What is the main role of the tank cap?

As is known, a running engine creates a pressure in the cooling system that differs from normal atmospheric pressure. This occurs due to the fact that the coolant heats up along with the engine, as a result of which it expands and increases in volume. As a result, the pressure inside the engine cooling system (ECS) increases, but it is not in contact with the external environment, and there is nowhere for it to relieve excess pressure.

Developers of modern cars do not fight the increased pressure in the ODS “radically” - they do not try to completely get rid of it. It is adjusted using the tank cap. Increased pressure in the SOD is used to shift the coolant boiling point. After all, it’s no secret that at normal atmospheric pressure for water it occurs at a temperature of 100 °C, for antifreeze – 105–110 °C, and for antifreeze – 120 °C. The operating temperature of modern car engines is very close to these critical values.

Replacement frequency

According to official regulations, the manufacturer provides for replacing the coolant in cars with carburetor or injection engines every 50,000–75,000 km. Such a long time interval is explained by the fact that it is at this interval of kilometers that the coolant begins to lose its properties. The use of used antifreeze is not permitted. Changing the coolant more often than once every 50,000 is unreasonable. km.

Signs of the need for urgent antifreeze replacement

The need to replace the coolant ahead of the official schedule may arise in several cases:

- If sediment has formed in the coolant. The presence of deposits in a substance indicates that it has begun to lose its properties. If sediment settles in a thick layer at the bottom of the expansion tank or in the pipes, it means that fluid cannot circulate effectively through connectors and channels. Refrigerant deposits are more noticeable at low air temperatures.

- Increasing the crystallization temperature of the coolant. To determine at what temperature a substance will begin to freeze, you need to check the density of the refrigerant. Diagnostics is carried out using a hydrometer. In the absence of a device, the increase in crystallization temperature can be determined visually. In such a refrigerant, yellow impurities appear. It will not be visible in the liquid itself, but can be clearly seen on the expansion tank cap in the space under the hood.

- Change in color of the refrigerant and formation of a brown tint. If the substance has acquired a browner color, this indicates the presence of corrosion deposits on the metal parts of the cooling system. Discoloration may be due to the fact that antifreeze has lost its functional properties.

- Drive unit overheating. If the problem is not related to mechanical defects in the car engine, you need to check the quality of the coolant.

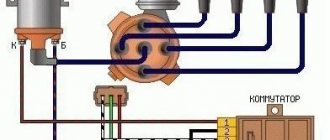

The design and principle of operation of the expansion tank cap

In order for the necessary pressure to be created in the SOD when the engine is running, the lid device ensures a tight, hermetically sealed closure of the tank. A safety valve is provided to relieve excess pressure. It operates (opens) only when the pressure inside the SOD becomes 1.1–1.5 kgf/cm2 (depending on the design of the lid and its manufacturer).

While it is lower, the valve is closed, and immediately after releasing the excess pressure to a value that is less than that indicated above - partial release of the air compressed in the tank - it closes. There is one more valve in the lid - the inlet valve, it is also called a vacuum valve. Its purpose is exactly the opposite of protective. The inlet valve serves to intake (suction) air into the SOD. The fact is that after stopping the engine, as you know, it begins to cool down. The coolant temperature also drops.

Inlet valve cover

At the same time, it decreases in volume, which is accompanied by a decrease in pressure inside the SOD. The coolant that enters the tank, upon its own heating, begins to flow back into the system, freeing up space for the air remaining in the expansion tank and ceasing to put pressure on it. Then there comes a moment when the pressure in the SOD is compared with the external atmospheric pressure. If at the same time the temperature of the coolant turns out to be higher than in the external environment, then it, continuing to cool, will further decrease in volume.

Features of the VAZ injector cooling system

Cooling in cars 21093,2109,21099 is liquid, but you need to understand that the radiator is cooled by the flow of incoming air and a fan, which increases the cooling intensity. Also, part of the heat is removed by the car's interior heater radiator at low temperatures.

The expansion tank is designed to compensate for the volume of liquid when heating, to top up and control the level of antifreeze.

The thermostat system provides temperature control, preheating of the VAZ engine, initial heating of the interior in winter, and only then ensures the inclusion of a large cooling circuit.

The temperature sensor provides control of the cooling system, allows you to monitor the engine temperature and regulate the operation of the fan.

The entire operating cycle of the cooling system is controlled using a power unit control system that takes into account all temperature parameters. It determines the optimal switching conditions and operating time of the structural elements of the system.

