Knocks in the chassis are a frequent companion in life for VAZ 2114 owners. Many elements that can cause knocking, bad roads, and low-quality parts can cause extraneous noise in the suspension. A common source of the problem is the angular velocity distributor, or CV joint (grenade). The process of replacing a part is simple, so you can change it yourself. The question is often asked which CV joint for the VAZ 2114 is better: regular or tripoid. Among the most common arguments: tripoid is more reliable, but it hums and vibrates at high speeds. The regular one is less reliable, but the car handles better at high speed. However, you can find opposing opinions and arguments on this matter.

This article was written thanks to the help and support of the Interior Design website. This is an information portal about interior design: new products, photos, videos, the best styles, options for the perfect combination and recommendations from professionals

There is no clear answer which type is better. Operation in harsh conditions showed that there is no fundamental difference in driving sensations and reliability. The main thing is to buy a high-quality grenade made of well-hardened metal, install it correctly and monitor the safety of the anthers.

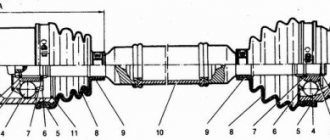

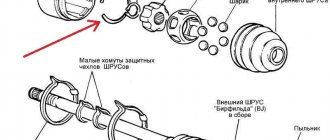

Scheme for disassembling the VAZ 2114 CV joint

Replacing the outer CV joint of a VAZ 2114

Hi all. We will replace the outer CV joint of the VAZ 2114. This is not a difficult job; if you have the tools, you can do it yourself.

Tools:

- good wrench and head for thirty

- hammer and screwdriver to hit

- pipe

- wooden block

- universal tongs and pliers

Vendor code:

- 2108-2215012 — external CV joint. I recommend installing a CV joint from GKN-Spidan, Loebro.

Step by step replacement

1. Remove the decorative cover of the hub nut and flare it.

2. We rip off the hub nut, if you can’t rip it off, then put the pipe on the knob for the lever.

3. Remove the wheel.

4. Unscrew the 2 ball fastening bolts.

5. Completely unscrew the hub nut.

6. Remove the rubber band securing the brake hose from the groove and pull the hub towards you so that the CV joint comes out of the hub.

7. As a rule, the boot is already torn, so we place the pipe on the inside of the CV joint and knock it out of its seat.

8. Remove the metal ring on the drive shaft. This ring comes with the new CV joint and needs to be replaced.

9. Fill the CV joint with lubricant, it is included in the kit.

10. We put the ring on the drive shaft.

11. We put on the boot, lightly coated with the same lubricant as in the CV joint.

12. We put the CV joint on the splines on the drive shaft and stuff it through a wooden adapter.

13. Move the boot closer to the CV joint and secure one side of the boot with a clamp. Tighten the clamp using pliers.

14. Fix the other side of the boot with a clamp. Tighten the clamp with pliers.

15. Mount the CV joint into the hub. Install the washer and tighten the hub nut. All this comes new complete with CV joint.

16. Fasten the two ball bolts. Use a pry bar to press the lever down and align the ball mounting holes.

Do everything slowly so as not to tear the new boot.

17. Install the rubber band into the groove that secures the brake hose.

18. Install the wheel and remove the car from the jack.

19. Tighten the hub nut.

20. Raise the car and remove the wheel.

21. Roll the nut and install the wheel.

Necessary tool

If you decide to do the repairs yourself, you will need the following tools to disassemble the car:

- Open-end wrenches for 17, 19. But it is better to have a full set on hand;

- Set of heads and knobs;

- Wheelbrace and jack;

- Pliers;

- Screwdriver;

- Hammer;

- Rag and gloves.

Useful : How to replace the internal grenade on a VAZ 2114?

Also make sure you have a complete replacement kit: grenade, boot, CV joint grease and two clamps. For convenience, you can drive onto a pit or overpass, and for safety reasons, set the car to the parking brake and put supports under the wheels.

