Result:

AvtoVAZ supports died within half a year. Moderately tough. Not reliable. MONROE worked for a year without any complaints. Very soft, really very soft. You need to be extremely careful when installing. I damaged one during installation and had to buy a new one. Overall, I was pleased with the MONROE supports. The assomies have been standing for 3 years now. They are tough. Very reliable. It's been 4 years of use. Never let us down. I recommend Assomi to everyone!

3. Rubber salen blocks.

Front hinge cushion 2108-2904050 – 2 pcs. Lower arm joint 2108-2904040 — 2 pcs. Rear extension joint 2108-2904046 – 4 pcs. Rod cushion 2110-2906040 – 2 pcs. Stabilizer strut 2110-2906050 – 2 pcs. Reason for replacing the salenblocks: Visual deformation + deterioration of rubber parts. Selection of salen blocks Rubber salen blocks were all installed from the manufacturer BRT. There is also an alternative manufacturer that is not inferior in its characteristics, this is Rosteco. I really like Rosteco products, but not polyurethane. I am against polyurethane parts, because at low temperatures they begin to creak. Tested by personal experience.

4. Spring

Reason for replacing springs I changed the springs due to deformation of the coils. The paint on the old springs was all peeling off and they were rusty. Choice. I supplied the springs to AvtoVAZ Article 2112-2902712. The color of the springs is black with red markings. I wanted to install springs with blue markings, they seem to be softer, but I couldn’t find them. Overall I was pleased with the springs. When installing the springs on the strut, I used SS20 sound insulators. Result: The front of the car rose a couple of centimeters. The noise on the bumps has disappeared.

5. Compression stroke buffer (Chipper)

Reason for replacing the bumper The old bumper became unusable and simply fell apart.

Choice. I installed the bumpers from the manufacturer PromTehPlast, white. Article: 2110-2902816. There are also yellow bumpers made in Syzran. I liked them less in appearance. For the white bumpers, I can say that it’s been 3 years since they’ve been on my car, they’re like new. I periodically check the chassis, everything is fine with them. 6. Protective casing (Boots of the struts)

Reason for replacing the boots of the struts There were numerous cracks on the boot of the struts, which indicated that they had already seen a lot.

Choice. Anthers should only be installed on BRT and the original. Unfortunately, we came across a cooperative. The lifespan of cooperative ones is 2-3 months, after which they fall apart before our eyes. Article: 2110-2905681. 7. Ball joint

Reason for replacing the ball joint. The chassis had knocking noises on bumps. Having rested the pry bar between the ball joint pin and the lever, press the pry bar and see the play. Play in the ball joint is unacceptable. Selection For the experiment, the following ball joints were taken: 1. TRW Article No.: JBJ156 2. AvtoVAZ Article No.: 2110-¬2904192 3. Track Champion Article No.: 2108-2904185ТЧ Result: I did not notice any difference between the ball joints. Everything is of good quality. I drove the first two for about 3 months. The last ones were TRACK. They have been standing for 3 years already. There are no problems observed. The rest are in stock. We liked the track because of its transparent boot, which in turn makes it possible to control the presence of lubricant before installation and the ingress of water into the support during operation.

8. Steering end

Reason for replacing tie rod ends.

At speed, it felt like the car was not driving smoothly, but seemed to be floating. I had to catch her on the highway. Lifting the wheel with a jack and moving the wheel from side to side with your hands, a clear play was visible. Choice. The following tips were taken for the experiment: 1. LEMFOERDER Article number: 2526001 left, 2526101 right. 2. Bel Mag (set of 2 pcs.), Article: BM.3106 3. AvtoVAZ Article: 2110-3414057 left, 2110-3414056 right. Result: Limferder died almost immediately. MTBF was 3 months. Next I installed the AvtoVAZ tips Article number: 2110-3414057 left, 2110-3414056 right. AvtoVAZ tips have served me to this day for 3-4 years. Bel Mag lies in the box and waits for its time. 9. CV joint (Grenades)

