If, when releasing the clutch pedal, the VAZ 2114 begins to slip or shake, then it is time to repair the VAZ 2114 clutch. The appearance of crackling noises and various noises can also indicate a malfunction of the mechanism. Typically, such problems are caused by wear of the driven disk or the formation of cracks in its surface.

Clutch for VAZ in working condition.

The first step is to visually examine the mechanism. Even if one or two elements are damaged, it is recommended to replace the clutch assembly. But if there is no extra money, you can change individual parts. For example, a driven disk. It needs to be changed in the following cases:

- The rubbing surface has cracks and significant wear;

- Damper springs dangle in their sockets. This means they are broken.

- The seating depth of the rivets is less than 0.2 mm.

Mechanism design

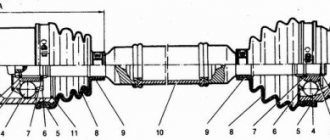

Structurally, the clutch on the VAZ 2114 consists of a total of 15 elements. Namely:

- Main shaft bearing having rollers;

- Clutch protection housing;

- Fork support bushing;

- Switch, also known as bearing;

- Press disk;

- Pressure spring;

- Secondary disk;

- Flywheel;

- Scale;

- Gearbox main shaft;

- Second bushing-switch;

- Carter;

- Plug switch;

- Fork toggle switch;

- Flywheel mounting bolt.

The clutch design on the “fourteenth” model cannot be considered very complex. In practice, you need to know four main points from him:

- Clutch with one disc brake;

- Type dry, closed;

- The driven disk has a device that dampens vibrations;

- The pressure spring is diaphragm.

The transmission does not start

If the engine was turned off, and everything was working, the gears would engage, but when the engine was started, the gearbox crunched, the lever rested, but the gears did not engage. Congratulations, most likely something to do with the clutch drive. If when the engine is not running all the parts are stationary, then when the engine is working, half of the parts rotate (flywheel, clutch and input shaft of the box), then the second half of the parts stand still, and in order to somehow synchronize them, you need to open the clutch. Then you can put it into gear.

Why might the clutch not open? The clutch drive may be damaged. The clutch drive can be either a cable or a hydraulic drive (clutch master and slave cylinders). Each of these mechanisms has its own settings and typical malfunctions.

First of all, adjust the clutch drive - tighten the cable, cable or rod of the working cylinder (piglet), if the drive is hydraulic

If nothing happens, it means the cable is torn/stretched (to be replaced). In a hydraulic clutch, this may be a malfunction of the master or slave cylinder, when the rod does not press enough, bypassing the fluid. This could be either a simple lack of fluid that will need to be added to the tank, or worn out seals. This problem is solved by replacing the repair kit, or replacing the cylinder, if it is completely rotten and the repair kit will no longer help, only complete replacement of the unit. It's easier with a cable - it's either broken or it's hard to move. If after pulling up there is no result, most likely it is something else.

What actions should be taken if the clutch slips?

First, let's try to extend the life of the disk. To do this, you can adjust the pedal stroke, and accordingly change the position of the disk relative to the flywheel. For this purpose, a special adjustment device is provided in the car interior or under the hood. By tightening the corresponding nuts, we can raise the pedal, thereby pressing the clutch disc harder against the flywheel. This method is recommended only for those who have not yet worn out the friction linings on the working part of the part. Therefore, it is not recommended to use it in all cases.

The most rational and correct solution is to replace the clutch, but before that, you need to get to the garage. This must be done with extreme caution. To avoid problems, you need to drive with the lowest number of revolutions. It is necessary to start moving “under load”. This means that the clutch needs to be released as smoothly as possible, but at the same time add a minimum of gas, or even not at all. Gear shifting should be performed according to the number of revolutions prescribed by the manufacturer.

Structure and functions of clutch

The mechanical drive of the VAZ 2114, when compared with hydraulics, has a much simpler, but equally durable design. It consists of:

- cable, adjustable in length in the sheath;

Cable location

- pedals that control the clutch from the passenger compartment;

- a device that controls the position and free play of the pedal;

- lever structure that transmits force from the pedal to the clutch fork.