Replacing the inner and outer CV joints on a VAZ 2114

Knocks in the chassis are a frequent companion in life for VAZ 2114 owners. Many elements that can cause knocking, bad roads, and low-quality parts can cause extraneous noise in the suspension.

A common source of the problem is the angular velocity distributor, or CV joint (grenade). The process of replacing a part is simple, so you can change it yourself. The question is often asked which CV joint for the VAZ 2114 is better: regular or tripoid. Among the most common arguments: tripoid is more reliable, but it hums and vibrates at high speeds. The regular one is less reliable, but the car handles better at high speed. However, you can find opposing opinions and arguments on this matter.

There is no clear answer which type is better. Operation in harsh conditions showed that there is no fundamental difference in driving sensations and reliability. The main thing is to buy a high-quality grenade made of well-hardened metal, install it correctly and monitor the safety of the anthers.

Scheme for disassembling the VAZ 2114 CV joint

Causes of malfunction

Among the main causes of CV joint failure:

- low quality metal and lubricant;

- insufficient amount of lubricant;

- rupture of the boot, entry of dirt.

The CV joint is a moving element, so it heats up when moving. A lack of lubricant or its lack of the necessary properties leads to wear of the hinges and the appearance of extraneous sounds. Due to the rupture of the boot, dirt gets into the grenade, solid particles harm the moving elements.

Fault diagnosis

The VAZ 2114 has 2 external and 2 internal CV joints. First you need to determine which one is knocking. The optimal test would be on a suspension diagnostic stand. If this is not possible, diagnosis by ear is possible.

Two signs indicate a grenade malfunction in a VAZ 2114:

- the sound resembles a crunch;

- It usually appears when turning.

The simplest and most accurate way to do a garage check is as follows:

- Place the car on a flat surface;

- Turn the wheels to one side (to the middle position or a little further);

- Drive off with medium speed. It is worth remembering that starting too smoothly may not reveal a crunch due to insufficient load on the CV joint, and starting too abruptly may lead to the drive flying out of the wheel.

- Repeat the operation by turning the steering wheel in the other direction. The appearance of a crunch indicates a malfunction of the outer CV joint on the side in which the steering wheel is turned.

Visual detection of ruptured anthers will also be a sign of a CV joint failure. If you discover a damaged protection for any grenade, it must be immediately removed, disassembled and cleaned. If there is enough grease and there is no significant wear on the hinges yet, it is enough to replace the boot and fill it with new grease. If the wear of the balls is obvious, it is better to change the grenade.

CV joint boot VAZ 2114 with a defect

It is more difficult to diagnose a malfunction of the internal grenade on a VAZ 2114. If it malfunctions, it crunches when starting off in a straight direction, and not when turning. But the same symptoms, for example, include play in the steering rack or wear on the engine mounts.

Sometimes the problem can be diagnosed from the pit by tugging on the drive from the gearbox side: strong play or the appearance of extraneous sounds indicate that the internal CV joint should be replaced.

Replacement

It is better to change a grenade yourself with an assistant.

Algorithm:

- remove the wheel, remove the wheel bolts and the hub nut washer;

- unscrew the ball from the steering knuckle;

- pull out the splined end of the outer CV joint;

- pull out the drive with the internal CV joint from the gearbox;

- if you plan to remove both drives, remove the internal grenade from the drive and insert it into the gearbox so that the differential does not move after removing the second drive;

- remove or cut off the anthers, thoroughly clean all hinges with a special liquid or just gasoline;

- when filling the CV joint, use a special lubricant suitable for these purposes; ordinary lithol does not have the required temperature characteristics;

- the retaining rings of each CV joint and the hub nut must be replaced;

- The inner CV joints are inserted into the gearbox until they are completely fixed; when adjusting, you can use a hammer with a wooden spacer.

It is quite possible to diagnose and replace a CV joint with your own hands. This does not require sophisticated car mechanic skills and engineering knowledge, but it allows you to get in touch with the car, see and feel how it works. Whatever the reason for the crunching sound, you need to check the condition of the grenade as quickly as possible. Delaying this will almost certainly mean bringing the part to the point of complete wear, and timely repairs will allow you to get by with “little loss.”

Signs of failure of the outer grenade (CV joint).

There are two options here:

- signs that your grenade has already broken

- signs that the grenade will soon come out and break .

How to understand that a grenade will soon break.

Of course, the first sign of a malfunction of the external grenade is a crackling sound . If you hear a crackling noise while driving with the steering wheel turned, it is definitely a CV joint. The greater the angle of rotation of the wheel and the harder you press on the gas, the louder the clicks. Another sign that does not always appear is vibration on the steering wheel at speeds greater than 80 km/h. The vibration is only slightly similar to the vibration from an unbalanced wheel. It usually manifests itself as a slight twitching of the steering wheel.

How to understand that the outer CV joint has broken.

If the CV joint breaks, the car will stop moving. In any gear engaged, press the gas, the speed increases, but the car does not move.

How to understand that it is the outer CV joint that has broken, and not the internal one or the clutch in general (the first signs of failure are similar to the signs of a clutch failure)? First of all, start the car and put it in any gear. Next, open the hood and look in turn at each of the shafts going from the box to the wheels (one short, the other long). If any shaft is spinning, it means that the CV joint has broken on this side.

I recommend not just visually looking at the shaft, but touching it with some long, hard object, such as a stick. The main thing is that there is nothing on it that could wrap around the shaft . When you touch the shaft with a stick, if it is spinning, you will feel a slight vibration. This is usually done in the dark, because it is difficult to understand whether a cylindrical object is spinning, especially in the dark.

Replacing the outer CV joint boot of a VAZ 2114

Yesterday late at night I came from the garage, as in that song “Tired, hungry and angry, but very pleased with myself!” Anthers have been replaced. And it was like this.

So for work we need:

- CV boots - 2 pcs.;

- Anther clamps - 4 pcs;

- Hub nuts - 2 pcs;

- CV joint grease - 1 tube;

- Head for 30 (I took it with touch control using a crowbar) - 1 piece;

- Well, and a bunch of other tools (wrench, tweezers, chisel, hammer, vocabulary of obscenities, etc.)

Work plan

So, let's begin. We remove the cap from the wheel (those who don’t have it have less work), remove the hub nut cap. Unscrew the nut, I used a dowel, take a 30mm socket and loosen the hub nut. Then loosen the wheel bolts.

All this needs to be unscrewed

We jack up the car and remove the wheel, immediately put it under the car (just in case), and unscrew the hub nut.

Unscrewed

We unscrew the bolts securing the ball joint to the steering knuckle (I unscrewed it with a balloon)

Those that are higher

We press the lever down using a crowbar, hold it in this position with your knee, and at this time we move the steering knuckle and pull the drive out of the hub (after turning the steering wheel to the left). Cutting off the old boot

Drive pulled

Well, then it’s time to remove the CV joint from the shaft. I read that it can be removed by lightly tapping the inside. It wasn't like that. I remembered all my swear words, but it didn’t do any good. It was too late to go to the store for a puller, so I took out a welding tool and invented a puller. With his help, the CV joint was removed within five minutes. But I couldn’t do anything with a hammer in two hours.

Here's a simple helper

After that, we take gasoline and thoroughly wash the CV joint, at least to this condition

It’s clean, and most importantly, it can be easily tossed and turned in all directions.

Well, then we apply grease inside, put the boot on the shaft and put the CV joint in place. To do this, we screw on the old nut and, with a short but sharp blow of a hammer, drive it until the thrust washer. We put the boot on the CV joint and secure it on both sides with clamps. We put the drive in the hub and attach a new nut.

Collected.

Next, install the wheel, lower the car and tighten the hub nut with the same force as it was unscrewed. And don’t forget to seal it

Energized. I used a dull chisel for this.

We repeat the same procedure on the right wheel. That's basically it, the boots have been replaced, the car is running, I now have a puller for CV joints and invaluable experience in removing them.

Removal

3. Drain the oil from the gearbox (see “Gearbox - oil change”).

4. Remove the hub cap and loosen the hub nut (see “Front wheel hub bearing - replacement”).

5. Loosen the wheel bolts (see “Wheel - replacement”).

6. Place the car on a reliable stand and remove the front wheel (see “Wheel - replacement”).

7. Loosen the three self-locking nuts securing the upper support of the suspension strut and unscrew the nuts a few turns (see “Front suspension strut - removal and installation”).

17 mm socket wrench

unscrew the two bolts securing the ball joint to the steering knuckle (see “Ball joint of the strut - removal and installation”).

30 mm socket wrench

finally unscrew the wheel hub nut (see “Front wheel hub bearing - replacement”).

10. Remove the shank of the outer hinge from the hub. If necessary, knock it out through a wooden block or press it out using a universal three-jaw puller (see “Front wheel hub bearing - replacement”).

Note: When removing the left drive, turn the steering wheel all the way to the right; When removing the right drive, turn the steering wheel all the way to the left.

11. Remove the brake hose from the bracket on the suspension strut. Carefully, without allowing too much tension on the brake hose, pull the lower part of the strut outward, remove the shank of the outer joint from the hub and carefully lower the drive onto the wishbone of the suspension.

12. Using the mounting blade as a lever (resting its end against the end of the internal hinge body), we move the hinge outward, overcoming the resistance of the locking ring.

13. Supporting the internal joint, carefully (being careful not to damage the drive oil seal with the splines of the joint shank) remove the joint from the gearbox and remove the drive assembly from the car.

How to change the CV joint on a VAZ 2114

Replacing CV joints on VAZ 2115, VAZ 2114, VAZ 2113

In front-wheel drive cars, one of the most problematic areas is the constant velocity joints. Abbreviated as CV joint or "grenade". The CV joint is a kind of ball bearing; its races have transverse grooves, which allows you to change the angle between the drive and driven axle shafts. All elements of the CV joint are made of ultra-strong alloys, the wear of which occurs extremely slowly, but, as practice shows, signs of a CV joint malfunction can appear even in a car that has recently left the assembly line of a car plant.

On cars of the VAZ family, it often becomes unusable after

55,000 km .

Causes and symptoms of CV joint failure on a VAZ 2115

The most common reasons:

- low quality CV joints, installation of fakes or defective spare parts;

- lack or poor quality of lubricants;

- damage to the boot and entry of abrasive debris or water into the mechanism;

- aggressive driving style and disgusting condition of the road surface.

One of the signs of replacing a VAZ 2114 CV joint is the appearance of a characteristic “crunch” . This sound can only be produced by balls that roll along grooves, because... have too much output. Working in close contact under constant load inevitably leads to changes in the properties of rubbing parts, their sizes, and the formation of wear.

Where there is no close contact of these elements and extraneous noise appears. The sound can appear at any time, but usually it occurs when turning, sharp acceleration, or overcoming obstacles. There are other signs indicating a hinge failure :

- slight jerks when starting the car or changing dynamics;

- play of the shaft located between the CV joints when trying to move it in different planes.

Which brand of grenade should I choose?

When searching for components, you should approach their selection with care. The CV joint is the main part of the car's drive and often fails, so you should choose a spare part not only for reasons of price, but also quality.

Useful : Replacing the external grenade of a VAZ 2114

It’s better to find the original; look carefully at the box in which the CV joint is sold, as you can often find a very high-quality fake. Also pay attention to the part number, it should be 2108-2215056 . The average price is about 2000 rubles .

When considering certified analog spare parts for purchase, you should look at the quality of workmanship. Even reading most of the positive reviews about a particular brand, you should not exclude the percentage of defects, which always exists.

Approximate prices

In Russia, purchasing a new CV joint for a VAZ 2114 will cost from 1,100 to 3,000 rubles .

Approximate prices depending on the type of auto parts:

- External grenade - from 1200 to 1500 rubles .

- Internal - from 1500 to 3000 rubles .

Estimated cost of a grenade depending on the brand:

- AvtoVAZ - from 1400 rubles .

- TRIALLI – from 1200 rubles .

- TORQUE – from 1200 rubles .

- LOEBRO - about 1900 rubles .

- HOLA – about 1200 rubles .

- FINWHALE – from 1100 rubles .

A used, but in good condition, grenade can be bought in Russia for 800-1200 rubles .

Features of the device and structure of the transmission mechanism

The fourteenth model is equipped with a five-speed gearbox similar to the unit installed on the G8, with the exception of the main pair.

According to consumer reviews, the lack of quality of the fourteenth gearbox includes the selection of gear ratios: a very short first speed and a long second. This drawback leads to a loss of vehicle dynamics when switching from first to second gear during acceleration.

The gearbox housing, rear cover and clutch housing are the main parts of the gearbox design structure.

Internal device groups:

- first (main pair);

- second (differential with gear ratios).

Main couple

The drive shaft functionality reduces the speed transmitted from the engine to the crankshaft. The transmission coefficient is 3.7. Thus, the main pair of the “fourteenth” is capable of reducing the indicated speed by approximately 4 times. The length of the gears can be changed by controlling the main pair mechanism. What affects acceleration and the maximum possible speed limit of the vehicle.

Differential with gear ratios

The differential gear ratios of the stock VAZ 2114 gearbox include: 3.636 (first speed number); 1.95 (second speed number); 1.357 (third speed number); 0.941 (fourth speed number); 0.784 (fifth speed number) and 3.53 (reverse speed number).

Having an idea of the structural features of the gearbox mechanism, it is necessary to begin preparing tools, materials and tools that will be useful during the removal and disassembly of the box.

Installation

1. Replace the retaining ring of the splined shank of the inner joint housing with a new one.

2. Apply grease to the spline and smooth surfaces of the shank.

3. Carefully insert the shank into the oil seal, trying not to damage the working edge of the oil seal with the shaft splines. At the same time, we direct the locking ring with the gap upward.

4. We vigorously insert the drive into the gearbox and make sure that the retaining ring of the inner joint shank is securely fixed and the drive does not move out of the gearbox housing.

5. We carry out further work in the reverse order of disassembly.

Warning! During assembly, a new hub nut must be installed.

Source

Order of Operations

Replacing the outer CV joint of a VAZ 2114, 2113 or 2115 is similar to working with an internal grenade. They are located on the shaft drive, which must be reached by performing many operations:

- To replace the outer CV joint of a VAZ 2114, if there is no inspection hole or overpass, you need to jack up the car and unscrew the bearing nut. IMG3

You need to remove the wheel; it can be used together with a jack for support.

Now you need to unscrew the 2 brake caliper bolts. One is located at the top, the other at the bottom.

The next operation is to separate the brake pads. This can be done using a flat-head screwdriver.

You need to remove the brake caliper along with the caliper and pads. The entire knot needs to be tied so that it does not hang.

Now unscrew the steering end nut and press it out using a puller.

Unscrew the two ball joint bolts, remove the wheel bearing nut, and remove the washer.

Now you need to unscrew the ball joint fastening in the direction of the steering knuckle, remove the grenade from the bearing hole, and pull out the shaft. If jerking doesn’t work, we help with a screwdriver. If the oil is not drained before work, the hole can be plugged with a rag.

The shaft needs to be carefully cleaned of the old grease, remove the old ring, put on a new boot, a new retaining ring.

Take a new grenade, squeeze new lubricant into its cavity, spread it over the surface, and install the hinge on the shaft.