Is a car a luxury or a necessity? This issue has not been raised in developed countries for quite some time. But as for its equipment, the opinions of motorists can vary greatly - and largely for financial reasons. But when it comes to comfortable conditions in the cabin during the hot season, most drivers are unanimous - you can’t do without air conditioning. That is why many automakers have begun to equip even entry-level models with this device. Climate control or an air conditioning system really helps out when the thermometer outside exceeds +30 degrees, and there are more and more such days every year. The only drawback of car air conditioners is that over time they cause an unpleasant odor to appear in the vehicle interior, which disappears after the device is turned off.

Instructions for cleaning the evaporator in a car air conditioner.

In such situations, the only solution is to disinfect/clean the air conditioning system. But before you begin these procedures, it is advisable to familiarize yourself with the theory: how the air conditioner works, what functions the evaporator performs, and why non-aromatic odors appear in the cabin. All this will help you understand how to clean the air conditioner evaporator at minimal cost or how to reduce the time and labor required to complete this operation. Advice on what means can be used to delay the relapse of the “disease” would also be useful.

Prevention period

The frequency of cleaning the device depends on its purpose.

For example, it is recommended to clean the filter elements of air conditioners for home use every six months. When it comes to office equipment, the frequency of work is once every three months. If the split system is installed in a cafeteria, retail space or other public facilities, cleaning is carried out once a month.

The need for prevention can be easily determined by the smell that appears after turning on the equipment. An unpleasant “aroma” indicates the appearance of bacteria inside and the need to remove them.

Masters note that during the maintenance process they often find mucus and various fungi inside

This is why it is so important not to delay repairs and call a specialist to carry out the work.

Malfunctions in which the air conditioner freezes indoors

If the air conditioner was working properly, no maintenance work was carried out, operating rules were not violated, but suddenly ice began to fall out of it, a breakdown probably occurred. Here is a table that will help you find out what exactly has gone wrong and how much the repair will cost.

*The table shows prices only for the work of the master. If replacement of parts is required to eliminate a malfunction, spare parts are paid separately.

If you notice ice and snow forming inside the split system, we recommend turning off the equipment and calling a technician. Operating a faulty air conditioner can lead to more serious damage to the split system. Don't hesitate, call from 8 am to 10 pm:

A RemBytTech specialist will respond to your call within 24 hours from the date of your request. He will carry out diagnostics in front of you and determine the reason why the air conditioner is freezing. He will calculate the cost of repairing the breakdown and, with your consent, will carry out repairs at home. a guarantee of up to 2 years on work and spare parts !

Why doesn't the air conditioner heat up?

The air conditioner does not defrost

But what if the heating function in the air conditioner is unavailable for some reason?

Let's consider several factors that may affect its operation:

- Very coldy. The electrical appliance simply may not be designed to heat rooms in such weather conditions. This is a common reason why the air conditioner does not heat properly. The power of some devices is not designed for such a strong temperature difference, so the device is not capable of heating the air in the room by more than 3 degrees. But provided that the temperature outside is from 0 to +5 °C, the device heats the air with the greatest efficiency.

- Heat is not supplied when there is air flow from the indoor unit. The air flow into the room has a temperature similar to that outside. There is clearly a problem with the compressor. There may be a breakdown in the four-way valve, which is the element responsible for changing the operating mode of the air conditioner. If there is damage, it cannot ensure switching of the operating modes of the device from summer to winter. In this case, the compressor will need to be replaced or repaired.

- The defrosting mode is broken or missing. Under such circumstances, the electrical appliance still operates in normal air cooling mode. Air supply units are functioning. But it doesn't work in heating mode.

Other reasons and adjustment methods

Some air conditioner models are equipped with a coil that generates heat, which is installed on the internal block of the device. A fan distributes heated air throughout the room. When the heating of the atmosphere is poor, it is worth checking the device for problems with the power supply of the coil or with the fan of the indoor unit.

