In a Chevrolet Niva car, the gas distribution mechanism is driven by a chain. This allows you to get better performance when operating the car. In engine models with a timing belt installed, teeth may slip when it is stretched. But, despite the higher technical performance, the chain also has some disadvantages. It is subject to stretching and may burst if the engine is used frequently at high speeds. When replacing the chain, you should pay special attention to the location of the Niva Chevrolet timing marks.

Marks are special notches that can be seen on the pulley of the gas distribution system. These marks must be aligned with those on the chain.

Photos of timing marks Niva Chevrolet

Part 2. Valve + piston = repair Niva Chevrolet NIVA Chevrolet 4+4

Then you should remove the element tension mechanism.

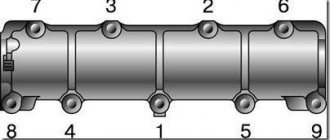

Location of TDC marks The marks are located on the camshaft sprocket, hole a, and on the camshaft bearing housing, protrusion b.

If the valve timing is incorrect, the engine will not operate normally. How to remove it correctly can be found in articles about the hydraulic chain tensioner of a Niva Chevrolet car. If you pull it towards yourself the distance will be removed along with the chain.

If after several revolutions there are no discrepancies, the fastening bolts on both sprockets are tightened, and the lock washers are installed in their original places. The adjustment of the timing marks ends here and all engine components are reassembled. Consequences of incorrect installation and adjustment: Characteristic extraneous clicks appear in the engine, which become louder as the speed of the machine increases.

The engine is unstable even at idle speed. The car's acceleration time increases significantly because the engine does not respond well to pressing the gas pedal. Acceleration occurs in jerks, during which clouds of black smoke may fly out of the exhaust pipe.

Valve wear accelerates many times over, and if the shafts are out of synchronization too much, the valves become deformed and their seats break.

Incorrect adjustment can also lead to a broken timing chain. It is recommended that when loosening the tightening, unscrew it by hand or with a deep-head wrench.

Parts and consumables:

The chain tensioner is being dismantled. How to remove it correctly can be found in articles about the hydraulic chain tensioner of a Niva Chevrolet car.

It is possible to do without removing the chain tensioner, but for this you need to have the appropriate skills. If you decide not to remove the tensioner, then you need to press out the tensioner plunger using a screwdriver.

We proceed to removing the crankshaft sprocket along with the chain. To do this, you need to manually pull it towards you about cm.

The location of the chain on the teeth changes. The best option is to move in increments of one tooth.

The sprocket is installed on the camshaft flange along with the chain. When the location of the chain on the sprocket changes, the holes in it will accordingly not coincide with the locating pin.

To do this, rotate the crankshaft in the required direction until the hole and the notch of the pin coincide. Now take the timing chain and lubricate it as well. First install it on the crank pulley gears, then on the oil pump and on the camshaft.

The chain should be tensioned from sprocket to sprocket, while observing the position of the pulleys according to the marks.

Install the timing belt tensioning component and tighten all nuts with a wrench. Having done this, check again that the marks match.

split for Chevrolet Niva

Also tighten the screws on the gears. The scrolling step is one tooth. The sprocket with chain is placed on the camshaft flange.

Niva Chevrolet

When the chain moves on the sprocket, its holes will not line up with the pin. You should turn the crankshaft in the specified direction until the mark and pin match

It is important to secure the part with a bolt and washer without tightening it completely. After turning the crankshaft twice with a special wrench, check the placement of marks on the camshaft gear and bearings

If the marks correspond, their adjustment has been successfully completed.

The cylinder head cover has been removed. Remove the cylinder head cover, see. Rotating the crankshaft, align the marks on the camshaft sprocket and its bearing housing. If the chain is installed correctly, the mark on the crankshaft pulley should align with the long mark on the camshaft chain cover. If the marks do not match, straighten the lock washer tabs of the camshaft sprocket bolt. Engage first gear to prevent the crankshaft from turning, remove the bolt and

Preparing tools and spare parts for timing belt replacement

Prepare a screwdriver and wrenches for “8”, “13” and “10” , devices for turning the crankshaft and additional parts:

- oil seal (frontal);

- new cylinder head gasket;

- pump gasket;

- tensioner;

- damper bar, limiter and chain stabilizer;

- sealant;

- motor oil and oil filters;

- coolant;

- crankshaft seal;

- gears.

