How to understand when it's time to change piston rings

When the car's oil consumption increased significantly, compression in the cylinders dropped. Before quickly rushing to the garage, you need to measure the compression, first on dry cylinders and then fill the cap from a bottle of oil and measure again and compare the results. If dry cylinder performance is lower, the piston rings must be replaced.

If not, then the rings have nothing to do with it, and you should pay attention to the caps and valves. Also, if low-grade oil is used, the piston rings may become stuck. This phenomenon usually occurs in cars whose engines have not been used for a long time, or have been used for very short distances.

You can decarbonize the rings as follows: unscrew the spark plugs and pour kerosene into the cylinders overnight; this will save you from loosening the carbon deposits.

Approximate price

On average, a major overhaul of a VAZ-2114 engine costs from 22,000 rubles.

Engine repair cost broken down:

- Dismantling – 500 rubles .

- Installation – 600 rubles .

- Replacing oil scraper caps - 2000-4000 rubles .

- Pulling the engine sump - about 490 rubles .

- Crankshaft grinding - from 900 rubles .

- Replacing the crankshaft bearing - about 330 rubles .

- Honing and boring on a standard block - from 1000 rubles .

- Replacing the valve cover - 420-620 rubles .

- Replacement of the engine mount - from 540 rubles .

Replacing the engine on a VAZ-2114 will cost approximately 5,500 rubles . This does not include the price of a new unit.

Dimensions and markings of piston rings VAZ 2109 – 2115

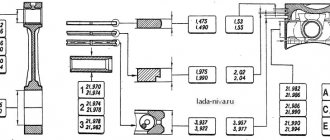

I will now give you the main dimensions of the connecting rod and piston group below in the figure.

The piston is cast aluminum. According to the outer diameter, the pistons are divided into five classes (A, B, C, D, E) every 0.01 mm. The outer surface of the piston has a complex shape. Therefore, it is necessary to measure the piston diameter only in a plane perpendicular to the piston pin, at a distance of 55 mm from the piston bottom.

Main dimensions of the connecting rod VAZ 2109 – 2115

Based on the diameter of the hole for the piston pin, pistons are divided into three classes (1, 2, 3) every 0.004 mm.

The classes of piston diameters and holes for the piston pin are stamped on the bottom of the piston (Fig. 4).

The piston is cast aluminum. According to the outer diameter, the pistons are divided into five classes (A, B, C, D, E) every 0.01 mm. The outer surface of the piston has a complex shape. Therefore, it is necessary to measure the piston diameter only in a plane perpendicular to the piston pin, at a distance of 55 mm from the piston bottom.

Dimensions of piston rings VAZ 2109 – 2115

Based on the diameter of the hole for the piston pin, pistons are divided into three classes (1, 2, 3) every 0.004 mm.

The classes of piston diameters and piston pin holes are stamped on the piston crown.

Piston markings VAZ 2109 – 2115

Where and from whom can I order the service?

If an engine overhaul of a VAZ-2114 is required, then there are several options:

- Take the car to a car service center.

- Contact a private master.

- Repair the unit yourself.

A major type of repair requires extensive knowledge, skills, experience, certain equipment and tools. Therefore, only a master of a service center can carry out a high-quality engine restoration. Car service centers issue a warranty certificate. You should contact private traders only on the advice of good friends. Among such workers there are often low-skilled people. In addition, they do not provide a warranty card.

Table of nominal sizes of cylinders and pistons

| Size group | Engine model VAZ 2109 – 21099 | Engine model VAZ 2113 – 2115 | ||

| Cylinder diameter mm | Piston diameter mm | Cylinder diameter mm | Piston diameter mm | |

| A | 76,00 – 76,01 | 75,965 – 75,975 | 82,00 – 82,01 | 81,965 – 81,975 |

| B | 76,01 – 76,02 | 75,975 – 75,985 | 82,01 – 82,02 | 81,975 – 81,980 |

| C | 76,01 – 76,03 | 75,985 – 75,995 | 82,02 – 82,03 | 81,980 – 81,985 |

| D | 76,03 – 76,04 | 75,995 – 76,000 | 82,03 – 82,04 | 81,985 – 81,995 |

| E | 76,04 – 76,05 | 76,000 – 76,005 | 82,04 – 82,05 | 81,995 – 82,000 |

By weight, pistons are sorted into three groups: normal, increased and decreased by 5 g. These groups correspond to markings on the bottom of the piston: “G”, “+” and “-”.

All pistons on the engine must be of the same mass group. Repair size pistons are manufactured with an outer diameter increased by 0.4 and 0.8 mm.

An increase of 0.4 mm corresponds to a marking in the form of a triangle, and an increase of 0.8 mm corresponds to a marking in the form of a square. The arrow on the piston crown shows how to properly orient the piston when installing it into the cylinder. It should be directed towards the camshaft drive.

Marking of the connecting rod: 1 – class of the connecting rod by weight and by the hole in the upper head. 2 – cylinder number

The piston pin is a hollow steel, floating type, which rotates freely in the piston bosses and connecting rod bushing. The pin is secured in the piston hole by two retaining rings. According to the outer diameter, the fingers are divided into three classes every 0.004 mm. The class is marked with paint on the end of the finger: a blue mark is the first class, a green mark is the second class, and a red mark is the third class.

Places where metal can be removed when adjusting connecting rod heads

The piston rings are made of cast iron. The upper compression ring has a chrome-plated barrel-shaped outer surface. The lower compression ring is scraper type. The oil scraper ring has chrome-plated working edges and an expansion coil spring. Repair size rings are marked digitally “40” or “80”, which corresponds to an increase in the outer diameter by 0.4 or 0.8 mm.

The connecting rod is steel, forged. The connecting rod is processed together with the cover and therefore they are individually non-interchangeable. To avoid mixing up the caps and connecting rods during assembly, they are marked with number 2 (Fig. 5) of the cylinder in which they are installed. A steel-bronze bushing is pressed into the upper head of the connecting rod.

Based on the diameter of the hole in this bushing, the connecting rods are divided into three classes every 0.004 mm. The class number 1 is stamped on the connecting rod cover. Based on the weight of the upper and lower heads, connecting rods are divided into classes, marked either with a letter or with paint on the connecting rod cover. Connecting rods of the same weight class must be installed on the engine.

| Classes of connecting rods based on the weight of the upper and lower heads | |||

| Mass of connecting rod heads, g | Class | Marking color | |

| top | bottom | ||

| 184+2 | 489+3 495+3 501+3 | F L B | Red Green |

| 188+2 | 489+3 495+3 501+3 | X M IN | |

| 192+2 | 489+3 495+3 501+3 | C N G | Blue |

The weight of the connecting rods can be adjusted by removing metal from the bosses on the upper head and on the cover to a minimum size of 33 and 32 mm (Fig. 6). After removing the metal from the connecting rod cap, it is necessary to mark the classes of the connecting rod on it by the hole for the piston pin and by weight.

Basic engine parameters

The following parameters are associated with the operation of a piston internal combustion engine.

- Top dead center (t.m.t.) is the uppermost position of the piston.

- Bottom dead center (BDC) is the lowest possible position of the piston.

- Crank radius - the distance from the axis of the crankshaft journal to the axis of its connecting rod journal

- Piston stroke is the distance between the extreme positions of the piston, equal to twice the radius of the crankshaft crank. Each piston stroke corresponds to a rotation of the crankshaft through an angle of 180° (half a turn).

- Stroke is part of the work cycle that occurs when the piston moves from one extreme position to another.

- Combustion chamber volume is the volume of space above the piston when it is at top dead center.

- Cylinder displacement is the volume released by the piston when it moves from top dead center to bottom dead center.

- The total volume of the cylinder is the volume of space above the piston when it is at bottom dead center. The total volume of the cylinder is equal to the sum of the working volume of the cylinder and the volume of the combustion chamber.

- Engine displacement for multi-cylinder engines is the product of displacement times the number of cylinders.

- Compression ratio is the ratio of the total volume of the cylinder to the volume of the combustion chamber.

Review of popular models of piston rings VAZ 2109 – 2115

There are many companies that produce piston rings, as well as many fakes, and there is simply not enough time to look through them all. Therefore, let's look at those manufacturers of piston rings that differ from others in normal quality and price. The first thing I want to recommend is SM piston rings.

Piston rings from SM

And

Piston rings from Mahle.

These companies produce piston rings for VAZ cars of various diameters and are perfect for us. They are most likely produced in China, because the original ones will cost much more. But this does not mean that everything is so bad, their quality is excellent. I still recommend rings from “SM”, because their price is much lower than that of “Mahle”, and the quality is the same, so why pay more and overpay for the brand.

The upper compression ring from these manufacturers is chrome-plated steel, but from the “SM” company it is copper-plated, this is clearly visible in the top photographs. The second compression ring is black and made of cast iron, but the ring from Mahle has a darker color. On the picture

The lower oil scraper rings are metal typesetting. The graphics on the left are “SM”, and on the right “Mahle”.

I recommend using metal oil scraper rings, because, unlike box-type rings, they fit perfectly in the cylinder, are resistant to overheating (they do not lose their spring properties) and their main advantage is that they work as two rings independent of each other. The rings are box-type, very afraid of overheating. When they overheat, they lose their spring properties and do their job poorly. And one more serious disadvantage: they require very careful running-in. At the slightest deviation from the running-in conditions, the working edges of the ring may break off in some places and allow oil to leak through.

Of course, there are other manufacturers of piston rings, but as usual they are complete fakes and sometimes it’s not possible to choose quality ones

Overhaul of the VAZ 2114 engine 8 valves with your own hands - all details

Many car enthusiasts, taking into account the price of a VAZ car and the possible cost of repairs in a car repair shop, are thinking about how to remove the VAZ 2114 engine with their own hands.

This article is intended specifically for thrifty and independent car owners, in which we will figure out how to remove the engine, install it back, what options for this procedure exist and how to check the compression after the repair. In addition, we will look at how to do this yourself without involving other people.

Applicability of CPG kits 1004006

The kits are designed for installation on 6-, 8- and 12-cylinder V-shaped engines YaMZ 130x140 family in supercharged and naturally aspirated versions, with old and new cylinder blocks.

Old cylinder blocks were produced before 08/10/2008 (before the changes were made). New cylinder blocks with modifications were produced after 08/10/2008.

Composition of the main serial CPG kits for YaMZ V6, V8, V12 engines

- Set 1004008

: sleeve, piston, O-rings. - Kit 1004005

: kit

1004008

+ piston ring kit - Kit 1004006

: kit

1004005

+ piston pin and circlips.

Applicability of CPG YaMZ

| YaMZ engines | Applicability of CPG kits for an old block | Applicability of CPG kits for a new unit |

| Engines YaMZ V6, V8 without supercharging 236M2, 236G, 236D, 236DK, 238M2, 238AM2, 238VM, 238GM2, 238IM2, 238KM2, 238AK | 236-1004005236-1004006 236-1004008-B | 236-1004005-B2 236-1004005-B3236-1004006-B2 236-1004006-B3 236-1004008-B |

| Engines YaMZ V6, V8 supercharged, Euro-1 236N, 236NE, 236NK, 236NB, 236ND, 236B, 236BI, 236BI2, 238B, 238BV, 238BK, 238BV, 238BL, 238BN, 238BE, 23 8D, 238DI, 238DK, 238ND3, 238ND4 , 238ND5, 238ND6, 238ND7, 238ND8, 238DE | 238B-1004005 238NB-1004005-A4238B-1004006 238NB-1004006-A4 238B-1004008 238NB-1004008 | 238B-1004005-B 238B-1004005-B2 7511.1004005-60 7511.1004005-61238B-1004006-B 238B-1004006-B2 7511.1004006-60 7511.1004006-61 238B-1004008-B 7511.1004008-60 |

| Engines YaMZ V12 naturally aspirated 240M2, 240BM2 | 240-1004005-A240-1004006-A 240-1004008 | |

| YaMZ V12 supercharged engines 240NM2, 240PM2 | 240N-1004005-A 240N-1004005-A2240N-1004006-A 240N-1004006-A2 240P-1004008-B 240P-1004008-V | |

| YaMZ V6, V8 supercharged engines, Euro-2, individual cylinder head 7601.10, 7511.10, 7512.10, 7513.10 | 7511.1004005-017511.1004006-01 7511.1004008-01 | 7511.1004005-407511.1004006-40 7511.1004008-40 |

| YaMZ V6, V8 supercharged Euro-2 engines, with a common cylinder head 236NE2, 236BE2, 236ND2, 7601.10, 238BE2, 238DE2, 7511.10, 7512.10, 7513.10 | 7511.1004005-107511.1004006-10 7511.1004008-10 | 7511.1004005-50 7511.1004005-517511.1004006-50 7511.1004006-51 7511.1004008-50 |

| YaMZ supercharged engines V6, V8, Euro-3, individual cylinder head 656.10, 658.10 | 658.1004005658.1004006 | |

| YaMZ V6, V8 supercharged engines, Euro-3, -4, -5, common cylinder head 6561.10, 6562.10, 6563.10, 65651, 65652, 65653, 65654, 6566, 65661, 6567, 65672, 65674, 6 5675, 658.10, 6581.10 , 6582.10, 6583.10, 6585, 65851, 65852, 65853, 6586, 65861, 65862, 6587 | 658.1004005-10658.1004006-10 658.1004008-10 |

Variety of STK products

In fact, everything is not limited to Prioras, Kalinas and GAZs. The STK company has manufactured many groups of pistons for a wide variety of machines. Today Samara Trading offers pistons for:

If we approach the issue more practically and classify pistons not by models and brands, but by their sizes (diameters and strokes), then STK is ready to offer pistons for virtually all cars.

STK pistons for VAZ cars are suitable for such cars as:

STK pistons for OKA, GAZ, Buran, PAZ and UAZ cars:

STK pistons for ZIL and URAL cars:

STK pistons for Volkswagen cars:

STK pistons for Opel and Ford cars:

Pistons for sporting purposes for VAZ cars:

Installation on PRIORU

We will describe the installation of STK pistons on a VAZ (PRIORA), since this particular car is the most purchased in our country and it is this car that most often has problems with the timing belt.

Despite the fact that making a replacement in your yard on your knees is an impossible task, the installation process does not hide any difficulties. First you need to disassemble the engine.

Many drivers sacrifice power for the sake of greater practicality - you can understand them, especially if you look at the aftermarket. If there is a break, you can fly into such repairs that it won’t seem like much, but this way you are protected.

Source