Some problems of this nature can be resolved by the consumer himself. The problem may be hidden in simple freezing of condensate in the internal tubes of an electrical appliance, which leads to their clogging and obstruction.

If it’s already frosty outside, then temporarily turning off the device will not help. The frost inside the tube will not melt due to freezing temperatures outside. You just have to wait for warming, or you can try to run a heating electric wire running along these tubes. This will help if there are no problems with the external unit.

Possible causes of condensation:

- Unprofessional installation work that compromised the integrity and operation of the air conditioner.

- There is a manufacturing defect in the device.

- The presence of microcracks through which liquid enters the device. The possibility of damage to components mechanically or due to improper operating conditions cannot be ruled out.

Under such circumstances, it is impossible to warm up the circuit. But if you try to switch the modes from heating to cooling, and after a while in the reverse order, the problem may be resolved. It may take several of these alternating switches for the plug to melt and slide out of the tube, freeing the passage.

Switching the air conditioner from cooling to heating

Due to the formation of cracks and other damage with the appearance of microscopic gaps, a drop in pressure in the freon circuit may occur. This becomes possible due to the loss of a small amount of refrigerant. Under such circumstances, the air conditioner will not cool or heat well.

The problem with refilling with freon will be eliminated by the service departments that provide maintenance. The actions are carried out through the fitting pipe located in the external block outside the building. Specialists use the manifold for nitriding, evacuation and refueling.

But you can determine this need yourself. To do this, you need to find and examine the scale of the unit, where the actual indicators of the presence of freon are indicated. By comparing them with those recommended according to the device data sheet, the need for refueling is identified.

Craftsmen use special thermometers to measure freon vapor as it enters the compressor. And the collector readings will indicate digital data on the pressure status. A temperature difference of more than 8°C between these two numbers indicates a need for refueling.

How to remove the fan turbine?

There are several options for dismantling the “squirrel wheel” hidden under the heat exchanger.

First, spin the drum and see if there is a technical hole in it between the blades on the right side. There should be a fixing bolt behind it.

It is not necessary to unscrew it entirely, you can simply loosen it.

Mistake #20

This cannot always be done with a regular screwdriver.

The fact is that this bolt in some models (Samsung, Daewoo and the like) is additionally attached to glue!

To tear it off you will have to use a socket and ratchet.

Another option involves hiding this bolt under the protective casing of the engine, which, in fact, rotates the drum.

You will have to remove either the protective casing from the engine or the engine itself with the rotary fan.

Mistake #21

After unscrewing, do not forget to mark with a felt-tip pen the exact location of this bolt on the shaft.

If, during reassembly, you accidentally move the shaft to the right or left from its factory position, this will lead to the blades starting to touch the housing and additional noise will appear.

Also, extraneous noise occurs when re-seating the screws and engine mounting screws into place. The problem is solved by using rubber spacers or gluing electrical tape between the ears and the places where the screws are attached.

Mistake #22

And if the shaft is assembled incorrectly, the impeller may jam and the engine will burn out.

Lift the radiator up and pull the fan out from its seat, or remove the engine itself from the turbine.

On many models, the turbine shaft sits very tightly, so you have to apply considerable force to pull it out! When installed in the reverse order, on the contrary, it does not want to go all the way into its place.

In this case, try going over it with sandpaper.

Also, do not forget to lubricate the small bearings into which the shaft is inserted, as well as the shaft itself, with technical vaseline or silicone grease with fluoroplastic.

Precision (accurate) air conditioners - features and purpose

They appeared as a type of cabinets that belong to the so-called group. “heavyweights” in air conditioning and ventilation. These include industrial air conditioners; they are used in rooms where the most precise maintenance of temperature, humidity, etc. is required.

Precision air conditioners in a computer data center

Most often, precision air conditioners are used in computer and exhibition rooms and museums. Server air conditioners - in laboratories, hospitals and clinics, telephone exchanges and other premises with equipment that requires particularly accurate microclimate data.