The reason for replacing the internal CV joints. At speed, when releasing the clutch pedal, there was a knocking sound, like metal hitting metal. It happened once and then disappeared until you released the clutch again. It was clearly audible on the highway. Choice. Now the market offers a large list of CV joints, both domestic and imported. When comparing CV joints, the choice fell on AvtoVAZ. I liked the quality of the metal processing (there are no rough traces of mechanical processing). Traces of heat treatment (tarnished color) are clearly visible. Clear manufacturer markings on the CV joint and boot. Article: 21080-2215056. Result: The metallic knock when releasing the clutch pedal has disappeared. Reason for replacing outer CV joints. The outer CV joints were replaced due to large play. The backlash is checked when the entire drive is removed. You hold the shaft with one hand, and with the other you move the CV joint from side to side. Also, when moving the car backwards, the engine jerked violently. The problem was solved after replacing the CV joint. Apparently he was wedged. The working play on the new CV joints was 3-4 mm, while on the old ones it was 10-12 mm. Choice. The CV joint was installed by AvtoVAZ Article: 2110-2215012. I chose it according to the same criteria as the inner CV joint.

10. Body reinforcements

1. Stretching the front struts UR2

Front strut stretching

Information from the official website of Tehnomaster: — the accuracy of car control when turning is increased; — increases vehicle stability when driving in a straight line; — deformation of the body is reduced when the car moves around corners and on uneven roads, which significantly reduces the likelihood of fatigue cracks appearing on the body;

Conclusion after installation: I cannot say that I felt any changes after installing this amplifier. Perhaps something has changed, but not significantly.

2. Bulkhead amplifier 2110 Information from the official website of Tehnomaster: — The removable bulkhead amplifier reduces the deformation of the bulkhead in the area of the crankcase mounting brackets and the movement of the crankcase mounting studs under a load on the steering wheel of ±40 N*m by half. — The movement of the crankcase after installing the amplifier is reduced by 2.5 times, and the steering wheel rotation angles are reduced by about 10 degrees. Explanation: with a load on the steering wheel of ±40 N*m, the steering wheel rotation angles without power are 53-54 degrees and 42-45 degrees with power.

Conclusion after installation: I cannot say that I felt any changes after installing this amplifier. Perhaps something has changed, but not significantly.

3. Stretch of levers (lower) – VAZ 2110-2112 (AR 0160 / AR10-2801070) Information from the official website Auto product: Confident cornering at speed. Increased body life. Reduces the movement of the front suspension arm bracket by more than 3 times. Reduces stress in the arm bracket and the spar-to-floor connector by 35%. Reduces stress in the bulkhead and right steering gear bracket by 8.5%.

Conclusion after installation: The result was pleasantly surprising. The car became tougher. Handling is better. I began to take turns more confidently. To be honest, I didn’t expect the result to be so noticeable. Perhaps this result was obtained as a result of installing the amplifiers described earlier.

Features of shock absorber struts on the VAZ-2110

Where is that shock absorber strut hidden in the shadow of the wheel?

Depending on the intensity of use of the vehicle and the quality of this suspension unit, the struts need to be replaced. The procedure for replacing this suspension part is familiar to most VAZ-2110 owners. The standard period for the maintenance of “tens” shock absorbers is about 35,000 km. This depends on the care of the driver, the manufacturer of the part and the operating conditions. In rural areas, the replacement interval is much shorter.

How to determine when it's time to change the struts? Signs of wear

Oil leaks on the strut housing.

Since disassembling a car's suspension is quite a labor-intensive task, before you undertake repairs, you need to determine whether the problem is really in the strut. To do this, you need to focus on the following indirect signs:

- A strong beating is felt on the steering wheel of the car.

- Body vibration increases significantly. Particularly strong vibration comes from the side of the faulty rack.

- The car begins to stop worse when braking.

- When turning, the car starts to skid.