Signs and possible consequences of a part malfunction

Most often, the consequence of a malfunction of the cap is boiling of the coolant, sometimes accompanied by the ejection of the coolant from the expansion tank - a common occurrence for VAZ cars. If this happens at engine operating temperatures, then most likely the plug does not hold the required pressure.

Car coolant boiling

Another reason for the same phenomenon is that due to a malfunction of the vacuum valve, air entered the ODS and formed a plug, which disrupts normal circulation, and therefore the cooling of the coolant. In winter, due to an air lock, the stove may not work well. Unpleasant consequences: loss of coolant, which has to be topped up regularly. This happens when, due to increased pressure in the SOD, liquid is “expelled” through the joints between the fittings and pipes put on them, through clamps.

- rupture of low-quality pipes or those that have not been changed for a long time (a picture familiar not only to VAZ owners);

- the appearance of a leak in the main or heating radiator;

- tears the thermostat housing (for Nexia it’s a common thing - into 2 parts);

- burst expansion tank.

A leak appears in the main radiator

All these signs and consequences of a malfunctioning lid are the result of increased pressure in the SOD. The latter is not uncommon for VAZ 2108, 2109 and especially 2110 cars with new-style tanks. Of course, it is obvious that the plastic of these expansion tanks leaves much to be desired, but, nevertheless, this is also due to a malfunction of the plug. So the lid, by regulating the pressure in the SOD, also protects its elements from mechanical damage.

What are the consequences of an untimely change?

If replacement deadlines are not met, the car owner will face the following problems:

- Antifreeze will not be able to perform its intended functions. This will result in the car's heating system not working as efficiently at low temperatures. In some cases, the stove does not function at all.

- Due to the appearance of sediment in the pipes and radiator of the car, the circulation of the working fluid will be disrupted. This will cause excessive heating of the power unit. Prolonged use of a machine with an overheated engine can lead to failure of the unit.

Refinement of a new part - what to do if it does not function?

When it turns out that the lid stubbornly refuses to relieve excess pressure and/or is not able to restore air losses in the SOD, it can be modified. For some reason, the most complaints come from owners of VAZ, model 2109, including those who buy new plugs. It is clear that the reason for the incorrect operation of the cover valves lies in the too much rigidity of their springs.

To modify the cover, for example, for a VAZ 2109, it must first be disassembled. This must be done carefully, using pliers and a thin flat-blade screwdriver. We must try to remember where everything stood so that the springs do not fly away to God knows where. After the lid for the VAZ 2109 tank has been disassembled, it’s time for the wire cutters. They need to shorten the springs: the large one, for the safety valve, usually by 1 turn, and the small one by 2.

Shortening the plug spring

For the second, the length of the removed segment is not critical - as long as it generally supports the vacuum valve when it is closed and does not resist the external air pressure of 0.03–0.1 kgf/cm 2 . With a large spring it is more difficult - as if not to overdo it. You need to look at its rigidity and the pressure at which the safety valve opened when checking the tank cap of the VAZ 2109. After shortening the springs, we assemble the cap in the reverse order. Before use, it is advisable to check again how it works.

How to drain antifreeze from a VAZ 2109

Felix antifreeze and expansion tank VAZ 2109

Today we got around to replacing the car's coolant. After reading the Internet, based on many reviews and feedback from store sellers, I decided to buy not antifreeze, but antifreeze. I decided not to skimp on it and took the most expensive one that was in the store, its name is “ Felix”

“red in color, very similar to pink, but everyone says it’s red, so be it, and at one time I changed the expansion tank, it was very dirty.

For beginners, I’ll tell you in more detail how to do it correctly. So, first we need to buy antifreeze or antifreeze, the choice is yours.

2. Open the cap on the expansion barrel ( RB

)

Expansion tank cap

3. Unscrew the drain screw on the radiator. If you stand in front of the hood, it is located in the lower left corner of the radiator. Do you want to put something under it so that it drains into some kind of container, I did this on the grass, so I didn’t need a container.

Radiator drain bolt

4. Next, unscrew the drain bolt on the engine itself, for me this bolt is located right behind the coil, it gets in the way, so it needs to be removed.

Coil

Engine drain bolt

5. Once everything has been drained, blow your mouth into the expansion tank so that all the residues fly out 6. Tighten all the drain bolts back 7. Fill the cooling system with ordinary water and start the engine, let it run for 5 minutes and turn it off, and do everything again - this gives us complete cleaning of old fluid; many use 5-minute flushing agents for flushing. 8. Once all the water has been drained, blow into the RB and screw everything back in, disconnect the hose from the injector (shown in the photo) so that there is no air lock.

