The crankcase ventilation system of the VAZ 2108 2109 21099 engine is designed to ventilate the crankcase from gases escaping from the cylinders. From the crankcase, gases flow through a hose into the valve cover, where they pass through the oil separating network and are drawn into the carburetor air filter. If the oil separator filters are dirty and oil no longer settles on them, oil will end up in the carburetor air filter. If the air filter is filled with oil, the crankcase ventilation system must be cleaned. But as a rule, many often do not do this, but disconnect the hose between the valve cover and the air filter and direct it to the side. The hole in the air filter is plugged with a champagne cork - and everything is in order. The air filter seems to be clean and no more oil is coming out. However, that's it for now. Sooner or later, the crankcase ventilation system will become completely clogged, then the VAZ 2108 2109 21099 engine will begin to press oil. Typically, it goes to the distributor through the camshaft oil seal.

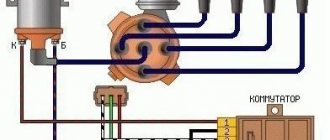

Presses oil into the VAZ 2109 distributor

In general, the preconditions for cleaning the crankcase ventilation (ventilation) system are as follows: - Air in the oil filter; — The bunker is in oil. The procedure for cleaning the window of a VAZ 2108 2109 21099: 1) First you need to disconnect all the hoses from the engine valve cover and remove the carburetor air filter.

Remove the tubes from the lid

2) Unscrew the accelerator pedal cable clamp from the engine cover.

Unscrew the accelerator pedal cable

3) Unscrew the two nuts securing the valve cover to the engine and remove it.

Removing the valve cover of the VAZ 2109

4) The lid will be covered in dirty oil.

Valve cover VAZ 2109

It will be necessary to remove the cover covering the oil separators and clean them of any stuck-on dirty oil.

Remove the oil separator strainer cover

To clean, it is necessary to disassemble the screens and moisten them with kerosene or gasoline until they are cleared of adhering oil.

Ventilation in the oil separating network of VAZ 2109

Some people pour gasoline on the nets and set them on fire: the oil burns, just rinse the nets a little with gasoline and that’s it.

Burn the oil from the network

5) You also need to be patient and try to clean the valve cover of the VAZ 2108 2109 21099 from adhering oil, especially the place where the oil separating mesh is installed.

6) There is also a small outlet on the valve cover, which is connected through a hose to the carburetor throttle valve. In my case, it was also completely clogged with hardened oil, and I had to clean the branch with a thin steel wire for about half an hour. 7) Next, you need to replace the clean oil separating mesh of the VAZ 2108 2109 21099 deflector and close it with a lid.

Clean the oil separator network

Before installing the valve cover in place, it is necessary to clean the surface of the motor from old sealant and dirt. It is also necessary to clean the rubber gasket of the valve cover itself. 9) Next, apply a thin layer of sealant around the edges of the valve cover to improve the seal. We put the cover in place and tighten the nuts securing it. 10) Connect all the hoses, connect the accelerator pedal cable and put the air filter in place. 11) For best seal, it is best to let the sealant dry for a couple of hours before driving. The work on cleaning the VAZ 2108 2109 21099 deflector has been completed. You will quickly notice that the engine consumes less oil during operation and less oil needs to be added.

Before installing the valve cover in place, it is necessary to clean the surface of the motor from old sealant and dirt. It is also necessary to clean the rubber gasket of the valve cover itself. 9) Next, apply a thin layer of sealant around the edges of the valve cover to improve the seal. We put the cover in place and tighten the nuts securing it. 10) Connect all the hoses, connect the accelerator pedal cable and put the air filter in place. 11) For best seal, it is best to let the sealant dry for a couple of hours before driving. The work on cleaning the VAZ 2108 2109 21099 deflector has been completed. You will quickly notice that the engine consumes less oil during operation and less oil needs to be added.

Category: Engine and its systems | Tags: VAZ 2109 repair, VAZ 2109 device

Contamination of the oil separator on engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 vehicles leads to malfunction of the crankcase ventilation system due to a decrease in its permeability and gas removal efficiency. As a result, the crankcase gas pressure increases, which leads to engine oil leakage through the engine oil seals and gaskets.