- If you let go of the steering wheel on a flat road, the car will drift strongly to the side.

- Even with a visual inspection, you can notice oil leaks on the shock absorber.

- If you ask someone to drive slowly and listen yourself, you can hear strange knocks and noises in the shock absorber, which is under suspicion.

Anthers

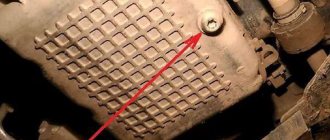

When carrying out repairs, you need to pay attention to the condition of the boot.

A new boot is inexpensive, it is better to replace it in any case.

It is better to replace it immediately, since the rubber is not intended for long-term use. If this element is well preserved, then when replacing it you should try not to damage it.

With your own hands

The beginning of the strut shock absorber leakage can be seen if you look under the boot.

Since service stations will charge money for diagnostics, many owners make do with the more popular method of checking.

This method consists of manually rocking the car yourself. The “ten” needs to be strongly shaken, and then the hands must be sharply removed. If the rocking of the body does not stop immediately, then most likely they have exhausted their service life.

Where is the support bearing installed and what function does it serve?

It is noted above that the MacPherson strut also acts as a steering knuckle. From below, rotation around the axis is ensured by a ball joint, through which the levers are attached to the rack.

If the upper strut support were not a limiter for the spring, then there would be no problems with rotation (the shock absorber rod can rotate freely).

But the spring, being in a preloaded state, creates a fairly strong force on the cups, and as a result on the support, which is rigidly attached to the body.

Therefore, a support bearing is installed between the support and the upper spring cup.

Thanks to this design solution, under the influence of the steering mechanism, the stand (assembled) can rotate around the axis, while the support remains motionless.

It is precisely the support bearing that provides the ability to rotate the shock absorber strut.

The danger of worn struts

Some car owners believe that failure of the front shock absorbers is not a problem, especially if the car does not even tilt to one side. In fact, problems with the front suspension can lead to the following troubles:

- The support bearings will fall apart, which can lead to an accident.

- The tires will begin to wear unevenly, and you can forget about wheel alignment. In addition, so-called “bumps” may appear on the tires.

- Wheel bearings won't last long either.

- Brake performance will become unsatisfactory because the pads will wear unevenly.

It turns out that one problem that is not corrected in time can lead to serious damage to the car.

Purpose and description

Dampers, commonly called Shock Absorbers, are mechanical devices that smooth out vibrations when a vehicle moves, converting mechanical energy into thermal energy. The struts are tightly connected and work in tandem with springs, springs, torsion shafts, cushions and other parts of the vehicle chassis.

It is necessary to observe the condition of the car and be sure how and when to check the shock absorber device, since they are the ones that keep the car in the correct direction and position. If one of the important suspension elements fails, and postponing the test leads to subsequent malfunction of the chassis parts.

Which ones to choose (items)

Original VAZ-2110 stand.

In the case of spare parts for the VAZ-2110, original consumables are not always the best choice. As for the most popular shock absorbers, they have the following article numbers:

- The front left shock absorber on the VAZ-2110 has article number 21100-2905403-30;

- Right - article number 21100-2905402-30.

The article number is stamped on the rack body.

Factory analogues can be recommended to those drivers for whom rigidity indicators are important. It is the original A-pillars that do an excellent job of transporting cargo, although for comfortable movement in the city they are clearly inferior to their softer counterparts.

Some drivers install sports struts that are significantly more rigid than even the factory parts. So they are trying to increase the life of this suspension unit. In any case, it is not recommended to install sports spare parts, since they are designed for completely different operating conditions.

Some people praise Samara spare parts, which are known as SS-20. They can be either oil or gas. Oil shock absorbers are much cheaper, but gas shock absorbers can operate over a wider temperature range. For example, in winter the rigidity of cheaper parts will increase significantly, although for some car owners this does not matter.

Front struts SS-20 series “Comfort” assembled.

