To check the engine cooling system and its components for operability, it is not at all necessary to drain the antifreeze and disassemble it. The diagnostic technique described in the article allows you to determine a malfunction of the thermostat, temperature gauge sensors and radiator fan based on the coolant temperature readings. The advantages of this verification algorithm are simplicity, speed, clarity, accuracy and accessibility.

Possible consequences of an air lock in a car's cooling system

The presence of air in the coolant leads to many unpleasant consequences. The normal circulation of antifreeze (antifreeze) is immediately disrupted and the main purpose of the cooling system begins to suffer:

- heat removal from the components of a running engine occurs unevenly;

- heating the air in the cabin does not provide the necessary comfort.

An experienced driver will immediately notice the twitching of the coolant temperature gauge needle and its boiling in the cooling system. An air lock in the coolant causes:

- overheating of engine parts and components at idle speed, which leads to temperature jumps;

- incorrect operation of the sensors - this causes malfunctions in the temperature indicator readings;

- inaccuracies in the operation of the thermostat, which can cause engine overheating;

- insufficient heating of the stove will cause fogging of the windshield and side windows, which will lead to limited visibility and the creation of an emergency situation on the road.

Useful tips

Please note that a decrease in the level of antifreeze or antifreeze does not always indicate problems with the cooling system. Coolant can go directly into the cylinders if there is damage to the cylinder head gasket, cracks in the head or block, etc.

In this situation, the engine often emits white smoke as the coolant escapes through the exhaust in the form of steam. In this case, the head or block must be removed; as part of the diagnosis, crimping of the block head is performed. Then a decision is made to repair the cylinder head or replace the element. Also, antifreeze or antifreeze may leak if problems arise with the engine block plugs. Leaks at the plugs will indicate that the engine plugs need to be replaced.

- It should also be added that with the onset of the cold season, it is very important not only to have coolant filled strictly to the level, but also to the density of the antifreeze. Remember, if you had to add distilled water during operation, the density of the solution decreases. In simple words, when the temperature drops, the liquid can freeze. Freezing often results in damage to both the cooling system elements and the internal combustion engine itself.

The coolant density is measured with a hydrometer; if necessary, the antifreeze concentration should be increased by adding concentrate. At the same time, mixing antifreeze and antifreeze of different brands is strongly not recommended.

It is also important to remember that coolant concentrate is a strong poison! Do not allow the substance to come into contact with your skin or eyes, and do not take it orally!

- Let us note once again that antifreezes or antifreezes based on ethylene glycol contain a package of active additives that prevent the formation of corrosion and have antioxidant and antifoaming properties. However, over time, the additives wear off and stop working.

As a result, the pump impeller is destroyed, the radiator “corrodes” from the inside, and the channels in the BC and cylinder head rust. Also, coolant decomposition products, combined with general contamination, can clog the system channels, disrupt the operation of the thermostat, etc. For this reason, the performance of the cooling system deteriorates, and the service life of its components is significantly reduced. In some cases, corrosion destroys the channels of the engine cooling jacket; antifreeze or antifreeze gets into the cylinders or into the lubrication system.

- If there are any doubts about the efficiency of the system, or the thermostat, etc. is suspected, an infrared thermometer allows you to measure the temperature of the hoses and pipes during the initial diagnosis. For a quick check, just turn on the heater in the cabin, then measure the temperature of the heater inlet and outlet hoses. The temperature should be almost the same. If obvious abnormalities are noticeable, this may indicate a need for repair.

Finally, we note that when placing hoses in the engine compartment, be sure to check for kinks. First of all, for example, after replacing pipes, you should make sure that the hose is not kinked. It is also important that the hose does not touch hot surfaces, moving parts or sharp edges.

Kinks impair coolant circulation, which can cause overheating under load. As for mechanical damage, moving parts can chafe the hose, sharp edges cause cuts, and contact with heated surfaces causes accelerated cracking of the pipes. The result is a coolant leak, which can cause the engine to overheat.

Why is antifreeze getting into the engine oil a serious problem? What consequences may arise for the internal combustion engine after driving on a mixture of coolant and oil.

Reasons why coolant starts to leak. How to find the location of an antifreeze or antifreeze leak yourself. Useful tips and tricks.

Purpose, design and operating features of the expansion tank of the liquid cooling system of an internal combustion engine. Possible malfunctions.

Why does engine oil get into antifreeze: the main causes of this malfunction. What will happen to the engine if oil is found in antifreeze or antifreeze?

Why do antifreeze or antifreeze enter the engine cylinders and what to do in such a situation. How to determine the presence of antifreeze in the cylinders yourself, repair methods.

What is engine coolant: purpose and features, differences. How to choose coolant, how to dilute antifreeze concentrate, mixing antifreeze.

The engine cooling system is responsible for maintaining the desired temperature. Modern engines, especially turbocharged ones, are quite demanding on cooling. The serviceability of the pump, the tightness of pipelines and radiators, and timely replacement of coolant will prevent rapid wear of engine parts and ensure the best performance. Periodic diagnostics of the cooling system will allow you to avoid emergency situations on the road and the costs of unscheduled repairs.

Causes of air accumulation in antifreeze

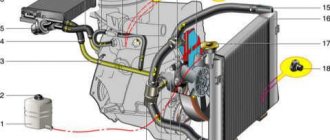

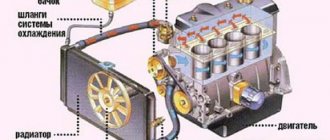

General diagram of a liquid cooling system

Closed liquid cooling systems are designed to maintain constant excess pressure (up to 100 kPa). The increased pressure made it possible to raise the boiling point of the liquid to 120 degrees. Since cars are used all year round, a concentrated, special non-freezing coolant was specially developed for them - antifreeze (antifreeze is the most popular). It consists of ethylene glycol, distilled water and anti-corrosion, anti-foaming, antioxidant additives. Antifreeze provides optimal thermal operating conditions for the engine of 80–100 degrees in any weather. The main causes of air locks are as follows:

- Air suction through insufficiently tight connections of pipes, hoses, fittings, tubes. This happens because when antifreeze moves through the system, a reduced pressure is created near the walls of the tubes, which draws in outside air in places with loose connections.

- Air is trapped in the cooling system when a wide mouth funnel is used to add or change coolant. A powerful flow of antifreeze blocks the path of air to the top. Antifreeze is always poured into the expansion tank or radiator in a thin stream.

Antifreeze circulation diagram in the engine cooling system Modern cars use a forced closed cooling system. Its main task is to ensure stable operation of the engine during the transition from cooling mode to heating mode and vice versa. This is not easy to achieve, since when the antifreeze is heated, its volume increases and excess pressure arises, and when it cools, the volume and pressure in the system decreases. The increased pressure compresses the air at the highest point of the system - the expansion tank. There is an air valve in the filler plug of the tank that operates in two directions. When the pressure increases, it bleeds excess air out; when the pressure decreases, it lets outside air into the system. It is the air valve that maintains constant excess pressure under any thermal conditions. If this device does not work correctly, excess air will begin to constantly accumulate in the cooling system.

Video: How not to air out the cooling system when filling with antifreeze

Lubrication system malfunctions.

There are few malfunctions of the lubrication system, but the consequences from them can be very serious. The following malfunctions of the lubrication system are distinguished:

- wear or damage to the oil pump;

- damage to the oil pump gasket;

- oil filter clogged;

- weak fixation of the oil filter;

- oil pressure sensor malfunction;

- pressure relief valve sticking;

- low oil level.

The main causes of these malfunctions:

- violation of operating rules (use of low-quality oil, violation of the frequency of oil and filter changes);

- unskilled performance of maintenance and repair work on the lubrication system; – maximum service life of system elements.

External signs of lubrication system malfunctions:

- low oil pressure;

- increased oil consumption.

A decrease in oil pressure is indicated by a corresponding lamp on the vehicle’s instrument panel. If the oil pressure drops, further operation of the vehicle is prohibited. The main possible causes of low oil pressure: wear or damage to the oil pump; oil filter clogged; oil pressure sensor malfunction; pressure relief valve sticking; low oil level.

Increased oil consumption is determined using a dipstick based on the oil level in the engine. On a number of cars, the engine oil level is electronically monitored (the corresponding warning lamp on the instrument panel). The main possible causes of increased oil consumption: damage to the oil pump gasket; weak fixation of the oil filter; malfunction of the crank mechanism; malfunction of the gas distribution mechanism; crankcase ventilation system clogged.

How to determine if there is a problem: symptoms, signs, diagnosis

Diagnostics are designed to help find the cause of malfunctioning cooling system. If antifreeze constantly disappears somewhere, boils, boils strongly in the cooling radiator, and the interior does not heat up, all this needs to be dealt with. If the antifreeze level regularly drops, air will take its place, which over time will form an air lock. In this case, you need to check the tightness of all connections of the engine cooling system. To do this, carry out a careful external inspection of the interfaces of rubber parts (hoses, pipes) with tubes and fittings with a warm, running engine. Pay special attention to the radiator pipes, water pump, thermostat and heater hoses. If a leak is detected, it must be eliminated by replacing the pipes or tightening the steel clamps.

The main burden of adjusting (while the engine is warming up) and maintaining a constant (while the engine is running) temperature in the cooling system falls on the thermostat. If the engine begins to warm up very quickly after starting, the electric fan starts almost simultaneously, and the arrow on the indicator tends to move into the red zone - these signs indicate a malfunction of the thermostat or an accumulation of air in the discharge pipe from the pump. The thermostat valve will be closed all the time, and the antifreeze will circulate only in a small circle.

Maintenance of the lubrication system.

During EO , check the oil level and the tightness of the system. The oil is added to the normal level. After a test run, stop the engine and check the operation of the centrifugal oil filter by ear.

During TO-1, the oil in the engine crankcase and the FTO filter elements are replaced (according to schedule); wash the FGO filter elements and the centrifugal oil filter.

During TO-2 , if the time is up according to schedule or in case of severe contamination of the oil, wash the lubrication system and breather.

When using CO , fill in oil corresponding to the upcoming season of operation. In preparation for winter operation, the oil cooler is turned off (and turned on for summer use).

How to bleed air using the VAZ model range as an example

VAZ models have a design advantage in the arrangement of cooling system components - a convenient position of the cooled throttle assembly (carburetor), which is the highest place in the cooling system. The procedure for a Lada Kalina car is as follows (the only tool you need is a Phillips screwdriver).

Fully open the heater switch (to the highest temperature);

Remove the valve cover protective screen;

Disconnected heating outlet hose from the throttle fitting

Remove the cap from the expansion tank

Video: How to remove air from the expansion tank

The second method of releasing air differs from the first only in that you do not need to force air masses into the neck of the expansion tank with your mouth. All operations are performed with the engine normally warmed up and turned off. This method does not involve any manipulations with the expansion tank cap. Immediately remove one of the two heating hoses from the throttle fittings. If coolant leaks, the hose is inserted into place and tightened. It may not work out the first time, then the operation must be done again. This method requires care and caution, since the antifreeze is heated to a temperature of 90 degrees and is under increased pressure.

The third method does not require any disassembly of the cooling system. True, its effectiveness is not very high. The car drives its front wheels onto an embankment so that the radiator cap becomes the highest point in the cooling system. The radiator and expansion tank caps are removed. The engine starts, the antifreeze temperature is brought to operating parameters. When reducing the volume of coolant, it must be constantly added to the amount recommended by the manufacturer. It is necessary to expel the air lock until bubbles stop coming out of the neck of the radiator or expansion tank.

Electrical thermostat test

WARNING: Always vent exhaust gases outside when performing this test. Failure to follow this instruction may result in injury.

NOTE: This procedure is most accurate when performed indoors when the ambient temperature is below 100°F (37.8°C). This test can be performed with the hood open or closed, with the engine warm or cold.

1. Check the coolant level in the radiator and expansion tank of the cooling system. If necessary, add coolant.

2. With the engine off, disconnect the cylinder head temperature (CHT) sensor plug connector and connect the coolant temperature monitoring wiring harness, using it as a jumper between the PCM and the CHT sensor. Connect a digital multimeter to the thermostat wiring. Now the voltage values (from 0 V to 5 V) can be monitored without disturbing the connection of the sensor to the electrical wiring.

NOTE: Performing this test with the A/C compressor clutch in gear engaged (running) will result in an incorrect diagnosis.

3. Move the gearbox to the “P” (“Parking”) or “N” (“Neutral” position).

4. Start the engine and let it idle throughout this test. Run the engine for 2 minutes, then record the voltage from the CHT sensor. Record the CHT sensor voltage every 60 seconds. When the overall trend of the CHT sensor voltage changes direction or the voltage changes only slightly (0.03 V or less) from the previous value, record this value as the thermostat opening voltage. Use the Coolant Voltage and Temperature Correspondence Chart below.

| Coolant temperature °C (°F) | SNT (V) |

| 20 (68) | 3,09 |

| 40 (104) | 2,15 |

| 70 (158) | 1,04 |

| 80 (176) | 0,79 |

| 90 (194) | 0,61 |

| 95 (203) | 0,53 |

| 105 (221) | 0,41 |

5. If the thermostat opening voltage exceeds 0.79 V and corresponds to a temperature less than 80°C (176°F), install a new thermostat.

6. If the thermostat opening voltage is less than 0.79 V and corresponds to a temperature greater than 80°C (176°F), the thermostat is working and does not need to be replaced. Refer to the Symptoms Chart for further instructions.

How to prevent the problem from recurring

At least there is a guarantee for the car service work.

The surest way to avoid unnecessary problems with your car is to trust the service to professionals. The structure of a car and an engine in particular is constantly becoming more complex. A modern cooling system consists of many irregularly shaped parts, tubes and hoses located at different angles. In a word, there are many places where air can accumulate in the cooling system. Professionals know all the intricacies of filling the antifreeze system and can easily replace the old fluid with a new one.

Engine overheating can be prevented with regular maintenance

There is no need to allow the engine to overheat, bring the antifreeze to a boil. At this moment, the coolant turns into steam, which, under high pressure (the system is closed) fills all the most inaccessible corners of the cooling system. In this case, the engine itself is at great risk of serious damage. It also takes a lot of skill and experience to remove air from your car's cooling system.

By contacting our car services, each client can count on professional assistance in the following matters:

- replacement of cooling system pumps and coolant;

- cleaning and changing the fan;

- pressure testing of the cooling system;

- replacing the expansion tank;

- thermostat installation;

- cleaning and replacing the radiator;

- comprehensive repair of cooling systems.

Our company has been successfully servicing cars for 8 years. During this time, we have managed to establish ourselves as a reliable partner who guarantees the fulfillment of our responsibilities at the highest possible level.

Each of our clients will be pleasantly surprised by low prices and a fundamentally new strategy in providing services. Sign up for the service today to feel confident behind the wheel of your car tomorrow.

Sign up for diagnostics

Application for tire storage

Estimation of repairs from photos

Diagnostics of the car cooling system helps to identify and eliminate problems leading to engine overheating. As a result of temperature violations, engine efficiency decreases, engine wear increases and fuel consumption increases.

Symptoms of airiness

How can you tell if there is an air lock in the cooling system? When this phenomenon occurs, several typical symptoms occur. Among them:

- Problems with the thermostat . More specifically, if after starting the engine the cooling fan turns on very quickly, then there is a high probability that the thermostat has failed. Another reason for this may be that air has accumulated in the pump nozzle. If the thermostat valve is closed, the antifreeze circulates in a small circle. Another situation is possible when the coolant temperature needle is at “zero” when the engine has already warmed up enough. Here again, two options are possible - a malfunction of the thermostat, or the presence of an air lock in it.

- Antifreeze leak . It can be checked visually by traces of antifreeze on individual elements of the engine or chassis of the car.

- The pump starts to make noise . When it partially fails, extraneous noise appears.

- Problems with the stove . There are many reasons for this malfunction, but one of them is the formation of an air lock in the cooling system.

If you find at least one of the symptoms described above, then you need to diagnose the cooling system. However, before doing this, it will be useful to understand what caused the possible problems.

no circulation in the engine why?

I removed the hoses from the heater and started the car, but nothing flows from the hoses, only when the temperature starts to rise, then it starts to drip, barely, barely, what could it be? Help! The stove is clean, the thermostat is working, the hoses are also clean and the pump is intact! The coolant level is also normal!

Actually, on a cold engine, antifreeze circulates in a small circle and does not get into the stove.

You're wrong! There is always circulation! At least on my engine! And the supply to the stove is not connected in any way to the thermostat! (look at the cooling diagram and where the fence for the stove is located!)

Holy shit! stove on a small circle..

to TS. why did you film?? the stove doesn't heat? —it’s airy, the pump is intact—did you take it off and check?

In that case, I’ll go learn the materiel.

Z.Y. Indeed, I was wrong. I just haven’t encountered it personally yet.

Last edited by Kerch; 02.12.2011 at 08:45.

In that case, I’ll go learn the materiel.

Z.Y. Indeed, I was wrong. I just haven’t encountered it personally yet.

LLC, you still don’t know a lot about our Cooling system ((((It turns out there were reviews of Auto for this reason! And the selection for the stove is located next to the entrance of the cold liquid from the big circle! And there shouldn’t be any heat.. Now I’m looking for a solution! I’m going to search for additional thermostat And move the fence for the stove to another place!

You can install a thermostat with a higher opening temperature (instead of the standard one at 82, stick it at 88 degrees)

It’s just that so far all four of my Nissans have been pleasing with warmth, so I didn’t delve into it))) I thought that the small circle was purely due to the engine. I was wrong, I will correct myself)))

Is the pump completely intact, as you checked? The engine seems to overheat instantly. As an option, we used sealant to eliminate the leak. Is there no oil in the coolant?

firstly, when you removed the hoses, antifreeze should have started pouring out of there. secondly, no one checks the system this way, since it will immediately become airborne, the circuit must be closed! How did you check the level? and thirdly, put everything back together as it was, fill it with antifreeze, put a paper clip in the radiator cap, stand on a hill (they wrote about this on the forum) and expel all the air pockets. You can drive around with a paper clip for a week while adding antifreeze to the reservoir. all problems with a cold stove are precisely due to air locks, since the stove is located above the level of the filler neck, it’s normal to bleed it once and that’s it! I myself have neither a pump nor a thermos at 88, it’s always hot in the car.

My stove used to heat well and there were no air locks, but now I rushed to another city and as I went the stove began to cool down. I stopped and stood for about 10 minutes. The stove was running, it warmed up, I drove off, it began to cool down again, I realized that there was no circulation! I turned off the engine when it was hot, opened the radiator cap, started the engine again, but the liquid in the radiator stood and did not rise, and if there had been circulation then coolant would have started to flow out! The funny thing is that with all these shortcomings the engine did not overheat and maintained normal operating temperature!

Wrong reason! I already wrote: Our engine has a very poor cooling system! Look at the diagram for yourself. WE have a fence for the stove where the cold antifreeze comes in! Look for yourself! We are mixing in cold water, while everyone else is pumping. That's the problem!

Yes, no, how can you not understand, my stove heated perfectly, but now it’s bad, and the reason is that the circulation in the engine has disappeared! I think I found the reason, in 3 days I’ll assemble the car, I’ll check if everything works, I’ll write back what the hell happened to me!

Good! I am waiting! But there is a funny thing: When the engine is revving, the thermostat opens! And the cold coolant enters the stove! (Do you happen to have an additional pump?)

LIKE THIS IS NOT SERIOUS THE JAPANESE MADE THE CORRECT COOLING SYSTEM. I DON’T BELIEVE IT!

- Answer

- Complain

I like

Where does the slurry go on its own? Into the expansion tank or out?

To clear a traffic jam, “driving uphill” may not help (the mountain must be steep, and the engine temperature must be above the thermostat response point). Remove the throttle heating hose and apply pressure to the expansion tank (just inflate with your mouth) until water flows from the heating hose. It’s better to do it together: one blows, the other puts on.

Even if there are no major leaks, the clamps need to be tightened; apparently they have weakened, and air is being sucked through the joints.

- Answer

- I like

- Answer

- I like

Inspect all the connections, tighten them, see where the air (gases?) in the system comes from somewhere. There was another case, although the gazelle had a 402nd engine, the thermostat jammed on the small circle, the cylinder head began to leak, in the expansion there was a jacuzzi with bubbles, but at the same time there was not a drop of antifreeze in the oil. By any chance, did you overheat the engine?

- Answer

- I like

- Answer

- I like

- Answer

- I like

Great option. The main thing is to download without fanaticism