Hose that needs to be removed

9. Pour liquid into the RB and look at the disconnected hose; when liquid flows out of it, put it in place and pour liquid until it is a closed circuit through which the working fluid - liquid (coolant) - is forced to circulate. The main elements of the circuit are an expansion tank, two radiators, a centrifugal-type vane pump, a thermostat and pipes.

When should you think about replacing?

The schedule approved by the manufacturer indicates that the replacement of antifreeze on a VAZ 2109 should be carried out:

- Once every three years, regardless of mileage;

- every 60 thousand km. mileage regardless of operating time.

The expediency of carrying out the operation is relevant when carrying out repair and restoration work with elements of the “cooling” circuit, preparation for which involves draining the coolant. Such work may include replacement:

- heater radiator or cooling system heat exchanger;

- thermostat;

- expansion tank;

- centrifugal pump;

- antifreeze temperature sensor.

Experienced mechanics do not recommend delaying the process of changing antifreeze for a long time. The loss of anti-corrosion and detergent properties, a decrease in the density of the liquid can lead to serious consequences, requiring significantly larger investments than the operation of replacing the coolant.

Required accessories

Maintenance of the engine cooling system is possible with at least 8 liters of special composition. In the service book, Lada specialists display a list of suitable coolants:

- Antifreeze AM;

- "OZHK LENA";

- "LENA-40";

- Antifreeze A-40M;

- SPEKTROL ANTIFREEZE;

- AGIP ANTIFREEZE EXTRA;

- Glisantin G 03.

The accessories are an open-end wrench set to “13”, a screwdriver and a container for draining antifreeze with a volume of at least 8 liters.

DIY technology for replacing antifreeze on injection VAZ 2109

The replacement concept involves draining the used compound through special holes and filling the system with new antifreeze. The designers provide two drain holes in the cooling system of VAZ engines:

- on the left side of the main radiator;

- on the front wall of the cylinder block.

Replacing antifreeze on VAZ 2109 engines is not possible without first dismantling the ignition module located on the front surface of the cylinder block:

- remove the negative terminal from the battery;

- disconnect the wires from the spark plugs;

- remove the ignition module power supply block;

- unscrew the bolts securing the module relative to the cylinder block and clutch housing;

- loosen the upper left bolt of the front engine mount;

- remove the module bracket from under the bolt;

- remove the module with wires from the engine compartment.

Draining of used antifreeze is carried out according to the following method:

- open the heater tap;

- connect the expansion tank to the atmosphere by unscrewing the cap (under such conditions, rapid flow of liquid from the system is ensured);

- place the container and unscrew the cap in the lower left corner of the engine radiator, wait for the liquid to drain;

- Unscrew the drain nut on the cylinder block and drain the coolant from the “jacket”.

For your information. If the drained liquid is dirty and rich in various inclusions, the system should be flushed with plain water:

- clog the drain holes;

- pour water through the expansion tank and close it;

- start the engine for 3-4 minutes;

- shut down and drain.

The operation is repeated until the waste water is clean.

Having removed all the liquid from the system, you should:

- install all drain fittings back;

- install the ignition module in reverse order;

- connect the vehicle's ground to the battery;

- pour new antifreeze through the expansion tank (see filling technology below);

- start the engine for 1-2 minutes;

- add coolant and close the expansion tank;

- warm up the engine until the cooling fan operates and turn off;

- if necessary, add coolant to the virtual average mark (between MIN and MAX).

Features of coolant replacement technology

The procedure for replacing used antifreeze on a VAZ 2109 is fraught with a significant pitfall: in the process of filling the system with a new composition, there is a high probability of air pockets appearing. When the engine warms up for the first time after replacing the coolant, it is necessary to monitor the engine temperature:

- the coolant temperature arrow is approaching the red zone, and the cooling fan has not worked and cold air is blowing from the heater - there is an air lock in the system;

- hot air comes from the stove, but the fan does not work at the set temperature (about 105-107 degrees) - the fan is faulty;

- The fluid level in the expansion tank tends to increase.

The correct method of filling the system with liquid will help to avoid the appearance of an air lock:

- pour antifreeze into the expansion tank (full filling of the container is allowed);

- disconnect the compound supply hose from the throttle assembly heating fitting;

- add the composition as the expansion tank is emptied;

- if there is a phenomenon of liquid leakage from the heating fitting of the throttle assembly, put on the antifreeze supply hose (you may need to create a slight pressure in the tank (one or two deep exhalations into the tank are enough);

- close the tank.

On carburetor “nines” the replacement process is carried out similarly. Temporarily disconnecting the hose from the carburetor heating fitting will help avoid the appearance of an air lock.