The very name “precision” suggests that they can regulate and maintain precise indicators of the indoor environment within established limits. In particular, the precision of maintaining a specific air temperature for precision air conditioners is plus or minus 1°C. It is this feature that distinguishes such equipment from conventional air conditioners for household use.

Installation of precision air conditioners - only professionals can do it

If you install precision air conditioners in a room with a built-in air humidity regulator, then, in addition to maintaining the set temperature, such a device will maintain the set humidity at the required level, which is especially important, for example, in museums - for exhibition exhibits. As a rule, precision air conditioners are made to order and are not mass produced.

Since for each case it is necessary to take into account all the indicators of the specific microclimate in the premises - accurate data on humidity, temperature and other parameters. For example, you may need to connect a precision device to a so-called “chiller”, i.e. to external cooling machine

Typically, precision air conditioners are made to order and are not mass produced. Since for each case it is necessary to take into account all the indicators of the specific microclimate in the premises - accurate data on humidity, temperature and other parameters. For example, you may need to connect a precision device to a so-called “chiller”, i.e. to the external cooling machine.

Circuit diagram of a precision air conditioner with an air condenser

There are precision air conditioners with bottom and top air supply. The first type of design involves air intake through the front panel of the air conditioner. And also through air ducts or special openings in the suspended ceiling. Cooled air escapes through the floor grates.

Precision air conditioner - bottom air supply

And the second type of design takes in air using the bottom, front or rear panel. Cooled air exits through the ceiling with special openings or a duct system.

Precision air conditioner - top air supply

Precision air conditioners also differ in the type of cooling. There are water- and air-cooled equipment.

Most often you can see such climate control equipment with a remote air condenser. In other words, this air conditioner can be made of two blocks. The main unit consists of a compressor, evaporator, fan, humidifier and automation. And the small block contains a capacitor and a fan. Such climate control equipment is more widespread due to the large power range and fairly easy installation of precision air conditioners.

Composition of a precision instrument of the first type

In turn, precision devices with a water condenser are essentially a monoblock, have a simpler design and are slightly cheaper than air conditioners with remote air cooling. There is one drawback - the operation of precision air conditioners of this type requires a source of running water, and this is not always available in certain conditions.

Circuit diagram of a precision air conditioner with a water condenser

Condensate evaporator or dissipator for air conditioner - why is it needed, what are the advantages?

Contents

When the air conditioner operates, warm air is constantly blown through the cooled condenser. As a result, moisture settles on the cold surface, which gradually flows into the installed pan. And if the system is assembled correctly, then it should be removed from it into the domestic or storm sewer system.

However, this does not always work out. Very often it is quite difficult to organize normal removal of condensate. You can’t lay a gravity sewer through your apartment in secret. Therefore, you have to pull a pressure pipeline line and install a drainage pump, which obviously will not decorate the room.

Then, to simplify the work, installers simply punch a hole in the outer wall and lead the condensate pipe outside. As a result, water begins to drip onto the heads of passers-by, onto the façade finishing and blind area, destroying it, as well as onto ebb tides, creating noticeable noise.

Article on the topic: What is an anion generator in an air conditioner

It should be said that bill No. 4619 dated January 26, 2021 has already been submitted to the Verkhovna Rada, which states that:

- discharging condensate onto the facades of houses is an administrative violation and entails a heavy fine;

- condensate from air conditioners should be discharged only to specially equipped places;

- Specially equipped places include domestic and waste sewerage, as well as tanks.

As you can see, the problem of draining condensate drains from air conditioners is very acute.

The air conditioner works, but does not cool - this is often called the most common symptom

First of all, you need to make sure that the air conditioner is configured correctly and all operating conditions are met!!! To understand at this stage where to move next, you need to find out whether the compressor is working.