The introduction of a cable into the design of the VAZ 2114 made it possible to eliminate complications with hydraulics, for example, very frequent leakage of fluid.

Adjustment

The adjustment procedure itself is quite simple and there is no need for special knowledge and skills. The whole process consists of adjusting the length of the cable sheath in relation to the adjustment unit, as a result of which the characteristics of the pedal stroke change. If you reduce the length of the shell, then, accordingly, the working stroke of the pedal will decrease, and, naturally, if you increase the length of the shell, its stroke will also increase. It is important to determine the moment at which the pedal begins to move the 125-135 millimeters necessary for us.

Correct replacement of the VAZ 2114 clutch step by step with photos

In general, what can I say... I bought a clutch. I decided to change it. Everything in the book is written that everything is simple... well, I went for a drive, and everywhere everyone had notes like “I went to a hundred to change the clutch.” But since the clutch died, and the pre-session budget does not allow me to pay 2.5 k to the service to change the clutch, and in general I want to change it myself! I went at 5 am to change it with a friend... well, we thought we’d get it done by 12 noon, so that we could then drive to the highway in Glinkovo near Sergiev Posad to break in the new clutch)) but that was not the case I faced many difficulties due to the fact that among us there were no car mechanics or specialists in this matter, but only a book...

Acceleration

A clear sign of clutch wear is when the vehicle accelerates. If the car does not accelerate in proportion to pressing the throttle, that is, the engine begins to oil, but the car does not move, especially uphill, then this is exactly one of the following reasons:

- The clutch drive is poorly adjusted (the cable is too tight or the hydraulic cylinder rod is too protruded, depending on the type of drive)

- Clutch disc wear

- Oil got on the clutch

- Someone pushed hard from the start and burned the disk. One start is enough to get a good burn.

So, the clutch drive is tightened for a reason, mainly when the basket is already tired and does not work within factory limits, that is, it has lost a little rigidity and in order for it to move away from the disc when pressed, you have to press deeper on it. Definitely a replacement. Another reason may be a cable with less rigidity than necessary; it stretches more than it should and does not press much. In order for it to work at least somehow, it has to be clamped more than required. We need to check, otherwise the basket will turn out to be working, I had this happen.

When the friction linings of the clutch disc wear out, the friction between the basket and the flywheel disappears. The same thing happens when oil gets on the disk - a common situation when the rear oil seal of the engine leaks. Here you need to remove the box and change the oil seal, because it won’t work like that. At the same time, you can change the disk, you can leave the basket, and look at the situation.

Worn “slightly burnt” clutch

But the clutch disc also becomes unusable if you press too hard at the start (street racers, hello!), the disc burns out immediately and loses its frictional properties, with the bonus of a burnt smell.

In general, if it smells burnt when driving, then this clutch stinks, especially when it is not pressed in enough and the disc is rubbing.

Order of Operations

There are two ways to change this node: regular and simplified. The second one is more accessible for self-repair - replacing the VAZ 2114 clutch without removing the box. The procedure for performing the work in the usual way is as follows:

- It is better to put the car in a pit, but if there is none, then you need to lift it with jacks.

- We remove the front wheels and de-energize the car by disconnecting the minus terminal from the battery.

- Now you need to disconnect the speedometer cable from the gearbox, remove the clutch cable, and turn off the gear drive.

- From the gearbox side, the motor support is dismantled, and the flywheel is removed.

- The flywheel should be examined for chips, cracks and other defects.

- The oil should be drained from the gearbox; you can take advantage of the situation and change the working fluid.

- The internal CV joints are removed from the gearbox, unscrew the fastenings and remove the gearbox.

- Now you can remove the bearing.

- Be sure to clean the shaft from working fluids, dirt and dust.

Installation of a bearing with a coupling on the input shaft. - We attach the basket to the flywheel.

- Subsequent operations are performed in the reverse order of the above.