In addition, the efficiency of cleaning crankcase gases that enter the engine valve cover from engine oil is reduced and they are released into the air cleaner housing, contaminating the filter element, contaminating the carburetor and spark plugs. Hence the “failures”, triple work and other failures.

dirty oil separator screens, its body and valve cover of engine 2108, (21081, 21083)

The procedure for cleaning the oil separator (oil deflector) of engines 2108, 21081, 21083

— Remove the valve cover from the engine

Read more: “Removing the valve cover from the engine.”

— Cleaning from contaminants

We wash the valve cover inside and out with engine oil and deposits with gasoline or diesel. Do not wash the rubber seal as it may break.

— Remove the oil separator (oil deflector)

Using a “10” wrench, unscrew the two bolts that secure the oil separator housing, remove the housing and the underlying oil separator mesh.

— We wash, clean and blow through the grids and the oiler body

For this we use gasoline, kerosene or diesel fuel. Clean the mesh cells with a wire brush. In case of severe contamination, you can use a special brush attachment on the drill and clean it with it. We blow the parts with compressed air (tire pump or compressor).

We also clean the crankcase gas supply and exhaust pipes in the engine valve cover.

After cleaning, install the oil separator into the engine valve cover and install it again.

Notes and additions

— If you detect a leak of engine oil through the oil seals and gaskets of the engine, as well as the appearance of oil in the air filter housing, lubrication of the electrodes of the spark plugs, on engines 2108, 21081, 21083, not only clean the oil separator, but also check all the elements included in the car crankcase system ventilation. See articles below.

More articles about the crankcase ventilation system of engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 cars

— Cleaning the crankcase ventilation system of VAZ 2108, 2109, 21099 cars

— Oil in the air filter housing, causes

— Increased oil consumption by carburetor engines of VAZ 2108, 2109, 21099 cars, reasons

— Drive oil for oil seals and engine oil seals, reasons

— Blue smoke from the muffler, causes

Way to solve the problem

When starting to clean the breather, first of all we look for a device under the hood and remove the air filter from it.

Before doing this, de-energize the car by disconnecting the negative terminal from the battery and turning off the ignition. There is an intake manifold under the filter - we will also dismantle it. After this, you can see the prompter itself - as a rule, its cover is secured with two bolts, which will have to be unscrewed. After removing the cover, the oil bumper will become visible - it is secured with a pin. Read more: 220 Volts in Watts

It is necessary to unscrew the nut located on the stud, but there is no need to remove the stud itself, because it will be difficult to put it back without dismantling the pan. We make a cleaning rod out of wire, which we use to clean the tube. There is a brush on the breather cover to extinguish the flame - we clean that too.

All that remains is to check the device. We start the engine, remove the plug from the oil filler neck, and cover the neck itself with your palm. You can feel with your hand whether there is pressure. Then the assistant should press on the gas until the speed reaches 100-130 km/h and check the compression again by applying the palm of his hand. A little pressure should already be felt.

To avoid problems with the release of working fluid through the prompter, it is necessary to constantly monitor its level

It is also important to pay attention to checking the filter and gearbox

Owners of old domestic cars, after several years of ownership, can easily write a directory of “diseases” of a particular car model. One of these “sores” is an engine malfunction in which engine oil is squeezed out through the breather. This phenomenon is most often simply called by people: “oil is driven through the breather” or “oil is thrown out through the breather.”

The problem is quite unpleasant and is accompanied by a large number of engine-related problems. It is this problem, as you probably already guessed, that we will talk about in this article. You will learn why oil comes out of the breather and how to solve this problem. Go.

As a rule, the problem occurs with the onset of cold weather, the breather freezes and the oil is squeezed out. This manifests itself in the form of oil drips that are visible from the outside of the engine. Failure to respond to this phenomenon in a timely manner can lead to serious engine damage.

Why is cleaning necessary and its frequency?

When the ventilation system is clogged, an emulsion containing soot and oil residues settles inside the engine, resulting in the creation of excess pressure, leading to damage to the seals. This leads to loss of sealing and oil leaks, which can be seen during an external inspection of the engine block. Crankcase gases are gases from engine cylinders that are not discharged through the exhaust valve, but are squeezed out into the crankcase through the gaps of the pistons and piston rings when the engine is running. This process occurs especially intensively in worn-out engines with high mileage. For VAZ 2101-2107, these are mileages of 80-100 thousand km.

