The mass air flow sensor is a mass air flow sensor. It is an electronic device that serves to count the amount of air entering the cylinders from the air filter.

Depending on the volume of air passing through the sensor over a certain time period, the corresponding information is transmitted to the electronic control unit via a pulse signal. Based on the pulse frequency, the ECU determines the ratio of fuel and air in the air-fuel mixture, and controls the operation of the injector injection.

On a VAZ 2110, this sensor is located on the outlet pipe of the air filter, connecting it to the corrugation.

Searched element

Mass air flow sensor VAZ 2110: replacement and installation instructions

We have studied the malfunctions and symptoms, what a mass air flow sensor is is now clear. If we succeed in checking, and we know that the flow meter is faulty, all that remains is to replace it. To do this, you need to prepare a replacement unit (you can buy a non-standard model) and a screwdriver. Visual inspection implies analysis, but let’s repeat it again:

- You need to turn off the engine and remove the key from the ignition.

- Pull out the sensor connector as shown in the photo.

- Now you can remove the hose on the inlet pipe. It is attached with clamps to the air filter. After removing the clamps, the hose can be dismantled.

- Now we can remove the mass flow sensor and perform the replacement.

Installing a new element is done in exactly the same way.

Experiment on washing the air flow sensor

How to check the mass air flow sensor for serviceability

There are several basic methods for checking the mass air flow sensor, which allow you to verify its malfunction.

Checking the mass air flow sensor in motion

The easiest way to diagnose a flow meter is to analyze the operation of the engine when the sensor is forcibly turned off. The check proceeds as follows:

- It is necessary to open the hood and disconnect the connector from the mass air flow sensor. After this, close the hood;

Next, get behind the wheel of the car and start the engine. The car should start to operate in limp mode, in which the Check Engine light will be on.

In such a situation, the amount of air in the fuel mixture will be determined depending on the throttle position; Try driving the car and pay attention to its dynamics in comparison with how the car worked before the mass air flow sensor was turned off. With the sensor turned off, the car should become “more lively”, that is, accelerate faster

If this is the case, then we can confidently talk about problems with the mass air flow sensor.

It is highly not recommended to operate a car for a long time with the mass air flow sensor turned off.

Checking the mass air flow sensor with a multimeter

You can diagnose a problem with the sensor using a multimeter. To do this, you must first understand the design of the device and its “pinout,” that is, the wiring of the wires on the board. There are 4 wires coming out of the mass air flow sensor. Depending on the MAF model and manufacturer, their colors may vary, but in most cases they are as follows:

How to clean the DMRV on a Priora

- Pink (or pink-black): wire to main relay;

- Green: wire to ground;

- Gray: wire to power;

- Yellow: signal input.

To check the mass air flow sensor, the multimeter must be set to constant voltage measurement mode and set the limit to 2 Volts. Next, you need to turn on the ignition, but do not start the engine. Once this is done, connect the multimeter's red lead to the sensor's signal input (yellow wire) and the black lead to ground (green wire). This can be done without “exposing” the wires by inserting the probes of the diagnostic device through the rubber seal of the connector.

Based on the measurement results, conclusions can be drawn about the state of the sensor:

Fully serviceable device (new): 0.996 - 1.01 Volts;

The sensor is in good condition, but has already worked: 1.01 - 1.02 Volts; The sensor has been working for a long time, but is still working: 1.02 - 1.03 Volts; The mass air flow sensor will soon need to be replaced: 1-03 - 1.04 Volts; The flow meter is close to failure, but continues to cope with the tasks: 1.04 - 1.05 Volts; The sensor needs to be changed: 1.05 Volts and above.

Some modern on-board computers allow you to view the voltage on the mass air flow sensor. In such situations, you can do without a multimeter.

Visual inspection of the mass air flow sensor

Experienced motorists can determine a malfunction of the mass air flow sensor by its appearance. The first step is to remove the mass air flow sensor, and then inspect it carefully. Signs of a malfunction are liquid getting into the air pipe and the mass air flow sensor (or the presence of mechanical damage).

- How to use a multimeter to check the performance of the MAF on a VAZ-2110: video tutorial

Most often, liquid may end up in the sensor for the following reasons:

- Increased oil level in the crankcase. In such a situation, oil enters the sensor;

- Clogged oil sump of the crankcase ventilation system;

- Untimely replacement of the air filter, due to which dirt gets onto the MAF hot air anemometer.

The easiest and most reliable way to diagnose problems with the mass air flow sensor is to replace it with a working device. For example, you can remove a suitable working sensor from another car, install it and make sure that engine operation has stabilized. In such a situation, you can immediately go buy a new sensor without diagnosing it with a multimeter or other methods.

Purpose of the mass air flow sensor

The mass air flow sensor is a complex electronic device that regulates the fuel injection system into the engine cylinders. It is responsible for how much air is contained in the engine. It is known that in order for the power unit to come into action, it is necessary that air and fuel be supplied in half. Then an atmosphere is created inside the equipment that is ideal for striking a spark and setting all mechanisms in motion.

The difference is significant. The system, receiving this information, trustingly follows it. The proportions of air and fuel are disrupted, and a slightly smaller amount of fuel is injected, which is called a “lean mixture.” Symptoms of this problem are a sharp decrease in engine power, controllability and dynamics. The consequence of this “disease” is the engine’s refusal to start. And then the driver has to puzzle over what actually happened.

Therefore, from time to time you should check the working condition of the sensor, so as not to waste much more time on engine diagnostics. There are several ways to check the sensor, but the most popular is diagnostics using a multimeter - a simple device that every car owner would do well to keep in his toolbox.

Principle of operation

The piston stroke occurs when fuel is burned with air in a ratio of 1:14, maintaining which ensures optimal operation of the power plant. When the proportion decreases or increases, the engine does not stop working, but there is excessive fuel consumption or a decrease in engine operating power. We need a mass air flow sensor so that air flows in portions. The operation of the unit proceeds as follows: the VAZ 2110 air flow sensor calculates the portion of fresh air, and then sends the data to the main computer, which, based on this information, calculates the portion of fuel.

The harder you push the gas, the more filtered air the powerplant requires. The mass flow sensor detects the increase and commands the electronics to increase the amount of fuel. When moving at the same speed, each portion should be equal to the previous one. The mass air flow sensor receives data on the load of the power unit, and then calculates the required portion of air. When the driver presses the pedal, the throttle valve opens, thereby increasing the volume of intake air - the load increases. When the pedal is released, the load drops.

Damaged sensor due to dust

Information about the operation and design of the mass air flow sensor

Again, we will not consider the historically outdated mechanical options with a weather vane and the General Motors frequency flow meter, which was used in conjunction with the January 4-series ECU. Modern flow meters for the VAZ 10 series operate on the principle of a hot-wire anemometer.

It is based on the properties of some metals to significantly change resistance depending on heat (the MAF sensor uses an alloy of iridium with platinum, which causes the high cost of the device). There are two resistors in the air flow: one is precision, the second can change the resistance using heat. Voltage is applied to it, the thread is heated until it matches the standard. Depending on the strength of the air flow, the thread cools and the resistance changes. By increasing the voltage across the resistor, the temperature and, accordingly, the resistance are restored. This happens in real time, that is, the control of the air mass is constant. At the output, the mass air flow sensor displays the signal voltage with an accuracy of hundredths of a volt. The received information is processed by the ECU to accurately dose gasoline into the fuel-air mixture.

All elements are arranged into a single electronic model, which is placed in the measuring channel (air duct).

Sensor device

View of the flow meter from the grid side.

DMRV sensor VAZ 2115: signs of malfunction, how to check, clean or replace?

The sensor is disassembled.

The platinum thread is visible in this photo.

Advertisements

As a result, air flow and temperature are converted into electrical impulses understandable to the ECU. This is a very gentle and accurate device; it allows you to calculate the cyclic filling of the cylinders with air and updates the parameters every 0.1 s.

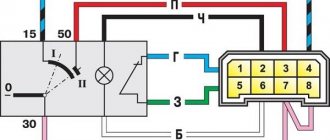

Mass air flow sensor diagram.

The working body of the sensor is a heated platinum thread. It heats up to operating temperature (from 100 to 1000 degrees), and when air enters, it cools down. The amount by which the filament temperature drops is converted into an electrical signal and, based on this value, the ECU calculates the mass and temperature of the air entering the combustion chamber. And based on this data, it prepares the required portion of fuel. In short - yes.

Visual inspection

As for visual diagnostics, first of all it is necessary to check the condition of the corrugation in which the flow meter is installed, as well as the device itself. If, as a result of the check, you see traces of motor fluid or condensation, then it is possible that the device does not work for this reason. In some cases, cleaning the device from contaminants allows the flowmeter to resume operation and prevent possible replacement. It should be taken into account that contaminants usually accumulate as a result of infrequent replacement of the air filter element (the author of the video about the regulator malfunction is the channel In Sandro’s Garage).

Demonstration of a faulty mass air flow sensor on Kalina, Priora, Grant, VAZ 2110-2112, 2114-2115

If you notice traces of engine fluid, then there is a possibility that the reason lies in a clogged oil seal, or the problem may lie in exceeding the permissible level of lubricant in the crankcase. When cleaning is complete, you will need to make a visual inspection of the regulator - on the front of it you can see the rubber seal that is used for sealing. The seal is necessary to prevent uncleaned air flow and it may be that the rubber band moves a little - this will lead to the accumulation of dust on the flowmeter grid.

Features, diagnostics and replacement of elements of injection systems on VAZ cars

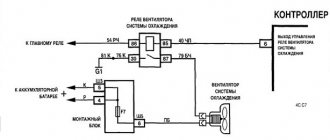

Below we will look at the main controllers!

Hall

There are several options for how you can check the Hall sensor of a VAZ:

- Use a known working device for diagnostics and install it instead of the standard one. If after replacement the problems in engine operation cease, this indicates a malfunction of the regulator.

- Using a tester, diagnose the controller voltage at its terminals. During normal operation of the device, the voltage should be from 0.4 to 11 volts.

The replacement procedure is performed as follows (the process is described using the example of model 2107):

- First, the switchgear is dismantled and its cover is unscrewed.

- Then the slider is dismantled; to do this, you need to pull it up a little.

- Remove the cover and unscrew the bolt that secures the plug.

- You will also need to unscrew the bolts that secure the controller plate. After this, the screws that secure the vacuum corrector are unscrewed.

- Next, the retaining ring is dismantled and the rod is removed along with the corrector itself.

- To disconnect the wires, you will need to move the clamps apart.

- The support plate is pulled out, after which several bolts are unscrewed and the manufacturer dismantles the controller. A new controller is being installed, assembly is carried out in the reverse order (the author of the video is Andrey Gryaznov).

Speeds

The following symptoms may indicate a failure of this regulator:

- at idle, the speed of the power unit floats, if the driver does not press on the gas, this can lead to an arbitrary shutdown of the engine;

- the speedometer needle readings float, the device may not work as a whole;

- fuel consumption has increased;

- the power of the power unit has decreased.

The controller itself is located on the gearbox. To replace it, you only need to jack up the wheel, disconnect the power wires and remove the regulator.

Fuel level

The VAZ or FLS fuel level sensor is used to indicate the remaining volume of gasoline in the fuel tank. Moreover, the fuel level sensor itself is installed in the same housing with the fuel pump. If it malfunctions, the readings on the dashboard may be inaccurate.

The replacement is done like this (using the example of model 2110):

- The battery is disconnected and the rear seat of the car is removed. Using a Phillips screwdriver, unscrew the bolts that secure the fuel pump hatch and remove the cover.

- After this, all wires leading to it are disconnected from the connector. It is also necessary to disconnect all the pipes that are supplied to the fuel pump.

- Then the nuts securing the clamping ring are unscrewed. If the nuts are rusty, treat them with WD-40 before unscrewing.

- Having done this, unscrew the bolts that directly secure the fuel level sensor itself. The guides are pulled out from the pump casing, and the fasteners need to be bent with a screwdriver.

- At the final stage, the cover is dismantled, after which you will be able to gain access to the FLS. The controller is replaced, the pump and other elements are assembled in the reverse order of removal.

Photo gallery “Changing the FLS with your own hands”

Idle move

If the idle speed sensor on a VAZ fails, this is fraught with the following problems:

- floating speed, in particular, when additional voltage consumers are turned on - optics, heater, audio system, etc.;

- the engine will start to stall;

- when the central gear is activated, the engine may stall;

- in some cases, failure of the IAC can lead to body vibrations;

- the appearance of a Check indicator on the dashboard, but it does not light up in all cases.

ADC codes

ADC code parameters relate to analog sensors of the control system:

- Throttle position sensor

- temperature sensor

- Mass air flow sensor

- Sensor L-probe

- Potentiometer CO.

Physically, ADC codes reflect the voltage that the sensor produces. Typically, these parameters are used to test sensor circuits. If fault codes occur associated with a low or high signal level of such a sensor, then the control system operates in backup modes. In this case, the value of the parameter related to this sensor is selected either from the emergency table or calculated using specified formulas, for example, the coolant temperature with a faulty temperature sensor increases during engine operation.

If, during a physical change in the parameter measured by the sensor, the ADC code remains a constant value, then the electrical circuit connecting the sensor is inoperative.

ADC values are dimensionless, but for the user in scanner testers they are translated into the voltage that a particular sensor produces.

Therefore, using an ADC code, for example, from an L-probe sensor, you can more clearly evaluate the work in the feedback loop system to maintain the stoichiometric composition of the mixture. If the L-probe sensor is inoperative, then the ADC code is in the range of 0.4-0.7V.

The ADC code value (output voltage) from the throttle position sensor can indicate the lower limit at which the system detects sensor error. A throttle position equal to zero corresponds to a voltage from the sensor of 0.52 V.

When the ignition is on, the output voltage from the mass flow sensor (ADC code) should be 1.00V.

The temperature sensor, throttle position sensor, mass flow sensor are powered by a voltage of 5.00V, which is supplied by the control unit. If the control unit produces an unstable voltage, then the sensor readings will change and the behavior of the system in this case is unpredictable.

Engine operating principle

Before you begin repairing the mass air flow sensor, it is important to understand the operating principle of the device as a whole. The controller mixes fuel with air. The optimal proportion is obtained only when the device provides correct data on engine air consumption.

If this does not happen, the air-fuel mixture becomes unbalanced and engine operation is disrupted. This, in turn, leads to a deterioration in the dynamics of the car as a whole and significantly increases fuel consumption.

How does the VAZ 2114 mass air flow sensor work?

A modern mass air flow sensor (also known as MAF in English) uses sensitive sensors and a special calculation algorithm to compare the resistance readings of two thermistors. One of them is a reference value, its value is constant. The second (made of platinum-iridium wire) is forcibly heated. The incoming air flow cools the wire, the resistance changes, and to equalize it with the reference, a larger heating current is required. It is the difference in current strength (in this design, voltage is measured using the Ohm's Law formula) that provides information to the ECU.

The measurement accuracy is 1/100 volt, so the slightest malfunction of the mass air flow sensor instantly affects the quality of engine operation.

How to make a fake MAF sensor

Here I found useful information on typical parameters. Made essentially as a note to myself.

For many novice diagnosticians and ordinary car enthusiasts who are interested in the topic of diagnostics, information about typical engine parameters will be useful. Since VAZ car engines are the most common and easiest to repair, we’ll start with them. What should you pay attention to first when analyzing engine operating parameters? 1. The engine is stopped. 1.1 Coolant and air temperature sensors (if equipped). The temperature is checked to ensure that the readings correspond to the actual engine and air temperatures. It is better to check using a non-contact thermometer. By the way, one of the most reliable in the injection system of VAZ engines are temperature sensors.

Signs of a malfunction of the mass air flow sensor on a VAZ 2110: how to rinse and clean it yourself

When the first signs of a malfunction occur, you should definitely check the mass air flow sensor, and then, depending on the situation, clean or replace the device.

Now let's talk about how to check our sensor. Today, two main methods of checking the mass air flow sensor are used.

- The engine is tested in operation with the mass air flow sensor disconnected. Simply turn off the power from the regulator and start the motor. When the mass air flow sensor is not present during startup, the electronic control unit turns on the power unit in emergency mode. The speed is adjusted to 1500 rpm. After disconnecting the sensor, drive a few kilometers and evaluate the dynamics and power. If the engine is running normally, then the sensor is the cause of the symptoms.

- The second method will require the use of a car tester or voltmeter. After starting the ignition, do not start the engine. The voltage threshold is set on the tester to 2V. The positive probe connects to the yellow wire on the sensor connector, and the black probe connects to the green wire. Next, refer to the table.

Index

Air flow sensor condition

The sensor is functioning normally

Not ideal, but still acceptable voltage readings

Maximum permissible values that indicate imminent sensor failure

The air flow sensor has failed and needs to be replaced

Quite often you can avoid replacing the mass air flow sensor by simply cleaning this engine element.

You should do the cleaning yourself in this way:

- Remove the pipe from the mass air flow sensor;

- Now remove the sensor from the pipe. Otherwise, high-quality washing will not work;

- To remove the sensor, arm yourself with sprocket keys in advance. Finding such kits is not a problem;

- Unscrew all the fasteners, remove the sensor from the pipe and assess its external condition;

- Often there are traces of oil deposits on the sensor. The purpose of cleaning is to make the device as good as new;

- Carburetor cleaner is often used to clean the air flow sensor;

- Inside the film there are sensors, which are small wires attached to a special resin. These elements must be carefully sprayed with cleaner so as not to damage the devices;

- Wait a while for the surfaces to dry. To speed up the process, use a can of compressed air;

- It is not uncommon to use alcohol instead of carburetor cleaner, which also works quite effectively;

- Proper cleaning of the mass air flow sensor involves treating the pipes from accumulated debris, dirt and dust;

- Having carefully processed all the components of the removed mass air flow sensor, wait until it dries, and then reassemble it. Cleaning is complete.

Spray cleaning

Statistics show that in about 80% of cases, simple cleaning can return the mass air flow sensor to its previous functionality.

Price issue

80% is not 100. Therefore, sometimes you have to change the sensor. And to replace it, you need to buy it.

There are three price categories for air mass flow sensors:

- Cheap. These are predominantly Chinese products, the price of which is up to 1000 rubles. It is strongly not recommended to purchase such regulators;

- Average. These include sensors from AvtoVAZ, domestic and some foreign analogues. These cost from 1500 to 2500 rubles;

- Expensive. High-quality, reliable, imported air flow sensors, the price of which can reach 5.5 thousand rubles. It’s hard to say how rational it is to buy them. But they will definitely last a long time.

It is not difficult to replace the mass air flow sensor with your own hands, even if you do not have any special skills in car repair. Having checked the condition of the device and determined that cleaning will not help, all that remains is to replace it.

- Place the car on a level surface, lift the hood and remove the negative terminal from the battery.

- Disconnect the sensor connector. We have already talked about its location, so there will be no problems with the search.

- Using a screwdriver, remove the clamping bolt of the clamp that secures the corrugation to the mass air flow sensor.

- The corrugation is removed.

- Using a 10mm wrench, unscrew the two bolts that hold the sensor to the air filter housing.

- After removing the failed oxygen sensor, install a new regulator in its place.

- Screw back a couple of bolts, secure the corrugation and secure it with a clamp.

- Reconnect the connector and return the negative terminal to the battery.

If everything is done correctly and the breakdown is correctly identified, then the engine will return to its previous performance and the error signal on the dashboard will disappear.

Replacing the device

To finally check the result of the repair, go out onto the road, do a test drive and be sure to try to press the gas pedal sharply. If the dynamics and power become the same as before the problems arose, you did everything correctly, and it was the mass air flow sensor that was the culprit of the malfunction.

Restoring the air flow sensor

They ask for a considerable price for a mass air flow sensor, and according to the laws of the market, this should be justified. It's simple, though! To a large extent, this is the price to pay for our ignorance - we have no idea how the mass air flow sensor works... and why it stops working. And also - for the opinion imposed on us by market traders: the mass air flow sensor is depressed - buy a new one!

The role of the mass air flow sensor is difficult to overestimate. In order for the controller to accurately control the operation of the injectors and ignition, it must, as far as possible, accurately know the actual air flow of the engine. If the mass air flow sensor starts to lie, the engine loses power, fuel consumption and exhaust toxicity increase, and acceleration dynamics worsen.

One of the common reasons for the malfunction of the mass air flow sensor on the “tens” lies in the features of the engine crankcase ventilation system. It has two circuits - a large one, which operates when the throttle is open, and a small one - for idle mode when the throttle is closed. In the latter case, crankcase gases are sucked into the throttle body through a channel with a hole diameter of 1.5 mm. Some of them pass along the idle line, through its regulator, at the same time coming into contact with the delicate film resistor of the mass flow sensor. In addition, the latter is located in the zone of action of reverse gas oscillations in the intake tract. Resin deposits change the characteristics of the resistor - and the sensor becomes false. By this time, the idle speed controller begins to act up in its own way - it sticks, jams, especially when starting the engine.

This is interesting: Do-it-yourself engine cooling radiator repair

Usually the mass air flow sensor is checked with a diagnostic device (for example, DST-6), but we will make do with a digital multimeter with a scale of up to 2 V. We insert a pin between the rubber seal and the yellow wire until it makes contact (photo 1). Now turn on the ignition and measure the voltage at this contact. Ideally, the result should be 0.99 V. Taking into account measurement errors, no more than 1.03 V. If it is higher, some people immediately replace the sensor with a new one. We won't rush. Having unscrewed the tricky screws securing the sensor's measuring element with pliers, we will instead select simple ones (4.9 x 20) for a Phillips screwdriver. This will make servicing the machine easier in the future. Let's work with the removed element. Let's prepare a washing device - an aerosol carburetor cleaner, the tube of which, heated in the flame of a match, will be bent at an angle of 90°. Then we cut it so that the stream is knocked out to the side, and the tube itself remains straight (photo 2). By introducing it to a depth of 10 mm into the upper channel of the measuring element of the mass flow sensor, we will flush the resistor. A few seconds later - again. As a rule, no more is required. Please note that the resistor does not allow any force - forget about cotton swabs, brushes, compressed air.

After allowing traces of the cleaner to dry, we insert the sensor into the housing and repeat the voltage measurements. Hasn't changed? Apparently, the MAF resource has really been exhausted. Usually, the “top ten” needs to travel 80–90 thousand, or even more, to do this. If the voltage drops to normal, we will drive. Of course, after washing the sensor in this way, some engine characteristics may change. It will be necessary to re-check the exhaust toxicity, in some cases (if the system allows) to adjust it - and so on. Well, is it possible to ease the operating conditions of the mass air flow sensor and extend its service life? We'll talk about this another time.

How to deceive the mass air flow sensor using ECU firmware

The good thing about the previous method is that its implementation does not require complex equipment or painstaking work. If you were able to check the voltage at the output of the flow meter with a multimeter (which means you at least have one), and know how to hold a soldering iron in your hands, installing a resistor in the wire gap will not be difficult. However, the dependence of voltage on air flow mass is nonlinear. And when the throttle valve opens, the error of the signal corrected by the resistor at rest will increase. Accordingly, the fuel-air mixture will not be ideal.

This means that you need to adjust the MAF calibration in the ECU firmware.

- We install the specialized tuning program “DFID Corrector” on the laptop.

- We connect the car scanner to the OBD-II connector and establish communication between the ECU and the computer.

After calibration, the data on mass air flow will be correct throughout the entire engine speed range.

How to deceive a Gazelle DMRV

#1 AlexandrVozjaev

For several months I studied the issue of removing the mass air flow sensor from the package, and even tried changing it to DBP. This is what came out of it, I present it for further study and discussion. Attached is double firmware for Mikas 71 for propane without air flow sensor. On gas, the car operates on two sensors: crankshaft and throttle. Switching along the 54th leg plus from the gas valve After the firmware, please make a mark on the block with a marker that the firmware is without air flow sensor. Conducted field tests. In December 2009 he handed over 2 minibuses, and at the beginning of February three more. All machines work every day. Some theoretic critics expressed that the firmware contains the wrong OZ, supposedly there is no dynamic correction. To check this, I traveled with a laptop and checked how the UZ behaved. When traveling between two stops, I chose a section where for several seconds the car drove steadily at a speed of 45-55 km/h. I drove with a new Euro-3 gazelle, and on a converted car without a mass air flow sensor (and even without a speed sensor!), the SVR is approximately the same and is 35g + -5g. The cars were empty, without passengers, but I conclude that the dynamic correction is calculated correctly, there will be no problems from an incorrect OZ. You can't hear any popping noises in the muffler or ringing fingers. This was all on gas, I didn’t check on gasoline, because no one drives on gasoline, they just start it.

A way to emulate the operation of a sensor without lambda trickery

If you don’t want to bother with installing plugs and electronic additional devices, there is a surefire way to directly fool the engine control unit. It is necessary to “reflash” the ECU program.

The program reduces the environmental level of emissions to EURO-2. In this case, the power unit does not need a catalyst at all. He is sure that it should not have been in the system from the factory. The mention of it is completely erased from the “brains” of the internal combustion engine.

Flaws

Incorrectly changing the program code or factory settings can have a detrimental effect on the operation of the motor. In certain modes, it will stop producing the required power, fuel consumption will increase, etc. No one can guarantee that the engine will not stop at any time. Because the crooked hands of programmers can change the wrong settings and get into the wrong places. The program can “fly off” at any time, and getting in the way is a bad prospect.

Cleaning the mass air flow sensor (MAF) on VAZ 2110, VAZ 2111, VAZ 2112

Welcome! Mass air flow sensor - in abbreviated form it is simply called mass air flow sensor, this is a very important and necessary sensor in the system, because thanks to it the controller (It is also called the brain) understands how much air is supplied to the cylinder at one time or another and, in connection with this, adjusts fuel supply to the car, thereby the car runs smoothly and without interruptions, but any of the sensors gets dirty or gradually fails, the same thing happens with the air flow sensor, it has platinum threads or, as they are also called, platinum spirals, when they contamination, the sensor begins to incorrectly read the air that goes into the cylinders and, in connection with this, the car begins to become dull in the literal sense of the word, it accelerates poorly, its speed fluctuates and it consumes gasoline more than usual, in this case there are two options, or change the sensor to a new one, or try to clean the old one, it’s up to you to decide which way you go, but cleaning the sensor does in some cases give very positive results, but not always.

Note! In order to clean the sensor from dirt, you will need special chemicals: These include liquid for cleaning the carburetor, but only when choosing this liquid, be careful because if you buy too strong a liquid (Meaning that corrodes the dirt very much), you can damage the sensor itself like this as it is not intended for this, for more details on how to choose a liquid, see the video clip at the very end of the article! (By the way, to clean the sensor, also stock up on a set of various wrenches, and if possible, stock up on a wrench with socket heads and pliers)

Where is the mass air flow sensor located? It is located immediately after the air filter housing ends and it is installed immediately behind it, so that you can understand its location in more detail, open the hood of the car and first find the housing itself inside which the air filter is located (For clarity, the housing is indicated by a blue arrow) and then If you find it, you can immediately look at the sensor itself, which is indicated by a red arrow in the photo; you will need to remove it for cleaning.

Sensor repair

Any electronic device has a huge disadvantage: sensitivity to the slightest power surges, pollution, aggressive environmental influences and many other factors. If even a tiny particle of dirt or dust gets into the air flow entering the engine, it will certainly settle on the sensor, which, being so vulnerable, attracts such troubles to itself like a magnet.

Continuing to work in this state, he is forced to increase the load, as dust ballast interferes with him. Consequently, it starts to fail. Also, if low-quality oil or bad gasoline is poured into the engine, all this first of all has a very negative impact on the electronic device. That is why it is so important to pay attention to air, oil and other filters and not to skimp on the quality of fuels and lubricants poured into the engine.

Having made sure that the VAZ mass air flow sensor is faulty, we move on to the next stage - repair. Repair consists of a good cleaning. But how is the mass air flow sensor cleaned and is it possible to do this work with your own hands? To begin with, you should remember, like a multiplication table, that in no case should you use the following for flushing:

For cleaning, use carburetor cleaning fluid. The most popular in this matter is WD 40, which has good technical properties and is safe for electronic devices. You need to wash the sensor carefully so as not to damage the thinnest plates and wiring.

After making sure that there is no more dust or debris in the device, you can, after thoroughly drying it, install it in place. As a rule, after such a simple procedure, the device should work like a good Swiss watch. We have discussed the most frequently asked questions regarding the mass air flow sensor. Now you know why it breaks, what needs to be done to protect it, and what to do if it suddenly malfunctions. We wish you good luck on the roads and good mood!

Briefly about the renovation

As a rule, MAF sensors that have become unusable cannot be repaired, except in cases where they require washing and cleaning.

In some cases, it is possible to repair the volumetric air flow sensor board, but this process will not prolong the life of the device for long. As for the boards in film sensors, without special equipment (for example, a programmer for a microcontroller), as well as skills and experience, it is pointless to try to restore them.

This project appeared due to the reluctance to buy a part that had been in use for about 30 (thirty) years for a quite considerable amount of 3,000 - 5,000 rubles. We can say that this will be a test of the pen in circuit design and programming of microcontrollers. If you're interested, see the continuation below the cut.

Mass air flow sensor device (English abbreviation - MAF)

- The housing is made in the form of a cylinder, the diameter of which coincides with the air duct of the intake manifold. Installed at the outlet of the air filter (using the example of a VAZ 2112). The housing itself is a calibrated measuring channel.

- To protect against foreign objects, a deflector and a metal screen in the form of a mesh are installed at the entrance. The correct air flow is formed through them.

- The air flows through the flow sensor itself, which operates on the thermal anemometric principle. There are two resistors installed inside (reference and variable), connected to a common circuit using a ballast circuit. Variable, precision, changes resistance when cooling and heating. The thread of this resistor is made of an alloy of iridium and platinum. The control board monitors that the resistance is the same. To do this, a platinum thread cooled by an air flow is heated by electric current. The resistor is constantly supplied with voltage, the value of which varies with an accuracy of 1/1000 volt.

- The value of this voltage is output by the MAF circuit to pin No. 5 of the connector. The signal is read by the ECU controller and programmatically converts this value into air mass (kg/hour).

In order for the fuel-air mixture to work efficiently, gasoline and air are mixed in a ratio of 1 to 15

Therefore, it is important that the mass air flow sensor produces accurate data

Prevention and testing of mass air flow sensor on VAZ 2110

As a preventive measure, we can recommend timely replacement of the air filter. The use of sports zeros shortens the life of the flow meter. In any case, regular cleaning of the air flow sensor will not hurt.

- We disconnect the sensor connector, having first removed the ground from the battery.

- Carefully unscrew the flow meter housing from the intake manifold flange.

- If dust deposits are detected, blow out the cavities with compressed air.

- Of course, you also need to clean the air duct and air filter box at the same time.

If the contamination is severe (with oil and moisture), you can use a special cleaner for flow meters or carburetors; the manufacturer does not matter. To do this, it is necessary to direct the jet not only to visible sensors, but also to hidden cavities where the platinum resistor (thread) is located.

After this, the flow meter is installed in its regular place and the functionality of the electronic part is checked.

Prevention of breakdowns and cleaning of the air flow sensor of the VAZ 2114

The flow meter sensor is located in a vulnerable place: exposure to temperature changes, moisture, dust.

Precision electronics located in the measuring channel fail when foreign objects enter.

- untimely replacement of the air filter;

- the use of so-called “zero” filters;

- loose connection of the mass air flow sensor with the air duct flanges;

- moisture entering the air intake;

- Debris left in the ductwork or filter housing after repairs and maintenance.

How to check the mass air flow sensor on a VAZ 2110 with a multimeter

A. Check the wiring harness and contacts. At this stage, the interaction between the ECU and the mass air flow sensor is tested. Performed with the connector removed and the ignition key in the “ON” position. You need to know the pinout of the sensor connector on the ECU side:

- Contact No. 1 is not involved in the test.

- Contact No. 2 - 12 volt power supply. A deviation of even 0.5 volts is not acceptable.

- Contact No. 3 - “ground”, mass.

- Contact No. 4 - 5 volt sensor power supply. Likewise: deviations are not allowed.

B. Having verified the integrity of the cable harness and the operability of the ECU, we check the signal voltage on the connected flow meter. Turn the ignition key to the “ON” position and do not start the engine! We connect a digital multimeter to ground and contact No. 5 of the air flow sensor.

The multimeter is set to 2 volt measurement mode with an error of 1/100 volt. These readings accurately indicate the condition of the flow meter, so the accuracy class of the tester must be high.

If the device shows a voltage within 0.99-1.02 V, your flow meter is new or in excellent condition.

Readings from 1.03 to 1.05 volts are acceptable, but the air flow sensor will soon fail. You can still drive with such a sensor, but the quality of the fuel-air mixture will be far from ideal.

If there is no voltage or its level is above 1.05 V, the flow meter is faulty and requires replacement.

Interchangeability

This issue is quite relevant, especially taking into account the cost of original products from the imported automobile industry. But it’s not so simple here, let’s give an example

In the first production models of the Gorky Automobile Plant, the injection Volgas were equipped with a BOSCH air flow sensor. Somewhat later, imported sensors and controllers replaced domestic products.

A – imported filament air flow sensor manufactured by Bosh (pbt-gf30) and its domestic analogues B – JSCB “Impuls” and C – APZ

Structurally, these products were practically no different with the exception of several design features, namely:

- The diameter of the wire used in a wirewound thermistor. Bosch products have a diameter of 0.07 mm, and domestic products have a diameter of 0.10 mm.

- The method of fastening the wire differs in the type of welding. For imported sensors this is resistance welding, for domestic products it is laser welding.

- Shape of a thread thermistor. Bosh has a U-shaped geometry, APZ produces devices with a V-shaped thread, and products from JSC Impulse are distinguished by the square shape of the thread suspension.

All the sensors given as an example were interchangeable until the Gorky Automobile Plant switched to film analogues. The reasons for the transition were described above.

Film air flow sensor Siemens for GAZ 31105

It makes no sense to give a domestic analogue to the sensor shown in the figure, since outwardly it is practically no different.

It should be noted that when switching from filament devices to film devices, most likely, it will be necessary to change the entire system, namely: the sensor itself, the connecting wire from it to the ECU, and, in fact, the controller itself. In some cases, the control can be adapted (reflashed) to work with another sensor. This problem is due to the fact that most filament flowmeters send analog signals, while film flowmeters send digital signals.

When is it time to clean?

But regardless of the type of sensor, over time it begins to function incorrectly due to contamination - the platinum measuring elements become covered with dust. Therefore, the question of how to clean the mass air flow sensor will always be relevant.

Why does this happen? The main reason for sensor contamination lies on the surface - the unsatisfactory condition of the air filter. If the filter element is of poor build quality, then it is not able to trap microscopic particles of dirt and dust that settle on the sensing element of the mass flow sensor.

As a result, the device is not able to accurately measure the amount of air and sends incorrect data to the ECU. It's not hard to imagine what this might lead to. Here we gradually approach some characteristic signs that may indicate that the sensor is clogged and needs to be cleaned:

- The need to clean the mass air flow sensor on a VAZ or other cars arises when the engine idles intermittently, in some cases they are too high - up to 1500.

- The car may jerk and have difficulty accelerating.

- Sometimes the engine does not start at all.

- Increased fuel consumption - sometimes up to 15 liters per 10 km.

- Check Engine light on the dashboard.

However, the above signs do not always accurately indicate contamination of the air flow sensor. A variety of situations can arise, and among them is one when the sensor itself is fine, but the fault lies in the hose that connects the device to the module.

In other words, although there are many obvious signs that a particular part of the car is faulty, they can indicate any other problem.

Functionality check

Before diagnosing the mass air flow sensor, you need to know the symptoms that allow you to determine the degree of performance of the MAF (abbreviation for the English name of the device) sensor in the car. We list the main symptoms of a malfunction:

- The consumption of the fuel mixture has increased significantly, while at the same time acceleration has slowed down.

- The internal combustion engine idles with jerks. In this case, a decrease or increase in speed may be observed in idle mode.

- The engine does not start. Actually, this reason in itself does not mean that the flow meter in the car is faulty; there may be other reasons.

- A message appears about a problem with the engine (Cheeck Engine)

Example of the "Cheeck Engine" message displayed (marked in green)

These signs indicate a possible malfunction of the mass air flow sensor; in order to accurately determine the cause of the failure, diagnostics must be performed. It's easy to do it yourself. Connecting a diagnostic adapter to the ECU (if this option is possible) will help to significantly simplify the task, and then determine the serviceability or malfunction of the sensor using the error code. For example, error p0100 indicates a fault in the flow meter circuit.

What are they needed for

The fact is that in order to achieve certain environmental standards in cars, catalysts are installed that “afterburn” the exhaust gases. To control this process, the engine control unit needs two values - the oxygen content before and after the catalyst.

It compares these indicators and regulates the fuel supply in the air-fuel mixture. If you simply remove the catalytic converter and install a flame arrester in its place, the two sensors will read the same. Since nothing is burned anywhere, the exhaust gases wash the first and second lambda probes unchanged.

This will “drive” the engine ECU crazy. The “Check Engine” icon will appear on the dashboard, the engine will run unevenly, the dynamic properties of the car will decrease, and fuel consumption may increase. All this will negatively affect the operation of the power unit.

To avoid this, they came up with the idea of installing lambda decoys - physical plugs or electronic systems to simulate the correct operation of the oxygen sensor.

They create for the control unit the effect of the correct operation of the catalyst, although it is not in the exhaust system.

Features of the mechanism

Before answering the question whether it is possible to drive without a mass air flow sensor, it is necessary to understand the constituent features of the device. The device is located in the air intake duct, immediately behind the filter. The block from the channel network is responsible for connecting to the control unit. In some modern vehicles, a different connection technology is possible.

It would seem that the operation of the damper is simple. The gas pedal is pressed, opens, the required volume of air is drawn in, the damper closes and a smaller amount is admitted. But in practice things are different.

When driving a vehicle, the driver constantly changes the performance by pressing the gas pedal, therefore the engine does not function equally.

Whirls occur and air cannot enter in the same volume, making calculations difficult.

The mass air flow sensor differs in design. You can ride with anyone as long as it fits the car. Highlight:

- mechanical;

- ultrasonic;

- thermal-anemometric.

The latter are used only on domestic VAZ vehicles. There will be a penalty if you use other components.

The devices are multi-component, but there are no moving parts. This fact explains the stability of operation even in difficult weather conditions and a long service life. It is not possible to repair it; it is easier to purchase a new one. The sensitive element is a nickel mesh or platinum wire.

The characteristics depend on the manufacturing company. A wire that transmits an electric charge is connected to a small structural part. The element heats up above the air temperature, can reach 100 degrees Celsius.

For nickel units the maximum threshold is 75 degrees, and for platinum units - up to 100 degrees.

- scheme;

- frame;

- radiator;

- sensor;

- pipe branch;

- net.

A constant pulse of electricity is required in order to cool the elements affected by the air flow. Direct determination of the air entry rate, that is, its volumetric characteristics, is determined by the degree of how the required current indicators change.

Old-style mechanisms determine this by frequency pulses transmitted to the control panel. Modern equipment models set the required indicators for heating elements and sensors for increasing or decreasing temperature. The element is placed on a special thin film, which is tightly mounted.

Principle of operation

The operating principle is as follows:

- a device is visited at the center of the film that controls heating, its degree and characteristics;

- temperature sensors are connected to the main heating zone, that is, where average indicators are observed;

- two other thermal sensors are located on both sides of the film (one is hidden behind the film, and the second is located directly in the path of the air flow).

When the vehicle is in an inactive state, the sensor will not react in any way, since the temperature of all elements is the same. This is explained by the fact that the incoming flows cool the device, while the performance of the other two remains unchanged - they do not react without driver intervention.

When the movement begins, a rapid passage of air into the equipment is observed, the sensors begin to work. It is from the volume of intake air and the degree of supply of electric current, which is required to compensate for adequate values, that the temperature difference is calculated.

This characteristic determines how much consumable fuel is required and the fuel ratio.

Is it allowed to travel?

You can drive without a mass air flow sensor - yes, but you should carefully assess the situation. When devices fail, the driver does not always have a spare one with him in his emergency kit. Also, sensors for some types of cars are extremely difficult to find, especially when it comes to brands of foreign cars.

In the event of a planned or emergency shutdown of the device, the vehicle operates in emergency mode. Only the throttle valve is responsible for preparing the air-fuel mixture.

The state of affairs cannot be called correct, since it provides ideal performance indicators, quickly breaks down and leads to breakdown of the constitutive parts of the mechanism.

What will happen if you drive without a mass air flow sensor for a long time, it is clear that the car will become unusable.

https://www.youtube.com/watch?v=hUdxKt6hgiE

When operating in emergency mode, only the damper determines fuel consumption. There is high fuel consumption. There will be no fuel savings, which is extremely unprofitable in Russian realities. The crankshaft rotation speed will be at least half a thousand revolutions per minute. There are no gradations.

You can determine whether the sensor needs to be replaced yourself. To do this, the device is turned off and only the throttle valve reads the readings. If, in the absence of equipment, the vehicle moves quickly, then it is faulty and requires replacement.