Important! You can install the timing marks of the pulleys with high quality if you have a reliable chain that prevents damage and stretching. If the old chain fails, you need to buy a new one.

Step-by-step adjustment and timing marks of the injection Niva Chevrolet

- Installation of the risk on a VAZ-2123 1.7 with 8 cells (according to the standard) is carried out on an inspection ditch. Put the car on the parking brake. Shoes are placed under the front wheels.

- You need to wash the engine and fender liners.

- The air filter is removed.

- Drain the engine oil, unscrew the oil filter.

- Drain the coolant.

- The valve cover fastenings are unscrewed.

- To prevent engine oil from leaking into the cylinder head area, it is recommended to replace the cylinder head gaskets.

- By rotating the crankshaft pulley, marks are set on the camshaft gear and bearings.

When to use low gear

For what purposes is a transfer case even needed, when does it make sense to engage the locking and downshift? Such seemingly simple, but at the same time serious questions will become clear when considering the following example. When driving on a country road on a hard surface, fourth gear is engaged. Suddenly, a large puddle with a soft, unreliable surface appears in front of the car. In such an obstacle the car can easily “sink”. To prevent this, you should engage a lower gear and slowly overcome such an obstacle without haste. This gear is designed specifically for driving on soft road surfaces, when even in first gear the car feels “hard”.

Low gear

It is worth noting that in order to engage a lower gear on a Niva Chevrolet, you need to stop - this is how the car’s differential is designed. But you don’t need to stop at all to turn the lock on and off. But is it worth using such additional and, without a doubt, useful functions of the machine often? Experienced drivers recommend using them in places where the dirt is not located on level ground, but with various potholes and the like.

Thus, the low gear of the Chevrolet transfer case is designed for comfortable off-road driving and overcoming various obstacles. In such a gear you need to drive slowly, you cannot accelerate sharply, because at this moment the wheels will receive a large load, as a result of which a real hole can form, from which it will be very difficult for the car to get out.

With this driving style, the motorist will better feel the movement of the wheels, as a result of which, when they “bury”, as evidenced by the chaotic movement of the car, it will be possible to immediately do something after overcoming the obstacle. Most often, this is done by changing the trajectory of the car.

It is also worth noting that when driving through sticky mud or deep puddles, you should never suddenly engage second downshift. At the same time, the torque increases, as a result of which the car can simply “choke”, stalling at the most inopportune moment.

Product description

Branded developments:

Innovative USPK technology was used in the production of oil and petrol resistant rubber:

BNKS-28AMN (synthetic butadiene-nitrile rubber) is used in the recipe.

Benefits for the car enthusiast:

Warranty 2 years unlimited mileage

- Availability: In stock

- Length: 16 cm x Width: 6 cm x Height: 3 cm

- Weight: 0.45 kg

- Product code: 4877

- Cash upon receipt (cash on delivery)

- Online payment by bank cards without commission

- Electronic wallets

- According to the organization's account (excluding VAT)

- Post office

- SDEK | DPD | PEC

- Business Line

- Energy | GTD (KIT)

- Baikal Service

- ZhelDorExpedition

- Dispatch from 1 day

- Delivery from 2 days

- Product didn't fit? Easily return it within 14 days

- Read about other store guarantees

Source

What's next?

The car is placed in fifth gear. Use a special 38 mm wrench to remove the nut on the crankshaft pulley.

Unscrew the spark plugs and make marks on the crankshaft, as well as on the camshaft gear. Then dismantle the pulley and unscrew the fastenings of the lower frontal cover. They are located on the engine sump. Unscrew the two damper mounting bolts. The last one is removed too. The oil pump gear clamps are bent. Then the bolt is unscrewed with a 17mm head.

The oil lines are removed from the tensioner using a brake pipe wrench. Afterwards you will need to unscrew the nut of the low oil pressure sensor from the tee. To do this, you will need a 22mm wrench. This procedure is required when using the “Pilot” tensioner.

Using a spark plug wrench, the tee is removed and a pressure sensor is installed instead. Using a 10mm wrench, unscrew the two tensioner nuts. The last one is removed from the place. The top nut is removed. It can be obtained with pliers or a tubular wrench.

The next step is to remove all three gears, as well as the chain. Use a screwdriver to remove the old crankshaft oil seal. It is necessary to thoroughly wipe the oil seal seat from dirt.

You will need a clean rag. It is also advisable to wipe the lid. After these procedures, a new oil seal is pressed in. To make it go in easily, you will need to pre-lubricate the elements with oil. An old oil seal is used as a mandrel (so that the part fits evenly into the hole).

Replacing the chain drive

7. Then remove the casing covering the motor. To do this you will have to remove several bolts. We remove the sedative. Unscrew the screw securing the oil supply pump. There is no need to remove the screw. It should only be loosened and left in place.

8. We begin to remove the tension element mechanism. We remove the MM line, remove the pressure sensor, after which you can remove the tensioner itself. 9. Remove the screw on the camshaft gear. We remove the gear. After this, remove the timing chain. At this point, the parsing process can be considered complete. Now let's assemble the mechanism. 10. We take the purchased oil seals and begin to install them in place of the old ones. First of all, we change the crankshaft oil seal. After removing the old component, clean the installation location and install a new oil seal. First, it is recommended to lubricate the new oil seal with engine fluid, for example. 11. Now we take the chain in our hands and also begin to lubricate it. After this, we put the drive on the crankshaft gear, the oil pump and then the camshaft. This sequence must be followed. When tensioning the chain, you need to ensure that the alignment of the marks is not disrupted.

How to set engine marks on a VAZ 2121

There is a standard 21213 NIVA, the engine of which has tractor traction at the bottom and lacks traction at speeds above 3000. Replacing the chain, all the sprockets, the camshaft with the bed did not solve the problem. Rearranging the chain on a tooth back and forth, too. It was noticed that the mark on the camshaft sprocket is not installed strictly opposite the protrusion; it can be placed half a tooth forward or backward. It was decided to check the valve timing. A device for adjusting valves with an indicator is welcome, but not at all required. However, I have it. The valve clearances must be properly adjusted!

When replacing the lower sprocket, check that the marks on the small sprocket and the pulley match. They correspond to TDC.

Having placed a mark on the pulley opposite the long mark 3 (TDC on the distributor drive cover), we mark marks 1 and 2 (5 and 10 degrees) on the pulley with a light marker (I used a white oil marker). We turn the crankshaft so that the standard mark on the pulley is opposite mark 1 (10 degrees) and mark 2 more marks - 5 and 10 degrees. on the other side of the zero mark. Also, by placing the extreme marks opposite the existing protrusions, we mark 15 and 20 degrees. We mark the zero mark on the second side of the pulley (now it is on both halves of the pulley). We have a scale marked on the crankshaft pulley - 20 - 15 -10 - 5 - 0 - 5 -10 - 15 -20 degrees. This is the easy way. You can make a scale out of paper, mark it more precisely, for example, with an accuracy of 1 degree, and stick it on the pulley. This method is a little more complicated, but also more accurate. I was quite happy with the 5 degree scale.

We install the crankshaft and camshaft according to the marks, as when adjusting the valves, the slider looks at the 4th cylinder. If there is an indicator, install it on the 2nd valve (intake of the 1st cylinder). We will use them to look for the moment of opening and closing of the valve. If there is no indicator, press the rocker up, using an open-end wrench 13-17. In this position, both valves of the 1st cylinder are clamped and slightly open (overlapping). Turn the crankshaft counterclockwise 10 -15 degrees. Using the applied marks, we find the moment when the intake valve begins to open by the appearance and disappearance of the gap between the rocker and the camshaft cam. We look at the pulley and the long mark on the cover, and count the degrees. For example, the mark is exactly between 10 and 15, we get 12.5 degrees. — the beginning of the opening of the intake valve. Let's remember. We move the indicator to the first valve (exhaust of the 1st cylinder) or control it by pulling the rocker up, turn the crankshaft clockwise, and find the moment when the exhaust valve closes.

For example, we got 15 degrees.

By simple calculations (in our head) we find the valve overlap point (15 + 12.5)/2 = 13.75 degrees. This point, located at TDC, is considered optimal. In our example, the overlap point moved 1.5 degrees after TDC. You can check the pie chart of the valve timing and compare the result:

On my car, the mark, with new sprockets and chain, turned out to be shifted forward by 5 (!) degrees. This is where the tractor came from. Perhaps VAZ specifically places this mark with an offset in order to increase the torque at the bottom, or maybe during assembly they use sprockets from Lada cars. In NIV, the block is slightly higher, which is why the mark shifts. Don't know. To correct the situation, a split (adjustable) sprocket was purchased and installed:

With its help, you can smoothly adjust the position of the camshaft relative to the crankshaft + - 1 tooth.

If we set it so that the overlap point does not reach TDC, we get earlier opening of the intake, an increase in power at high speeds and a drop in traction at low speeds, and vice versa, the overlap point after TDC - we have tractor traction at low speeds, and stupidity at high speeds. Exact recommendations like “how many degrees should I turn?” no one will give it to you. It all depends on the condition of the engine and personal feelings. However, you should not go more than half a tooth away from the point of zero overlap. It must be remembered that at large angles the pistons may collide with the valves. I made it so that the overlap point was shifted by 2.5 degrees before TDC, I got a good pick-up after 3000 rpm, and at low speeds the thrust remained almost unchanged. After all the manipulations, it is necessary to re-set the ignition timing, and it may be necessary to adjust the idle speed.

Source

Evaluating the position of the marks and setting the valve timing

To start work, you will need the following tools: keys for “8”, “10” and “13”, installation and a special key for cranking the crankshaft.

It is possible to accurately determine the need to replace the timing chain only after the fact. You need to remove the valve cover, set the piston of the 4th cylinder to top dead center (TDC) and look at the marks.

Step-by-step instructions for diagnosing and setting valve timing:

- We remove the negative terminal from the battery, put the car on the handbrake and engage neutral gear.

- Preparation - unscrew the air duct from the mass air flow sensor to the throttle assembly, disconnect the accelerator cable, the hose of the vacuum brake booster and crankcase ventilation. Remove the valve cover along with the rubber band by unscrewing the fasteners.

- We set the 4th piston to TDC - use a wrench to turn the crankshaft so that the mark on its pulley coincides with the mark on the engine cover, and the mark on the camshaft sprocket matches the pointer on the valve cover. If the marks on both sprockets match, the valve timing is normal. If not, we continue working.

- To fix the crankshaft, put the car in first gear. Unbend the tabs of the camshaft pulley bolt lock washer.

camshaft pulley

Unscrew the bolt and remove it along with the lock washer. Be careful not to drop them into the engine pan.

Press the tensioner plunger with a pry bar and loosen the chain. Then remove the pulley from the camshaft and carefully move the chain in the desired direction by 1 tooth. Place the sprocket on the camshaft and tension the chain. If the hole on the camshaft pulley no longer aligns with the locating pin in the flange, rotate the crankshaft slightly to the side until synchronized.

Screw the bolt and washer back, but do not tighten it. Rotate the crankshaft 2 turns and check the marks. If they do not match, repeat the procedure the required number of times.

When finished, tighten the camshaft bolt and bend the petals of the support washer, putting the car in first gear. Assembly is carried out in reverse order.

When reassembling, do not forget to install a new valve cover gasket, even if the old one has no external damage. The chain tensioner can be replaced with a mechanical “Pilot” with a longer service life.

How to replace the chain tensioner on a VAZ 21213-VAZ 2131

Cars of the Niva family are very old models, in my opinion the very first cars went back to 1977 if memory serves, but these are new times and the car is still being produced and refined, so here are the chain tensioners that AvtoVAZ installed on its cars in Depending on the year of production, they may differ from each other, so for example, somewhere before 2000 or even higher, these cars of the Niva family came with the most common spring chain tensioners, these tensioners are very easy to remove, but one of their drawbacks (Or maybe an advantage) is the fact that they do not tension themselves, that is, from time to time you have to tighten them yourself, which is very inconvenient, but this is for someone, because it only takes 1-2 minutes to tighten the chain tensioner!

Now let’s look at a new type of tensioner that came on cars that were produced much later, so to speak, during Russia and not during the USSR, and so in new times, the so-called hydraulic chain tensioner was installed on this family of cars, its whole advantage is that you won’t need to constantly tighten it, that is, it was installed at the factory, and you, as they say, forgot about it, but it’s not so simple, if this tensioner suddenly jams or something else happens to it, then you will have to change it to a new one , and today you will learn how to replace this type of chain tensioner in this article. (By the way, you can see what a hydraulic chain tensioner looks like in the photo below)

By the way, if you have a regular tensioner of an old model, but it looks like it is shown in the photo, then read more about how to replace this unit in the article entitled

Removing the chain tensioner

1) At the very beginning of the operation, use a wrench to unscrew the tube that is connected to the hydraulic chain tensioner itself, and after this tube is unscrewed, disconnect it and move it aside.

2) Then, using a wrench or a socket with a universal joint (If it is difficult to get to), unscrew the two nuts that secure the hydraulic tensioner to the car engine (One of the nuts is not visible in the photo, but when you look at this tensioner on the car, then you will immediately understand where the second nut is, since it is located nearby) and then carefully remove it from the hole in which it is located.

Installing a new

Installing a new tensioner occurs in the reverse order of removal, and by the way, after installation, close the hood and sit behind the wheel of your car, then try to start the car and if that chain rattle disappears, then you did everything correctly and that’s why the chain rattled the tensioner itself.

Checking the tensioner for wear

- If you have removed your old tensioner and think that it is in working order and there is no point in changing it, then first rinse this tensioner in a container filled with gasoline (Rinse the tensioner at your discretion, just if all the dirt comes away from it, then it may even improve its performance like this how small particles of dirt will not interfere with the movement of the plunger itself, but more on that a little later), and after washing, thoroughly dry this tensioner or simply blow it out with compressed air.

- After washing and drying it, let's look at what it consists of, namely the plunger itself, which is also indicated under the number 1, and the tensioner housing, which is indicated under the number 2.

- Now, after studying this material, let's move on to checking, firstly, inspect the tensioner plunger itself; in no case should there be any kind of defects on its surface, such as, for example, scuffs, deep scratches, etc.

- Then inspect the body itself; there should also be no nicks, dents, etc. on its surface.

- And finally, perform another fairly simple check, namely, grab the tensioner plunger itself with your hand and then try to move it; if the plunger sticks in any place, then replace the tensioner with a new one.

Build process

- The front cylinder head cover is installed and a layer of sealant is applied.

- The bolts are tightened.

- The air filter is installed, sealant is applied and the pan is screwed on.

The fitting is unscrewed to bleed air from the block before filling with coolant. Pour liquid into the radiator. After it leaks out of the fitting, the lamb is screwed into place. Filling the engine oil. The hose and crankcase ventilation tube are connected to the fittings, and the copper wires are connected to the ignition coils.

The tips of the high-voltage wires are connected to the spark plugs. It is possible that after unscrewing the spark plugs, the remaining water in the wells penetrates the cylinders. Using a long knitting needle and a clean rag, it is easy to remove moisture from them.

Consequences of incorrect installation and adjustment

- Characteristic extraneous clicks appear in the engine, which become louder as the vehicle speed increases.

- The engine is unstable even at idle speed.

- The car's acceleration time increases significantly because the engine does not respond well to pressing the gas pedal.

- Acceleration occurs in jerks, during which clouds of black smoke may fly out of the exhaust pipe.

- Valve wear accelerates many times over, and if the shafts are out of synchronization too much, the valves become deformed and their seats break.

- Incorrect adjustment can also lead to a broken timing chain. This, in turn, can puncture the radiator, break the fan and other engine parts.

- The engine constantly overheats, and the consumption of engine oil and antifreeze can increase significantly.

As can be seen from this article, correctly set timing marks are the key to long and uninterrupted engine operation. There is nothing complicated about this; even a novice car enthusiast can do it.

It is important to take your time, follow the above sequence of actions, and also try not to drop the sprocket lock washers into the engine sump. Because it will be very difficult to get them from there

The Chevrolet Niva from the SUV family is equipped with a chain drive in the timing mechanism. The operational properties of a chain are much greater than those of a belt drive. The chain also has better technical characteristics, which affects the transmission torque. If a loose belt causes the pulley teeth to slip, a weakened chain does not allow this to happen. But with the operation of the car, the gas distribution chain also tends to wear out, stretch, burst and become unusable, which requires its replacement

At the stage of replacing the chain, it is important to carry out the installation following the marks. This article will tell you what tags are, their purpose and how to set them on a VAZ-2123.

Carburetor repair for dips and jerks

Carburetor repair may be necessary if the engine idles unstable, and adjusting the quantity and quality screws does not always help. Often the reason lies in over-enrichment of the mixture, which may be a consequence of incorrect adjustment of the float system or malfunctions in the vacuum economizer system for power modes. In the latter case, a torn diaphragm may need to be replaced or the economizer valve through which fuel is leaking may need to be repaired.

Model 2121 may cause jerking, swaying or dips when moving. In this case, there may be several reasons for their occurrence, which may require carburetor repair to eliminate them. Dips that appear when the throttle valve is slowly opened are often associated with clogging of the idle jet. Here it is necessary to adjust the fuel level and check the level of clogging in the main fuel jets.

If the car gives a deep failure when trying to open the first or second throttle chambers, then in addition to clogged nozzles, the reason may be poor installation of small diffusers in the corresponding sockets.

When the Niva 21213 gives slight twitches at low and medium speeds and accelerates sluggishly, it may be due to poor fuel dosage on the shut-off valve side due to its wear. In this case, repairs are needed in terms of replacing the shut-off valve with a shut-off needle made of metal with a valve that has this needle made of a different material.

Cars of the 2121 series sometimes give failures when any sudden opening of the throttle valves, which then disappear within 5 seconds when the engine is running at the same pace. Often such problems are associated with a malfunction of the accelerator pump, which leads to a lack of or an incorrect drop in gasoline flows. A similar situation can result from a diaphragm rupture, a rubber O-ring on the sprayer holder being destroyed, or the lower part of the valve being destroyed.

If you find an error, please select a piece of text and press CtrlEnter.

Adjusting the chain according to the marks.

When replacing a chain, installing a new one should be done in several stages:

- collecting the necessary tools: screwdriver, set of keys for 8, 10 and 13. Wrench for rotating the crankshaft

- The car is placed on a viewing hole or raised using a jack. The wheels are fixed with shoes or a stop.

- Before starting work, you must turn off the fan and unscrew the radiator mounts. All pipes, except the air duct, remain in place; the antifreeze does not drain.

- After this, the valve cover is dismantled. After all the fasteners have been unscrewed, you must carefully remove it, preventing dirt from getting inside.

Installation

After removing all elements of the system, you need to carry out proper installation and configuration, for this you need to do the following:

- Install the mounting bolt on the shoe.

- We check that the shoe does not move on the axis, tighten the bolt

- We install new gears, they must clearly coincide with the existing marks

- We install the clamp, if it does not sit in its place, you can file it a little

Before installing the chain, take engine oil and lubricate it, then put it on the new elements as follows:

- We put it on the crankshaft gear

- Then to the oil pump

- Then to the camshaft

After replacement, the tensioner is installed in place, the marks of which must coincide with the chain tension; after checking, we tighten all the bolts. Lubricate the gasket with sealant located on the timing cover and install it in place. We install the pulley and two belt rollers in place and tighten the bolts that secure them. Engage 4th gear and tighten the pulley nut. We install all existing pipes, hoses, radiator, fan in their place, and fill in antifreeze. We start the engine for a couple of minutes and check how it works; if everything works properly, we install the protection with the boot in place.

Valve train chain

If during engine operation there is a ringing sound that resembles the operation of a diesel engine, then most likely the Niva Chevrolet timing chain needs to be replaced.

Replacement

If you do not replace it in time, it may break while driving. To replace, do the following:

- Installing the car in the pit

- The motor protection with boot is dismantled

- We raise the handbrake; it is advisable to place special supports under the wheels

- Drain the antifreeze and remove the radiator and fan

- Carefully disconnect the accelerator cable going to the air filter from the valve covers and pipes

- We remove the crankshaft sensor, loosen the bolts that secure the generator

- Move the generator aside and remove the belt.

- We unscrew several bolts that secure the water pump, and then remove it

- We dismantle the tension and bypass roller of the belt

- Remove all interfering pipes

- Cover the cylinder head to prevent debris from getting into it.

- After unscrewing the mounting bolts, remove the camshaft gear

- Remove the oil pipe along with the hydraulic tensioner

- We remove the chain and all gears of the oil pump, crankshaft and camshaft

- We take a new oil seal and install it on the timing cover

Installation

When the Niva Sherole timing chain and all necessary system elements have been removed, you need to correctly install and configure the new parts, for this you need:

- Take the fastening bolt and install it on the shoe

- We check that the shoe is stationary and then tighten the bolt

- We install the new gears in their place so that they coincide with the existing marks

- We install the clamp, if for some reason it does not sit in its place, we file it

Before installing the chain, it must be lubricated with engine oil, after which it can be put in place as follows:

- First on the crankshaft gear

- After that, to the oil pump

- And finally on the camshaft

To ensure better operation and fixation of this mechanism, it contains special timing marks Niva Chevrolet

If they are not taken into account when installing the chain, this can lead to the gas distribution system becoming out of synchronization and increased wear of parts.

Adjustment by marks is carried out in several stages:

- All necessary tools are prepared

- The car is installed on the pit

- The fan is turned off and the radiator mount is unscrewed

- Removing the valve cover

When all the preparatory steps have been completed, the following adjustments are made:

- Rotate the crankshaft until the bearing and camshaft marks match. If the chain is installed correctly, the existing marks on the chain cover and crankshaft will match. If they do not coincide, we adjust the position of the phases

- To make this adjustment, loosen the fastening at the lock washer, then use a 13 key to remove the washer along with the camshaft sprocket

- We set the first gear so that the bolt that secures the crankshaft gear does not turn. Unscrew the fastening bolt and lock washer

- We remove the tensioner.

- Pull the chain towards you and remove it from the sprocket

- To adjust it, move it one tooth

- We begin to turn the crankshaft until the notches coincide

- Install the lock washer. We place the bolt in the place for fastening, but do not tighten it

- Rotate the crankshaft and check if the marks match. If they match, then the work can be considered completed

It is important that the marks match as accurately as possible, since the correctness and stability of the engine will depend on this

How is the replacement made?

If chain stretching is detected and the decision is made to replace only the hydraulic tensioner, then this is an incorrect assumption. It is necessary to replace all parts: chain, hydraulic tensioner, seals, gaskets. Replacement is done in the following sequence, using all the necessary tools:

Use a spanner wrench to unscrew the tube fitting, which has a “10” head. The tube is designed to supply oil to the hydraulic tensioner.

Having loosened the fitting, the tube is removed and moved upward so that it does not interfere with further work. The two nuts securing the device itself are also unscrewed using a “10” wrench.

The device is ready to be removed from its mounting location. We grab the protruding part with our hands and pull out the device. There is a gasket on it, which also needs to be removed to replace it with a new one.

A used device cannot be repaired and requires the installation of a new one. Before installation, it is necessary to coat the gasket with a layer of sealant to prevent oil leakage.

Replacing an old device does not require serious mental and especially physical effort. Installation of a new one is carried out in the following steps:

- The device is inserted into the new seat, having first checked that the structure is identical to the old tensioner.

- Screwed in with two fastening nuts.

- The tube is inserted and secured.

It is simply impossible to make a wrong replacement. After installation, the operation of the motor and the tension of the new chain are checked. An important point is to replace the timing chain in order to 100% protect the car and your health from unexpected breakdowns on the road. This article will tell you how to replace the chain.

Now the owners of the Chevrolet Niva can, without doubt and without errors, correct the existing problem with weakening the chain tension. Remember that if your car has traveled more than 100 thousand km, and there are no characteristic sounds from under the hood, then do not neglect the situation, but disassemble and check the looseness of the chain and the functionality of the tensioner. Happy renovation work!

Recently, an old friend of mine came to see me in his old Chevrolet Niva with the characteristic sound of an extended chain.

In addition to the timing kit, I had the foresight to purchase even a front cover gasket, a crankshaft oil seal and a kilo of marinated meat. I could not refuse such an offer. So, Niva Chevrolet replaced the timing chain and front crankshaft oil seal.

First, let the engine cool to an acceptable temperature. Remove the pipe by unscrewing the bolt by 10 and loosening the clamps.

Next, we unscrew the eight nuts by 10 and move aside the throttle cable and all the pipes that will interfere with us, remove the valve cover.

Remove the air conditioner belt by unscrewing the bolt 13 of the tension roller.

Then loosen three 13mm nuts and one bolt of the generator belt tension roller and remove it.

Now comes the fun part. To unscrew the pulley nut, we need a 38mm socket. Since the elongated head does not fit under a regular wrench (the radiator is in the way, but we don’t want to remove it), we use a pry bar, carefully sawed off from the hub key of some large car.

Everything fits perfectly. Unscrew the nut and remove the crankshaft pulley.

Unscrew the deflection roller.

We dismantle the reinforcing plate.

We unscrew the six nuts securing the front timing chain cover to the block and the three bolts securing it to the pan and remove it.

Set the top dead center. The key on the crankshaft should align against the mark on the block.

The mark for the camshaft sprockets is against the ebb of the camshaft housing.

Next, unscrew the oil supply pipe and two nuts 10 of the chain tensioner.

Next, unscrew the tensioner shoe, damper and remove the timing chain.

Compare the new and old timing chain. It could be worse.

New timing kit.

Reinstall the chain, guide and tensioner shoe. We tighten the chain by hand and check that the marks match.

To make it convenient for us to check the marks after installing the front timing cover, we find the factory mark on the crankshaft pulley and mark it with a white marker. This mark at TDC should be opposite the center of the crankshaft sensor.

We install the front cover, crankshaft pulley and tensioner. Let's check the marks again. We install all the removed parts in the reverse order of removal. Fill with fluids, start the engine and enjoy.

>

Useful post?

Yes

No

Why are timing chain marks set?

The engine of any passenger car has 2 shafts: camshaft and crankshaft. In most cars they are connected by a belt drive. On a Chevrolet Niva car this is a chain transmission, and a single-row chain is used there. The advantages of such a system are obvious: the chain, unlike a belt, never slips on the pulleys and lasts much longer. However, the chain can stretch over time, and the teeth on the shaft sprockets can wear out or even break. This will lead to desynchronization of the camshaft and crankshaft. Their work will not be coordinated, so the engine may fail

Therefore, when adjusting or replacing the timing chain, it is very important to align the engine shafts in accordance with the marks on the pulleys and timing case. This is not easy to do, since, firstly, the marks are located in hard-to-reach places, and secondly, they need to be set very accurately, since the chain, unlike a traditional belt, cannot be slightly tensioned if necessary

Replacement video

The gas distribution system of any engine must work correctly. If problems occur in its operation, this leads to premature wear of the motor and numerous breakdowns. To accurately adjust the timing, special marks are used, according to which the shafts in the engine are aligned. We will tell you about the correct placement of marks on a Chevrolet Niva car in this article.

Consequences of incorrect installation and adjustment

The gas distribution mechanism greatly influences the operation of the engine, so when replacing parts and setting marks, you must be careful and avoid mistakes. But if this does happen, the engine will immediately let you know about it.

If there is a serious error, the engine will not start. If the phase shift is small, the electronic engine management system compensates for this by adjusting the ignition. If the phases are shifted by half a tooth or a gear tooth, the system is not able to compensate for such a shift.

This leads to the following consequences:

- sudden loss of traction - the car responds poorly to pressing the accelerator pedal;

- deterioration in fuel efficiency;

- the engine runs intermittently, even at high speeds;

- the coolant temperature rises, causing engine overheating with all the ensuing consequences;

- premature wear of the camshaft, burnout of valves, broken chain followed by major engine overhaul.