If the crankcase ventilation is not cleaned in a timely manner, the operation of the fuel supply system will be affected. In carburetor engines, the air filter and the carburetor itself become dirty; in injection engines, the throttle assembly, inlet pipe and sensors become dirty. All this leads to a decrease in power, problems with operation, and in some cases a complete stop of the engine. To avoid this, additional elements are introduced into the ventilation system to clean crankcase gases from emulsions containing oil.

If the crankcase ventilation system is not cleaned in a timely manner, the hoses crack due to excess pressure. This causes excess air to be sucked into the engine. Carburetor engines are not so sensitive to this problem, but in injection systems the quality of the mixture sharply deteriorates, the stability of the engine is disrupted and its power is reduced.

The best option is to clean the crankcase ventilation on a VAZ classic immediately before changing the oil. This frequency allows you to keep the system in order, change cracked hoses on time, extend the life of the engine, and reduce fuel consumption without loss of power.

News

06.07.2019

The full range of LIQUI MOLY products is in stock in Yekaterinburg. more details

17.06.2019

New catalogs for selecting spare parts on the website PlentyCar.ru. more details

11.06.2019

Congratulations on the holiday June 12, 2022 and office work schedule. more details

In the Plenty Car online store you can buy auto parts for Japanese cars (Toyota, Mazda, Honda, Isuzu, Lexus, Mitsubishi, Nissan, Subaru, Suzuki), European cars (Ford, BMW, Citroen, Peugeot, Alpha, Lancia, Fiat, Land Rover, Mercedes, Opel, Renault, Rover, Volkswagen, Audi, Skoda, Seat, Volvo, Saab, Jaguar), American cars (Chevrolet, GM, Chrysler, Cadillac, Hummer, Infiniti, Jeep, Pontiac) and Korean cars (Daewoo, Hyundai, Kia, SsangYong). If you were unable to find spare parts for your car yourself, contact our specialists. All information on the site is for reference only and is not a public offer as defined by Article 437 of the Civil Code of the Russian Federation.

Oil gets into the filter

During the regulated replacement of the air filter, some motorists are perplexed as to how the oil gets inside. You can understand this by understanding the design of internal combustion engines with an injector or carburetor.

The more your engine has been running, the more the connection may become apparent. The point is the formation of crankcase gases that occur during the combustion of fuel entering the crankcase. They are usually vented completely from the cylinders, but due to severe engine wear, ring sticking and coking, some gases remain inside, creating high pressure. This leads to damage to the seals. If they are damaged, the engine begins to eat up oil.

Causes of the problem

There can be several reasons for oil getting into the air filter:

- Excessive wear on the piston rings of an engine with a carburetor or injector can lead to unsatisfactory collection of excess lubricant that enters the crankcase from the cylinders. Increased pressure occurs, causing oil to be squeezed out using the oil slinger and vent valve. A clogged main reflector drain does not allow the mask to return to the crankcase, which is why it flies out along with the gases.

- Clogged paths that carry gases from the crankcase beyond the throttle lead to oil and gases entering the filter.

- Clogged filter. When the engine does not have enough air, it begins to suck it from other sources, including from the crankcase.

What can be done to prevent oil from getting into the VAZ 2109 engine?

First you need to check the compression of the VAZ 2109 engine. The main indicators of problems with the rings and piston system are dark or bluish smoke, as well as a constant decrease in the oil level.

If the compression is good, the problem is less serious. It is possible that the whole issue is a clogged filter element or hoses that remove gases from the crankcase. In this case, you need to replace the filter and wash it, or replace the hoses that remove gases from the crankcase.

Also, do not forget that grease in the air filter is a sign of possible problems due to which the engine may completely fail. In this case, you will have to spend money on major repairs. There is an unwritten rule according to which prevention of any component is cheaper than repair work. Thus, you need to look in and check the main components of the car more often. This will allow you to promptly detect a breakdown in the initial stages, saving your money in the future, since you will be able to avoid expensive and complex overhauls of the power unit.

Car air filter

Many people believe that the air filter is an ordinary unit and does not require special care. Especially if it has a modern, expensive air-purifying element. As a result, many motorists rarely check its condition and drive until it looks like an ordinary rag. Not everyone knows what happens as a result of such indifference. In this article we will touch upon the question of what the VAZ 2109 air filter element is and what exactly it is intended for.

