01/26/2022 7,962 Heating and air conditioning system

Author: Ivan Baranov

Drivers have long been accustomed to the comfortable conditions in the cabin provided by air conditioning. Therefore, its breakdown significantly affects the well-being of the driver and passengers. Repair and maintenance of car air conditioners is usually carried out by specialists at a service station, but in order to save money, the driver can do this with his own hands, having the necessary tools at hand. The article describes how to detect malfunctions in a car's air conditioner and repair it yourself.

The air conditioner consists of several elements that form a closed system with a front and rear circuit through which freon - coolant - moves. Circulation through the rear and front refrigerant circuits is carried out by a compressor. The compressor compresses the freon, providing pressure in the system. In the compressor, the refrigerant is heated and comes out as a gas. Freon enters the condenser, where the system cools the gas and it turns into condensate.

Then the refrigerant is cleared of impurities in the receiver-dryer and moves to the thermostatic valve (TEV). Next, the liquid refrigerant enters the radiator, where it again turns into a gaseous state. At the same time, it cools the air by absorbing heat from it. The radiator greatly cools the air as it passes through it. Cooled air enters the cabin. Freon returns to the compressor through the rear circuit, and the cycle repeats from the beginning.

Diagram of the car ventilation and air conditioning system

Any element of the air conditioning system may become unusable, which will affect the operation of the entire system. Therefore, you need to figure out what malfunctions may arise, how to diagnose them, why this or that malfunction occurred, and how to fix it.

[Hide]

Let's feel the pipes under the hood

Do you see the thick and thin aluminum tubes? They usually run from the front along the right mudguard to the shield that separates the engine compartment from the passenger compartment.

Touch the thick pipe of the air conditioning system - it should be very cold.

Touch the thick pipe of the air conditioning system - it should be very cold.

Grasp the thick tube with your hand (beware of rotating parts!). Within a few seconds after starting the engine, the low pressure pipe should become cold. And after about a minute - ice cold. If the tube takes a long time to cool, it means the air conditioner is faulty.

How it works

A mobile climate control device is not much different from a regular refrigerator in our kitchen. This is a sealed system with a closed circuit through which refrigerant gas circulates.

- When the system starts, the compressor compresses the refrigerant, causing it to become very hot.

- Hot gas under high pressure is driven into a condenser, which is popularly called an “air conditioner radiator,” where it cools and turns into liquid.

- Once in the receiver-dryer, the liquid refrigerant is filtered from dust and other impurities. The freon then enters a thermostatic expansion valve (TEV), which returns it to a gaseous state. The expansion valve is the transition point from high pressure to low pressure in the system.

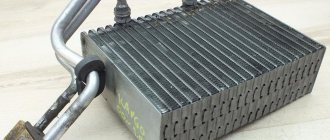

- The next destination is the evaporator, somewhat similar in structure to a small radiator. The temperature of the gas entering it tends to zero, and interacting with the warm air in the cabin, it begins to boil, cooling the radiator to an icy state.

- The fan “blows the cold away” from the evaporator into the cabin. Completing the cycle, the refrigerant again enters the compressor.

Passing through the evaporator channels, the air leaves moisture on its surface. It falls into the pan and is removed through a special condensate drain.

Be careful on the secondary market!

Are you buying a used car? Keep in mind that repairing a faulty air conditioner can cost a fortune. Don’t be too lazy to have it diagnosed by specialists before purchasing. Even if the seller claims that everything is fine.

- Find out how to quickly cool the interior after parking in the heat here.

- Do you want to pass the inspection without problems? Then you need a high-quality “Behind the Wheel” first aid kit with the optimal composition and the best fire extinguisher according to the results of our tests. An ideal addition would be a motorist's set in a convenient bag.

Fix it before it gets hot! 5 main air conditioner breakdowns

Has your air conditioner stopped working? Frequent air conditioner malfunctions

The main part of any climate system is its compressor. Signs indicating a malfunction: clanging or shuffling noise during operation; oily smudges are traces of refrigerant. Moisture and dirt enter the system through a leaky housing. Other problems include breakage, natural wear and sagging of the compressor drive belt, and jamming.

A common failure is damage or obstruction of the main line. This tube is a very fragile thing. Corrosion, unprofessional repairs, and poor quality components can disrupt the transport capability of the system. A faulty compressor picks up dirt from the outside, leading to blockages in the lines. Sometimes pipes deteriorate due to minor accidents that dislodge the components of the air conditioner from their seats. In a tight engine compartment, even a few millimeters can be the last for delicate elements.

The capacitor often becomes unusable. Dirt clogs the honeycombs, reducing the efficiency of the air conditioner, which becomes increasingly reluctant to regulate the temperature. Over time, the metal begins to rot under the dirty crust and the part becomes inoperative. A dirty radiator causes it to overheat. The first sign that it’s time for a car wash is when the air conditioner turns off spontaneously when driving in city traffic jams. The problem disappears at speed.

To the problems that arise due to dirt, you can add malfunctions in the electronic climate control system. Usually these are broken contacts. Because of this, the high pressure sensor may not work: it rises to a critical level and freon is discharged from the air conditioning circuit through the emergency valve. The air conditioner does not blow and does not cool.

Among other things, there is a violation of the tightness of the system due to damaged gaskets. The connecting elements must remain flexible to maintain operating pressure. Over time, they “tan”, crack, and become deformed. Refrigerant begins to leak. Regular washing and preventive maintenance, which maintains the working condition of all connecting elements, will help prevent this process (again!). Therefore, you need to turn on the climate control system even in winter - for 10 minutes 1-2 times a month.

An unpleasant odor is a gas emitted by colonies of microorganisms that have multiplied on the walls of the evaporator and the lines of the system. Soot, fumes and suspended polluted air become a favorable environment for new “settlements”. In addition to this, the drainage hole often becomes clogged and water begins to accumulate in the drainage channel. If you feel that your car constantly smells like a “full ashtray”, the air seems “heavy”, cold, but not fresh, then it’s time to clean your car’s air conditioning. You can entrust this work to a service, or do it yourself. Special aerosols will help with this. They are sprayed inside the car with the windows tightly closed and the air conditioner running at full power in recirculation mode. A more effective option is to dismantle the evaporator and clean it. The main thing in this case is not to start the problem by sacrificing your health.

Checking electrical circuits yourself

- You will need a test lamp to check electrical circuits, a simple multimeter with continuity testing and DC current measurement functions. Below is the sequence of checking elements according to the algorithm: from simple to complex.

- Check the integrity of the fuse of the air conditioning control unit, sensors, air conditioning compressor, fans.

- Check the power supply to the relay block (after turning on the ignition, there should be a constant “+” at the power terminal), and the presence of control signals. Using a wire, you can bridge the power contacts instead of a relay. If the chain is working properly, you will hear a click - the clutch has closed with the compressor pulley. If there is no relay as such, power is supplied to the clutch by the control unit. On the compressor itself you will see a connector with one (“+”) or two wires (“-” and “+”). Check if power is supplied to the connector when the engine is running and the air conditioner is on.

- Ring the circuit from the compressor clutch activation relay to the clutch itself. The power terminal of the clutch, to which the relay supplies “+” from the battery when control voltage is applied to the coil, must be connected to ground. To check, connect one terminal to the positive of the battery, the second to the contact in the relay block. If the clutch does not ring, disconnect the connector on the compressor and measure the clutch resistance (should be within 4-6 Ohms). If the winding is fine, the problem is in the wiring. You can verify the break using a multimeter in dial mode.

On constant rotation and combined type compressors, you can additionally check the valve resistance (should be about 8 ohms).

Filter clogging

The air conditioner, having a simple system, has a whole system of filters that provide a flow of cold or warm air. They purify the liquid and remove moisture from the system. It is the clogging of the filters that can lead to a malfunction of the air conditioner in the car. Initially, performance will simply drop, and then complete failure will follow.

Filters require special attention after refilling the air conditioner.

After detecting signs of a malfunction of the air conditioner in your car, it is important to promptly contact a car service for diagnosis, refueling or repair. Timely professional service is the key to success and relative savings. Prices for air conditioner repairs at a car service center depend on the complexity of the work performed.

Condenser is dirty or broken

The condenser is responsible for cooling the liquid, which reduces the temperature of the supply air from the system. In other words, it lowers the temperature of the refrigerant (refrigerant) that takes away heat and releases cooled air. Refrigerants are liquids that change from liquid to gas at temperatures below 0°C.

Condenser contamination leads to poor performance, which is not enough for cooling. That is why the air conditioner automatically turns off.

Why is this happening?

If the air conditioner suddenly stops working or turning on, you should not immediately go to the nearest service station and pay for diagnostics and repairs. You can check the unit yourself - many faults can be fixed with your own hands. If the air conditioner does not turn on, experts recommend checking the main units. And to understand what to check first, you need to know some causes and symptoms.

In fact, there are only three reasons why this device may not turn on. This is a non-functional start button, poor or absent contact on the compressor, as well as a low amount of refrigerant. These are all things to check if your air conditioner won't turn on.

How often should you recharge your car's air conditioner?

A completely sealed climate system loses up to 15% of its total refrigerant every year. Even a properly working air conditioner in a new car should be inspected every 2-3 years. For a car older than 6 years, the inspection should be annual, because over time, the joint gaskets wear out, and microcracks appear on the lines. There are several types of freon, depending on the year of manufacture of the car. Typically, there is a sticker somewhere under the hood telling you the type of refrigerant. Refrigerator oil is renewed together with freon.

Disassembly and repair of the car air conditioning compressor

How is a car air conditioning compressor repaired? Complete disassembly of the compressor is a rather labor-intensive operation. It consists of several steps:

- disconnect all tubes and wires from the compressor;

- remove the compressor itself;

- remove the clamping coupling;

- disassemble the body and separate the cylinder block;

- remove the valve plate;

- remove the piston group.

After disassembly, all parts are washed and degreased. Worn elements are replaced. Rubber gaskets are also replaced, even if they look intact on the outside. After assembly, lubricant is poured into the compressor and it is sent to a diagnostic stand.

After testing on the bench, the repaired unit can be installed back on the car. Before refueling, it is necessary to carry out a vacuum to completely clean the system.

freon leak

Freon leak “sniffers” are extremely sensitive and it is often difficult to find the exact problem area with them.

A visual inspection kit with yellow glasses and an ultraviolet lamp works much more effectively. Freon leak “sniffers” are extremely sensitive and it is often difficult to find the exact problem area with them. A visual inspection kit with yellow glasses and an ultraviolet lamp works much more effectively.

Fan failure

If the air conditioner fan does not turn on, this is another reason why the compressor and the air conditioner itself may not start. The function of the fan is to further cool the refrigerant. However, not all air conditioners have this element, and breakdowns are quite rare. Symptoms are noise during operation or a complete absence of any rotation. The temperature inside the car will be slightly higher than necessary.

Causes include worn bearings, electrical problems, mechanical defects and damage.

Cleaning the air conditioning system

Various aerosol cans for antibacterial treatment of air conditioning are sold at many auto parts stores.

Most of them have detailed instructions for use. There is no need to pour the mixture into all existing deflectors. It is important that the aerosol passes through the cabin radiator. Various aerosol cans for antibacterial treatment of air conditioning are sold at many auto parts stores. Most of them have detailed instructions for use. There is no need to pour the mixture into all existing deflectors. It is important that the aerosol passes through the cabin radiator.

Condensation on the surface of the cabin radiator sometimes leads to an unpleasant odor in the cabin. In such a humid environment, bacteria actively multiply, especially if the owner rarely uses air conditioning. It is their numerous colonies that cause the stench. If you use the air conditioner more often, the condensate flowing from the radiator will partially wash away the uninvited guests. If the smell is strong, you will most likely have to use heavy artillery. A special installation (the so-called “samovar”) is connected to the air suction channel from the street and a vaporous composition is driven through the system for a long time. Also, before each hot season, you can independently carry out antibacterial treatment of the system. An aerosol can is inexpensive. Anyone can handle the operation.

Repairing the radiator

The air conditioner radiator is located in such a place that it is constantly exposed to various objects: dirt, pebbles, water, salts, etc. Over time, it wears out, corrosion processes occur, and equipment depressurizes. This manifests itself in the fact that the system does not cool the air and water begins to drip.

The best solution in this situation is to buy a new unit, since if you repair the capacitor yourself, there is a high probability that depressurization will occur in another place. Water will drip again and new repairs will be required. In addition, if special equipment, welding and tools are used to troubleshoot problems, the working lines are blocked, which affects the power and productivity of the air conditioner.