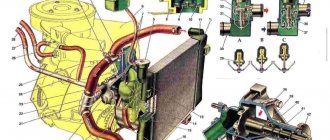

Engine cooling system VAZ-21083

1 – expansion tank; 2 – expansion tank plug; 3 – steam removal hose; 4 – hose from the expansion tank to the thermostat; 5 – radiator supply hose; 6 – radiator outlet hose; 7 – left radiator tank; 8 – aluminum radiator tubes; 9 – sensor for turning on the electric fan; 10 – right radiator tank; 11 – drain plug; 12 – radiator core; 13 – electric fan casing; 14 – electric fan impeller; 15 – electric motor; 16 – pump gear pulley; 17 – pump impeller; 18 – camshaft drive toothed belt; 19 – heater radiator outlet pipe; 20 – pump supply pipe; 21 – tap; 22 – heater radiator; 23 – hose for draining fluid from the heating of the inlet pipe to the carburetor heating block; 24 – carburetor heating block; 25 – exhaust pipe; 26 – heater supply pipe; 27 – hose for draining fluid from the heating of the inlet pipe and the carburetor heating unit; 28 – coolant temperature indicator sensor; 29 – thermostat.

https://youtu.be/https://youtu.be/EK7_GSpECNo

_

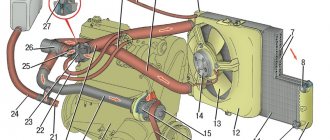

VAZ-2111 engine cooling system (with fuel injection system)

1 – expansion tank; 2 – plug; 3 – steam removal hose; 4 – hose from the expansion tank to the thermostat; 5 – coolant temperature sensor in the outlet pipe; 6 – throttle unit; 7 – radiator supply hose; 8 – radiator outlet hose; 9 – left radiator tank; 10 – right radiator tank; 11 – drain plug; 12 – radiator core; 13 – electric fan casing; 14 – electric fan impeller; 15 – electric motor; 16 – pump gear pulley; 17 – pump impeller; 18 – camshaft drive toothed belt; 19 – heater radiator outlet pipe; 20 – pump supply pipe; 21 – tap; 22 – heater radiator; 23 – coolant drain hose from the throttle pipe; 24 – coolant supply hose to the throttle pipe; 25 – coolant temperature indicator sensor; 26 – exhaust pipe; 27 – heater supply pipe; 28 – thermostat; 29 – coolant level sensor.

What should the temperature be?

The temperature arrow tends to the red zone - soon overheating

According to the international automobile convention of December 1, 1992, where 92 representatives of the auto industry gathered, it was decided to establish a single standard for engine operating temperature.

This indicator is 90 degrees Celsius with a maximum permissible deviation of no more than 3 degrees Celsius.

With the development of the automotive industry and a sharp leap in technology in the 2000s, in 2004 it was decided to revise this indicator. So, having considered all the facts and analyzed the design features of many cars, it was decided to establish a floating indicator with marginally acceptable standards, which, today, is 85-105 degrees Celsius.

Operating range on the VAZ-2114

If we consider cars produced at the AvtoVAZ plant, including the VAZ-2114, then the operating temperature range for engines is considered to be 87-103 degrees Celsius. If we consider this issue from the point of view of functionality, then this is the optimal indicator.

If the temperature drops below the limit level, then the Samara-2 engine loses dynamics and power, and if it is higher, it can simply boil and cause great damage. Therefore, if malfunctions associated with the cooling system occur, they must be eliminated as soon as possible.

Cooling system design

Before considering cooling system malfunctions, as well as methods for eliminating them, novice motorists should study the cooling system.

So, let's look at what elements it consists of:

Cooling system design

1 – element in the form of a plug for the expansion tank; 2 – expansion tank; 3 – hose for draining liquid from the pipe; 4 – hose passing between the radiator and the expansion tank; 5 – hose leading from the radiator; 6 – tank to the left of the radiator; 7 – aluminum tube; 8 – plug systems; 9 – tank to the right of the radiator; 10 – drain plug; 11 – middle of the radiator; 12 – casing for electric fan; 13 – plastic wings of the electric fan; 14 – electric motor; 15 – toothed pump pulley; 16 – pump impeller; 17 – camshaft drive belt; 18 – engine block; 19 – pump pipe; 20 – radiator hose with supply function; 21 – heater radiator hose with drain function; 22 – hose supplying coolant to the throttle pipe; 23 – exhaust pipe; 24 – hose for refilling; 25 – heater radiator hose with supply function; 26 – thermostat; 27 – coolant temperature sensor; 28 – coolant level indicator sensor.