Engine VAZ 2109

In order for the resulting combustible mixture in a VAZ 2109 engine with a carburetor or injector to burn completely, it is necessary that the air content in it be 15-20 times higher than the fuel content. As a rule, a car consumes about fifteen cubic meters of atmospheric air per hundred kilometers, which may contain particles of dust, grains of sand, plant seeds and other debris. Without a filter, these particles can end up inside the engine, regardless of what kind of injection system it has: injector or carburetor, and subsequently will have an abrasive effect on the rubbing parts, which will lead to premature wear.

The air barrier on the VAZ 2109 is designed to solve this problem. In addition to its main purpose, it, in turn, copes well with the function of a muffler and fuel cooler.

Diagnosis and elimination of causes

If a problem occurs when the engine throws oil through the breather, inspect the intake system, crankcase ventilation and perform engine diagnostics. To eliminate the consequences and the cause, start with the air filter and its housing. We replace the clogged filter element and remove oil on the components with a cleaner.

Diagnosis of why oil was squeezed out through the breather: video

- Check the engine oil level by first turning off the engine and waiting at least 15 minutes. The level should not exceed the maximum mark on the dipstick by more than 5 mm. Excess oil must be pumped out through the dipstick hole.

- Inspect the crankcase ventilation system for cracks and blockages in the pipe, oil clots in the oil separator, check the functionality of the PVC valve (if equipped). Contaminants are removed by washing with solvent, gasoline, diesel fuel or kerosene. Failed elements must be replaced.

- We diagnose the condition of the engine. First of all, we unscrew and inspect the spark plugs. The presence of a black glossy coating clearly indicates excess oil in the combustion chamber. We consistently measure the compression in the cylinders.

Normal value

for diesel 24–30 atm

, for an injection car

12–14 atm

, for a carburetor at least

10 atm

.

The exact value for your model can be calculated by multiplying the engine compression ratio by 1.4

.

The spread between cylinders should not exceed 1 bar. A decrease in compression indicates a leak in the combustion chamber due to burnout of the valve, piston, wear or stuck piston rings. If compression is normal, but there are traces of oil in the chamber, you need to check the valve stem seals.

How to clean the breather?

To clean the breather, you need to disconnect the pipe, remove it from the engine and disassemble the housing, remove the oil separator and valve (if equipped). Wash all parts with gasoline, kerosene or diesel fuel, removing oil deposits. Dry and reassemble in reverse order.

How to disassemble and clean the breather: video

How to clean oil from an air filter: video

Cleaning crankcase ventilation. — logbook Lada 2109 Rhapsody 2000 on DRIVE2

On a warm weekend day I decided to carry out maintenance on the valve cover. I’ve never done anything like this, but after reading it on the Internet, I decided to do everything myself.

So for work we will need: a set of keys, a new valve cover gasket (I bought a white silicone one), new pipes (although you can clean the old ones), 2 new rubber bushings for the cover, a couple of liters of gasoline, a stiff brush, an old toothbrush and a piece of wire for cleaning thin pipe coming out of the lid.

so in order: 1. Remove the pan with the air filter.2. Loosen the clamps and remove the pipes and hoses from the valve cover.3. Using a 10mm wrench, unscrew the 2 nuts securing the cover and the accelerator cable bracket. Remove cover 4. Turn the removed cover over and use a 8mm head to unscrew the 2 bolts and remove the oil separator housing.

taken from Murzilka

5. We take out the grids, I had 6 of them and thoroughly wash everything (the grids, the body and the lid itself from the inside).

taken from Murzilka

Here is a photo of the screens before and after cleaning: Photo of the cleaned valve cover and oil separator: 6. We collect everything in reverse order.

I installed new pipes (easier than cleaning the old ones), a new cover gasket (although the old one was also silicone and was in excellent condition), and changed the oil a bunch, new air and fuel filters.

Price: 1,500 ₽ Mileage: 188,500 km

The road is clear

Now let’s take a closer look at how this happens, how the oil gets from the crankcase to the filter.

- Due to excess pressure, oil particles break out of the crankcase.

- Initially they get inside the oil deflector.

- Next, overcoming the valve, they “move” inside the pipe, which is connected to the purifier body.

- Result: oil traces appear in the filter.

As you can see, everything is quite obvious.

Now let’s look at diagnostics, as well as correction of typical situations using specific examples with cars. That is, let's see how the search for the cause of oil particles getting into the filter should go.

How to treat it

Here’s a common case: a car enthusiast discovered oil in the air filter of a VAZ 2109. You need to figure out what the essence of the problem is. If you do not pay attention to the situation, the consequences can be disastrous, including major engine repairs.