Watch the DIY VAZ 2114 clutch replacement in the video:

Buying a unit is a rather complicated question, since it is sold both in parts and as an assembly. The manufacturer provides article numbers for each, since he lists them as different parts. He believes that these are completely different details. You can use analogues in your work. So, many VAZ owners prefer to purchase the SACHS collection (3000-951-211), but its cost is 3 times higher. Tuning analogues are offered by Brembo and ATI, the average price is about 10 thousand rubles.

Nuances of the device's operation

The bracket houses the brake and clutch pedals. They are located on a common pedal axis. A cable comes from the clutch pedal, the second end of which is attached to the release fork. Fastening is carried out using a bracket and two nuts. The cable is attached to the car body, resting against the buffer clip.

Valeo kit

For the clutch to work effectively, be sure to pay attention to the pedal travel. The optimal stroke size is 12-13.5 centimeters. Adjusting the clutch on a VAZ 2114 is not difficult. But first, measure this very move.

To do this, measure the distance from the center of the pedal between the minimum and maximum pedal pressure, that is, when you press the pedal to the floor. If the stroke is small, the cable fastening nut is unscrewed slightly and the missing millimeters of the cable are removed. If the stroke is too large, proceed in the same way, only the extra millimeters are removed.

The maximum stroke is 160 millimeters.

Price issue

Unfortunately, over time the clutch can fail. Therefore, it will have to be changed. And how much such a purchase will cost is of interest to many car owners.

The current cost of a new set is 3-5 thousand rubles. The service of replacing it at a car service costs about the same. Therefore, think before you send your car for repairs or do the replacement yourself.

New device

Vibration

A faulty clutch can cause vibration, this is not surprising, because the assembly undergoes a rotational movement and imbalance causes vibration.

It happens that after replacing the clutch with a new one, vibration appears. It would seem that everything seems to be new, but when starting off there is some kind of vibration and jerking. Most likely, you came across a restored basket, the so-called refurbished, that is, the clutch is changed at a car service center, the old set is sent to the factory for restoration, and sometimes such imperfections happen. Such a set usually costs less than a new one, but it’s not a fact that they won’t push it on you under the guise of a new one. The box should say refurbished

.

On an old, battered clutch, if when starting off, the damper springs have become loose, or the basket begins to fall apart; if vibration occurs while driving, the basket is most likely torn; a slight vibration may indicate slight wear of the basket, especially if only the disk was replaced at the last time. In general, the clutch is a part that must be dynamically balanced; if the center of mass is suddenly disturbed, then in any case vibration will result at certain engine speeds. The flywheel will not give such a vibration for no reason, it just comes off and punches everything in its path if it is not screwed on properly.

Basic faults

The clutch is an essential part of a car using a manual transmission. In addition to knowledge about how the clutch works, it is important to have an understanding of malfunctions.

The most common of them:

- The clutch does not disengage completely. Air entering the release drive creates the feeling of a sinking pedal, as a result of which the driver cannot completely disengage the clutch;

- the clutch does not engage. Common cause: cable break;

- The clutch pedal refuses to return to its original position. Cause: the return spring has failed or is disconnected;

- loud noise when disengaging the clutch. The noise indicates wear of the release bearing;

- The clutch is not fully engaged. There are many reasons: wear of the drive disk linings, faulty springs, small pedal travel.

Improper operation and late replacement

Frequent causes of the above malfunctions are:

- untimely clutch adjustment;

- frequent and sharp jerks when the car starts to move;

- high engine speeds when the pedal is not fully released;

- towing a car;

- manufacturing defect;

- Typically, replacement involves installing a new release bearing, which is part of the clutch mechanism.

Observing clear signs of a malfunction, drivers are often in no hurry to replace it. This attitude leads to complete destruction of the elements and the car’s unsuitability for use.

Clutch replacement price

You need to decide whether you will trust the services or make the replacement yourself.

Estimated cost for replacing the clutch and adjacent parts in service centers:

These prices include the cost of specialist work. Replacing it yourself allows you to save a lot: the average price of a clutch kit is 3,000 rubles.