Main malfunctions and ways to solve them

The operating temperature of the engine is directly affected by the health of the cooling system.

Almost every node can affect changes in this indicator in both directions, so it is necessary to monitor its serviceability and prevent changes. It is temperature fluctuations that can lead to breakdowns of other engine systems. So, let's look at the components of the cooling system, their malfunctions and solutions.

Cooling radiator

Dirty engine radiator

The radiator is considered one of the most reliable parts. There are not many reasons that can lead to product failure, but they can be prevented. A clogged part can lead to an increase in engine operating temperature, but regular cleaning of the internal and external surfaces will bring it back to normal.

The formation of cracks can cause the radiator to leak, but this problem can be dealt with. There are two methods to solve the problem: soldering the surface or replacing the product completely. Thus, repair and restoration work normalizes the operation of the part, as well as the operating temperature in the system.

Pipes

Dirt and rupture of the SOD pipe can lead to a change in the operating temperature of the motor

The cooling system pipes can directly affect the temperature increase in the system. This is due to the fact that if cracks or delaminations form in them, it may happen that the coolant begins to leak out. In turn, the lack of “cooling” will lead to an increase in temperature, which can affect both the operation of the main power unit and increased wear.

Water pump

Leaks on the cylinder block from the timing side indicate that the pump has failed

The water pump or water pump should drive coolant through the system , but if this unit breaks down, low pressure can lead to slow cooling, which in turn will increase the operating temperature of the engine. Often, the water pump will simply leak and driving the car will no longer be possible.

The fault can be easily treated by replacing the part.

Thermostat

Thermostat operation diagram at different temperatures

Description of design

The cooling system is liquid, closed type, with forced circulation. The tightness of the system is ensured by the inlet and outlet valves in the expansion tank plug. The exhaust valve maintains pressure in the system when the engine is hot (due to this, the boiling point of the liquid increases and steam losses are reduced), it opens at a pressure of about 1.1 kgf/cm2. The intake valve opens when the pressure in the system decreases relative to atmospheric pressure by 0.03–0.13 kgf/cm2 (on a cooling engine). The thermal operating conditions of the engine are maintained by a thermostat and an electric radiator fan.

The coolant pump is a vane, centrifugal type, driven from the crankshaft pulley by a camshaft drive timing belt. The pump housing is aluminum. The roller rotates in a double-row bearing with a “lifetime” supply of lubricant. The outer ring of the bearing is locked with a screw. A toothed pulley is pressed onto the front end of the roller, and an impeller is pressed onto the rear end. The distance from the mating surface of the pump cover to the outer end of the pulley should be 52±0.5 mm, and to the outer (facing the block) end of the impeller - 39.8±0.1 mm. A thrust ring made of a graphite-containing composition is pressed to the opposite end of the impeller, under which there is an oil seal. If the pump fails, it is recommended to replace it as an assembly.

The redistribution of liquid flows is controlled by a thermostat with a solid heat-sensitive element. On a cold engine, the thermostat valve closes the pipe leading to the radiator, and the liquid circulates only in a small circle (through the thermostat bypass pipe), bypassing the radiator. On VAZ-2108, -21081, -21083 engines, the small circle includes the heater radiator, intake manifold, carburetor throttle assembly heating unit (on engines with semi-automatic starting - and the liquid chamber of the semi-automatic starting device). On the -2111 engine, fluid is supplied to the heater and the throttle assembly heating unit.

Possible consequences

A high level of heating of antifreeze or antifreeze is normal for a running internal combustion engine. The only question is how much the coolant warms up, and whether the temperature exceeds the established boiling limits.

Oil leak through the oil seal

It is impossible to say exactly at what temperature antifreeze or antifreeze will boil. It all depends on the specific manufacturer who adds certain additives to the composition.

In fact, antifreeze is purified water with special additive components. They largely determine the quality and temperature stability of the liquid. In this case, the coolant can be painted in different colors. The dye itself does not affect the properties, but allows you to divide antifreezes and antifreezes into several categories. Some of them can be mixed, while others absolutely cannot be added to one expansion tank at the same time.

If we talk about at what degrees the antifreeze will begin to boil, then we need to proceed from the physicochemical properties of the liquid and the additives used. Previously, boiling occurred as in the case of ordinary water, that is, at 100 degrees Celsius. But in modern antifreezes the boiling temperature limit is higher, as a result of which the coolant boils at approximately 101-108 degrees Celsius.

It is difficult to determine the exact boiling point to the nearest degree. This depends on the specific manufacturer and its features of manufacturing the coolant. It is recommended to start from your own coolant used in your car. This way you will find out whether the antifreeze in the tank boils at a temperature of 100 degrees Celsius or more.

Boiling is indicated by obvious signs when antifreeze literally shoots out from under the lid. This informs the motorist that the coolant is boiling. Therefore, it is necessary to take appropriate measures to avoid undesirable consequences.

Some motorists underestimate the degree of threat posed by boiling and seething antifreeze. As a result, they do not pay attention to it, continue driving and think that they will solve the problem when they get to the house, garage or the nearest car service station on their own.

We recommend: Wires for lighting - buy copper starter (starter) wires at a good price in the VseInstruments online store

But if you do this, you can provoke serious troubles and cause dangerous breakdowns of the engine and related systems. The consequences of boiling depend on how severe the engine overheating due to boiling coolant is. There are 3 stages:

- weak;

- average;

- strong.

Let's start with the safest low overheating of the internal combustion engine. If literally 10 minutes have passed since the coolant began to boil, but no more, problems are practically eliminated, that is, there is no serious threat to the integrity of the engine.

This happens quite often, since not all drivers immediately notice signs of boiling. Often, the corresponding sensor on the dashboard indicates that the engine temperature limit has been exceeded. If the sensor gives a signal, it is recommended to immediately turn off the motor. Without doing this, the engine pistons may begin to melt.

Mild overheating is nothing terrible or dangerous for modern vehicles. It is only important to stop in time so that overheating does not begin to develop into medium and strong forms.

The next level is the average level of engine overheating, caused by the boiling of antifreeze or antifreeze in the system. This is a more serious situation that can lead to the following consequences:

- formation of cracks and deformation of the cylinder head;

- occurrence of oil leakage through the seals;

- damage to the piston ring partitions;

- burnout of the cylinder head gasket.

This happens when the coolant continues to boil for more than 20 minutes.

Moderate and low levels of overheating are mainly encountered by those motorists who are negligent in servicing the cooling system, forget to add antifreeze on time and do not change the coolant according to the recommendations.

Severe overheating is rightly considered the most undesirable. If it occurs, the car owner risks losing the engine, which will require major repairs or a well-deserved send to a landfill.

If the engine temperature has been below the red line for a long time, literally all components of the internal combustion engine will suffer. But this is not the worst scenario. In practice, there have been cases when prolonged severe overheating caused the engine to explode.

But the situation reaches severe overheating extremely rarely. Even in the initial stages, most drivers manage to turn off the engine and take a number of other measures aimed at preserving the engine and ensuring their own safety.

In fact, severe overheating is followed by a wave of destructive phenomena. The pistons burn out first, then the melted metal ends up on the piston walls, the pistons themselves fail, and the cylinder block is deformed. Do not forget about the destruction of the lubrication system, crankshaft, etc. Ultimately, the piston may pierce the block wall, and the engine is unlikely to be returned to its previous state.

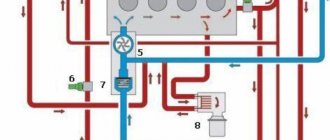

The principle of operation of cooling VAZ 21093,2109,21099

The cooling pump drive is driven by the timing belt. The total volume of the system, including the stove, is 7.8 liters. Temperature control is carried out using a sensor installed on the cylinder block jacket. The temperature indicator is displayed on the instrument panel.

During operation of the VAZ engine, liquid from the block jacket passes into the radiator (where heat is removed) or into the thermostat (short circuit - to warm up the engine). Next, the liquid is pumped into the cooling jacket of the VAZ injector power unit. The pipelines circulate and heat the fuel mixture in the intake manifold and throttle valve area.

The cooling system communicates through pipes with the radiator of the interior heater of VAZ 21093,2109,21099. The coolant pump is centrifugal. The system is equipped with a collapsible tubular plate radiator with plastic tanks.

The internal surface of the radiator is increased by using aluminum tubes and cooling plates; it does not have a filler hole; topping is done in the expansion tank. Which also has a sensor for turning on the electric fan. The tank has a filler plug with valves (inlet and outlet). To drain the cooling liquid from the system, unscrew the drain plugs of the tank, cylinder block, and radiator.

CO elements

The cooling system used on the VAZ 2109 operates at low pressure. After studying the components, you will learn about their functions and features.

| Element | Peculiarities |

| Pump | It ensures efficient, stable operation of the system. The pump is used to pump cooling liquid, which facilitates its movement along a small or large circuit. The pump consists of a housing, an axle with a pulley located on it connecting to the timing belt, and a plastic impeller. The latter allows the coolant to move. A bearing lubricated with antifreeze is installed between the axle and the housing. Because of this, the presence of water in the system is unacceptable. Otherwise the bearing will collapse |

| Thermostat | Plays an important role, although in practice the CO can do without it. The system works in such a way that the engine first warms up to operating temperature (about 90 degrees Celsius), after which it is necessary to further cool the liquid. First, the coolant moves along a small circuit - through the jacket into the stove radiator, and then the excess is returned to the expansion tank. But when the operating temperature is reached, the thermostat begins to move the coolant flow into the radiator. A thermostat can be called a mechanical valve that automates the operation of the CO. Hot liquid acting on the bimetallic plate of the thermostat deforms it, which is why the coolant supply valve to the radiator can open or close |

| Radiators | The SO VAZ 2109 has a pair of radiators - a stove and a main one. Their design is the same regardless of whether you have a carburetor or an injector. At the same time, there is a noticeable difference between the main and stove radiators. The main one is larger in size, they perform different functions, plus the main one has holes for a sensor that turns off the fan. If the stove radiator can be connected to operation at any time by pressing a button, then the main radiator operates in automatic mode when certain operating parameters of the CO are achieved |

| Expansion tank with plug | A constant pressure is maintained inside the CO, which ensures efficient coolant circulation. On the VAZ 2109, the system is designed so that at high pressure the liquid does not boil when it reaches 100 degrees, but at higher parameters. This increases engine reliability. Pressure support is provided by an expansion tank with a cap and a pair of mechanical valves - inlet and outlet. The inlet valve is activated if the pressure drops to 0.13 atm. The second one comes into operation at the moment when the pressure is above 1.3 Atm. |

| Pipes, clamps | Do not underestimate the role of pipes and clamps in the CO, since it is through them that the coolant is supplied to the required points. When replacing, under no circumstances use cuttings from other pipes that do not correspond to the parameters used previously. Plus, if at least one pipe is damaged, everything will have to be replaced as a set, and not separately |

| Sensors | Looking at the radiator (main), below you will see a pair of wires and a yellow device twisted into the hole. This is the electric fan switch sensor. Another sensor is also located in the motor block - temperature. It transmits information to the electronic control unit or pointer |

| Electric fan | As a standard, the VAZ 2109 is equipped with fans equipped with 4 blades. But if you want to achieve greater efficiency, we recommend replacing it with a 6-blade electric fan. This will increase the air flow while maintaining the original power and rotation speed. Heat from the heater radiator begins to flow inside the cabin when the tap is opened. There is a fan under the hood connected via a rheostat. It regulates the rotation speed of the impeller. The switch is located under the audio system, near the heater damper control levers. |

Thermostat

When planning to replace an electric fan, work should be done through the engine compartment. No need to dismantle the snail .

CO pump

Features of the fan and thermostat VAZ 21093,2109,21099

The electric fan includes an electric motor and a four-blade impeller, the blades of which have a variable angle of inclination and pitch to reduce noise levels. To increase efficiency, the VAZ fan system is equipped with a casing attached to brackets.

The electric fan is mounted on rubber bushings. The fan is triggered by a signal from a sensor installed in the radiator tank. In this case, the contact closure temperature is approximately 99'C, and the fan shutdown temperature is 94'C.

The system thermostat provides priority warming up of the engine and regulates the thermal regime. The optimal coolant temperature is within 90-98'C. The thermostat includes a body and a cover, rolled together with the valve.

Driver actions

Having noticed that antifreeze begins to boil in the expansion tank, you need to take a number of mandatory measures. Don't wait for the coolant to start splashing out onto the hot engine. Once the liquid boils, there are corresponding reasons.

Pour antifreeze into the car

You already know at what temperature antifreeze usually boils in cars, what causes overheating and what consequences this can lead to. Therefore, no one wants to encounter something like this in their own car. It is necessary to start cooling the engine using available methods, not forgetting that the coolant is now under high pressure.

There are several useful tips and a certain algorithm of actions that allows even a beginner to figure out what to do if antifreeze suddenly boils.

- Be sure to try to quickly unload the engine. To do this, you can put the gearbox in neutral and drive until it comes to a complete stop.

- Turn on the fan and stove at the same time. Even if it’s hot outside, the heater will take away some of the heat, thereby speeding up the process of the engine temperature dropping.

- After stopping the car, turn off the engine. At the same time, leave the stove in working condition.

- Pull the handle or press the button to open the hood from the passenger compartment and access the engine compartment. There is no need to stand in front of the hood and open it, as hot steam will immediately come out.

- By opening the hood slightly, steam will come out and fresh air will begin to flow into the engine. Wait a while. Then lift the hood and lock it. It is better to have gloves or a rag with you so as not to grab possibly hot elements with your bare hands.

- Do not try to open the expansion tank cap immediately. Otherwise, you risk your own health. Liquid under pressure, even if the lid is opened slightly, can splash out and get on your skin.

- Wait about 30 minutes. At this time, you can try to find a driver who will take you to the service station, or call a towing service.

- When the engine has cooled down a little, open the expansion tank cap. Surely the coolant has become much less than the proper level. Add liquid into the reservoir in small portions. At the same time, the stove is still working.

- There is no need to immediately pour in a large volume of antifreeze if its level becomes minimal after boiling. Abrupt mixing of cold antifreeze or antifreeze with hot coolant can provoke dangerous negative consequences.

- If you can only get to the service station on your own, after adding coolant and cooling the engine, start it and set off on the road, trying not to load the engine. When the temperature again reaches above 100 degrees, stop, turn off the engine and wait for it to cool down again.

You can't sit and do nothing either. If the coolant continues the boiling process, the engine will overheat first to medium and then to high levels. You already know about the consequences of such heating.

Based on everything discussed above, we can speak with confidence about the seriousness of the problem of coolant boiling. To prevent such situations, carefully monitor the condition of the cooling system, check the functionality of the main components and try to carry out timely maintenance.

Sources

- https://luxvaz.ru/vaz-2109/322-sistema-ohlazhdeniya-2.html

- https://expertVAZ.ru/2109/sistema-ohlazhdeniya-kak-rabotaet.html

- https://ladafakt.ru/sistema-ohlazhdeniya-vaz-2109-inzhektor.html

- https://vaz-remzona.ru/sxema-oxlazhdeniya-vaz-2109/

- https://ladamaster.com/sistema-okhlazhdeniya-vaz-2109-inzhektor

- https://7road.ru/drugoe/net-cirkulyacii-v-sisteme-ohlazhdeniya-2.html

- https://www.vazzz.ru/vaz-2109-tsirkulyatsiya-ohlazhdayushhej-zhidkosti/

- https://avtomechanic.ru/vaz-2109/dvigatel-vaz-2109/konstruktsiya-sistemy-okhlazhdeniya-vaz-2109

Features of the VAZ injector cooling system

Cooling in cars 21093,2109,21099 is liquid, but you need to understand that the radiator is cooled by the flow of incoming air and a fan, which increases the cooling intensity. Also, part of the heat is removed by the car's interior heater radiator at low temperatures.

The expansion tank is designed to compensate for the volume of liquid when heating, to top up and control the level of antifreeze.

The thermostat system provides temperature control, preheating of the VAZ engine, initial heating of the interior in winter, and only then ensures the inclusion of a large cooling circuit.

The temperature sensor provides control of the cooling system, allows you to monitor the engine temperature and regulate the operation of the fan.

The entire operating cycle of the cooling system is controlled using a power unit control system that takes into account all temperature parameters. It determines the optimal switching conditions and operating time of the structural elements of the system.

Useful tips

For the purposes of this article, we note that antifreeze can not only boil, but also foam. At the same time, the temperature of the antifreeze does not increase. This happens when:

- air entering the expansion tank;

- low-quality antifreeze;

- mixing antifreeze from different manufacturers;

- using coolants not recommended by the car manufacturer due to different chemical compositions;

- Damage to the cylinder head gasket. Then it allows air to pass through, and when it enters the cooling system, it forms foam.

It must be taken into account that minor foaming is acceptable, but if there is a large amount, it is necessary to flush the cooling system and replace the antifreeze with a higher quality one.

We also recommend reading an article about what consequences can occur for the engine if antifreeze gets into the engine cylinders. From this article you will learn about the reasons why antifreeze or antifreeze gets into the cylinders, as well as what this leads to.

Antifreeze has its own service life and with its long-term use the chemical composition changes and the cooling properties decrease. This fluid must be replaced with a new one; replacement is carried out with flushing.

Diagnostics of the VAZ 21093,2109,21099 engine cooling system and fault detection

If problems arise with the engine cooling system, the causes should be determined, starting with the most probable and simple ones:

- If there is a coolant leak, first check the fluid level in the system. In cars 21093,2109,21099 this is done using the level indicator or when inspecting the expansion tank.