To find out the answer to the car enthusiast’s sacramental question – “why does it throw oil directly into the air filter?” – initially we prepare everything that may be useful to us:

- a pressure gauge, more precisely, a compression gauge, the simplest one equipped with a flexible tube with a thread at the end;

- set of wrenches;

- spark plug key;

- rags, gasoline, brush.

To find out why the engine drives oil into the filter, we proceed as follows.

- We look at the exhaust smoke – we don’t notice a black or blue tint. This means that stuck piston rings can most likely be ruled out.

- We check the oil level with a dipstick - it turns out that there is no excess oil product either.

- We measure the compression of the cylinders. To do this, we unscrew the spark plugs on a warm engine, according to the relevant instructions attached to the compression gauge, take measurements on each of the cylinders, and check the passport data. We find out that the compression corresponds to the standard specified in the car’s registration certificate.

- We notice that there is also oil in the filter pipe, which extends from the breather.

- We dismantle the breather, that is, the crankcase valve. To do this, first remove the valve cover.

- Remove two bolts from the valve cover.

- We take it out, then clean the stack of oil deflector screens with gasoline. We also wash the breather itself with gasoline.

- We perform assembly in reverse order.

This is how you can understand why the VAZ 2109 has oil in the filter, and then fix the problem. Let us add that some car owners simply remove the breather tube from the air intake duct, then lower it down under the engine. However, this serves only as a temporary measure and does not in any way solve the problem itself.

Next we consider another typical case. Suppose there is oil in the air filter of a VAZ 2110 car. We have the following at hand:

- compression gauge;

- spark plug key;

- set of keys, screwdrivers.

As described earlier, we first look at the exhaust and also measure the compression. If the compression is low, we recommend disassembling, diagnosing and repairing the engine. But, let’s say, here, too, the compression turned out to be normal. Then we proceed as follows.

- We find out that there are no deposits at the breather pipe, and that the air-cleaning element has been replaced recently.

- We remember that the engine usually has difficulty starting.

- As an option, we clean the throttle assembly.

- To do this, first remove the decorative engine cover.

- We dismantle the air pipe ventilation hose and find traces of oil inside it. The throttle body's ventilation duct is probably clogged.

- Having loosened the clamps, remove the hoses of the throttle heating channel, as well as the gas tank ventilation system.

- We dismantle the cable and also unscrew the two nuts of the throttle assembly.

- We thoroughly wash the removed throttle assembly with gasoline or a special product with partial disassembly.

We also add that when a VAZ 2112 has oil in the filter, you need to act in the same way.

How much does such a renovation cost today?

Of course, there is always the option of giving the task to servicemen: they say, there is oil in the air filter, look for the reasons! How much will they charge for this? Most likely, they will simply suggest cleaning, for example, the throttle assembly. Well, here are the approximate average prices for eliminating such a malfunction.

| City | Price |

| Moscow | 900 rub. |

| St. Petersburg | 850 rub. |

| Samara | 700 rub. |

| Ekaterinburg | 800 rub. |

| Novosibirsk | 800 rub. |

If you puzzle the technicians solely by searching for an answer to the question of why oil is leaking from the engine into the air filter, then they will probably give the correct answer, and you will have to pay about half as much as for a regular diagnosis of a moderate breakdown.

Now read about replacing the silent blocks of the front arms of the VAZ 2107 and replacing the generator bearing of the VAZ 2110.

Causes

It is much more important to understand why oil is flowing through the breather in the engine, since this will allow us to establish the cause and eliminate it. On your own, or with the help of specialists, is no longer of fundamental importance.

It is interesting that some reasons may not be directly related to the ventilation system at all.

Among the main causes of oil in the breather are the following:

- Severely worn piston rings and piston rings. This leads to the fact that a large volume of gases enters the crankcase of the power unit, and standard ventilation does not have time to cope with them. As a result, increased pressure in the internal combustion engine and squeezing out oil through the breathing valve.

- The oil separator drain channel has become clogged over time. As a result, the separated oil has no choice but to mix with the gases passing by it.

- Problems with the air filter. Or rather its pollution. When operating, the motor requires a large volume of air. If the filter becomes clogged, the engine senses a lack of air and begins to suck it in from other available sources. This is basically a ventilation system.

- Excessive oil volume in the system. A common mistake made by beginners who change the oil themselves for the first time and fill in more than required. The excess ends up in the ventilation.

