During its operation, the engine heats up to a very high temperature threshold. This circumstance is very fraught with problems for all surrounding elements. This is also dangerous for those people who are in the cabin. That is why a special complex was developed in order to “pacify” elements ready to boil.

This allows you not to worry that something will “boil” during operation. The latest VAZ 21214 models are equipped with a four-cylinder 8-valve gasoline engine system. It was here that the fuel injection system found its application. This is reflected in this set.

How does cooling work on the VAZ 2121 Niva?

The lifespan of a Niva SUV engine largely depends on how efficiently the VAZ-2121 cooling works. After all, overheating is the first enemy of the power unit, leading to expensive repairs.

This is why the serviceability of the components and elements of the cooling circuit is so important. In order to be able to service them and identify malfunctions, you need to understand what the circuit consists of and how the Niva’s cooling functions.

Possible problems and their causes

Like any vehicle system, the cooling circuit must be regularly monitored and worn parts replaced. The first indicator of possible problems will be the level of coolant in the expansion tank. The main breakdowns of the cooling systems of VAZ Niva models:

- Maximum engine heating with cold main radiator pipes means the thermostat is broken. The part cannot be repaired, only replaced.

- Electric fans in injection systems turn on uncontrollably or do not start at all. This is an indicator of a breakdown of the sensor that transmits data to the controller.

- A faulty sensor on the cylinder head causes incorrect data on the control panel or its complete absence.

- A constant decrease in antifreeze level indicates a leak somewhere in the circuit.

Vehicle cooling network design

The cooling system of the VAZ Niva is quite effective and has undergone virtually no changes since its creation. It includes the following units and elements:

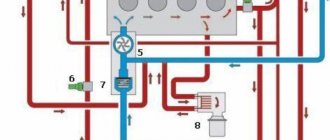

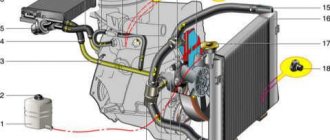

Temperature control in the Niva engine cooling network is carried out in different ways. In the carburetor model VAZ-21213, a sensor is built into the cylinder head, connected to the temperature indicator on the dashboard. On the VAZ-21214 model, where the fuel is supplied by an injector, there is a second sensor mounted in the pipe on the cylinder head. It is connected to a controller that prepares the fuel mixture depending on the heating of the power unit and turns on the fans.

There are 2 more differences in the cooling design of engines with a carburetor and an injector:

- on cars with direct fuel injection, 2 electric fans are installed on the radiator instead of 1 mechanical;

- The heating pipes for the lower part of the carburetor in model 21214 provide heating for the throttle body.

In VAZ-2131 Chevrolet Niva cars, the cooling system is generally similar to a regular Niva with an injector. The VAZ-2131 heater radiator is not equipped with a tap, which is why antifreeze flows through it all year round.

Fuse diagram for carburetor VAZ Niva

The only difference between Niva mounting blocks with injection and carburetor systems is related to the block. It is located under the hood of the car in a compartment specially designated for this purpose. His diagram looks like this:

Location of fuses Niva 21213

This scheme is relevant for all models of the family produced from 1997 to 1999.

Operating principle

The Niva's cooling circuit operates under pressure, since in normal mode it does not communicate with the atmosphere. The coolant is antifreeze with a freezing point of -40 °C. It is a solution of water with ethylene glycol, the amount to fill the system is 10.7 liters. It also boils at an elevated temperature, +110 °C.

The key element in the operation of the system is the thermostatic valve, which distributes fluid flows depending on the heating of the engine. Inside the thermostat there is a damper controlled by a temperature-sensitive element. When heated, it moves the damper, opening another path for the flow. In general, the scheme works according to the following algorithm:

In the summer and transition period in VAZ-21213 and 21214 cars, the passage of coolant through the heater radiator is limited by a tap. There is no such tap on the Chevrolet Niva; the heating is turned off by redirecting the air flow past the heat exchanger.

Main fuse box

Scheme

p, blockquote 12,0,0,0,0 —>

p, blockquote 13,0,0,0,0 —>

Purpose

p, blockquote 14,0,0,0,0 —>

| 1 | 16A Heater fan electric motor Relay (winding) for headlight wipers and electric motors for headlight wipers in all wipe positions except the initial Relay (winding) for turning on the rear window heating Electric motors for the rear window cleaner and washer Electric motor for the windshield washer |

| 1* | 16A Lamps Horns Socket Lighter Brake light |

| 2 | 8A Relay and electric motor of the windshield wiper Turn signal lamps and relay-interrupter for direction indicators and hazard warning lights (in turn signal mode) Turn signal indicator lamp Tail lights (reversing light lamps) Generator excitation winding (when starting the engine) Differential lock activation indicator lamp in the transfer case Indicator lamp for turning on the parking brake Indicator lamp for the emergency condition of the service brake system Indicator lamp for insufficient oil pressure Fluid temperature indicator in the engine cooling system Fuel level indicator with a warning lamp for fuel reserve Indicator lamp for battery charge Indicator lamp for closing the carburetor air damper Tachometer Electric heater motor Relay headlight cleaners and washer (with the headlight cleaner and washer switch button not pressed) Headlight wiper electric motors in all brush positions except the initial one* |

| 3 | 8A Left headlight (high beam lamp) Indicator lamp for turning on the high beam headlights |

| 4 | 8A Right headlight (high beam lamp) |

| 5 | 8A Left headlight (low beam) |

| 6 | 8A Right headlight (low beam) |

| 7 | 8A Left front light (side light) Right rear light (side light) License plate lights Indicator lamp for turning on side lights |

| 8 | 8A Right front light (side light) Left rear light (side light) Instrument lighting lamp Heater control lever backlighting lamp Cigarette lighter lighting lamp Illumination lamps for switches and switches |

| 9 | 16A Direction indicators and relay-breaker for direction indicators and hazard warning lights Rear window heating element and relay (contacts) for its activation |

| 9* | 8A Warning lamp and oil pressure gauge Coolant temperature gauge Fuel level gauge with reserve warning lamp Parking brake warning lamp Brake fluid level warning lamp Turn indicators and corresponding warning lamp Carburetor choke control warning lamp Battery charge warning lamp Carburetor shut-off valve Tachometer Rear lights (reverse light) Differential lock warning lamp Turn signal relay interrupter Heated rear window (control circuit) |

| 10 | 16A Sound signal Cartridge for connecting a portable lamp Interior lamps Tail lights (brake lamps) |

| 10* | 8A Voltage regulator Generator excitation winding |

| 11 | 8A Turn signal lamps and relay-breaker for turn signals and hazard warning lights (in hazard warning mode) Rear fog lamp |

| 12 | 8A Daytime running light relay, daytime running light lamps |

| 12* | 8A Headlight cleaner and washer relay (with the headlight cleaner and washer switch button pressed) Headlight washer electric motor Headlight cleaner electric motors at the moment of start-up and when the brushes pass the initial position |

| 13 | 8A Rear lights (fog light lamps) Electric motors for headlight cleaners at the time of start-up and when the brushes pass the initial position Relays (contacts) for headlight cleaners Electric motor for headlight washers |

| 14 | 16A Cigarette lighter |

| 15 | 16A Backup Heated rear window (power circuit) |

| 16* | 8A Hazard warning switch and direction indicators in hazard warning mode Rear window wiper and washer |

Fuse number 14 or number 1 at 16A is responsible for the operation of the cigarette lighter, depending on the year of manufacture.

Possible faults

To avoid problems with engine overheating, it is necessary to monitor and maintain the Niva’s cooling system.

You should check the antifreeze level in the expansion tank more often. Due to the reliability of cooling, there are not many malfunctions in it:

- When the car heats up to maximum in any weather, and the main radiator pipes are cold, the thermostat has broken. The element is not repaired, only changed.

- Electric fans turn on at random, including when the engine is cold, but if they overheat, they may not start. This means that the sensor transmitting temperature data to the controller has failed and must be replaced.

- When the indicator on the panel gives inaccurate data or does not show the temperature, you need to change the second sensor located in the cylinder head.

- The fluid level in the tank is constantly decreasing. It is necessary to look for and eliminate leaks in the pipes or in one of the radiators.

It is important to periodically check for play in the water pump shaft. Its appearance indicates wear of the bearing; it is necessary to change the pump as soon as possible.

Antifreeze Niva, basic practical issues

Answer: AvtoTAZ poured blue-green antifreeze for a very long time. But since 2012, almost every car I've seen has been a red G12. But there are still batches of cars filled with antifreeze.

What can be added and what can be mixed?

Answer: G11 and G12 cannot be mixed. Translated into Russian, blue-green and red-orange cannot be mixed.

- How to competently switch to G12? If you simply drain G11 and fill in G12, there will be no benefit except wasted money. The result will only be obtained after a “chemical” cleaning of the cooling system.

- Why do you recommend replacing “blue” with “red”. And so everyone works well. True, I have already changed several thermostats.

Answer: According to German articles on cooling, one of the reasons for thermostat failure is precisely low-quality antifreeze. We are talking about the film that jams the thermostat valve.

“Red” antifreeze is filled in, but for some reason when the engine heats up, it expands very much (can be seen from the level in the expansion tank).

Answer: it was filled with low-grade body slurry. When heated, water increases in volume up to 8-10%, antifreeze within 1%.

Antifreeze Niva, concentrate or ready-made?

Answer: Now I supply ready-made antifreeze, but we have a large country, so in a number of regions antifreeze with a crystallization temperature of minus 40 and below is required. Then you need to order the concentrate and dilute it according to your operating conditions.

The next question follows from the previous one and it usually comes from Yakutsk, Irkutsk, the Yamal Peninsula and other “resort” places in our homeland. What are the ratios for greater frosts than minus 40?

Answer: I provide data from Neste documentation.

50% -50% (water-concentrate ratio) – pour point minus forty.

40% water - 60% conc. freezing threshold minus 50 degrees.

25% water - 75% conc. freezing threshold minus 65-70 degrees

But don't get carried away. The freezing threshold increases, but other characteristics worsen.

What antifreeze do you use and complete orders?

Answer: I prefer the products of the Elf-Total concern and the antifreeze of our northern neighbors, the Finns. Manufacturer: Neste. This is if we talk about applicability to the Niva and UAZ family.

Antifreeze Niva, how much do you need to replace?

Answer: There are about 8 liters of coolant in the system. It can be drained as much as possible if you park the car on a slope, with the left side at the bottom. When the plugs on the block and radiator are open, almost everything drains. The quantity in Niva and Shnivy is the same.

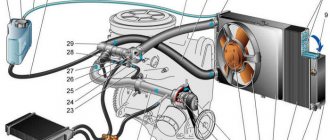

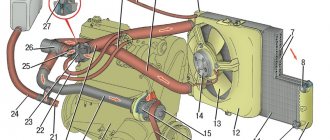

Engine cooling system

The cooling system is liquid, closed type, with forced circulation. The tightness of the system is ensured by valves in the expansion tank plug. The inlet valve is normally open (the gap between it and the rubber gasket is 0.5–1.1 mm) - in this case, the system communicates with the expansion tank. When the engine heats up, the liquid expands and is forced into the tank; when it cools, it returns back. The inlet valve closes when there is a sharp increase in pressure in the system (boiling liquid), while the outlet valve is also closed. It opens when the pressure in the system reaches approximately 0.5 kgf/cm2, which increases the boiling point of the liquid and reduces its losses. The thermal operating conditions of the engine are maintained by a thermostat and a radiator fan. On a carburetor engine, the fan is mechanically driven and mounted on the coolant pump pulley. On an engine equipped with an injection system, two electric fans are installed in front of the radiator and are activated by command from the electronic engine control unit.

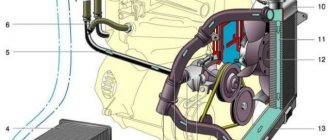

Carburetor engine cooling system

Injection engine cooling system

1 – expansion tank; 2 – expansion tank plug; 3 – pipe for draining fluid from the heater radiator; 4 – hose for draining fluid from the heater radiator; 5 – heater tap; 6 – heater radiator; 7 – hose for supplying fluid to the heater radiator; 8 – hose for supplying fluid to the carburetor heating block; 9 – hose for draining fluid from the carburetor heating unit; 10 – thermal vacuum switch of the recirculation valve; 11 – thermostat bypass hose; 12 – coolant pump cover; 13 – fan impeller; 14 – coolant temperature sensor for the instrument cluster; 15 – radiator supply hose;

16 – radiator; 17 – radiator cap; 18 – radiator drain plug; 19 – fan casing; 20 – radiator outlet hose; 21 – coolant pump drive belt; 22 – coolant pump housing; 23 – hose for supplying coolant to the pump; 24 – thermostat; 25 – coolant supply hose to the throttle body; 26 – coolant drain hose from the throttle body; 27 – coolant temperature sensor for the injection system; 28 – electric fan impeller; 29 – electric motor; 30 – electric fan casing.

How to properly replace coolant?

You need to start replacing the coolant on a VAZ 21214 by choosing a suitable refrigerant . You can choose the original coolant, or choose one of the available analogues. The original antifreeze has been produced since 2014. Name of liquid: Antifreeze LADA G12. Designed for use at temperatures down to -40 degrees Celsius. Product number: 88888-2000010-82.

When choosing a liquid, you need to pay attention to its labeling. For Niva (including VAZ 21214) you need a coolant with an operating temperature no higher than -40 degrees. The following liquids are suitable:

- Antifreeze of domestic production. You need to take a high-quality coolant. The marking “Antifreeze -40” means a freezing temperature of -40 degrees. For regions in the Arctic Circle, antifreeze labeled “Antifreeze -65” is suitable. An example of a suitable liquid: Felix antifreeze.

- Standard antifreeze. Both domestic and foreign coolants are suitable. Here again the minimum operating temperature is checked. It is equal to -40 degrees Celsius. Example: products from G-Energy or SINTEC. Felix Carbox antifreeze will also work.

It’s also worth considering that the original LADA antifreeze is sold in an already diluted form. But when purchasing concentrate from other companies, it should be diluted. The exact proportions are written on the coolant packaging.

Tools and materials for work

Then you need to figure out the tools and materials.

The list of tools for replacing coolant in a VAZ 21214 looks like this:

- Container for draining used antifreeze. Volume - 12 liters.

- Thick and durable coolant drain hose.

- Wrenches for 13 and 15. It is recommended to have box, open-end and ratchet wrenches of the appropriate size in the kit.

- Funnel for filling the radiator and expansion tank.

- Round nose pliers for removing the receiver hose.

- Cooling system flushing products.

- Antifreeze to replace. The Niva’s cooling system holds 10.7 liters. Therefore, 11 liters are purchased, with a small reserve in case of leaks.

- WD-40 for cleaning screws.

Vehicle preparation and safety precautions during operation

The next step is to prepare the car for replacing the coolant. It goes like this:

- The Niva is driven onto an overpass or placed above an inspection hole.

- The car is firmly secured: it is put into speed and the hand brake is applied. It is recommended to install wheel stoppers.

- The motor is allowed to cool. Working with hot antifreeze is inconvenient and hazardous to health.

It is also worth remembering safety precautions . Here are a number of simple but important recommendations:

- Antifreeze should not come into contact with eyes or respiratory tract. This liquid is toxic and is a strong poison.

- Work should be done in a ventilated area. Coolant fumes are not beneficial to health.

- You should wear comfortable, loose clothing. The work uniform does not restrict movement and does not interfere with the process of replacing antifreeze.

- Coolant must not get into the fuel. This will have a very negative effect on the operation of the motor.

Now you can proceed to the actual replacement procedure.

The stable operation of the engine will depend on the cooling system of the VAZ 21214

During its operation, the engine heats up to a very high temperature threshold. This circumstance is very fraught with problems for all surrounding elements. This is also dangerous for those people who are in the cabin. That is why a special complex was developed in order to “pacify” elements ready to boil.

This allows you not to worry that something will “boil” during operation. The latest VAZ 21214 models are equipped with a four-cylinder 8-valve gasoline engine system. It was here that the fuel injection system found its application. This is reflected in this set.

Relay and fuse diagram for VAZ Niva

Car owners are well aware that the VAZ 21214, 21213 (Niva) fuse box is a critical detail that requires detailed study. Knowledge of the electrical circuit allows you to avoid many problems and carry out timely diagnosis of breakdowns. Since the family has existed for many decades, it has managed to go through a number of radical changes - the transition from carburetor to injection engines, for example. This did not entail a radical change in the location and content of the mounting blocks, of which there are two in the cabin and one under the hood.

Features of work

A cooling system in any vehicle is needed in order to prevent overheating - this is the most important “point” in the work here. And in modern cars, such complexes also “take on” additional functions:

- are responsible for heating the air itself in the heating system, its air conditioning and ventilating flows;

- cool the oil in the lubrication system;

- cool exhaust gases intended for recirculation;

- cool the air in the turbocharging system.

The advantage of the cooling kit for the VAZ 21214 injector is its effective uniformity. The low noise level is also a positive aspect.

The cooling system in the VAZ 21214 is designed very cleverly: it must also prevent excessive cold in the engine - otherwise it will work unstably, there will be power losses, and fuel consumption will also increase. This will happen due to condensation of the fuel mixture (it begins to burn poorly and part of it flows into the crankcase).

What should be the optimal engine temperature? It should be maintained between 85-90°C. It is no longer recommended to exceed the limit of 105°C.

Replacement frequency, how much and what kind of fluid is needed

According to the manufacturer's recommendation, it is necessary to replace antifreeze or antifreeze on VAZ-21214 cars every 3 years or after a mileage of 60 thousand kilometers. If the car is used in more severe conditions, then it is advisable to replace it more often - every 30-40 thousand kilometers.

In addition to the recommended coolant change intervals, there are other reasons why it is necessary to change the fluid in a car's cooling system:

- loss of coolant properties. You can check the quality of the antifreeze used using a test strip, which is sold in the same places where the liquid itself is sold. Place the strip in the expansion tank, then pull it out. The strip comes with a color scale, according to which you can understand how much longer the car can be used before replacing the coolant;

- change in color of the coolant to tan or red. This means that rust has appeared in it;

- the appearance of sediments, flakes and dense formations in the liquid.

The coolant for the VAZ 21214 Niva injector should have a freezing point no higher than -40 degrees. Typically, the manufacturer fills in TOSOL TS-40 (manufacturer in Dzerzhinsk). When replacing antifreeze, it can be replaced with antifreeze with G12 approval; it is safer for the entire cooling system. You can also use original Lada G12 antifreeze, which is suitable for all cars of this manufacturer.

Antifreeze volume table

| Model Niva | Engine capacity | Antifreeze volume | Original/recommended fluid |

| VAZ 21214 | 1.7 | 10.7 | Lada G12, TOSOL TS-40 |

| VAZ 21213 | 1.6-1.7 | 10.7 | |

| VAZ 2121 | 1.4-1.8 | 10.6 | |

| VAZ 2131 | 1.7 | 10.7 |

Design Features

The cooling principle for the VAZ 21214 itself is liquid (which means circulation will occur in the reverse order). Filling is carried out using an expansion tank.

The reagent here is water with ethylene glycol. It will freeze only at the lowest possible temperatures, and with the help of various additives it can also increase the service life of the oil seal, as well as slow down the corrosion process of all other parts of the car

The cooling system for this brand of car will include the following components:

- radiator;

- heat exchanger located at the storage tank;

- radiator part;

- expansion tank;

- thermostat;

- centrifugal pump;

- radiator fan;

- pipes;

- control details;

- the so-called engine “cooling” jacket;

- a pipe that drains liquid from the heating radiator;

- liquid supply hose to the heating radiator;

- coolant pump cover.

Operating principle

The cooling system of VAZ Niva models does not come into contact with the atmosphere in operating condition, and therefore requires pressure. The coolant is antifreeze with a freezing point of 40 degrees Celsius. The composition of the solution is water and ethylene glycol. The total volume of the cooling circuit is 10.7 liters. Antifreeze can boil after a temperature of +110 degrees Celsius.

The main functional unit in the system is the thermostatic valve, which distributes the coolant flow depending on the engine temperature. The thermostat, controlled by a temperature-sensitive sensor, regulates the direction of movement of antifreeze. A simplified work flow looks like this:

- Before the internal combustion engine warms up to operating temperature (+90 degrees Celsius), the cooler moves along a small circuit (interior heating radiator, thermostat, power plant) using a pump.

- The damper opens towards the large circuit where the radiator is located, at a temperature of + 80 degrees Celsius. Afterwards, virtually the entire cooler moves along a large circuit, mainly cooling through the radiator.

- The small ring is not blocked, but a minimum of antifreeze enters it due to pipes of a smaller diameter.

- In model 2121, the fan is mounted on the axis of the water pump and constantly directs the air flow to the (BC). Cooling fans in Niva 21214 and 2131 are paired with electric drive. They are activated alternately or together using a temperature sensor (switching temperature is about 100 degrees Celsius).

- When heated, excess antifreeze is sent to the expansion tank, increasing the pressure in the system, which reduces the boiling threshold of the coolant.

In summer and during transition periods in models with an injector, the movement of the cooler is limited by a special tap. The Niva Chevrolet model does not have such a blocker, so the heating is turned off by directing the air flow past the heat exchanger.

Main element device

As for the cooling radiator, it is impossible to imagine the operation of the engine as a whole without it. It is represented by these components:

- upper and lower tanks;

- core;

- fastening parts.

Its main purpose is to cool the mixture coming from the water jacket to the required temperature standard. Good thermal conductivity is facilitated by the fact that it is usually made of brass. The core contains transverse plates. Once here, the reagent is divided into many streams - this allows you to get a more effective result.

The principle of operation goes like this:

- The pump constantly “moves” liquid into the VAZ 21214.

- The system operates in such a way that water circulates in a circle, washing the heated walls of the blocks and cylinder.

- In this case, engine overheating can be avoided, and heat will be guaranteed to be removed from important parts.

- Then the mixture goes through the radiator, and after that it is released into the environment.

- Thus, the cyclicity is completed - now the cooled liquid will have to repeat it again for the VAZ 21214.