Analogs

In addition to domestic parts, you can install front struts from other manufacturers, which will cost much more:

- Sachs;

- Monroe;

- Brillstein;

- Kayaba;

- KONI.

Although installing expensive parts on domestic cars is not always economically justified, some people prefer to spend a large sum once, but then do not have to worry about replacement for several years.

Aston racks are another analogue of domestic production.

Front shock absorber replacement procedure

Before you begin the front suspension repair procedure, you need to prepare the necessary set of tools. In addition to the standard set of wrenches and screwdrivers, you will need a device for compressing the springs on the struts and a special puller for ball pins. It is advisable to have WD-40 liquid, since rusty and rooted bolts will definitely be encountered during the repair process.

The replacement process will proceed as follows:

- First, the nuts that connect the support to the body cup are unscrewed.

Using a 13 mm spanner, unscrew the nuts securing the upper support.

- The supports are released.

- The rod ends are removed. To do this, it is advisable to use a special puller.

We take out the cotter pin.

Unscrew the nut.

Press out the finger.

- The lower part of the strut is disconnected from the steering knuckle.

We unscrew the nuts of the bolts with a head of 19, then knock them out.

- The stand is removed and replaced with a new one.

Pull back the fist and remove the stand.

Before releasing the rod, you need to compress the shock absorber spring. It’s better to immediately fill the ball pin with Vedashka, since it will be very difficult to remove it without a special puller, and a VD-40 puller won’t hurt.

To compress the springs we use special ties.

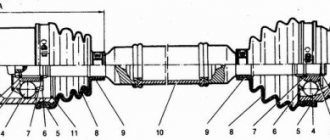

12.5. Removing the shock absorber strut and disassembling it

We remove and disassemble the shock absorber strut in cases where it is necessary to replace the upper support, spring, telescopic strut or install a new shock absorber cartridge into it.

We carry out the work on an inspection ditch or a lift, but you can get by on a flat platform.

There are two options for dismantling the shock absorber strut: one allows you to avoid subsequent adjustment of the steering wheel alignment angles, the second allows you to quickly complete the work with more compact units, but after that it is necessary to adjust the steering wheel alignment angles. We replace the telescopic stand according to the second option.

EXECUTION ORDER

The nuts of the strut housing are often sold complete with a cartridge, so you can unscrew the standard ones with a chisel.

We assemble the stand in the reverse order, working with the compressed spring as carefully as possible.

| ||||||

Wheel alignment, is it necessary?

Many VAZ-2110 owners are interested in whether it is necessary to do a wheel alignment after replacing the front strut. This procedure is optional only when replacing the rear struts.

When replacing front shock absorbers, wheel alignment is a mandatory procedure.

You can replace the strut yourself, but to adjust the wheel alignment you need to go to a service center.

Bench testing

If you are unsure of the accuracy and correctness of your own conclusions regarding the proper operation of the racks, it is recommended to rely on specialists who perform diagnostics on a vibration stand. Naturally, the verification procedure is paid, but with the help of verification, you can get an opinion from specialists and precise instructions for the next action.

We recommend:

Replacing the front wheel hub bearing - step-by-step instructions

To avoid wasting money, you should use the following tips:

- Check the computer settings by technicians to diagnose a specific vehicle model.

- Taking into account the age of the machine, the weight of the body, settings and standards may have certain discrepancies.

- Check wheel alignment and tire pressure before the test.

- Contact a good service center that suits you individually.

Checking the racks is not as simple as it might seem initially; it is a very difficult and laborious process, taking into account every little thing and detail.

conclusions

Of course, suspension repair work is quite complex and labor-intensive.

This is not easy to do without a special tool. But domestic motorists often make do with even a standard set of keys, which is available in every garage. The strut spring is compressed using a wire, and the ball pin is knocked out using various available devices. A VAZ is not a foreign car, so the car tolerates such treatment.

Didn't find the information you are looking for? on our forum.