- Valve jamming. The breathing valve itself, that is, the breather, may jam. It ceases to perform its functions fully. Hence the oil.

- Worn timing belt or valve burnout. Because of this, gas from the crankcase may end up in the space above the valve. Then it enters the crankcase, the pressure increases, and the oil is squeezed out.

As you can see, you shouldn’t immediately blame the breather for all the troubles.

Lada 2109 purple 1.5i carbon › Logbook › The breather is clogged and the valve cover mesh is covered

Gift to everyone. I haven’t written anything for a long time, but then it happened!.. The breather was clogged and the valve cover mesh was covered! Because of this, such pressure was created in the engine compartment that oil poured out of all the smallest cracks! There was a metallic knock in the breather!

The car held the idle speed perfectly, but as soon as it was time to move off, stepping on the gas, the engine compartment was filled with oil and the car began to choke and stall =((. And so in order to eliminate this reason, I had to open the head, and also buy a new valve gasket, valve cover mesh and sealant. Having opened the whole thing and getting to the mesh, I realized that this is 100% the reason! It was clogged to such an extent that a speck of dust would not get through! I threw the mesh into a solution with a solvent, cleaned it and rubbed it, it was useless, I had to buy a new one! Having replaced the mesh and cleaned the breather tube itself, I installed a new gasket under the valves, filled it with sealant and put it back =) Started the car... everything was super good! =)) It worked for about 10 minutes and then it stalled...xDDDD...ran out of gas.

Drives oil through the breather: diesel and gasoline internal combustion engines

Engine diagnostics for oil leaks through the breather requires an integrated approach. There is no need to disassemble the power unit to check. It becomes clear that at the initial stage you should assess the condition of the breather, make sure it is working and clean the device if necessary. The oil level is also checked using the dipstick. If everything is fine with the level and there are no other additional signs of a problem, then it is optimal to replace the breather with a known good one.

After making sure that the breather is working properly and ventilation is at an acceptable level, you will need to make a series of measurements and assess the condition of the CPG. As already mentioned, the cause may be failed rings, that is, you will need to measure the compression in the engine.

how to measure compression in cylinders correctly

. From this article you will learn about why, how and with what tools this procedure is carried out to obtain accurate data.

Also, the color of the exhaust gases can additionally indicate the need to measure compression. To check, just start the engine and then evaluate the exhaust. If the engine smokes blue or gray smoke, then this may be a sign of engine oil getting into the cylinders due to worn piston rings. When checking compression, you need to take readings in each individual cylinder. In the normal state of the CPG, compression should be at 11 MPa and above (it is recommended to consult the technical literature in relation to a specific type of internal combustion engine). If a run-up is detected according to the readings in the cylinders, the differences should not exceed 1 MPa.

A clear decrease in compression even in one of the cylinders may well indicate that gas leaks are occurring, causing oil to flow through the breather. It should be added that compression can also be reduced as a result of valve problems. For a more accurate determination, you should examine

spark plug

or only one spark plug on the problem cylinder. The presence of abundant gray-black oily deposits is a sign of malfunctions associated with the cylinder-piston group. If the compression is low, but there is no carbon on the spark plug, then there are likely problems with the valves

timing belt

Failure to reduce compression will indicate that further checks will be related to the ventilation system. The method for testing this system will be considered using the example of the domestic VAZ 2110 model. Other cars may have some individual features, but the general principle will be similar.

- At the very beginning, you need to disconnect the tubes from the valve covers, breather and air duct pipe. Then the degree of contamination should be assessed. If the tubes are clogged or dirty, then they can be cleaned with carburetor cleaner or gasoline. Afterwards you will need to blow them with compressed air or dry them naturally.

- Next you need to get to the oil separator by unscrewing the fixing bolts and removing its cover. After this, the oil separator itself is removed. This device is made of special plates. It is necessary to disassemble the element and wash it. Washing can be done in gasoline and then dried.

- At the same time, it is recommended to inspect and flush the valve, and also check the stroke of the rod. This is possible after removing the device. Valve jamming can also be eliminated by washing. The entire list of actions described allows you to keep the crankcase ventilation system clean and maintain its functionality.