- If the level has changed, inspect the engine compartment for leaks. As a rule, the main reasons are: worn pipes and clamps, damaged engine cooling radiator or heater.

- In case of jet changes in the tank at 3000 rpm. It is necessary to check the fluid circulation. To do this, open the cap of the expansion tank and determine the uniformity of antifreeze flow. The causes of poor circulation may be a clogged system or a malfunction of the circulation pump.

When parts need to be replaced

When is it necessary to replace the VAZ 2109 coolant and cooling system elements? The fluid must be changed regularly after a certain period of use. Parts are not changed periodically, but only after a breakdown. One of the causes of breakdowns is overheating due to a malfunction of some element in the cooling system. The following signs of engine overheating can be observed:

- the coolant temperature is higher than normal and can exceed 120ºС, this is indicated by a special sensor;

- there is a sharp drop in engine power;

- the sound of the engine changes, a ringing metallic knock appears;

- oil consumption increases;

- Coolant consumption increases significantly.

As a result of overheating, after you open the hood, you will see deformed parts - bent cylinder head, gasket edging, burnout of some parts. Repairing deformed parts does not make sense; they need to be replaced.

Causes of VAZ engine overheating

- A faulty thermostat can cause the engine to overheat. If on a warm engine the upper pipe is hot and the lower pipe is cold, the thermostat is jammed and the antifreeze flows only in a small circle. Or the thermostat will only turn on a large circle, which will not allow the VAZ engine to warm up to the required operating temperature. In this case, the thermostat should be replaced.

- Another reason for excessive engine heating may be airing of the cooling system; in this case, the system must be pressed and air removed from all cavities.

- At high temperatures, the fan does not turn on - there is a problem with the temperature sensor, fan relay or the wiring harness to it.

- Sometimes the radiator honeycombs become clogged, which sharply reduces the intensity of heat transfer. It is necessary to thoroughly clean the radiator; it must be done carefully to avoid damage to the cells.

These are the main reasons that affect the quality operation of the VAZ 21093,2109,21099 engine cooling system; with their help, you can identify and eliminate malfunctions, ensuring reliable and durable operation of the engine.

Text version

Auto repair

You need to prepare the container in advance, you need to prepare everything, there is such a thing, it’s just like it won’t run once, of course you won’t run?

Even here the cartoon offended us, we don’t get the plug on the expansion valve, unscrew it, I broke it for you, in general, the process has begun, I’m no longer a crap antifreeze. Lost shade after parting this word radiator faucet no one unscrews the faucet product antifreeze cold day.

Replacing antifreeze

He ran, it would also be advisable to close the generator so that this salon doesn’t get caught, you can click it, it will come in handy for anyone small! This is how it turned out, then we move on to washing, so I bought such a product, I don’t know the connection. Each one is located differently, let's look further, find a watering can, cover all the plugs on the radiator with blocks, maybe it's not too tight, you need to tighten it!

They tightened the Dothrak and tightened it, oops on the radiator, too, all the liquid was running, I added an additive to the radiator, confiture, is it a sticky thing? I filled in the additive according to the instructions, the leaking stopped now when I replaced the antifreeze, okay, it’s just a matter of overcoming this additive: Usually we pour warm water if it’s cold outside.

Replacing antifreeze for VAZ 2108

Often she will pass there, you can hear the street, you can open it, or rather unwind it. The pipe that goes to heat the carburetor can be done.

Already all the child is on fire now when the upper scale is standing where it will go. Then we can add more water to the radiator and return the industrial ones to work.

You need 10 minutes to wash and I’ll take the benefits in short? How int glad with the boiling water will go let's go do it it's done cherry radiator this same hour let's let everything washed all clean and pretty. Now we’ll give one more round of water from the radiator.

21099

Screw me with hot water again, let’s fill it with water for five minutes, let’s work and pour it in directly. The antifreeze system is empty, we will fill ourselves with antifreeze, we will not tighten it too much, we have unscrewed it. Heating the carburetor so that everything would surely leak out, the air would not be held in anything by the perry, we top it up, we fill it.

The ambassador tightened the radiator, everything was twisted especially should be enough: In principle, in principle, it’s blue, then my son, if you see that you h1 on the antifreeze barrel has changed color from red to red or blue, too, to red, then that’s it. It's time for me, it loses its properties or we are the last antifreeze, eggplant bushes and almost all the last drops: