Front-wheel drive and CV joint

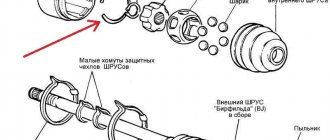

What is a CV joint? This is a kind of hinge, which is responsible for equal angular velocities. The VAZ CV joint, or as this part of the grenade is called, serves to transmit torque directly to the wheels of the car. The design of this part, although responsible for important running parameters, is a fairly simple design. Thus, a car grenade consists only of a ball-type bearing, rotating not along its axis, as is customary, but across it.

Note. In other words, a hinge or grenade connects axle shafts that are at an angle to each other. At the same time, we should not forget that this angle is constantly changing, and the grenade or CV joint is the part that normalizes all this.

The principle of operation of the grenade is as follows: the hinge allows the drive front wheel to make turns in different directions without difficulty. And it is noteworthy that the design of all grenade joints in different cars, including the VAZ 2110, is the same.

Design Features

It is worth noting that although all grenades are the same in design, their sizes may be different. In particular, you should know that in the same car, two grenades of different sizes are intended for each wheel. These hinges are as follows:

- an internal joint that transmits rotation from the gearbox gear to the shaft;

- an external joint designed to transmit rotation from the shaft to the hub.

Since the CV joint is a hinge, it is not surprising that its design must have independent elements, simply called balls. It is they who transmit the rotational motion from the leading to the driven part.

Note. There are as many as six balls in a grenade. They don’t sit in the CV joint just like that, but are placed in a special holder. The clip itself is located between the body and the inner cage. It seems to sit on a driven shaft, which is a bowl.

Replacing the external grenade of a VAZ 2110

The body itself and the holder are equipped with special grooves, which allows the balls to move along them. As for the joints of the structure, it is reliably protected by a boot, which is a rubber elastic cap.

Determination of CV joint failure and causes of failure

Faulty grenade VAZ 2110

Before starting the process of replacing a grenade, it is recommended to determine which grenade needs replacement. Simply feeling the shaft play on the overpass is an accessible method for determining the malfunction of a particular grenade. As a rule, a working grenade should not create any play at all.

Note. It is worth noting that a faulty grenade does not necessarily occur on older cars. This situation is often observed when the CV joint fails on a car that has recently left the assembly line.

What are the main reasons why a grenade fails? Here they are, listed below:

- the quality of the grenade, which can be low or high (often a fake is sold instead of the original part or a defect is established);

- lubricant that is either completely absent or available in insufficient quantities;

- failure of the boot (see How to replace the boot on a vase), which leads to damage to the grenade (the boot is protection and if it is missing, various abrasive debris and water get into the grenade mechanism);

- incorrect driving style (aggressive driving style);

- poor condition of roads (especially important here in Russia).

So, you can determine the malfunction of the CV joint yourself, as mentioned above, by detecting play in the shaft. In addition, the malfunction of a grenade, like any other part or mechanism of a car, is caused by a change in properties, dimensions, formation of a hole, etc. As mentioned above, the grenade is a hinge, the structure of which contains elements that rub and are under constant load. If the CV joint is a kind of bearing, then its races must have transverse grooves. This is what allows you to change the angle between the drive and driven axle shafts. Since the grenade, forcing the car to move, transfers significant force to the wheels, over time it loses its performance and wear is formed on the part. It also increases the gap. And where there is no close contact between mechanisms and parts, knocking, noise, etc. occur.

Torn boot on a VAZ 2110 grenade

The appearance of a characteristic crunch when turning the wheels is the main sign of failure of the grenade, which most experienced drivers know about. Such a sound can only be produced by metal balls rolling along the gutters.

Note. Such a crunch can appear at any time, but, as a rule, when turning the wheels or sharply accelerating from a standstill. In addition, a characteristic sound may appear when overcoming obstacles.

Slight jerks when the car starts moving will also help to identify signs of a CV joint malfunction. Also, experts recommend changing driving dynamics to quickly identify faulty grenades. As was said, there are two types of grenade: external and internal. How to determine the malfunction of an external grenade, or as it is also called an external grenade, was indicated above.

Note. The external CV joint differs from the internal one, first of all, in that it is smaller in size and fails much more often than the internal CV joint.

- To determine the malfunction of the external grenade in another way, you need to turn the steering wheel and move away. If the grenade is faulty, it will begin to “crunch”.

- To determine the malfunction of the internal grenade, you will need to drive not in a curved manner, as when checking the outer CV joint, but in a straight line. The internal grenade will especially clearly signal with a sound signal that it is time to replace it when overcoming holes, snowdrifts or shallow ditches.

- You can finally check the malfunction of the grenade on the lift. The front wheels will be suspended and if the CV joint is faulty, a characteristic crunch will appear.

Removing and disassembling the internal hinge of Lada Priora (VAZ-2170)

We carry out the work when replacing a hinge or its cover. Remove the front wheel drive (see “Removing the front wheel drives”).

We clean the outside of the hinge and clamp the drive shaft in a vice with soft metal jaw linings.

Using sliding pliers, squeeze the large clamp by the protrusions and pry the end of the clamp with a screwdriver...

... disconnect the clamp and remove it. Similarly, remove the small clamp.

Slide the cover off the hinge body. Using a rag, remove the grease from the end of the hinge housing.

When replacing the hinge cover, we use a file to mark the relative positions of the body, holder and hinge separator so that they take their original places during assembly.

Use a screwdriver to pry up the inner hinge retainer...

...and remove the lock. We move the hinge body along the shaft...

By striking the end of the joint cage through a soft metal drift...

...remove the cage with the separator and balls.

The drift should not transfer force to the cage and balls to avoid damaging them. Using a screwdriver...

...remove the retaining ring from the shaft groove. Remove the protective cover of the joint from the shaft. To inspect the hinge parts, take out the balls and arrange them in order. We remove the clip from the separator.

We remove the old grease from the hinge body and wash it in kerosene. Wipe the hinge parts with a rag and blow with compressed air.

We inspect the balls, separator, cage and internal cavity of the body. Scratches, dents, cracks, and traces of corrosion are not allowed - we replace such a hinge.

We clean the shaft of old grease and apply a thin layer of new grease to it. We put a new joint cover on the shaft and install a new retaining ring in the groove of the shaft. We put a separator on the end of the shaft (the conical part to the cover).

Using a hammer with a plastic striker, press the cage onto the splined part of the shaft. Rotate the separator until the marks align.

We insert the balls into the separator windows. To hold the balls in the windows, we apply lubricant to them (CV joint-4).

We put the same lubricant into the cavities of the hinge body and the cover, apply it to the balls and the separator - 80 g in total. We put the hinge body on the inside of the hinge according to the marks and install the lock. We check the mobility of the hinge body - it should move without jamming.

We put the cover on the hinge body and install a small clamp. We install the hinge body approximately in the middle position from its longitudinal movement relative to the shaft.

Using a screwdriver with a thin blade, we move the edge of the cover away from the hinge body to equalize the air pressure inside and outside the cover. We secure the cover with a large clamp.

Video on the topic “Lada Priora. Removing and disassembling the internal hinge”

Replacing the outer and inner CV joints of the drive on VAZ 2110, 2112, Kalina, Granta, Priora, 2109, 2114 Replacing the outer grenade and internal boot of the VAZ 2112 drive Disassembling and assembling the CV joint (grenade)

Replacing a grenade

Before you begin the process of replacing a grenade, you need to arm yourself with the following tools:

- lift;

- a sledgehammer or large hammer;

- an ordinary hammer;

- heads for 17 and 30;

- balloon type wrench;

- a chisel, not necessarily sharp;

- a flat screwdriver, preferably a slotted one;

- wrenches 13 and 17;

- crowbar or pry bar;

- pipe;

- a special puller designed to replace CV joints;

Special puller for CV joints

And, of course, you should purchase a new CV joint kit.

New CV joint kit

Dismantling an old grenade

Let's start the replacement process:

- first you will need to unscrew the nut that sits on the shaft using a 30mm socket, a wrench and a pipe;

Replacing the external grenade of a VAZ 2110

Note. Don't worry if the nut is a little jammed, because if you apply a little force, the pipe and collar will easily unscrew it.

- After the nut is unscrewed, the lift should be installed.

– , , .

| Lada, Lynxauto CO-4600, | + 11:06, 18 1336 |

| () | 09:08, 18 5956 – |

| FJ-218 2108-2110 Finwhale FJ218 | 01:01, STODETALEY |

| | / | Ruville 77201S | 12:23, 22 “-… |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 14:44, 22 “-… |

| | / | Lada 110,111,112/Samara Ruville 77201S | 22:48, 24 |

| LADA 2110/ 2109 SKF VKJA5708 | 21:16, 24 |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 03:41, 24 |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP | 10:46, 13 Zakaz28rus |

| | / | Ruville 77201S | 08:05, 20 |

| | / | Ruville 77201S | 09:25, 15 Gabarit |

| | / | Ruville 77201S 77201S | 15:44, |

| INKO 415016 415016 | 15:43, |

| INKO 415001 415001 | 15:43, |

| INKO 315007 315007 | 15:42, |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP | 10:53, 22 |

| | / | Ruville 77201S | 07:07, 20 |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 828001 | 07:12, 1 Gabarit |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville 77201 S | 08:03, |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 08:00, |

| | / | Ruville 77201S | 03:59, |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87-: Ruville 772 01S | 04:13, 16 |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> : Patron PCV1081 | 04:09, 16 |

| , / , | 07:05, 22 |

| | / | Ruville 77201S | 11:35, 7 AutoSup |

| Ruville, (+) 77201S | 15:27, 21 Boost24 |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88>PCV1081 | 11:34, 21 |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- 77201S | 11:05, 21 |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville 77201 S | 09:01, 18 … |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88> | 19:23, 17 Autoclub02 |

| . / 2108-2215010;2108-2215011;2108-2215012;L-302040; | 12:28, 15 24 |

| | / | Ruville 77201S | 10:56, 15 24 |

| INKO 415016 | 09:14, 15 24 |

| INKO 415001 | 09:14, 15 24 |

| INKO 315007 | 09:13, 15 24 |

| lada 2108 2109 2110 LD-001 | 07:16, 15 24 |

| lada 110 95-, samara 86-, samara forma 89-, Skf. VKJA8972 | 00:21, –… |

| . 22*22*50 lada 110 95- 2108 2109 86- 21099 89- Zekkert .gs-3263 | 00:02, – |

| . 22*22*50 lada 110 95- 2108 2109 86- 21099 89- Zekkert. GS3263 | 06:56, –… |

| LADA 2108-09/99/2110-12 86- Ruville 77201S | 23:59, – … |

| 22x50x22: 2108-09, 2110,2111,2112 1.1-2.0i 88 Patron. PCV1081 | 23:24, –… |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88 Patron. PCV1081 | 23:13, –… |

| | / | Ruville 77201S | 10:11, CARakoom |

| LADA: 110 1.5/1.5 16V/2.0 I 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville. 77201S | 08:08, –… |

| lada: 110 1.5/1.5 16v/2.0 i 95-, 111 1.5/1.5 Ruville .77201S | 06:41, –… |

| : 2108-09, 2110,2111,2112 1.1-2.0i Patron. PCV1081 | 05:25, –… |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP 828001 | 03:34, – … |

| . 22*22*50 Lada 110 95- 2108 2109 86- 21099 89- Zekkert GS3263 | 13:12, 21 Jc-Market |

| . 22*22*50 Lada 110 95- 2108 2109 86- 21099 89- Zekkert GS3263 2110, 2108, 21099 … , 1 | 13:12, 21 Jc-Market |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> | 15:58, 13 AutoPart02 |

Nissan X-Trail › Logbook › Inner left front grenade - damn it)))

I don’t even know where to start)) How much time I wasted: - searching for useful information on the Internet; — visited all the investigations in the city; — called investigations in cities that are closer; — how many people have I troubled with my problem))). etc. Finally I made up my mind and ordered a low-quality substitute for Febest (0211-T30LH). By the way, it’s cheaper at www.repart.ru/.

Internal CV joint, gearbox side (0211-T30LH)

When purchasing the car, I immediately noticed the torn boot of the inner left grenade. Well, okay, I thought))).Then I’ll put on the dust cover and that’s it)))…that’s not the case. I called some stores in the city (I was looking for a boot), everywhere from 1500 rubles. and higher. I decided to wait and order through existential for 750 rubles. Febest (0215-071T)

Internal CV joint boot (0215-071T)

While I was waiting for the boot, I wrapped a bag))) with lubricant)). I noticed a slight vibration especially during acceleration. Well, it’s a small thing)))… I waited for the boot. I changed it, it took about 2 hours to replace it… Then I went for a ride)) only then I read on the Internet about the vibration during acceleration. Everyone who wrote about vibration mentioned the torn left boot! In existential terms, the cheap Febest substitute at that time cost 4,700 rubles, a couple of months later it began to cost 3,200 rubles.)) Having already driven 6-7t.km. The vibration has increased and it’s not bad))) (by the way, the boot is still intact) I was thinking about a used drive unit, but if X-trails have this problem, then it makes sense to take a used one. I read on the Internet that the left front drive fits from Nissan Cefiro (A33), from Nissan Primera (P12) and, with minor modifications. I was more inclined towards the drive from the Nissan Cefiro (A33), because... The internal grenade will be stronger)).

But nowhere in Kurgan was there a used drive (((in other cities a used one from 5-7 t.r. immediately disappears. To order through the website www.japancar.ru/ it also costs about 5 t.r. and so on will come...unknown((In the end, I made up my mind and ordered Febest (0211-T30LH) 2860 rubles, I couldn’t continue to worry myself and those around me)) Only reviews about those who installed Febest were not found as a substitute((about the fact that Febest is complete shit..., this okay)) let’s see how long it lasts and if the vibration goes away))

As soon as it arrives, I’ll change it right away))

Replacing a grenade on a VAZ-2112

The entire drive was removed to replace the inner and outer CV joints.

If we talk about replacing this unit on a VAZ-2112 car, it should be noted that this work is not as simple as it might seem initially. You can make it yourself if you have certain skills. To do this, you need to follow the instructions given below, and also have tools and consumables.

Equipment and materials:

- Hammer.

- Screwdriver.

- Head at “17”, “19” and “32”.

- Driver with extension.

- Lubrication.

External grenade

What is needed besides a new grenade

Don't forget to check the presence of the boot, two clamps and lubricant.

The car must be secured first. It will need to be set to speed, and shoes should be installed under the wheels (you can use a brick or a wooden beam). Next, you will need to remove the decorative cap and unscrew the nut that holds the hub. You need to use a head with an extension (you can take a piece of pipe). Once the hub is unscrewed, you can begin to unscrew the bolts that hold the wheel.

Next, the CV joint itself is removed:

- You should lift the car wheel on the side where the CV joint is being replaced.

- Completely unscrew and remove the hub mounting nut.

May require a long lever, a VERY long lever!

- On the steering knuckle, you need to unscrew the two bolts that secure the ball joint.

- Turn the steering wheel to its farthest point.

- Move the steering knuckle and strut to the side.

- Remove the splined end of the CV joint from the hub.

Pull out the outer CV joint

Order of Operations

If there is no inspection hole or overpass, you need to prepare a place for repairs. Raise the car with a jack, put on the handbrake, provide the work area with good lighting, and support the wheels with clamps.

Replacing the inner CV joint of the VAZ 2110 and other models is carried out in the same way as the outer joint. They are both located on the shaft drive, which you need to get to first:

- On the crankcase protection, two nuts are unscrewed at the front and rear.

- You need to drain the oil from the box - 40 percent of the total volume.

- When replacing the right CV joint on a VAZ 2110, the wheel bolts come off on the right; if the left one is changed, the wheel bolts come off on the left.

- The outer hinge fasteners are completely unscrewed.

- Now you still need to jack up the car and remove the wheel.

At this stage, two hub bolts securing the grenade become accessible; they need to be removed.

- The hub needs to be separated from the rods, this is done with a pry bar.

- The stand is pulled forward and the CV joint pin is removed from the hub.

- The shaft drive is removed and set aside.

Now you need to remove the inner grenade from the box. With the hood open, you need to insert a pry bar between these elements. Then the tool jerks the hinge towards the box. The grenade should move. If this does not happen, the operation is repeated again. If the CV joint moves, then both hinges and the shaft can be removed from the wheel arch area. - You need to remove the covers from the grenades; to do this, use pliers or special pliers to open the small and large clamps.

- The boot must be inspected for integrity. If the cover is damaged, it must be replaced. If the boot is in good condition, you can simply move it away.

Use a hammer to remove the inner hinge. They need to hit the clip hard. The grenade should fly off. The same action must be performed on the other side.The rings are removed from the shaft drive, new ones are installed in their place and the boot is put on.

- The new grenade is also installed using a hammer. It and the boot need to be lubricated.

- The covers are secured to the hinge and shaft with clamps.

- A nut is screwed onto the grenade, then the hinge is driven into the box.

- Further operations are similar to the first, but are performed in reverse order.

What is this?

By grenade, service station technicians and motorists understand a device through which torque is transmitted to the steering wheels of a car without loss of power characteristics of the power unit.

If you operate the vehicle carefully and carry out maintenance on time, the grenade will last as long as possible. But poor quality of the road surface, savings on maintenance, aggressive driving - all this leads to the rapid failure of the constant velocity joint.

The driver of a VAZ 2112 understands that the CV joint has failed by the following signs:

Sometimes a grenade can be repaired. But more often than not, its malfunction is detected already at the stage when the part is severely worn out. Auto repairmen are advised to replace such auto parts with new devices.

Causes of constant velocity joint failure

What can cause the failure of this element of the car:

- Poor quality boot is the first reason and the most important. If the boot on a grenade is made of low-quality material, it will quickly wear out, and all sorts of debris will begin to get inside the grenade.

- Loosening the boot clamp also allows sand and dust to get inside the CV joint.

- Other defects of the boot (see), such as a cut of the clamp, rupture of the boot or its stretching also lead to bad consequences.

- An insufficient amount of lubricant, or, even worse, its absence in the constant velocity joint housing, leads to rapid wear of the bearing and, as a result, wear of the entire part.

Determining the need to replace the internal grenade

Before any repair, it is important to make sure that there is a malfunction. And now we will do this with the CV joint:

- Often, a malfunction can be determined by the sound emanating from the suspected component of the car.

- A joint malfunction is detected while driving or starting the car.

- Of course, sounds can come from a faulty shock absorber strut, or from the engine. Let's learn how to determine what kind of sound should come from the CV joint and when it appears.

- The sound of a faulty grenade is the grinding of metal on metal, similar to a crunch, breaking of metal, or a stone hitting a bearing or other drive mechanism.

- When can this sound be heard? If such a sound appears when turning, it means that you need to change the outer grenade, not the inner one.

To more accurately determine the malfunction of the unit, you should carry out diagnostics in the inspection hole. The following describes how to do this yourself:

- The car is driven into a viewing hole. Wheel chocks must be placed under the rear wheels, and the car must be set to the parking brake.

- Next, you should raise the car with a jack so much that one of the front wheels is lifted off the ground.

- Then you should turn the wheel by hand. When the wheel rotates, a sound appears - there is a malfunction in the internal grenade. If you turn the wheel at the same time, then rotate it, and only then does the sound appear - there is a malfunction in.

- After carrying out such an operation, it should be done on the second side (with the opposite wheel).

Now that the breakdown has been identified, you can begin repairs. Replacement of the internal grenade on the VAZ 2112 begins!

Pricing factors

Today, most car owners are trying to make financially profitable purchases. But a cheap part does not always turn out to be of high quality. This must be remembered when choosing a CV joint for a VAZ 2112.

To make the purchase profitable, you need to visit different places where this part is sold and compare the performance parameters and cost. The price at different sales points will vary greatly. It is important to understand that the cost is influenced by the following factors:

- Quality.

- State.

- View.

- Originality.

- Company manufacturer.

- Place of purchase.

- The need for product delivery.

- Seller popularity.

Varieties

CV joints are divided into different types depending on the type of structure and installation location. Depending on their location, grenades are:

- External (connect the axle shaft to the wheel hub).

- Internal (connect the gearbox to the axle shaft).

According to their design features, products are distinguished:

- Ball-type (torque is transmitted using balls moving along grooves).

- Cam (consist of shaped disks and forks, can withstand heavy loads).

- Tripod (differed by the presence of spherical rollers).

- Twin cardan joints (represent two connected cardan joints).

As of now, there are grenades on the VAZ 2112:

- New.

- Used in good condition.

- Old, requiring minor repairs.

Also, similar products are classified according to manufacturer into two types:

At the place of purchase, auto parts are:

- From the online store.

- From the car market.

- From a store selling spare parts for VAZ cars.

- From the auto disassembly point.

- Purchased from an ad.

According to the manufacturer, the CV joints on the VAZ 2112 can be sold in the following brands:

How to check functionality

First you need to check how the external and internal grenade works. When replacing, the process will be different, as will the symptoms.

If the outer link fails, the main signs of failure will be the appearance of a specific sound, similar to a crunching sound. The reason is the wear of the grooves, and the movement of the balls remains the same, as if the element is in good condition. It becomes more obvious as soon as the car begins to turn, or when the gas pedal is pressed sharply.

To make sure that it is necessary to replace the outer CV joint boot on a VAZ 2110, you will need:

- When starting, you can organize small jerks.

- You can quickly pick up speed and then slow down.

- Move the shaft transversely between the CV joints. If it senses play, the grenade requires replacement.

The internal grenade needs to be replaced less frequently than the external one. As a rule, its malfunction can be detected during ordinary straight movement, or when passing complex routes.

On a VAZ 2110, replacing the inner CV joint must be carried out after a short check:

- Raise the drive wheels to launch the grenade to the maximum angle.

- Start the engine.

- Turn on first speed.

- If a specific crunch occurs, replacement cannot be avoided.

The procedure is similar to checking an external element. The main thing is to listen to see if a sound characteristic of the problem appears.

approximate cost

In Russia, you can buy a new grenade at a price from 700 to 1300 rubles .

Approximate prices depending on the type of CV joint:

- Outdoor – from 700 rubles .

- Domestic - about 1200 rubles .

Approximate prices depending on the manufacturer:

- AvtoVAZ - about 1100 rubles .

- PRAMO - from 700 rubles .

- LGR – from 980 rubles .

- Lucas - about 1300 rubles .

- Hofer - about 1200 rubles .

- Pilenga – from 850 rubles .

An old spare part in Russia is sold for about 400-500 rubles .

Where to buy?

If a grenade is needed for a VAZ 2112, then the owner of the car should decide on the place of purchase and the type of part. Car mechanics are advised to take new original spare parts due to their ideal compatibility with the car and long service life. Such a CV joint can be purchased at an auto parts store for VAZ cars or an online store.

If you don’t have enough money to purchase a new auto part, then you should consider the old versions of grenades. They are sold at car dismantling points, at the car market, by advertisement.

Replacing the outer CV joint on a VAZ 2112

On cars with front-wheel drive, instead of a driveshaft with crosspieces, constant velocity joints (CV joints) with axle shafts are used. Both crosspieces and CV joints tend to fail. This article discusses in detail: replacing the external grenade of a VAZ 2112, visual photos for a better understanding of the process and practical advice from an auto repair specialist.

- Why does the CV joint fail? Principle and working conditions

- How to determine if a hinge is faulty? Diagnostics

- What will you need?

- Replacement

- Removing the axle shaft

- Grenade replacement

- Installing the axle shaft on the car

How to avoid CV joint failure?

A grenade flew out, movement is not possible.

Advice! To avoid early failure of the part, it is not recommended to start abruptly with the steering wheel turned in any direction.

Those parts that are installed on new cars can easily serve for 100-150 thousand kilometers. This cannot be said about those spare parts that are sold separately in car shops or markets.

Why does the CV joint fail? Principle and working conditions

A torn boot is the cause of all troubles with grenades

- A car's wheel is its dirtiest part. The wheel is constantly in contact with the road, and the road is not always asphalt, but often dirt or sand.

- The outer grenade usually wears out much faster than the inner one, since it is closer to the wheel and is more subject to overload when driving on uneven surfaces.

- Anther breakage. One of the reasons for grenade failure is a violation of the integrity of the boot. This usually happens due to a torn boot clamp, a cut of its fastening, or a cut in the boot itself.

- It also happens that the boot loses its rubber properties over time and stretches. Then it does not fit tightly to the axle shaft.

- For all these reasons, dust gets inside the outer CV joint, and even worse, sand and dirt.

- If harmful substances get inside the grenade, the bearing fails - it collapses or jams.

If you notice a torn grenade boot, this means that on a VAZ 2112, replacing the CV joint is simply necessary for its further safe operation.

Malfunction prevention

In order for this part to last as long as possible, it is necessary to completely eliminate the possibility of dirt and water getting under the rubber cuffs of the CV joint. If there is the slightest damage, this part must be replaced with a new one.

For this purpose, it is better to use original spare parts that are made from high-quality rubber. If you purchase counterfeit cuffs, the procedure for replacing this part will have to be carried out too often.

Another reason why the CV joint often fails is its insufficient fastening to the main gear shaft. If the bolts are not tightened well enough, then over time they begin to unscrew randomly. In this case, the outer CV joint moves significantly away from the shaft, and with a significant gap, knocking noises will be observed in the transmission. If this malfunction is not detected in time and the fastening bolts are not tightened, then in a short time the CV joint will be completely “broken.”

How to change the CV joint and how to determine the malfunction of this part is described in detail in the article. The operation of replacing the CV joint will not take much time, but if you do not want to fix this problem yourself, you can always turn to a car repair shop for help.

How to determine if a hinge is faulty? Diagnostics

At any service station, before repairs, they carry out diagnostics of the unit that is going to be repaired. Let's do it ourselves:

- Are there any strange sounds while driving your favorite car? One possibility could be a faulty CV joint.

- Most often, a CV joint in need of repair manifests itself during turns (not necessarily sharp ones). When turning the car, a sound comes from the hood, similar to metal jamming, the sound of metal breaking, metal grinding on metal.

- If such sounds appear even when driving straight, then the CV joint definitely needs to be changed!

Advice! Do not ignore sounds that occur when operating the vehicle. In some cases, this can cost the lives of the driver and passengers.

- After sounds similar to a malfunctioning grenade appear, it is necessary to diagnose the front chassis of the car in a pit or overpass, or, as a last resort, just in the garage.

- To do this, you need to lift the car using a jack. Raise the side from which the sound was heard. Don't forget to put wheel chocks under the rear wheels of the car.

- When the wheel can rotate freely, you should rotate it around its axis and listen for sound. If the sound does not appear, then you should turn the wheel in the direction of the turn at which it occurred.

- When a sound appears, it will become clear that the VAZ 2112 CV joint is faulty and requires replacement as soon as possible.

- If the sound still does not appear, then check the other side (the other wheel) in the same way. By the way, if the sound appears, check it anyway - you may have to change both grenades.

Removing the drive, boot and CV joint

To replace the outer CV joint, follow the following procedure:

- We place the car on the inspection hole and support it with wheel chocks.

- Using a 30mm socket, loosen the hub nut. If the nut does not break off, then you can extend the key with a pipe.

- Raise the car with a jack in the right place and remove the wheel.

- We unscrew the bolts securing the ball joint of the lower arm to the hub.

We squeeze out the tie rod end with a puller.

- Unscrew the drive shaft nut completely.

- We pull out the hub by grasping the brake disc and pulling the shock absorber strut towards us.

To change the boot and hinge, you will have to climb into the inspection hole. To remove the CV joint, remove the clamps that hold the boot. Next, we get rid of the old boot, which is easier to do with a knife. Use a rag to remove grease from the hinge. Then you need to knock down the inner race, for which we lightly hit the attachment with a hammer, which must be rested against the end of the hinge. Next, we thoroughly clean the CV joint from dirt, sand, dust and grease.

Replacement

After all the preparations, you can begin the process of replacing grenades with a VAZ 2112.

Removing the axle shaft

- Perhaps this is the most interesting thing in the process of replacing a grenade.

- Place the car on a level platform, inspection hole. Install wheel chocks.

- First, remove the hubcap from the wheel, if you have one installed.

- Now you need the help of a partner. He should take a driving position and press the brake pedal hard.

- In this case, you should take a 30 socket (in some cases 27 or 32) and a large wrench. The head is put on the hub nut, which secures the grenade to the hub (located in the middle of the wheel) and unscrew it with a large wrench.

Unscrew the nut with a large lever!

Advice! It will take quite a lot of effort to complete the last step described. Therefore, the longer the driver you take, the easier it will be to unscrew the nut.

- Then you can unscrew the wheel bolts and remove the wheel.

- Spray the splined surface of the hinge with rust remover. Most often, an additional remedy is needed - you can’t just knock it out.

- When the wheel is removed, it is necessary to free the hub from the ball joint. To do this, take a suitable head and unscrew the two bolts securing the ball joint to the wheel hub.

- When the hub is freed from the ball joint, you can try to remove the splined surface of the grenade from the hub. Remove the entire hub nut and metal washer.

- Now you need to take a copper (bronze) adapter and a hammer, and with their help we knock the splines out of engagement. If necessary, add more WD.

- When the splines are disengaged, move the strut to the side and remove the axle shaft from the hub.

Instructions for replacing the outer CV joint of a VAZ 2112

Advice! During operation, make sure that the internal grenade does not jump out of the gearbox housing - this is an unnecessary loss of oil.

Next, we will consider the most profitable option for replacing a grenade on a VAZ 2112 - replacement without removing the axle shaft from the car.

Grenade replacement

Two methods will be considered:

- Remove the boot from the grenade. To do this, use pliers to cut through the fastening clamp and, using a screwdriver, remove the boot from one side. Turn it out so that it does not interfere with further work.

Complete removal of the CV joint boot of the VAZ 2112

- Now again you will need the help of a partner. He needs to hold the axle shaft tightly so that it does not jump out of the gearbox. It is recommended to rest the axle shaft against something (usually a lever or anti-roll bar).

- The outer grenade must be turned with the slots up. This gives access to the grenade's internal bearing.

- It is necessary to place a copper adapter on the inner bearing and knock down the grenade with a hammer. When knocking down, the axle shaft must be rotated so that the bearing moves evenly and does not jam.

- After the outer CV joint has been removed, you can begin installing a new one.

Note! Above is the IDEAL option for removing the CV joint. And then we will talk about how it happens MOST OFTEN.

- After removing the grenade from the hub, the axle shaft is removed and pulled out of the gearbox housing. Place a container under the flow of oil from the box so that you do not have to drain the oil. Ideally, a special plastic plug is inserted into the gearbox hole.

- The axle shaft is clamped in a vice for ease of further work.

- The boot is removed from the grenade, but remains attached to the axle shaft. It turns inside out so it doesn't get in the way. If you plan to replace the boot, then it is either cut off immediately or removed after removing the grenade.

- We remove the grenade in the same way as above. We hit the bearing with a pointer and a hammer, and it comes off the axle shaft.

The grenade is removed as shown in the photo

- If we change a grenade, then we change it. If, for example, we are only replacing a torn boot, then we do the following.

- The boot is removed and a new one is put on the axle shaft.

- The grenade is thoroughly washed with a brush in gasoline and then wiped. Then you need to fill it with special lubricant for CV joints.

- If you install a new grenade, then do not forget to fill it with enough grease and distribute it evenly there by turning the bearing.

Advice! Before installing the grenade on the axle shaft, pay attention to the condition of the retaining rings. Replace them if necessary.

- A new or repaired grenade is installed on the axle shaft much easier than it is removed. One sharp blow with a hammer through the attachment and the grenade is in place. Experienced mechanics can even put a grenade on by hand.

- Next, you need to put the boot on the seat in the grenade and secure it with clamps. There are special clamps for grenades (do not use plastic ones). Metal clamps are installed using pliers and a screwdriver.

Advice! Clean the spline joint, both on the grenade and in the hub, with a metal brush and lubricate.

Now the VAZ 2112 axle shaft with a changed external constant velocity joint is ready for installation on the car!

Installing the axle shaft on the car

- The axle shaft is inserted into the gearbox housing. Its other end is inserted into the hub until it stops.

Bend the strut and put the hub on the grenade splines

- Next you need to reattach the ball joint.

- Don't forget to put the metal washer back on and tighten the nut that secures the grenade to the hub.

- Reinstall the car wheel and lower the car from the jack onto the wheels.

- Again, the partner must press the brakes as hard as possible. You take the wrench and socket and tighten the nut with good force!

- Next you need to tighten the nut. This is done with a hammer and a blunt chisel type attachment. This is done to prevent the nut from unscrewing.

That's basically the whole replacement. If something is not clear in the text, remember that you can always watch a visual video that will show it all live.

Assembling the inner CV joint

Careful disassembly of unfamiliar components and assemblies is the key to trouble-free assembly.

In practice, it is not always possible to keep track of all the subtleties and nuances. Fortunately, the constant velocity joint cannot be called an overly complex unit, therefore, after reading our article and watching the accompanying videos, you will know how to assemble the inner CV joint. In modern cars, only 2 types of designs are used for internal CV joints.

- “Receiver” - used in the vast majority of external grenades, and on some cars as an internal CV joint (for example, Volkswagen Transporter T4). The unit consists of the following parts: a housing with a splined part that fits into the wheel hub, a separator, a race, balls and a retaining ring.

- “Tripod” is a three-pin joint that works in relatively small angles (up to 25º). Nevertheless, this is quite enough to compensate for suspension travel, displacement of the power unit and gearbox in turns, when driving over uneven surfaces, which is why the Tripod is most often used for the manufacture of internal CV joints. Structurally, it consists of a body in which running tracks are machined, a hinge with rollers and a locking ring.

Rzeppa

As an example, let's take the internal velocity joint of the VW Transporter T4. In order to assemble a ball CV joint, you need:

- fix the drive shaft in a vice;

- put a boot with a metal shield on the shaft;

- install a limiting ring;

- the housing with the separator and inner race can be assembled separately. It is necessary to put the separator on the holder and place it inside the housing. Then, turning out the cage and separator, insert one ball at a time. The video shows the assembly process of a CV joint fixed in a vice. Initially, a race, separator and housing are put on the drive shaft. Then, as in the previous case, balls are inserted into the grooves one by one.

Tripod

It is much easier to assemble a tripod-type CV joint. All you need is:

- install the boot on the drive shaft in advance;

- place a hinge with rollers on the slots;

- fix the hinge by installing a retaining ring (there is a groove for it on the drive shaft);

- generously lubricate all rubbing pairs;

- install the housing;

- fix the anthers;

- manually develop the mechanism by making several turns in different directions.

For a visual representation, we suggest watching a video of the assembly of the outer and inner CV joints.

Important points when replacing

Useful tips that will not only help you assemble the inner CV joint correctly, but also extend the life of the joints and angular velocities in general.

- If you notice a torn boot in time and the CV joint has not yet begun to crunch before disassembly, you can get by by washing the unit and replacing the lubricant.

- Litol, grease or graphite grease cannot be used as a lubricant. Only special grease for CV joints is acceptable.

- If you disassembled the old CV joint to wash it and replace the lubricant, mark the location of the race and separator relative to the body. When removing the balls, arrange them so that you can then install them in their original places.

- Gasoline, a small brush and clean rags work well for washing.

- Factory crimp clamps are considered disposable. If you reinstall them, be prepared for the fact that when the wheel is turned out (especially in cold weather), the boot may come off. As a result, installing a new one or washing an old grenade will go down the drain. You can crimp such clamps with thin pliers.

It is most convenient to compress and release retaining rings with special pliers. Without them, assembly and disassembly may require more time and nerves.