INSPECTION AND CLEANING OF THE VENTILATION SYSTEM

On the VAZ-2110 this is done like this:

1. Disconnect the pipes from the breather, valve cover, air pipe and check the degree of clogging. If necessary, they can be washed in gasoline or kerosene and then dried;

2. Unscrew the nuts securing the valve cover and remove it. On the inside there are two bolts securing the oil separator roof, which must be unscrewed;

3. Remove the unscrewed cap and remove the oil separator.

It is a package of special plates that can be disassembled, washed each plate separately, assembled back and put back in place.

Since the design of the system may be different on other cars, it is performed somewhat differently. But this does not change the essence of the work - all elements are removed and washed. As for the exhaust gas control valve, which can be installed in the ventilation system, assessing the degree of contamination and cleaning it is not difficult.

It is removed, the stroke of its rod is checked, and if it jams, then the valve is simply washed in gasoline, dried and put back in place. This is all maintenance work on the crankcase ventilation system. They are not difficult to perform, and every car enthusiast can do it. Finally, we note that it is recommended to clean the ventilation every time the oil is changed.

Breather oil: what to do and how to find the cause

Let's start with the fact that during engine operation, so-called crankcase gases accumulate in the crankcase. To prevent excess pressure from being created, there is a special valve for ventilation. This solution allows the closed crankcase to communicate with the atmosphere. This valve is the breather. In simple words, a breather on an internal combustion engine is actually needed to equalize the pressure inside the engine.

It should be noted that in the crankcase gases mix with oil mist. As a result, lubricant particles enter the breather. Although there is a special oil trap inside the device, a certain part of the oil may escape out. Given this information, minor contamination of the system is acceptable, which is normal. In cases where a lot of lubricant leaks, you should look separately for why oil is leaking from the breather.

Oil leaks through the breather lead to clogged channels, in some cases soot is formed, etc. Excess soot gets into the engine crankcase, and the lubrication system becomes coked. As a result, loaded parts are less well lubricated and engine wear accelerates. Let us add that traces of oil will not necessarily be visible from the outside in the engine compartment. On engines with a carburetor, if there is a leak through the breather, oil in the air filter housing or on the filter element itself is a characteristic sign of a malfunction.

On injection engines, traces of oil getting into the throttle area are noticeable, the power unit also loses its throttle response and power, and fuel consumption increases noticeably. It turns out that to check it is necessary not only to inspect the outer surfaces under the hood, but also to remove the air filter, throttle assembly, etc.

Why does oil leak through the breather?

If oil appears from the breather, there may be several reasons

Taking into account various features, before self-diagnosis, you need to pay attention to additional symptoms

- First of all, the oil presses as a result of significant wear of the piston rings. This means that gases from the combustion chamber penetrate through the seal into the crankcase, after which too high pressure is created there. Excess pressure causes oil to flow out through the breather.

- Another possible cause could be a clogged oil deflector drain. In this case, gases and oil particles that are no longer able to pass through normally exit through the breather rather than through the cleaner.

- Also on the list is a significant reduction in air filter capacity. In this case, the engine simply does not have enough air at the inlet. The result is the appearance of oil in the filter housing and on the filter itself.

- Possible problems with the breather itself should not be ruled out. As a rule, the valve fails, the passage hole in the breather becomes clogged, etc. Normal ventilation is disrupted, exhaust gases enter the internal combustion engine crankcase and increase the pressure.

- In some cases, overfilling engine oil much higher than the recommended level causes the excess to leak out through the breather. It turns out that excess oil simply presses out of the engine. In such a situation, you should check the lubricant level and adjust it if problems are detected.

see also

- Ventilation in the grow box calculation

- Repair of supply and exhaust ventilation system

- Metal pipes for ventilation

- Car ventilation and air conditioning system cleaner

- Woodworking shop ventilation project

- Ventilation pipe umbrella

- Installation of air conditioners and ventilation

- Fuel tank ventilation

- Fan with check valve for ventilation in the toilet

- Cabin ventilation valve

- How to clean bathroom ventilation

Replacing the breather of the gearbox VAZ 2108

Frequency of oil changes in VAZ gearbox 2108

-2109-21099

- 1

- Transfer - 2

- oil drain plug

The oil change frequency is every 75,000 km or every 5 years.

Gearbox crankcase capacity

- five-speed - 3.3 liters;

- four-speed - 3.0 l.

It is recommended to drain the oil immediately after the trip, while the Samara Lad is still hot.

Keep moving oil level

always closer to the upper mark, but it should not exceed the upper mark, otherwise oil may leak out of it.

Gearboxes

.

