As practice shows, replacing the cable connecting the clutch drive with the gearbox on a Lada Priora is very rarely required. It breaks quite infrequently. The most common problem with it is the threads; its components become frayed. For this reason, the clutch mechanism begins to jam regularly and the pedal eventually does not want to return to its place.

The replacement procedure is not particularly complicated, but it does require time and some effort. For work you will need the following tools and materials:

- a set of keys;

- flat screwdriver;

- cable clamp.

You can get to it in Priora only through the engine compartment. To do this, of course, you will need to open the hood. The cable itself is located next to the gearbox.

In what cases does an element need to be replaced:

- when broken;

- due to jamming;

- due to stretching;

- in case of failure of the mechanism regulating its length.

Do-it-yourself Lada Priora clutch cable replacement step-by-step instructions

We change the muffler on a VAZ-2112 with our own hands

. As practice shows, replacing the cable connecting the clutch drive with the gearbox on a Lada Priora is very rarely required. It breaks quite infrequently. The most common problem with it is the threads; its components become frayed. For this reason, the clutch mechanism begins to jam regularly and the pedal eventually does not want to return to its place.

The replacement procedure is not particularly complicated, but it does require time and some effort. For work you will need the following tools and materials:

- a set of keys;

- flat screwdriver;

- cable clamp.

You can get to it in Priora only through the engine compartment. To do this, of course, you will need to open the hood. The cable itself is located next to the gearbox.

In what cases does an element need to be replaced:

- when broken;

- due to jamming;

- due to stretching;

- in case of failure of the mechanism regulating its length.

Removal process

First of all, you will need to dismantle the air filter:

- remove the cable itself, using a leash to remove it from the fork of the drive that disengages the clutch;

- using 17 keys (2 pieces), partially unscrew the two nuts holding its shell on the gearbox crater bracket and pull it out;

- under the dashboard, located directly in the car interior, tighten the nut with an 8mm wrench from the pedal itself.

You just have to remember that getting to the place where the lower part of the cable is attached to the pedal will be quite difficult.

Access is hampered on one side by the engine compartment partition, and on the other by the lower edge of the instrument panel. The work space is significantly limited. But performing the required operation is quite simple - using a flat-head screwdriver that fits the length.

It will be much more difficult to remove the staple. To make it easier to operate, the pedal is raised as high as possible. Ideally, the bracket should appear above the opening. The main thing is to remove the fastening from the cable itself. In the future, it is easy to put on the bracket either using pliers with long lips, or from the side of the power unit with your hands.

Next you will need:

- remove the expansion tank of the engine cooling system;

- dismantle the thermal insulation of the engine on the left side;

- Unscrew the bolts and remove the fastening brackets holding the rubber boot in place (both on the left and on the right) and remove it completely;

- Using a screwdriver, carefully remove the retaining bracket from the fastening axis of the cable guide;

- the latter, in turn, is removed from the foot drive finger.

It is important not to lose the plastic sleeve installed there. Without it, the cable cannot be attached. If it becomes unusable, you need to put a new one on your finger.

If it becomes unusable, you need to put a new one on your finger.

Finally, all that remains is to pull out the mat holders (there are 2 of them). This must be done carefully, since they are plastic and break easily.

After this, you need to remove the rubber cover installed in the partition of the engine compartment and finally pull out the damaged cable.

How to install

Before installing a new cable, you need to thoroughly lubricate both the bushing and pin on the pedals. The plastic composition Litol-24 is best suited for this.

Then the end of the cable is threaded into a hole located in the bulkhead of the engine compartment on the passenger compartment side of the car so that it ends up in the engine compartment. The rubber cover is also tucked in there.

The gear tip driver is put directly onto the clutch drive pin and secured with a bracket.

The end of the shell is secured with a nut to the pedal bracket. Make sure that the fixation is secure. It is unlikely that anyone will like to, if something happens, climb there again due to a poor-quality connection.

Next, under the hood, the lower part of the shell is stuck into a special hole on the gearbox bracket.

The leash is screwed onto the end of the cable (there is a thread there) - the latter should protrude approximately one turn outward, but no more.

Now comes the time to adjust the clutch drive. Upon completion of this process, the pedal is pressed all the way two or three times and then the setting is repeated.

The working surface of the tip driver must be treated with the above-mentioned lubricant.

All that remains is to make sure that the entire mechanism is now working properly and install all previously removed parts in place.

You can learn more about the process in the video below:

Replacing the release bearing of Priora

In order to change the part, you will have to remove the gearbox. You can find detailed instructions for removing the gearbox here (link to page).

After removing the box, you need the following:

The first step to removing the bearing is to find the antennae of a special spring retainer. Next, we remove the two ends of the antennae from the bearing holder. To do this, you need to apply a little force and pull the antennae out of the two holes. Now the bearing together with the holder can be easily removed from the guide sleeve. In order to inspect or replace the part itself, you will need to remove it directly from the holder

To do this, use a flat-head screwdriver to press out the four metal tabs in several places on the case. Now the part can be removed and replaced with a new one. When installing a new bearing, pay attention to its visual condition (there should be no defects or cracks). After installation and lubrication, unscrew the part while checking its operation for any extraneous noise.

In addition, no noticeable backlash should be recorded. Reinstalling the gearbox.

Now you know how to change the release bearing on a Priora!

Important points

Please note that there are counterfeit auto parts on sale today. Please note that most new, original release valves contain light-colored factory-applied lubricant.

In addition to the above, we recommend that you purchase release levers that are made only of metal. In addition to the presence of a metal body, make sure that in the places of fastenings, the so-called lugs (clamps), the metal coating is of a uniform color without signs of hardening at high temperatures. Pay special attention to checking the part for the so-called backlash (should be absent or minimal). Rotate the product, listen to see if there is any noise when it rotates.

In order to choose a Priora clutch release bearing, you need to know what clutch system you have installed (which manufacturer). For example, Valeo also has its own, original bearings that are not interchangeable. And on the contrary, it guarantees full compatibility and correct operation with various clutch systems on Kalina and Priora cars. Plus, there are good reviews about the quality and long service life.

Replacing the clutch cable of a VAZ 2110

Replacing the clutch cable of a VAZ 2110 with your own hands

The other day, while changing gear, my clutch pedal suddenly dropped. My first thoughts were that either the clutch cable broke or the clutch cable came off the fork. I opened the hood, saw the broken clutch cable and sighed with relief. The fact is that failure of the clutch pedal does not always mean replacing the cable. It happens that the clutch fork breaks, then you need to remove the box and change the fork, and that costs 1000-2000 rubles just for the work.

Stupidly, I towed my car home when it was possible to drive without a clutch. I just didn’t know that you could start in first gear and start driving right away. In addition, you can change gears without a clutch; to do this, you need to shift the throttle at the moment of shifting.

The price of a VAZ 2110 clutch cable is approximately 220-280 rubles. In the store I ask jokingly that I need a clutch cable for a dozen that will never break! They answer me: change the car. I bought a clutch cable for a VAZ 2110 in Balakovo. Of all, he was the most expensive.

You can replace dozens of clutch cables in various ways:

- Remove the frill and the windshield wiper (to make it easier to get to the attachment of the cable end to the clutch pedal)

- Without removing the frill (method for those who are able to take the lotus position)

The standard instructions for replacing the VAZ 2110 clutch cable involve removing the frill and windshield wiper, but I decided to take the shortcut and not disassemble anything.

Replacing the VAZ 2110 clutch cable without removing the frill

We unscrew the clutch cable fastening using a 19 key. Next, you need to remove the cable tip from the clutch release fork, but since The cable was torn, so we didn’t have to remove anything. We move into the cabin and unscrew the nut securing the cable near the clutch pedal using a 8 key. Unhook the bracket securing the cable tip to the clutch pedal. To do this, you will need to raise the clutch pedal as much as possible and use a screwdriver to pick up the clip (if you removed the frill and the windshield wiper, then you need to remove the bracket in a more convenient way from under the hood). We pull out the clutch cable through the interior. I have some wires running in the channel along with the clutch cable, about which nothing is said in the replacement manual. Because of this, the cable didn’t want to go through, the large cable fastening washers in the engine compartment were in the way, I unscrewed them. We push the new clutch cable from the passenger compartment under the hood. We fasten everything in the reverse order. The most difficult moment here is to put back the bracket securing the cable tip to clutch pedals. The fact is that it is very difficult to get there, which is why the standard instructions recommend removing the frill and the windshield wiper. But I decided to replace the staple with my own clip, which I made from a regular paper clip. I carefully fastened my clip into the recess of the pedal mount and clamped it with pliers for reliability. If you wish, you can lubricate the clutch cable with engine or transmission oil, but it is better to use grease (such as a CV joint) so that it does not freeze in winter. However, lubricating such a cable inside the casing with thick lubricant is problematic.

In fact, replacing the VAZ 2110 clutch cable with your own hands is quite simple. I did this procedure for the first time. The replacement was carried out in the winter outside in the evening with a flashlight in hand. I spent 2 hours replacing the clutch cable. I spent most of my time in the pedal area when removing and installing the cable.

Adjusting the clutch pedal VAZ 2110

The clutch pedal travel (all the way to the mat) should be 125mm (+-5mm). The maximum permissible pedal stroke is 160 mm. To adjust the clutch, you need to unscrew or tighten nut No. 2, after completing the adjustment, tighten lock nut No. 1. Tighten the rubber washer as much as possible to the fork.

You can adjust the clutch so that the pedal is lower than the brake pedal, then it will grab almost immediately after the pedal leaves the floor. If you make the clutch pedal high (higher than the brake pedal), then when you lower the clutch it will grab almost at the very end. A pedal that is too high can accelerate wear on the basket.

Replace the clutch cable on the “ten” yourself..

Clutch adjustment on Lada Priora -

How to change the ignition switch on a Prior with an immobilizer

The main signs of a clutch malfunction are a decrease in travel and sticking of the clutch pedal, extraneous clicks, poor vehicle traction, or unclear gear shifting due to incomplete disengagement of the clutch. All these malfunctions indicate that periodic clutch adjustment is necessary. Priora, like all VAZ cars, needs such maintenance.

Video of clutch adjustment on Priora.

Components of domestically produced cars quickly become unusable, and many motorists of our cars have long become accustomed to this idea. In addition, it is worth taking into account your driving style, as well as the quality of the roads you most often drive on. However, the parts still do not last forever, and some of them have to be changed or the elements of the mechanisms must be adjusted. One of the “unreliable” and “capricious” elements of the Lada Priora car is the engine clutch mechanism with the gearbox. The main signs of a clutch malfunction are a decrease in travel and sticking of the clutch pedal, extraneous clicks, poor vehicle traction, or unclear gear shifting due to incomplete disengagement of the clutch. All these malfunctions indicate that periodic clutch adjustment is necessary. Priora, like all VAZ cars, needs such maintenance

It's no secret that it is important to have a working clutch on your car: safety and predictability on the roads depend on it. Incorrect cable tension will cause the pedal to dangle idle, and the device itself will experience increased wear on the friction linings of the driven disk due to additional friction on the crankshaft flywheel

The speed will decrease significantly due to the loss of torque; changing gears will also be problematic with a sticking pedal and the clutch not completely disengaged. Adjusting the mechanism may include either adjusting the clutch cable or completely replacing it along with the sensor and bushing. The following will be discussed below: How to adjust the clutch on a Priora by changing the gap from the cable to the adjusting screw.

Replacing the clutch cable.

The clutch device in the so-called loose state causes a number of problems: clicks and loosening of the pedal, insufficient coupling of the driven disk with the crankshaft flywheel and other troubles, as mentioned above. The work of adjusting the clutch on a Priora will not take much time, plus it is quite simple, and every car enthusiast can do it in his own garage. We drive the car into the pit. To prevent it from dangling back and forth, we fix it with wheel chocks. We open the hood of the car, look at the space to the left of the battery, where the clutch fork along with the cable is located. It is this cable that needs to be adjusted. Using a regular ruler, you need to measure the distance from the base of the clutch cable to the adjusting screw. For the machine in question, this segment should be equal to 27 mm. The main condition that must be met is 100% measurement accuracy. Deviations up or down (25 or 28 mm) will not lead to positive results. So, the cable is put back into the clutch release fork, then the clutch pedal is depressed several times. It’s better to work with a partner, this way things will go much faster. If the pedal continues to click, the adjustment can be made again. The main thing you should achieve is that the pedal moves smoothly, without sticking or clicking. However, it is not always possible to correct the situation with the clutch only by adjusting the cable. If there is a break in the spare part or there is a tight action in the casing, then it is necessary to replace the clutch cable and, if necessary, other components of the mechanism.

Level control and topping up

Replacing the VAZ 2114 clutch with your own hands

To diagnose the fluid level you will need a white napkin:

- Start the car engine and drive for 10 minutes, this will allow the transmission to warm up.

- Checking the level is carried out on a flat surface. Stop the engine and wait about ten minutes until the transmission fluid drains into the pan.

- Open the hood and locate the dipstick to check the level. It is located on the right side of the engine compartment.

- Wipe the dipstick with a napkin and reinstall it in the hole, then remove it. If the fluid level is normal, it will be located between the two marks on the dipstick.

The service station channel in Simferopol published a video demonstrating the procedure for changing the lubricant in a Solaris automatic transmission.

Removal process

First of all, you will need to dismantle the air filter:

- remove the cable itself, using a leash to remove it from the fork of the drive that disengages the clutch;

- using 17 keys (2 pieces), partially unscrew the two nuts holding its shell on the gearbox crater bracket and pull it out;

- under the dashboard, located directly in the car interior, tighten the nut with an 8mm wrench from the pedal itself.

Access is hampered on one side by the engine compartment partition, and on the other by the lower edge of the instrument panel. The work space is significantly limited. But performing the required operation is quite simple - using a flat-head screwdriver that fits the length.

It will be much more difficult to remove the staple. To make it easier to operate, the pedal is raised as high as possible. Ideally, the bracket should appear above the opening. The main thing is to remove the fastening from the cable itself. In the future, it is easy to put on the bracket either using pliers with long lips, or from the side of the power unit with your hands.

Next you will need:

- remove the expansion tank of the engine cooling system;

- dismantle the thermal insulation of the engine on the left side;

- Unscrew the bolts and remove the fastening brackets holding the rubber boot in place (both on the left and on the right) and remove it completely;

- Using a screwdriver, carefully remove the retaining bracket from the fastening axis of the cable guide;

- the latter, in turn, is removed from the foot drive finger.

It is important not to lose the plastic sleeve installed there. Without it, the cable cannot be attached

If it becomes unusable, you need to put a new one on your finger.

Finally, all that remains is to pull out the mat holders (there are 2 of them). This must be done carefully, since they are plastic and break easily.

After this, you need to remove the rubber cover installed in the partition of the engine compartment and finally pull out the damaged cable.

Adjustment instructions

The Lada Priora is equipped with a clutch cable with a ratcheting mechanism. The cable is backlash-free and does not require adjustment, but manufacturers recommend this be done during every maintenance.

Clutch cable

To adjust the cable on the Lada Priora, you need to prepare a screwdriver and a ruler. The procedure then consists of the following steps:

- To perform work, you must open the hood.

- First you should disconnect the mass air flow sensor and.

- After this, a cable will be visible, at the end of which there is a plastic clip.

- Before adjustment, it is necessary to set the cable to its original position: overcoming the resistance of the spring, push the cable clamp forward until it stops in the direction of movement of the car.

- This clamp should be pulled towards you and the distance between it and the plug should be measured, it should be 27 mm.

- The distance is adjusted by turning the tip counterclockwise. In this way, an increase in distance can be achieved.

- Twist the clamp until the distance is 27 mm. Accuracy is very important here.

- Now you can release the cable and place it in the fork.

- After completing the steps, you need to get behind the wheel and press the pedal three times until it stops.

- Then again you need to measure the distance, it must be exactly 27 mm, otherwise we adjust until the desired distance is achieved.

- Next, you should insert the tip into the groove of the mechanism fork and release it. Thanks to the spring, the tip driver clamp is installed without any gap.

- After adjusting the cable, you need to return everything to its place, start the engine and check the operation of the mechanism.

After adjustment, the clicks disappear and the clutch release pedal operates softer.

Clutch pedals

When the clutch pedal travel is large, the clutch is not completely disengaged, so it still comes into contact with the flywheel of the power unit. When the stroke is low, the driven disk does not turn on completely, which leads to slipping and loss of torque.

You should measure your pedal stroke if the following symptoms occur:

- jerks appear when starting to move;

- noise and shock when shifting gears;

- the pedal gets stuck.

The symptoms described indicate that the mechanism requires adjustment. You can diagnose its operation on Priora yourself. To do this, start the engine, slowly release the PS and start moving. If, when the PS is released, the car immediately begins to move, this means that there is no free play. If the car does not budge even with the pedal fully released, then its travel exceeds the norm. The brake pedal should be at the same level as the brake pedal. In this case, its full stroke will be in the range of 125-135 mm. Fluctuations up to 160 mm are possible.

We measure the free play of the pedal

When making adjustments, loosen the first cable adjusting locknut located in the engine compartment on the bracket.

Locknuts for adjusting free play

By tightening the second locknut, the distance and stroke of the PS are adjusted. Thus, the desired result is achieved. After completing the procedure, the first locknut is tightened.

If you adjust so that the brake pedal is located above the brake pedal, then the clutch will barely leave the floor. If it’s lower, it will set almost at the very end. If the PS is located too high, the basket wears out faster. The ideal option is that the brake and clutch pedals should be at the same level.

Loading …

In order to extend the life of any mechanism, you should use it carefully. You should not constantly keep your foot on the PS; it is better to place it on the left on the floor. During each technical inspection of the Lada Priora, it is recommended to monitor the free movement of the PS and the clarity of gear shifting and, if necessary, make adjustments.

Features of clutch adjustment

Vehicles Lada Priora, Kalina and Granta are equipped with clutch cables equipped with ratcheting devices. By their design, the cables are backlash-free, so their adjustment is theoretically not necessary, but in fact, the manufacturer recommends that car owners periodically adjust the device.

To correctly adjust the cable on Lada Kalina, Priora and Granta cars, prepare a screwdriver and a ruler (or caliper) and follow these steps:

First you need to open the hood, after which the cable should be installed in its original position. To do this, you need to move the lower part of the cable a little forward, that is, in the direction of its movement, this must be done until it stops. When moving the cable, you may feel a slight force on the return spring; this should not scare you.

Next, using a ruler or caliper, you should measure the distance. Which one is shown in the photo, you need to mark the distance from the beginning of the fork to the cable lead. To do this correctly, you must also hold the cable and fix it in one position. Take a measurement, ideally it should be 2.7 cm, but of course, if you are faced with the need to adjust on a Lada Priora, Kalina or Grant, then this distance will be either larger or smaller. Therefore, you should bring it to the required parameter; to do this, you need to rotate the cable lead in one direction or the other.

After these steps, you will need to insert the tip of the cable into the groove of the fork, then the element itself can be released

Please note that there should be no gap at all.

In general, the cable adjustment procedure is completed. Now you only need to press the pedal a few times to make sure everything is working properly

After several presses, measure the distance on the cable again; if necessary, adjust the device again.

No matter how new the clutch is, the owners of Lad Prior, Grant and Kalin periodically need to make adjustments to the pedals.

The need for adjustment may occur when:

- constant jerking when starting to move;

- the appearance of shocks when trying to turn on one or another speed;

- sinking of the pedal itself.

These symptoms indicate that the pedal needs to be adjusted correctly. Ideally, the clutch pedal should be located at the same level as the brake - then the full stroke should be about 12.5-13.5 cm, but in practice this figure can be increased to 16 cm. To correctly adjust the pedal, prepare two wrenches of the appropriate sizes.

- Using a wrench, loosen the cable lock nut, which is installed in the engine compartment.

- Next, you need to use another wrench to start tightening the second locknut, so you can correctly set the required gap. When the process is complete, the first locknut should be tightened until it stops.

Please note that if you set the pedal so that it is lower than the brake, then the grabbing will appear when the pedal just leaves the floor. Accordingly, if the brake pedal is lower, then the clutch will occur almost at the end. Ideally, these two pedals should be located at the same level (video by Time R).

DIY replacement instructions

How to replace an oxygen sensor:

- The car is driven into a pit, the engine protection is dismantled.

- Locate the wiring from the regulator so you can get to the device.

- Next, the clamp is cut and the plugs are disconnected. Wait a few minutes for the motor to cool down.

- Using a 22mm wrench, the regulator is unscrewed.

- The new controller is installed in place of the old one, the assembly steps are repeated, only in the reverse order.

Price issue

The cost of the device depends on the manufacturer. On average, prices for oxygen sensors range from 1300 to 2600 rubles.

What is an oxygen sensor, or as it is also called a lambda probe, can be found out in the article. This publication will discuss how to replace this sensor if it breaks down on a car. The technological process is not particularly difficult, so even the most ordinary car owner can dismantle and subsequently install the DC on his car.

Replacement algorithm

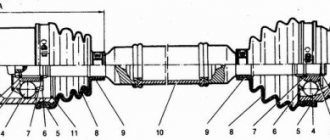

Location of the clutch cable under the hood.

- Open the hood and remove the air filter housing. To do this, remove the sensor (mass air flow sensor), unscrew the clamp and remove the housing itself from the mounting holes.

Scheme for dismantling the air filter housing.

We use a key set to 17. Spray with WD-40 if it’s difficult.

We carefully pick up this bracket with a screwdriver.

Installing the cable is not all because you need to adjust its tension. To do this, you need to pull the cable all the way forward by the threaded end. Taking a caliper, measure the distance from the clutch release lever to the cable. It should be 27 mm .

Next, we assemble everything in reverse order.

How to know when it's time to change the cable

The following signs indicate the need to replace the clutch cable:

- Clicking sounds appear when you press the clutch pedal. They can be eliminated by tightening the cable. If such manipulations do not help, the part will have to be replaced.

- Periodic pedal jamming .

You should not delay replacing the cable, because it can break at the most inopportune moment. In such a situation, you can engage first gear and start from the starter. The car will roll forward with the starter and start, you will have first gear to get to the service station or parking lot! But this is dangerous and we do not recommend doing this. Moreover, this can be bad for the starter.

Source

How to Identify Incorrect Clutch Adjustment

As drivers say, the clutch can be in two wrong positions.

- Weak.

- Overstretched.

What does it mean? When the clutch is “weak”, it means that the release bearing is not fully pressing on the “petals” of the drive plate. This means that separating them is difficult. Accordingly, an unpleasant grinding sound of the box will sound. It will become very difficult to shift into gear. There is a risk of the gearbox shaft gears breaking. When the clutch is tightened, the picture is somewhat different, the gear engages perfectly, no difficulties arise. But! Under heavy loads, the disks begin to “slip.” That is, the engine roars with all its might, but the car does not pick up the required speed. There is a smell of burnt friction material. This means that the cable is too tight and the adhesion between the discs is broken.

Attention! Both options for incorrect adjustment lead to breakdowns and costly repairs later. Therefore, at the slightest sign of a violation, it is necessary to properly regulate the clutch drive.

How to install

Before installing a new cable, you need to thoroughly lubricate both the bushing and pin on the pedals. The plastic composition Litol-24 is best suited for this.

Then the end of the cable is threaded into a hole located in the bulkhead of the engine compartment on the passenger compartment side of the car so that it ends up in the engine compartment. The rubber cover is also tucked in there.

The gear tip driver is put directly onto the clutch drive pin and secured with a bracket.

The end of the shell is secured with a nut to the pedal bracket. Make sure that the fixation is secure. It is unlikely that anyone will like to, if something happens, climb there again due to a poor-quality connection.

Next, under the hood, the lower part of the shell is stuck into a special hole on the gearbox bracket.

The leash is screwed onto the end of the cable (there is a thread there) - the latter should protrude approximately one turn outward, but no more.

Now comes the time to adjust the clutch drive. Upon completion of this process, the pedal is pressed all the way two or three times and then the setting is repeated.

The working surface of the tip driver must be treated with the above-mentioned lubricant.

All that remains is to make sure that the entire mechanism is now working properly and install all previously removed parts in place.

You can learn more about the process in the video below:

Removal, replacement, installation of the crankshaft and its bearings

Symptoms: the clutch pedal has moved to its lowest position, the free play of the clutch pedal has increased.

Possible cause: Clutch drive cable is damaged.

Tools: socket set, wrench set, flat screwdriver, solid oil.

1. In the car interior, under the dashboard, unscrew the fastening nut of the clutch cable support to the pedal bracket using an 8-mm wrench. Remove the stop from the bracket.

2. Disconnect the locking bracket and the housing of the driven disc lining wear compensation mechanism from the clutch pedal pin (use a screwdriver).

3. Remove the plastic bushing from the pedal pin. Inspect the bushing for wear and, if present, replace the bushing after applying grease to it.

4. Remove the clutch release cable seal from the hole in the front panel (in the engine compartment of the car).

5. Pull the tip of the cable in the direction of straight-line movement of the car, and then remove it from the groove located on the clutch release fork.

6. Unscrew the fastening nut of the cable end to the bracket on the gearbox using a 17mm wrench. Prevent the cable end from turning by holding it with a second wrench.

7. Remove the cable end from the slot in the bracket, and then pull the cable out of the hole in the front panel.

8. Remove the clutch cable from the vehicle.

9. To install a new clutch drive cable, first pass it through the hole in the front panel, and then fasten the housing of the driven disc lining wear compensation mechanism to the clutch pedal pin.

Note. Before installing the wear compensation mechanism on the clutch pedal pin, lubricate the pin bushing with grease.

10. Fix the cable sheath stop on the pedal bracket.

11. Install the sealing element of the clutch cable sheath into the slot in the front panel.

12. Install the cable end into the gearbox bracket, and then tighten the cable nut.

13. Screw the driver onto the lower tip of the clutch drive cable so that the tip protrudes relative to the driver end to a height of 0 - 1 mm.

14. Install the clutch release cable to its original position as follows:

– move the lower tip of the drive cable all the way forward in the direction of straight-line movement of the vehicle;

– hold the tip in an extended position;

– measure dimension L (the distance between the clutch release fork and the driver). The distance L should be 27 millimeters;

– if the permissible value does not correspond, set it by rotating the leash in the desired direction.

15. Insert the end of the drive cable into the groove located on the clutch release fork, and then release it. The leash must be installed on the fork without play under the action of a spring.

Note. Before installing the tip guide on the clutch release fork, lubricate its surface that contacts the fork with grease.

16. Depress the clutch pedal all the way three times, then measure distance L again (see point 14).

17. Repeat the adjustment if necessary.

It wouldn't hurt to know

What do most owners of new Lada Priora do? Naturally, they treat the body with Movil or something similar against corrosion; they don’t have any more problems at the initial level. However, there were complaints about squeaking when pressing the clutch pedal; sometimes it was present when the engine was warm, sometimes only when it was cold - the essence is that there is a problem.

Of course, everyone immediately starts reading the “primer book” on how to correctly adjust the clutch on their Priora, which sometimes helps, but the fact of the matter is that sometimes. After this, owners can try several more methods, after which the squeak may disappear:

- Replace the drive cable, some drivers praise the “tenth”.

- Check the presence of a spring in the automatic tension mechanism; sometimes the effect can be achieved after replacing the standard part with a spring with greater elasticity.

- A certain percentage of car enthusiasts get rid of the crackling noise by lubricating the fork and the plastic cable nut.

- Lubricate the installation site of the plastic bushing on the pedal bracket with lithol.

- Remove the boot from the fork lever and lubricate the gearbox input shaft with graphite grease from a can.

It is worth considering another effective method, shown in the video, which is used by experienced car enthusiasts. Its essence is as follows:

- Disconnect the mass air flow sensor and remove the air filter.

- Remove the clutch release rod plug.

- Release the cable from the clutch fork.

- Pour 30-40 ml of gear oil from a syringe.

- Move the fork back and forth 10-15 times.

- Reinstall the cable, plugs and filter.

Using the example of the second part of the article, it becomes clear that adjusting the clutch drive does not always bring the desired effect in the fight for acoustic comfort. Although, from a technical point of view, the procedure is necessary, since it ensures productive operation of the car.

Good day everyone.

Like many, I was somewhat annoyed by the creaking, clicking clutch pedal. The solution I saw was to install a spring in the tip of the clutch cable, it seems like it was installed on Priors from the factory.

In general, it’s not difficult to take and install a spring - the method has long been known and there are many posts about eliminating it, but I’ll write what difficulties I personally encountered (handedness was pumped up to lvl 80).

Mechanics

Mechanically, the clutch operation process is extremely simple. Let's analyze it from the moment the movement begins. After starting the engine, the car is in neutral gear (starting the engine in gear is bad manners). The clutch is depressed all the way - this means that it is turned off, the driven and pressure plates have separated, that is, a moment is created to change gear. The gearshift lever is moved to position 1, and first gear is engaged.

The pedal is smoothly released (the clutch is engaged), at this moment the most important thing happens: the distance between the pressure plate and the driven one is constantly decreasing, and the force transmitted by the engine has already set one disk in motion, which makes the moment of “collision” of the two disks become difficult. If the pedal is released abruptly, they will quickly touch, which means that the disc will stop (imagine that you are walking and tripping on a stone - much the same thing happens to the engine)

The engine may stall, or in the best case, the car will simply “bite.” At such moments, the “petals” on the driven disk suffer greatly - the more “flattened” they become, the closer the time for replacing the “hitch” is. If the discs come into contact smoothly and the driven disc is slowly set in motion, the car starts from a standstill.

Replacing the clutch cable on a VAZ 2110

In most cases, a breakdown of a manual transmission on a “ten” is not associated with any serious problems in the box itself. The most frequently broken component in a tens manual transmission is the clutch cable, which can be replaced on your own. Therefore, next we will talk about how to properly replace the clutch cable (see the video “How to remove and adjust the clutch cable on a VAZ 2110, 2111, 2112” below).

Why does the clutch pedal fail?

On a “ten” that has a solid mileage, the clutch pedal often begins to fail, and there may be two reasons for this:

- Broken clutch cable;

- Malfunction of the clutch fork.

Clutch cable rupture on a VAZ-2110 occurs when the vehicle is not used properly for a long time, for example, in extreme conditions. This part cannot be repaired, and therefore it is simply replaced. How to open the hood if the cable is broken? At the same time, even if the clutch cable breaks, you can get to the desired location without towing. To do this, you need to set the first gear, start the car and start driving. The transition from one gear to another, in this case, occurs when the gear is set to neutral. Having reached the desired location, it will be possible to replace the clutch cable without removing the gearbox.

If the clutch fork malfunctions, then dismantling the manual transmission will be required.

Clutch cable replacement process

Even an inexperienced car enthusiast can replace the clutch cable on a “ten”. However, if you carefully study the repair manual that came with the car, there is a clear indication that you should first dismantle the windshield wiper and remove the panel under the wipers (the so-called frill). Once these parts are removed, you can proceed to the clutch cable replacement procedure.

DISASSEMBLY OF A BROKEN ROPE

- Using two 19mm wrenches, the broken cable is removed from the bracket located on the gearbox by unscrewing the nut holding it;

- After the cable tension is loosened, it is pulled out of the fastening;

- Fix the clutch fork with one hand, and pull out the cable with the other.

UNLOCK THE CABLE FROM THE CLUTCH PEDAL

If the panel under the wipers and the windshield wiper were removed in advance, then further removal of the cable will occur only in the engine compartment. This is due to the fact that access to the casing protecting the clutch pedal is open. This casing is located next to the hydraulic brake booster.

- We unscrew, using a Phillips screwdriver, the fastening screws of the casing, and dismantle it;

- Using the same screwdriver, you need to hook and pull out the locking bracket that secures the cable head to the pedal bushing;

- We dismantle the cable.

If the panel under the wipers and the windshield wiper were not previously removed, the retaining bracket will have to be removed directly from the car interior, and not from the engine compartment. This work is very inconvenient, but, nevertheless, it is done like this:

- Raise the clutch pedal to the highest point of its trajectory, after which the bracket is dismantled, and then the cable itself;

- Using the “8” key, twist the support plate and pull the cable into the car interior.

INSTALLING A NEW CLUTCH CABLE

- Dismantle the bushing located on the clutch pedal pin - the old cable was put on it (if the bushing is very worn, it should be replaced);

- Using lithol, lubricate the cable guide and clutch pedal pin;

- The end of the clutch cable is threaded from the car interior into the engine compartment;

- Attach the cable to the pedal;

- Hook the cable and clutch fork;

- Secure the cable in the bracket on the gearbox.

How to adjust the clutch cable

After the clutch cable has been replaced on a VAZ 2110, it is necessary to adjust it. The point of this procedure is to set the correct pedal stroke. The free play of the pedal, which is measured by the distance from the floor of the car to its top point, should be in the range of 12.5 - 13 cm. If such measurements are not very convenient, then it is recommended to simply adjust the clutch pedal so that it is level with the other pedals.

- Slightly unscrew the nuts securing the cable (they are located on the gearbox bracket);

- Using adjusting nuts, adjust the location of the cable tip, fixing it and checking the trajectory and position of the clutch pedal;

- After the pedal is adjusted, tighten the fastening nuts.

At this point, all adjustment steps required after replacing the clutch cable are completed.

Video: How to remove and adjust the clutch cable on a VAZ 2110, 2111, 2112

How to check the clutch on a car

For detailed diagnostics of clutch system elements, additional equipment and often their dismantling are required. However, before moving on to these complex procedures, you can simply and quite effectively check the clutch and make sure that it has failed or not without removing the box. four simple ways to do this .

Check at 4 speed

For cars with a manual transmission, there is one simple method by which you can verify that the manual transmission clutch has partially failed. The readings from the car's standard speedometer and tachometer located on the dashboard are sufficient.

Before checking, you need to find a flat section of the road with a smooth surface about one kilometer long. You will need to drive along it by car. The algorithm for checking whether the clutch is slipping is as follows:

- accelerate the car to fourth gear and a speed of about 60 km/h;

- then stop accelerating, take your foot off the gas pedal and let the car slow down;

- when the car starts to “choke”, or at a speed of approximately 40 km/h, sharply give the gas;

- During acceleration, you must carefully monitor the speedometer and tachometer readings.

If the clutch is working properly, the arrows of the two indicated instruments will move to the right synchronously. That is, with an increase in engine speed, the speed of the car will also increase, inertia will be minimal and is determined only by the technical characteristics of the engine (its power and the weight of the car).

If the clutch discs are significantly worn , then at the moment you press the gas pedal there will be a sharp increase in engine speed and power, which, however, will not be transmitted to the wheels. This means that the speed will increase very slowly. This will be expressed in the fact that the speedometer and tachometer needles do not move to the right synchronously . In addition, at the moment of a sharp increase in engine speed, a whistle will be heard .

Checking the handbrake

The presented test method can only be performed if the hand (parking) brake is properly adjusted. It should be well adjusted and clearly fix the rear wheels. The algorithm for checking the clutch condition will be as follows:

- set the car to the handbrake;

- start the engine;

- press the clutch pedal and engage third or fourth gear;

- try to start, that is, press the gas pedal and release the clutch pedal.

If at the same time the engine jerks and stalls, then everything is in order with the clutch. If the engine runs, then the clutch discs are worn out. The disks cannot be restored and either adjustment of their position or complete replacement of the entire set is necessary.

External signs

The serviceability of the clutch can also be indirectly judged simply when the car is moving, in particular uphill or under load. If the clutch slips, then there is a high probability of a burning smell in the cabin , which will come from the clutch basket. Another indirect sign is the loss of dynamic characteristics of the car during acceleration and/or when driving uphill.

The clutch "drives"

As stated above, the expression “drives” means that the driving and driven clutch discs do not move completely apart when the pedal is depressed. As a rule, this is accompanied by problems when engaging/shifting gears in a manual transmission. At the same time, unpleasant creaking and grinding sounds are heard from the gearbox. The clutch check in this case will be performed according to the following algorithm:

- start the engine and let it idle;

- fully depress the clutch pedal;

- engage first gear.

If the gear lever is installed in the appropriate seat without any problems, the procedure does not take much effort and is not accompanied by a grinding noise - this means that the clutch does not “drive”. Otherwise, a situation occurs when the disc does not disengage from the flywheel, which leads to the problems described above. Please note that such a breakdown can lead to complete failure of not only the clutch, but also lead to a malfunction of the gearbox. The described breakdown can be eliminated by bleeding the hydraulics or adjusting the clutch pedal.

Source

Why do you need a clutch cable and when to change it?

Thanks to the clutch, torque is transmitted from the transmission to the power unit. The gearbox is connected to the engine by a vehicle, which is a metal cable. It is with the help of the vehicle that the car starts, gears are changed and braking is carried out. Thanks to this lever mechanism, the car moves.

Lada Kalina is equipped with a ratcheting mechanism, thanks to which the length of the cable is adjusted. During clutch operation, the friction linings of the disc are constantly worn out, and the tension of the vehicle changes. The tension is adjusted using a ratchet mechanism.

In theory, the ratchet mechanism works as follows:

- due to the tension of the cable, the clutch release fork (VVS) rotates, causing the spring to compress;

- when compressed, the spring causes compression of the clamps located on the tip of the vehicle;

- Thus, the tip is released, the vehicle is tensioned.

In reality, drivers often have to make frequent manual adjustments.

Clutch cable and adjustment mechanism

Signs that your vehicle needs adjustment or replacement:

- the appearance of extraneous sounds when the clutch is disengaged;

- gears shift poorly;

- insufficient traction;

- the clutch does not disengage completely;

- The clutch pedal (PS) has failed.

Before you start adjusting the vehicle on the Lada Kalina, you should check its condition. The vehicle requires replacement if it is rusty, torn or has any damage. To check the condition of the vehicle, it is necessary to remove the air filter.

Automatic tension cable

The design of the clutch cable with automatic tension differs from the usual one only in the tip attached to the pedal. Otherwise, the entire structure remains unchanged. Installation of a tip with auto tension first appeared in 2007 on the Lada Priora. Subsequently, such a cable was borrowed by Niva, Grant, Kalina and Vesta cars.

The principle of operation of such a tip is based on a ratcheting mechanism; over time, when the cable is stretched, the spring of the tip automatically jumps over the “tooth” on the ratchet mechanism, thereby producing tension.

This design principle allows the car owner not to resort to adjustments for a very long time.

The cost of the cable in stores starts from 400 rubles and above, depending on the manufacturer and store.

Flaws

The main disadvantage of the cable is the increased noise level. According to reviews from owners of cars with an automatic clutch tension adjustment mechanism, the cable can make cracking and grinding noises when pressing the pedal.

Correctly adjusting the cable or replacing it with a new one will help get rid of this symptom.

About working on the clutch cable on LADA Priora

Initially, on domestic passenger VAZs with a rear-wheel drive system, the clutch was engaged thanks to an ordinary hydraulic system. The principle is exactly the same as that of the brake drive: all the pressure from the main cylinder is supplied to the so-called working cylinder. Only modern cars, such as, for example, the Lada Priora we are considering, received a front-wheel drive system; the specialists of the automobile manufacturer abandoned this principle of operation of the device in question, which greatly facilitated maintenance. The company has developed a reliable and very simple system for engaging a car clutch using a cable, now it is the main one in the entire system. The principle of the rocker arm, so to speak, is applied here, that is, when pressing the lower part of the corresponding pedal while sitting in the car, its working part, located at the top, passing through the rod (the so-called base), certainly begins to go in a completely different direction, plus everything else at this time she pulls the cable straight and, of course, behind her.

The second end of the cable is located on the drive fork of the clutch system. When the pedal is pressed, the clutch is released, thus directly enabling shift/on. transfer.

How to adjust the Priora clutch: removing clicks

To adjust the clutch, when clicks are constantly heard while driving, you need to use a seemingly simple object - an ordinary ruler. Mostly the clicks come from the clutch control unit. To prevent this you need to do the following:

- open the car hood;

- inspect the area to the left of the battery;

- to inspect it, you need to pull it out of the plug;

- using a regular ruler, you need to measure the distance between the base and the adjustable screw;

- the distance must be 27 mm, if more or less, the clicking will continue.

↑ Route planning

In the CityGuide system, the route is built to the final destination, with the ability to add intermediate stop addresses. To get directions, you first need to select the map you need. You can enter your destination in several ways:

- through the search string;

- by specifying the address;

- from the POI menu;

- in history;

- from saved points to favorites.

- indicate a location on the map by touching the device screen;

- select a route from those previously saved in the navigator’s memory.

The choice of the finishing point is a signal for constructing a route. After completing the work, the system displays the result on the screen, visualizing the path and hints. Navigation of the Lada Vesta car provides for the construction of two types of routes: the shortest and the optimal. The construction of the optimal route is carried out for optimization reasons, taking into account distance, speed limits, class of roads and the possibility of avoiding potential traffic jams. You can set the route type in the navigation menu. If along the way there is a need to deviate from the specified trajectory, the route is automatically rebuilt.

Replacing the clutch cable "Priors"

To remove and install this element of the clutch drive, you need a small set of tools:

- mount;

- screwdriver;

- pliers;

- wrenches 8 and 17.

The operation of dismantling the drive begins from the Priora interior. It takes two people to do this.

One presses the clutch fork, and the second removes the core mounting bracket from the pedal. Of course, you can do it alone, but it’s more difficult. Then, using a size 8 wrench, unscrew the housing fastening near the pedal. Using a screwdriver, carefully push the hole seal into the engine compartment and remove the cable there.

Now work under the hood of the Priora. First of all, disconnect the battery terminal, since you will have to work near the starter wire. Then remove the air filter. This will provide free access to the mechanism fasteners. Now that he has left the interior area, release the shell lock with the key 17. When the core is loosened, the tip is freely removed from the socket in the clutch engagement fork. Remove the casing from the groove, and the entire drive is free. It can be changed.

How does an automatic cable tensioner work?

In the release drive on the VAZ 2170, there are no gaps as a concept, hence the name - backlash-free clutch. The ratchet mechanism serves to compensate for the working length of the cable as the driven disk linings wear out

To understand the process, it is important to accept the following data:

- During operation, the driven disk wears out and its linings become thinner - as a result, the release bearing and basket springs shift towards the gearbox.

- Accordingly, the fork at the place where the cable is attached moves towards the radiator.

- The spring located on the bushing of the adjusting mechanism is compressed at this time and tightens the clamps of the cable tip.

- As a result, the tip is pulled out of the driver, due to which the wear of the disc linings is compensated.

For those who don’t yet know how to adjust the clutch on a Priora themselves, it is important to take into account the moment when the linings are new. In this case, when releasing the pedal, the ratchet bushing will only lightly touch the bracket without releasing the clamps

Therefore, the toothed tip of the cable will not move relative to the housing.

How to install

Then the end of the cable is threaded into a hole located in the bulkhead of the engine compartment on the passenger compartment side of the car so that it ends up in the engine compartment. The rubber cover is also tucked in there.

The gear tip driver is put directly onto the clutch drive pin and secured with a bracket.

The end of the shell is secured with a nut to the pedal bracket. Make sure that the fixation is secure. It is unlikely that anyone will like to, if something happens, climb there again due to a poor-quality connection.

Next, under the hood, the lower part of the shell is stuck into a special hole on the gearbox bracket.

The leash is screwed onto the end of the cable (there is a thread there) - the latter should protrude approximately one turn outward, but no more.

Now comes the time to adjust the clutch drive. Upon completion of this process, the pedal is pressed all the way two or three times and then the setting is repeated.

The working surface of the tip driver must be treated with the above-mentioned lubricant.

All that remains is to make sure that the entire mechanism is now working properly and install all previously removed parts in place.

You can learn more about the process in the video below: