The formation of soot and coke in a gasoline or diesel engine is a natural process that occurs in a closed combustion chamber of the fuel-air mixture.

Carbon deposits are essentially a layer of unburned deposits on the walls of the chamber. Over time, this layer becomes thicker and at a certain point can cause malfunctions of the power unit.

Let's look at the main signs and consequences of engine coking, as well as ways to clean it yourself without disassembling it.

Why is carbon deposits dangerous in an engine?

The carbon deposits formed in the engine significantly worsen its performance. This is due to the fact that:

- The carbon layer has poor thermal conductivity, so it impairs the removal of excess heat and the engine overheats.

- In turn, as a result of overheating, the motor power decreases, its other characteristics deteriorate, and its service life is reduced.

- Also, carbon deposits formed in the combustion chambers often cause detonation and glow ignition, which can result in serious engine damage.

What could be causing the deposit?

The main factors influencing the intensity of carbon deposits are:

- technical condition of the engine;

- quality and suitability of the motor oil and fuel used for the given engine;

- vehicle operating conditions.

For example, the use of low-grade fuel, with a high content of heavy fractions, can lead to the formation of a large amount of soot in a very short time. Which, if normal fuel was used, would take many years to form.

Methods for removing carbon deposits from an engine

1. In some cases, you can remove carbon deposits from the engine by filling the car with high-quality fuel and driving it at high speed for 10-15 km. This method does not always help and in this case you have to resort to more effective methods that also do not require disassembling the engine.

2. Carbon deposits are removed using a special solution that can be prepared:

- mixing 50% acetone;

- 25% kerosene;

- 25% motor oil.

The finished mixture must be poured through the hole for the candle into each cylinder, 100 ml. It is advisable that the engine be warm at this time and it is best if this carbon removal procedure is timed to coincide with a scheduled engine oil change.

First, even before pouring the solution, it is necessary to do some work to prepare the engine for cleaning. The purpose of this preparation is to prevent compression in the cylinders. How to achieve this depends on the design of the particular engine.

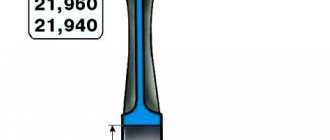

The simplest option is to install temporary metal plates between the valve stems and rocker arms, being careful not to disturb the valve adjustment. The plates should be about 0.8 - 1 mm thick and approximately 10 mm wide.

Having completed the preparation, you need to unscrew the candles and pour the prepared solution into the cylinders.

After this, the spark plugs are screwed back into place and the engine crankshaft is cranked 10 to 15 times using the starting handle. Or they crank the crankshaft by rotating the drive wheel hanging on a jack, while engaging the gear.

Then you need to remove the previously installed temporary plates.

The solution must be left in the cylinders for 10 - 15 hours, then unscrew the spark plugs and turn the crankshaft again, making about 10 revolutions.

- drain the engine oil;

- replace the oil filter;

- fill in new oil;

- Reinstall the cleaned spark plugs;

- start the engine.

After cleaning the engine, it is recommended to drive the car on a good road at high speed.

After a run of approximately 100 km, almost all of the carbon deposits will be removed. Do not forget that after driving 500 km you need to change the oil and oil filter in the engine again, as there will be a lot of dissolved impurities in the oil.

How to avoid carbon deposits

To avoid the formation of plaque, soot, and coking of moving and stationary parts of an internal combustion engine, the following preventive measures should be carried out:

- Fill with high-quality motor oil.

- The ignition, the valves, and everything that is needed for the correct operation of the internal combustion engine must be correctly adjusted. The more completely the supplied fuel burns, the less carbon deposits will be on the pistons, valves and combustion chambers. There should be no over-suction or overflow. Therefore, the condition of pistons, cylinders, connecting rods, injectors, spark plugs, valves, valve seals will increase the period of formation of soot and coke.

- Change oil and filters in a timely manner. If you fill in the cheapest oil, then at least you need to change it more often (for example, after 7 thousand kilometers). The cleaner the engine oil, the correspondingly cleaner the parts will be (no soot and coke). When using high-quality expensive motor oils, the replacement schedule is 15 thousand kilometers.

- Pass maintenance in a timely manner.

- Fuel with quality fuel. The fuel liquid contains resins, their content must comply with the standards. Therefore, it is better to refuel your cars at large gas stations.

Also, if desired, before updating the engine oil according to schedule, you can do a “soft” cleaning to prevent the formation of layers of soot and coke.

When high oil consumption begins, problems with the engine have already begun, for example, these are signs that:

- piston oil scraper rings are stuck or worn out;

- not working valve stem seals;

- burnout of valves or coking of valves;

The conclusion from everything described above is that the cost of effort and money for prevention is much less than repairing a coked engine.

This video describes how to decarbonize parts of the cylinder-piston group.

What is the service life of the cylinder-piston group of the fifty-kopeck scooter motor? For the most common design with a cast iron sleeve, it is small - 12-15 thousand kilometers. And the “unknown” Chinese have less in total. But that's if you take care of her. And it's okay to drive!

The survivability of parts does not depend on the eminence or “nationality” of the manufacturer. Namely, how you drive, what you fill, and how you maintain it. Tested from personal experience. I had a 50cc Suzuki Adress scooter. It seems like a “Japanese”, but after I killed him quite harshly: I drove to the maximum forever, looked after him poorly, etc. - then he “swelled” quickly for me, despite the “Jap”.

The piston engine can “die” much earlier - twice as fast. The most common reason is a combustion chamber that is excessively clogged with soot. Carbon deposits significantly complicate the removal of heat from the piston, causing overheating of both it and the entire engine, which causes premature wear of the rubbing surfaces. There are often cases of piston rings being “stuck” by carbon deposits, and when they stop springing, the rings lose their ability to maintain compression pressure (compression) - and the engine loses power. Therefore, you can count on the factory-provided resource of the piston group only if you remove carbon deposits every 5-6 thousand kilometers.

To “deal with it” most conveniently, remove the power unit from the “stool”. You will say that the design of some scooters (say, Honda, Daelim) allows you to remove the cylinder without removing the motor. But why should you hunch before him? And then, an inexperienced mechanic may be able to remove the cylinder and piston, but then it is unlikely to reassemble it without damaging the parts. In addition, dismantling the power unit is no more difficult than disassembling a manual meat grinder.

Useful video

Watch the video showing an effective means for removing carbon deposits in the combustion chamber:

And in this video, step-by-step instructions for decarbonizing an engine using kerosene and solvent:

A car with proper mileage and an unknown history... We drive, refuel, and don’t think about anything bad. A visit to the oiler, draining and filling, a mechanic’s conclusion - the oil immediately became dirty. It is not known whether this is due to the long service life of the engine or whether the lubricant replacement period has simply been missed... or is it of mediocre quality? Or maybe the work hasn’t completely merged. Definitely, there is no need to be upset - there is a way out.

Causes of carbon deposits on spark plugs

After a run of 15-20 thousand kilometers, spark plugs require cleaning. They don't necessarily stop functioning, just cleaning the electrodes and the inside of the spark plug will improve the quality of the spark. To keep track of mileage, spark plugs should be checked and cleaned every service.

Carbon deposits on the main or side electrode appear due to the use of low-quality fuel. Gasoline with a large number of harmful impurities, after detonation of the mixture, settles on the electrodes as a thin film of oxidizer. If you constantly use fuel of this quality, you will have to clean the spark plugs very often.

Also, one of the reasons for the occurrence of carbon deposits is incorrect adjustment of the car carburetor. If it is not adjusted accurately enough, then a much larger amount of gasoline and air will flow than is required to start and smoothly operate the engine.

The final reason for electrode deposits to appear too often is the weather. At sub-zero temperatures (especially if the car is outside), starting the engine is more difficult and not always the first time. Therefore, it is also advisable to clean the spark plugs after the winter driving period.

We explain: how to flush a car engine from carbon deposits without disassembling it yourself

Symptoms

Before flushing the engine from carbon deposits inside, it is worth figuring out whether there is any at all. The presence of foreign inclusions in the combustion chamber is indicated by:

- difficult cold start;

- engine tripping;

- smoke from the exhaust pipe is blue or black;

- reduced compression;

- excessive consumption of fuel;

- detonation and overheating of the internal combustion engine at high speeds.

The presence of a problem is also indicated by the unclear response of the internal combustion engine to intensive throttling and polluted exhaust. In advanced cases, burning particles may fly out of the pipe. But this is only possible in the absence of a catalyst.

If such symptoms are detected, you definitely cannot hesitate. Exacerbation is fraught with the emergence of critical situations:

- valves coke;

- rings become dirty;

- ignition occurs not from a candle, but from smoldering burning (glow ignition).

Experienced mechanics recommend two-stage cleaning: removing carbon deposits and cleaning the oil system. However, with the latter, not everything is so simple.

Cleaning deep contaminants in the lubrication system

In extreme cases, thorough cleaning of the oil system is necessary. It is quite natural that it will not do without easy disassembly of the motor. In general, the procedure is divided into three episodes:

- Removing the pan and valve cover. Mechanical cleaning using aggressive chemicals and grinding tools.

- Reassembly and flushing of the power unit assembly with special oil or liquid added to regular lubricant.

- Removing the tray for manual cleaning again.

The pan is, first of all, a collection of all kinds of resinous dirt. What happens if you immediately pour detergent into an internal combustion engine with an unknown history, without cleaning the oil sump. Everything is obvious - the sludge will rise and clog the oil intake screen. A red oil can will light up on the instrument panel - the engine will operate in oil starvation conditions. You will have to disassemble everything and clean it manually.

Cleaning

The above actions, according to experts, apply only to seriously contaminated engines. If high-quality lubricant was used and its replacement interval was observed, then the technology for flushing the engine from carbon deposits without disassembling is quite applicable:

- Prepare the cleaning mixture.

- Remove the spark plugs.

- Align the pistons level with each other.

- Pour 50 cubes of detergent into each combustion chamber.

- Screw in the candles.

- Leave for 7-10 hours.

- Remove the mixture igniters.

- Add 25-50 ml of cleaning agent to each cylinder.

- Turn the engine with the starter.

- Put the candles back.

- Start the power plant.

- Fill the oil system with accelerated flushing for the time specified in the instructions.

- Turn off the engine.

- Change oil and filter.

Attention! Under no circumstances should you start an internal combustion engine with the combustion chamber filled with cleaning solution and spark plugs screwed in. There will be water hammer, and the engine will have to be overhauled. The described procedure can damage the catalyst.

For particularly dirty engines

This method involves the use of a “five-minute” rinse as the most concentrated preparation.

And it is used in two stages. First, the package is divided into two halves. The first part is poured in equal portions into the spark plug holes of each cylinder. After a couple of minutes, the engine needs to be cranked several times manually - with a crooked starter or by the drive wheel with the gear in gear. Using a medical syringe, equal portions of a highly effective five-minute flush are poured into the cylinders. The procedure is repeated.

Secondly, you need to again divide the remaining half of the drug into equal parts according to the number of cylinders, again pour the flush through the spark plug holes - and leave the engine to “acidify”, wrapping the spark plugs in their places for less evaporation. After a few hours - for example, the next morning - the spark plugs need to be unscrewed and, turning the crankshaft using the starter, the remaining flushing fluid must be expelled from the cylinders.

After which the spark plugs finally return to their places and the car sets off on a 30-40 km run, during which it is necessary to maintain increased engine speeds - in the range of 3000 - 4000 rpm.

The first minutes after decoking the engine using the intensive method, a lot of smoke comes out of the exhaust pipe - the flushing preparation burns out.

During engine operation at high speeds, the working mixture removes dissolved deposits and contaminated product residues from the cylinders. The rings, actively moving in their grooves, help remove carbon deposits from them. After this, you need to change the oil and filter.

After double soaking the pistons and cylinders with a “five-minute” flush, the engine should be allowed to run for about half an hour at 3000 - 4000 rpm.

To monitor the results, you can use a compression meter or a leak test - engine diagnostics based on air leakage. On the Daewoo Lanos 1.5, which we posed for while writing this article, the leak test indicators changed as follows:

| Cylinder number | Air leakage before flushing, % | Air leakage after flushing, % |

| 1 | 50 | 35 |

| 2 | 30 | 25 |

| 3 | 50 | 25 |

| 4 | 30 | 25 |

Thus, after decoking the cylinder-piston group of the Daewoo Lanos engine with a mileage of about 210 thousand km, the compression in the cylinders leveled out. After removing carbon deposits from the pistons, its performance returned to the natural values typical for this engine model at the specified mileage.

The Leak test showed a positive result of engine flushing using the intensive method: air leakage from the two worst cylinders was reduced by half, from the two best cylinders - by 17% in each.

Main signs of engine deposits

Carbon deposits and coke are the main products during the combustion of low-quality fuel. Under the influence of high temperature, when the amount of air is not enough to completely burn the fuel-air mixture, coke is formed. It settles in the form of dense deposits on the surface of the walls of the combustion chamber. Small particles separated from the coke form carbon deposits.

An important role in carbon formation is played by motor oil, which, if the tightness of the engine components (piston rings, valve seals) is insufficient, enters the combustion chamber. By burning with fuel, oil accelerates the process of deposit formation.

Carbon deposits in the engine lead to the following main malfunctions:

- problems with cold starting of the engine;

- when the engine is running, it smokes and runs unstable;

- exhaust gases mixed with burning;

- increased oil consumption;

- loss of power;

- increased fuel consumption;

- engine detonation and overheating at high speeds

What is soot

Since the piston is the first part that takes the load from the ignition of the combustible mixture (takes the blow), it is constantly exposed to temperature, mechanical and chemical influences.

Soot is the formation of a layer as a result of burnt chemicals contained in the supplied fuel. Fuel contains various additives and impurities. When decomposed fuel substances come into contact with hot internal combustion engine parts (pistons, cylinders, valves, connecting rods), these substances stick to the hot metal and settle. Carbon deposits form especially quickly on the pistons due to incomplete combustion of the fuel-air mixture and the breakdown (decomposition) of engine oil. In other words, carbon deposits are deposits that interfere with the normal operation of the internal combustion engine, so it must be removed. Carbon removal is also called decarbonization.

The formation of carbon deposits on intake valves, piston heads, and walls of combustion chambers is the most common occurrence.

The composition of carbon deposits includes ash and carbon compounds. Solid deposits of ash + impurities and particles of unburned fuel and motor oil, also called coke. If there is a lot of coke on several parts, this is already coking of the engine.

Possible consequences of carbon deposits in the engine

It not only reduces operating efficiency, deteriorates overall performance, leads to high consumption of fuels and lubricants, but also increases the risk of serious engine damage and, as a result, expensive repairs. Main possible examples of such consequences:

- Formation of carbon deposits on the valves - the valve cannot close completely.

- deposits on the rings - rings become stuck.

- potassium ignition effect - uncontrolled ignition of the mixture from smoldering.

Cleaning the piston rings

The rubbing surfaces of pistons and cylinders, as well as the grooves for piston rings, are subject to the formation of varnishes on them. Since carbon deposits and varnish can clog the grooves for the piston rings. Due to the fact that the groove is clogged, the piston ring will expand, which will lead to damage to the cylinders (scores and scratches will appear). Therefore, if there is carbon deposits and varnishes on the upper side parts of the pistons, then operating the car in this situation will lead to premature wear of the cylinders, the repair of which will cost much more. Such reasons lead to a major overhaul of the car engine.

During operation, if the piston rings are expanded, the protective layer - hone - will be torn off from the surface of the cylinders, the cylinder liner will undergo rapid wear and the piston rings themselves will wear out.

Clogging the ring gap or groove, causing the ring itself to expand, can also cause the ring to break. Accordingly, if the piston ring breaks, the cylinder and other parts of the cylinder-piston group (CPG) will be subject to enormous wear.

It may also be that the presence of carbon deposits and varnish in the groove for the piston ring can coke the rings (they will become immobile). This phenomenon is called coking or sticking of the internal combustion engine rings.

If the piston ring has become stuck and motionless, then the compression will be less than with a properly functioning ring. And, as we already know, low cylinder compression of an internal combustion engine increases fuel consumption, forms large layers of soot and coke, increases the likelihood of engine failure during startup and creates interruptions in engine operation. Due to the fact that the tightness is broken due to the presence of the piston ring, more oil enters the cylinder, hence the increased consumption of engine oil (eats oil). An excessive amount of oil on the piston and cylinder walls does not burn and makes the carbon deposit larger and larger. Each subsequent operation of such an engine without repair will lead to coking of the entire engine.

Engines with a turbocharger provide better fuel combustion, increase power and reduce consumption. The structure and operating principle of turbochargers is not so difficult to study.

The deposits that appear on the valves cause them to jam in the guide bushings, and the valve supply and exhaust openings become smaller.

The process of cleaning piston rings can also be done with or without disassembly. Without disassembling the engine, liquids such as LAVR, XADO are used to clean the piston rings. The procedure for performing the work is the same as discussed above.

Carbon deposits and coke are the main ways to get rid of them from an engine

There are two main options that can be used to clean the motor, let's look at each of them:

- clean the power unit with any flushing agent;

- disassemble the engine and mechanically remove deposits

As for flushing oils and fuel additives, this cleaning will remove small deposits in the fuel system, lubrication system, combustion chamber and other places only if the contamination is insignificant. Otherwise, in case of heavy contamination, such additives will not wash away the deposits and the cleaning effect will not be achieved. Sometimes you can even make the situation worse and cause harm.

Many motorists are interested in the question of how to flush the engine from carbon deposits without disassembling it? Therefore, we will consider a method in which the unit does not need to be disassembled.

- We unscrew the spark plugs on gasoline cars, or potassium plugs on diesel cars.

- We pour a special “decarbonization” liquid into the cylinders through the spark plug wells.

- We wait several hours - the cleaner softens the deposits.

- We screw in the spark plugs and start the engine. The softened carbon burns out and is removed from the cylinders.

After this procedure, you cannot use the oil and oil filter remaining in the engine; they must be replaced. Getting into the engine crankcase, the washed composition saturates the oil and filter with abrasive particles that are aggressive towards the cylinders.

To achieve the maximum effect of engine cleanliness, it is necessary to use a mechanical cleaning method. Its principle is simple - the motor is disassembled and cleaned of carbon deposits and coke manually using an abrasive tool. Then it is washed with detergents with high surface activity. This method allows you to clean all hard-to-reach engine elements, including lubricant supply channels and other elements.

What types of engine cleaning products are there?

To clean the engine from dirt and oil, just water and a regular brush are not enough. There are many special products on the market that can make the cleaning process more effective. In addition, washing machines capable of delivering a high-pressure jet come to the aid of the car enthusiast, which, however, requires special care.

Experts do not recommend using fuel such as gasoline or kerosene to remove engine oil from an engine. After such cleaning, heating will lead to smoke.

Specialized preparations for cleaning the engine compartment from oil vary in composition and are very effective. The products available on the market are divided into universal ones, which can be used to easily deal with any type of dirt, and highly specialized ones, which are created to eliminate a specific type of dirt or plaque.

Manufacturers provide customers with sprays and liquids, as well as concentrated gels. Household chemicals, which can be found in any home, are not suitable for cleaning engine oil from a power unit: the active chemical substances in its composition, most often acids or alkalis, have a detrimental effect on plastic or rubber elements and provoke oxidation of metal surfaces.

Advantages of engine cleaning without disassembly

Obviously, the main advantage is the absence of the need to disassemble the power unit. Mechanical disassembly is a complex and time-consuming process that requires an impressive amount of work. Carrying it out just for the sake of removing carbon deposits is impractical. This procedure is typical when performing major engine repairs.

It is worth noting that before performing the cleaning procedure, you should seek advice from professional mechanics. A completely cleaned engine is beyond the power of even very strong chemicals, and its incorrect use can cause damage.

The most common risk is blockage of the channels by particles separated from carbon deposits. Sometimes, in such a development of events, it is better not to touch the engine - this will allow it to be used for some more time. Otherwise, when you try to wash it, the likelihood of subsequent repairs is very high.

How to properly decarbonize

In stores and car markets you can find many different automotive chemicals to combat such problems. All sellers, of course, claim that their product copes better with the task. In reality, everything may turn out differently. We will consider exactly those methods and means that have positive reviews. These include:

- Mitsubishi Shumma – supplied in spray form;

- GZox – spray for spraying into cylinders through spark plug holes;

- Lavr – liquid for filling;

- BJ-211 – sold in liquid form.

With the help of all the listed drugs, decarbonization is performed without changing the oil, which is convenient, but what is the effectiveness? With a relatively small amount of deposits, the products are quite effective and cope with their tasks.

Diesel engine decarbonization

Due to the nature of the operation and the type of fuel used, ring decoking is often required on a diesel engine. This is due not only to the penetration of oil into the combustion chambers, but also to the presence of heavy fractions in the fuel itself. Therefore, this work is especially difficult in such power units. This procedure consists of removing carbon deposits formed during operation from engine parts.

Decarbonization of piston rings can be done independently or by specialists from a car service center. The only question is the timeliness of this procedure. The sooner the problem is identified and corrected, the less costs will be required to restore the power unit. If you discover something is wrong and decide to act on your own, then you can unscrew the engine using liquid or volatile agents sprayed into the cylinder. But it is worth knowing some peculiarities of working with this type of internal combustion engine. In order for soft decoking to be successful and without additional harm, it is necessary to dismantle the nozzles. At this stage, difficulties may arise, because not every car owner will have the necessary keys and accessories in the garage.

Still, the best decarbonization is possible only with complete disassembly of the unit, since you can get to absolutely all the secluded places where carbon deposits could be located. These include grooves for O-rings, valve seats and many others. Simply spraying the product will only slightly reduce its concentration, so it is recommended to carry out this procedure at the earliest stages of soot accumulation.

The work is performed as follows for both diesel and gasoline engines:

- First you need to unscrew the spark plugs from a gasoline engine or remove the injectors from a diesel engine.

- Engage fifth gear so that you can turn the crankshaft with all pistons in the middle position.

- One by one, you need to spray a carbon remover into each cylinder.

- Wait 8 to 15 hours, periodically turning the crankshaft so that the chemical penetrates into the area between the piston and the walls.

- After waiting the specified period, it is necessary to remove dirt using a syringe or other device and thoroughly blow it out with compressed air.

- Reinstall the spark plugs and start the engine. Effective operating time is 15 minutes at 1500 rpm.

- After cleaning, replace the spark plugs with new ones.

Rating of the best engine decarbonizers

There are a lot of tools on sale for stripping engines. During the period of servicing motors of different power and types, a certain list of the best ones was identified, which you can also use. All of them can be divided into three types depending on consistency:

- foam;

- aerosol;

- liquid.

All have their own advantages and features. Let's take a closer look at each type.

Top foam decoking of piston rings

Decarbonization is an unpleasant procedure because the parts are located deep in the engine. Getting to them is not so easy, and all chemicals act unnoticed by the eye. But with a small amount of carbon deposits, they are quite effective in cleaning oil scraper rings. After this procedure is carried out in a timely manner, the engine runs noticeably better.

Can you highlight the TOP best products that clean piston rings well?

- Lavr complex;

- Mitsubishi shumma engine conditioner;

- G zox injection carb cleaner;

- Lavr express.

Cleaning the piston with such preparations can significantly extend the life of the internal combustion engine and alleviate the worries of car owners.

Lavr complex

Many professionals perform early decarbonization using Lavr complex. The drug is sold in spray bottles. Shows high efficiency even after one application. Quickly dissolves carbon deposits and restores compression.

Mitsubishi shumma engine conditioner

This chemical is considered one of the best, but to achieve maximum efficiency it is better to use it for a mileage of up to 40 thousand km. The sooner, the less carbon deposits and the likelihood of reduced compression. The active formula quickly dissolves dirt even in the most inaccessible places. Sprays using a long tube.

G zox injection carb cleaner

Another foam cleaner for the chamber, throttle valve and all the insides of the engine. The product is sold in a convenient bottle with an injection tube. It is recommended to use every 10 thousand km. Should be used on a well warmed up engine.

Lavr express

A chemical product called Lavr express is excellent at removing oil stains. It is one of the simplest means for removing deposits that have formed on internal combustion engine parts. Penetrates into all crevices and helps remove deposits to the surface using active foam. Easy to apply, just spray.