Malfunctions of the cooling system are expressed in the partial or complete failure of its elements such as a radiator, pump, cooling fan, thermostat, temperature sensor, or coolant leak. At the same time, the efficiency of the cooling system is significantly reduced, which leads to overheating of the engine, and this in turn reduces its service life, as it has a detrimental effect on its parts.

Read more about what the main signs of a cooling system malfunction are and how to identify them in this article.

Signs of a malfunctioning cooling system

| Characteristic signs of a faulty cooling system | Possible causes of failure |

| Engine overheating |

|

| Engine hypothermia |

|

| Coolant leaking outside |

|

| Coolant leaking inside |

|

There are four external signs of trouble to check your cooling system. So, these include:

- engine overheating during operation;

- engine hypothermia (the engine warms up slightly, for example, in the cold);

- coolant leaking out;

- Coolant leakage inside (into other vehicle systems).

In addition, problems in the cooling system can be judged by the warning light on the dashboard (red float or yellow expansion tank). Each car is equipped with a corresponding indicator, which is activated when the coolant boils. Also, when the engine overheats, its power drops significantly, the dynamic characteristics of the car decrease, and in the worst case, when it has already boiled, steam can come out from under the hood (from the radiator or tank). All this is very harmful for the engine, because when it overheats, it wears out, which significantly reduces its service life, and can even completely damage the engine.

If there are external coolant leaks on the asphalt under the car or on individual parts of the engine compartment, the car owner may notice corresponding stains. Antifreeze has a specific sweet smell, so you can often sense a leak accordingly. If a fluorescent element is added to the antifreeze, the leak can be detected using an ultraviolet lamp. However, this must be done in advance, when pouring new fluid into the system.

Internal leaks are more difficult to detect. If antifreeze gets into the engine oil, the car's exhaust gases will be in the form of white smoke. Also, when checking the condition of the engine oil, there will be a white mass similar to sour cream in it. This directly indicates that there is antifreeze in the oil. Accordingly, it is necessary to carry out diagnostic and repair work with a complete replacement of both fluids.

Problems with internal pressure

Lada Granta engine cooling system: malfunctions and methods for eliminating them

Knowing from the instruction manual what pressure should be normal when operating your specific engine, all two main problems may arise.

Here we are talking about why there is no pressure in the system, that is, it is excessively low, or why it is higher than normal, and how to reduce it now.

Overpressure

If the pressure is higher than normal, the components of the cooling system and the internal combustion engine itself may fail. There are cases of radiator rupture, pipes being torn off, hoses being deformed, etc.

When, during the operation of a car, one or another cooling pipes fly off every now and then, this indicates an excessively high internal pressure. Moreover, the reason is always the same. This is a faulty safety valve. We have already talked about this in the topic about why antifreeze is thrown out of the expansion tank. I strongly advise you to re-read it. The problem is solved extremely simply. You need to remove the old cap on the tank or radiator and install a new one.

This cap is actually a valve. Moreover, in modern cars it is double, and is simultaneously responsible for air leaks and releasing excess pressure.

Pressure deficiency

When the pressure in the system drops, the first thing you can do is identify it by the weak heating of the air coming from the car's stove.

There are several reasons for a drop in pressure:

- Valve cover stuck. It is stuck in the open position, that is, the seal is broken and air is leaking. If you unscrew the cap after the engine has warmed up, you will hear the hiss of escaping air. If it is absent, the valve does not work;

- Antifreeze is leaking. It is not always possible to find the source of the problem. Therefore, you can carry out a simple check using a pump, pressure gauge and simple tools. The pump is connected to the tank and pumping begins. You need to achieve 1.4-1.6 bar. Now look where the coolant is leaking from;

- Coolant deficiency. When there is more antifreeze than needed, it will be released through the valve when heated. If there is little liquid, boiling occurs faster than normal, air pockets form and low pressure is observed in the system. Here you just need to monitor the antifreeze level.

Anything can happen in the life of a motorist. But statistics clearly show that most engine problems are directly related to the cooling system and coolant. You need to at least learn how to mix antifreeze correctly and constantly maintain the required level in the tank.

Good luck to everyone on the roads!

Subscribe, leave reviews, ask questions that interest you!

(2 ratings, average: 5.00 out of 5)

Causes of cooling system malfunction

There are many reasons that lead to partial and even complete failure of the cooling system. Depending on which nodes were damaged, the following main causes of failure are distinguished:

- violation of maintenance of the cooling system (in particular, the car owner forgets to periodically add/change antifreeze or uses coolant with parameters inappropriate for the car);

- use of low-quality system parts (pipes, taps, radiator);

- using poor coolant that does not meet the requirements;

- critical wear or complete failure of individual elements of the vehicle cooling system;

- performing poor-quality repairs or maintenance of both the engine in general and its cooling system in particular;

- significant clogging of cooling surfaces.

However, the reasons listed are only a generalization of the problems with the mentioned system. The real reasons are the wear and tear of specific components.

Basic malfunctions of the engine cooling system

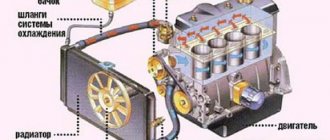

The cooling system of a car engine consists of a large number of individual parts - radiator, fan, pipe system, sensors. If at least one element does not work correctly, the entire system begins to work worse. Therefore, the cause of the breakdown may be:

- Radiator clogged . It is this element that is intended for the forced removal of thermal energy from the engine. If it becomes clogged externally (a large amount of dust and dirt gets into its slots) or internally (the core becomes clogged with a significant amount of rust and liquid sediment), then the efficiency of the unit is sharply reduced. Accordingly, the radiator, like the entire cooling system, must be periodically cleaned both outside and inside using special cleaners or improvised means.

- Faulty pump . For this reason, the cooling system either leaks from under the cooling pump bearing, or the circulation of liquid through the cooling jacket is disrupted. There are several reasons for pump failure. Among them are banal wear of its blades or internal parts, weakening of the drive, and violation of tightness. Often, corrosion can be observed on metal impellers, but the plastic impeller simply breaks off and turns.

- Incorrect operation of the thermostat . The main task of this unit is to block the flow of antifreeze or antifreeze into the radiator until the engine has warmed up sufficiently. On most cars, it opens only when the coolant temperature reaches +87... +95°C. Accordingly, if the thermostat is stuck open, the engine will take a very long time to heat up, especially in cold weather. If the thermostat is stuck and does not open at all, then the temperature in the system will be higher than normal until it boils.

- Cooling fan malfunction . Depending on the type of its drive, there may be many reasons. For example, a mechanically driven fan may have loose drive tension. If the drive is electric, then the cause of its failure may be a faulty thermal relay or drive motor. If the drive is hydraulic, then the reason most likely lies in insufficient pressure (low level) of oil in the system.

- Depressurization of the system . Coolant leaks can occur in a variety of places. For example, on the pipes, their connections (on clamps), in the radiator housing, on the pump, on the cooling jacket of the cylinder head. If the cylinder head gasket burns out, the coolant mixes with the engine oil. This not only leads to a decrease in antifreeze levels, but also to a deterioration in oil performance, which puts additional stress on the engine.

- Temperature sensor malfunction . Information from it is sent to the electronic control unit, and based on it, the ECU issues commands to form an optimal air-fuel mixture, turn on/off the cooling system fan and other commands. You can check the temperature sensor using a multimeter.

- Low coolant level . Even if the cooling system is completely sealed and there are no leaks, the level of antifreeze in it still drops over time. This happens due to its evaporation. This process is quite long, but the car owner needs to periodically monitor the appropriate level and, if necessary, add or completely change the coolant if the end of its service life has come.

- Radiator cap valve leaking . In this case, the pressure in the cooling system will be below normal. Because of this, the liquid will boil even when the engine is idling. Coolant is also discharged into the expansion tank, but only after the engine is stopped. There will also be a large consumption of antifreeze.

Most malfunctions of the cooling system cause an air lock to appear, and as a result, engine overheating and malfunction of the heater radiator.

Another malfunction can be considered the use of antifreeze with inappropriate parameters, for example, ordinary water. As you know, in cold weather it crystallizes, which usually leads to mechanical failure of the elements of the cooling system. Therefore, you need to choose antifreeze in accordance with the requirements of the car manufacturer .

Repair of radiator and expansion tank

The radiator may have the following malfunctions:

- dents, holes, cracks on tanks;

- breakages and cracks on the frame plates;

- violation of tightness in soldering areas;

- damage to cooling plates or tubes;

- clogging due to the adhesion of insects;

- scale deposits.

Dirt and scale are removed in installations where the detergent is heated to 70–85 °C; its circulation and subsequent flushing of the radiator are done with water. To clean the surface of the radiator from adhering insects, use a special solvent, which is applied to the radiator and then washed off with water.

If brass tanks have dents, they are straightened on a wooden lining with a mallet. Small cracks are sealed with soft solder. Damaged upper and lower radiator tanks are repaired by applying patches. The patch and the damaged area are cleaned, tinned and soldered to each other. If it is impossible to solder damaged tubes, they are plugged by soldering the upper and lower ends. But it is allowed to plug no more than three pipes for the entire radiator. If there are more damaged tubes, they are replaced with new ones or the radiator is changed completely. Breakages and cracks on the radiator mounting plates are welded using gas welding. Checking the radiator for tightness. If there is a coolant leak from the radiator, if it is impossible to find the location of the leak, the radiator is checked for leaks. To check on a car, the radiator is filled with water, the pipes are closed with plugs, leaving one open. Through an open pipe, air is supplied to the radiator at a pressure of 1 kgf/cm2. The location of the leak is determined by where the water appears.

Due to poor access to the radiator, it is more convenient to check it by removing it from the car with a cold engine.

To remove and install the radiator and expansion tank, you must:

- drain the coolant from the engine and radiator;

- disconnect the electrical wires from the fan switch sensor and from the fan;

- disconnect the hoses from the radiator and expansion tank;

- remove the four guide casings (top, right, left and bottom), taking into account that to remove the top casing it must be removed from the special retaining grooves; to remove the right and left casings, you need to unfasten two latches on the left casing, and three on the right, to remove the lower casing you need to unscrew the three bolts securing it to the radiator;

- remove the electric fan with the guide casing assembly by unscrewing the nuts securing the guide casing to the lower radiator mounting bracket and the nuts securing the casing to the radiator, remove the casing with the electric fan assembly;

- Unscrew the nuts securing the radiator to the lower radiator mounting bracket and the radiator mounting bolts, remove the radiator;

- Unscrew the bolt securing the expansion tank and remove the tank from the car.

After removing the radiator and expansion tank, close the filler neck and radiator pipes, leaving one open, and supply air through it at a pressure of 1 kgf/cm2. Place the radiator in a bath of water and observe the appearance of air bubbles, which will indicate the location of the leak. The disassembled radiator without coolant inside should not be stored for more than two days, as corrosion may begin. It is recommended to close the holes with plugs or fill the radiator with drained coolant.

If the radiator is covered with scale, oil, and rust on the outside, you should blow it with compressed air, rinse with water, and carefully clean the air channels with wooden pins. When repairing a radiator with epoxy glue, apply epoxy glue to the damaged areas with a spatula and wrap them with a strip of fabric soaked in the same glue.

To make it easier to thread the fabric between the tubes, use tweezers. When working with epoxy glue, you need to remember: epoxy resins are poisonous.

Installation of the radiator and expansion tank is carried out in the reverse order. The repaired radiator must be checked for leaks. If a car has a radiator with an aluminum alloy core and plastic tanks, then they are usually not repaired, with the exception of replacing some pipes, but replaced completely. The expansion tank of the cooling system is made of transparent plastic. Individual small cracks in the seam that connects the upper and lower halves of the tank can be welded using a soldering iron to heat the plastic. If the crack length is more than 20 mm, the tank should be replaced. The swollen tank is also replaced. Blistering can occur as a result of the exhaust valve sticking in its plug, which leads to increased pressure in the cooling system.

Methods for troubleshooting a cooling system

The choice of cooling system repair method depends on the reasons that caused its malfunction. We list them in the same order as the reasons.

- Radiator clogged. It must be cleaned from the outside and preferably rinsed from the inside. As a rule, the radiator is removed from the car for cleaning. In parallel with cleaning, you can check its tightness. Please note that if the car is equipped with two radiators, for the engine cooling system and for the air conditioner, then both radiators must be dismantled and cleaned.

- Pump failure. This unit cannot be repaired, so immediately replace it with a similar one. The choice of pump is based not only on the manufacturer, but also on the material of the impeller - metal or plastic.

- Problems with the thermostat. There is a similar situation here; usually the thermostat is not repaired, but replaced with a new one.

- Cooling Fan. If the fan impeller is damaged, then it must definitely be replaced. If the mechanical drive has loose tension, it should be tightened to the appropriate value. If the belt is damaged, it should be replaced with a new one. If the thermal relay or drive motor fails, these components must also be replaced. In rare cases, you can try to restore the electric motor (repairing bearings, rewinding the winding). The hydraulic fan drive needs to be topped up with oil and the condition of the bearings checked.

- Depressurization of the system. A fairly common cause of failure, which is however difficult to diagnose. This is due to the fact that the leak can be very small and located in a hard-to-reach place. The first thing you need to do is check the condition of the engine oil to see if there are any white clots in it, which are the antifreeze leaking into it. If this is the case, then you need to check the condition of the cylinder head gasket, the cylinder head plane itself, the condition of the heat exchanger and its gasket, and the condition of the cylinder block for leaks. And of course, you need to check all the pipes to see if there are any traces of leaking coolant on them, and also inspect the elements of the engine compartment to see if there are any traces of antifreeze on their surface. When a coolant leak occurs from the radiator or a crack in the pipe, then as a temporary measure, you can pour antifreeze into a sealant that will plug the leak.

- The temperature sensor has failed. Needs replacement with a new similar one. First you need to remove it from the car and perform additional diagnostics using a multimeter (ohmmeter) and/or thermometer.

- Low antifreeze level. If there is insufficient amount of coolant in the service interval, it must be added (in this case, you must be aware of which antifreezes can be mixed with each other and which cannot!), or replaced with a new one.

- Broken valve on the radiator cap. Usually the cap and its valve cannot be restored, so it must be replaced. However, you first need to check the radiator cap for functionality.

It is better to carry out the listed repair work yourself if the car owner has relevant experience in performing similar work. Otherwise, it is better to seek help from a car service center.

Prevention of normal operation

A properly functioning cooling system of any car is able to ensure normal engine operation even at very high ambient temperatures. A decrease in its effectiveness is usually caused by the fact that the car owner does not pay due attention to checking the operation of the system. In fact, in order for the cooling system to work smoothly and without interruption, you need to follow a few simple rules:

- While driving, constantly monitor the coolant temperature gauge, as well as the warning light that lights up when it boils. If the indicator lights up, you must stop the car as soon as possible and try to find out the reason.

- Constantly monitor the coolant level in the system. Typically, according to regulations, antifreeze is changed after approximately 60...120 thousand kilometers. Other automakers recommend changing it every two to three years. However, it would not be superfluous to monitor the appropriate level during the service interval, especially if you suspect that the engine cooling system is not working correctly.

- Use antifreeze with the prescribed characteristics. In the documentation for any car, the manufacturer directly indicates what coolant needs to be poured into the system. This applies to its class, compliance standard and quantity. The manufacturer is also less often indicated, but this is rather an exception and direct advertising.

- Check the cooling system for leaks. In particular, whether there are external or internal antifreeze leaks. Along with eliminating the leak (if any), you must also remember to add fluid to the required level or replace it with a new one.

- Check the condition of the radiator. Often its outer surface becomes clogged with dust and dirt, which significantly reduces its performance.

- Do not overload the engine. In particular, it is not recommended to frequently develop excess power on the engine. For example, when driving an overloaded car, using a sporty driving style (at high speeds, with slipping, sudden starts), towing heavy trailers. All this significantly wears out both the engine as a whole and its cooling system in particular.

- Periodically clean the cooling system. This can be done when replacing antifreeze with a new one, or when clear signs appear that the efficiency of the system has decreased.

By following such direct advice, the car owner can not only ensure the normal operation of the cooling system, but also significantly extend its service life.

Useful tips

Please note that a decrease in the level of antifreeze or antifreeze does not always indicate problems with the cooling system.

Coolant can go directly into the cylinders if there is damage to the cylinder head gasket, there are cracks in the head or block, etc. In such a situation, the engine often smokes white smoke, since the coolant exits in the form of steam through the exhaust. In this case, the head or block must be removed; as part of the diagnosis, crimping of the block head is performed. Then a decision is made to repair the cylinder head or replace the element. Also, antifreeze or antifreeze may leak if problems arise with the engine block plugs. Leaks at the plugs will indicate that the engine plugs need to be replaced.

It should also be added that with the onset of the cold season, it is very important not only to have coolant filled strictly to the level, but also to the density of the antifreeze. Remember, if you had to add distilled water during operation, the density of the solution decreases

In simple words, when the temperature drops, the liquid can freeze. Freezing often results in damage to both the cooling system elements and the internal combustion engine itself.

The coolant density is measured with a hydrometer; if necessary, the antifreeze concentration should be increased by adding concentrate. At the same time, mixing antifreeze and antifreeze of different brands is strongly not recommended.

It is also important to remember that coolant concentrate is a strong poison! Do not allow the substance to come into contact with your skin or eyes, and do not take it orally!

Let us note once again that antifreezes or antifreezes based on ethylene glycol contain a package of active additives that prevent the formation of corrosion and have antioxidant and antifoaming properties. However, over time, the additives wear off and stop working.

As a result, the pump impeller is destroyed, the radiator “corrodes” from the inside, and the channels in the BC and cylinder head rust. Also, coolant decomposition products, combined with general contamination, can clog the system channels, disrupt the operation of the thermostat, etc. For this reason, the performance of the cooling system deteriorates, and the service life of its components is significantly reduced. In some cases, corrosion destroys the channels of the engine cooling jacket; antifreeze or antifreeze gets into the cylinders or into the lubrication system.

To prevent possible consequences and avoid a number of problems, the coolant must be changed once every 2 years. This is especially true when it comes to antifreeze. It is advisable to make the replacement by flushing the cooling system. Also today there are new generation antifreezes of the G12+ type, which are designed for 3-4 years of service.

If there are any doubts about the efficiency of the system, or the thermostat, etc. is suspected, an infrared thermometer allows you to measure the temperature of the hoses and pipes during the initial diagnosis. For a quick check, just turn on the heater in the cabin, then measure the temperature of the heater inlet and outlet hoses. The temperature should be almost the same. If obvious abnormalities are noticeable, this may indicate a need for repair.

Finally, we note that when placing hoses in the engine compartment, be sure to check for kinks. First of all, for example, after replacing pipes, you should make sure that the hose is not kinked

It is also important that the hose does not touch hot surfaces, moving parts or sharp edges.

Kinks impair coolant circulation, which can cause overheating under load. As for mechanical damage, moving parts can chafe the hose, sharp edges cause cuts, and contact with heated surfaces causes accelerated cracking of the pipes. The result is a coolant leak, which can cause the engine to overheat.