Cleaning the fan of a VAZ 2108 2109 21099 car. If the engine supplies oil through the distributor or throws out the air filter. the breathing apparatus must be cleaned. The lower mark indicates the minimum permissible oil level

. Shoe holder 2108 2109 21099 — logbook. If the oil level drops below this mark the gears will not be well lubricated. List VAS 2108 will quickly fail.

Replacing the breath of a VAZ Classic gearbox

Don't try to do this with a haircut. Ventilation valve VAZ 2108 Replacement of ball bearings VAZ 2108 and others. I've already tried it. Breathing box (What should I do?) VAZ-forum 2108. Didn’t work.

The breathing checkpoint is where it is.

where is the VAZ gear fan

- classic advice on this matter

is replacement

.

breathing

what it is and why HERE:

1.

Before changing the oil, remove the rubber cap, wash it and wipe the hole in the breathing tube with wire. Then replace the cap.

2.

Unscrew the oil drain plug, having first replaced the oil tank with the satellite gearbox. We clean the VAZ 2108 fan when we set the fan speed to short. Drain the oil and tighten the oil drain plug.

3.

Remove the oil level indicator (sensor).

4.

Add new oil through the dipstick using a funnel.

5.

Wipe the pointer with a cloth and reinstall it.

6.

Remove the probe and check the oil level in the VAZ 2109 again. If necessary, add oil to the gearbox to the upper mark.

7.

On earlier transmissions (without an oil rod), the oil filler neck is located above

8.

Disconnect the plug and fill the VAZ 21099 gearbox with oil using a syringe from the bottom edge of the oil filler.

https://vaz2109.net/dvigatel/sapun-vaz-2109.htmlhttps://twokarburators.ru/prochistka-sistemy-ventilyacii-kartera-dvigatel-2108-2109/https://carmanuals.ru/vaz/vaz- 2109/tehnicheskoe-obsluzhivanie-avtomobilya/ochistka-i-promyvka-detaley-sistemy-ventilyacii-karterahttps://vaz-russia.com/remont-vaz-2108/ochistka-sistemyi-ventilyatsii-kartera-na-vaz-2108- vaz-2109-vaz-21099.htmlhttps://autotexnika.ru/zamena-sapuna-kpp-vaz-2108/

The principle of operation of the breather

During operation, gases accumulate in the engine crankcase. To remove them, there is a ventilation system called a breather. This makes it possible to reduce the pressure in the motor itself. Because there are always air masses with tiny particles of oil in the crankcase, a little lubricant sometimes passes into the breather along with the air flows.

There is a mesh here to catch the oil. But some drops still manage to penetrate. So slight contamination of the filter system is quite normal. But if there is too much oil, then it is worth thinking about the reasons for its entry. Oil particles contribute to clogging of channels and increase the amount of soot. The latter gets into the crankcase and cokes the channels through which the oil flows. As a result, the performance of the entire lubrication system will deteriorate.

If there are specific signs by which you can determine what is driving oil through the breather. In a carburetor engine, traces of lubricant may appear in the filter housing. Significant lubricant marks may also be observed on the filter component itself.

In injection engines, deposits appear on the throttle assembly. In this case, the engine may lose its power, and fuel consumption may increase.

Troubleshooting

The first thing you need to pay attention to is the color of the exhaust, blue or black smoke, a sign of burnt valves or problems with rings. Next, you should check the compression in all cylinders. The value on gasoline internal combustion engines should be within 11-13 MPa. Disconnect the pipes from the valve covers, air intake and breather

Assess the degree of contamination. If the pipes are very dirty or clogged with oil deposits, use gasoline to clean them or a special carburetor cleaner. Check the condition of the oil separator. Unscrew the required bolts to get to this unit. Remove the oil separator and assess its condition. If necessary, clean or rinse followed by drying. Inspect and, if necessary, flush the breather valve. There are situations when the valve gets stuck, resulting in exhaust gases entering the crankcase and creating excess pressure. Remove the part and wash it; in most cases, this will resolve the issue of squeezing oil out of the breather.

Helpful advice! To distinguish stuck rings from a burnt-out valve, it is enough to perform several manipulations. After checking the compression in the cylinders, determine the cylinder with the lowest value. Then inspect the spark plug of this cylinder; if the rings are lodged in this cylinder, the spark plug will be covered with a thick oil layer. If the valve is burnt out, the spark plug will appear normal without any major abnormalities.