When working, it should “buzz” and vibrate a little:

- if the compressor works, then the reason is most likely a lack of refrigerant (freon). To make sure of this, you need to check the pressure (connect pressure gauges). In most cases, leakage occurs in the connections of copper pipes at the indoor and outdoor units. There are only 4 such connections that need to be checked and, if necessary, leaks repaired (poor-quality rolling or a cracked nut as in the photo). Often, oil remains in the “sore spot” and dust sticks to it. Read the signs of freon deficiency in a separate article.

- If the compressor does not start, then without special preparation it will not be possible to eliminate the problem. Because there can be many reasons. The main ones are: the compressor starting capacitor does not work;

- compressor power contacts are burnt out;

- temperature sensors are faulty;

- the compressor itself has failed;

- damage to the control board.

Water leaking from the air conditioner is an equally common situation.

The reason for this phenomenon often lies in a clogged drainage tray or drainage hose. It is necessary to disassemble the indoor unit and thoroughly clean the drainage system. To do this, you can read the detailed instructions on “how to clean an air conditioner.”

I have come across air conditioners with defects in the condensate collection system. Water periodically flows from the block due to imperfections in the design. I will not “fire” the models. In this case, it is difficult to find the cause. You have to disassemble the indoor unit and, during its operation, study how the condensate drains. And as luck would have it, it is precisely at these moments that the drainage system functions normally!

Cleaning the evaporator - preparatory stage

Cleaning is included in the list of services in every car service, and it’s not so difficult to do it at home. It will not take you much time and effort, but be patient, especially if you are doing this for the first time. To clean it yourself, you need a regular set of tools, as well as washing liquid for air conditioners, which can be bought at any auto store. You shouldn’t skimp on liquid and it’s better to buy anti-fungal liquid.

Before carrying out work, it is worth drying the evaporator a little from the moisture that has already accumulated on it . To do this, turn on the air conditioner to supply hot air, turn off the air supply from outside, turn on circular air circulation inside the cabin and open the windows in the car. The regulator must be set to the maximum air flow rate. This procedure should be performed within 10–20 minutes.

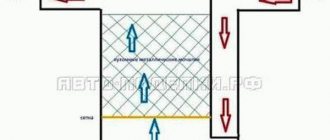

Cleaning is carried out both with and without removing the evaporator. We will consider the second case, since it is still not recommended to remove the evaporator yourself. In most cars, it is located near the heater fan, which in turn is located behind the glove compartment on the passenger side of the car. Using a screwdriver, carefully remove the glove compartment, then the sound insulation, and begin the cleaning process.

Article on the topic: Ford Transit at what temperature does the air conditioning turn on in winter

Operating principle

Let's consider how an air conditioner works, the operating principle of which is based on a change in the phase state of the medium, achieved by cooling the heat exchanger and then passing air from the street through it.

Diagram and principle of operation of the air conditioner

The air conditioning process includes several stages, among which experts distinguish:

- Supply of a working substance under low pressure of 3–5 bar in a gaseous state and having a temperature of +10 to +20 °C from the external unit through the filter to the compressor.

- Compression in a compressor, during which the freon pressure increases to 15–25 bar, which naturally leads to an increase in the temperature of the substance to +70–90 °C.

- The supply of refrigerant to a condenser cooled by air supplied by a fan, as a result of which, when interacting with the cooled surfaces of the heat exchanger, the working medium transitions to a liquid state.

- The passage of high pressure refrigerant through a copper tube made in the form of a spiral. After the thermostatic valve, the working substance has low pressure and temperature; this stage is necessary to lower the boiling point of the refrigerant, which, together with evaporation, is partially observed in the throttling device itself.

- The entry of freon, which has low pressure and temperature, into the evaporator-heat exchanger. In it, absorbing warm air from the room, the refrigerant passes from liquid form into the gaseous phase, simultaneously releasing cold air directed by the fan into the room.

The described cycle ends with freon in the form of a low-pressure gas being supplied to the compressor inlet and the process repeats.

Where do dirt and mold come from?

When heat is “sucked out” from the air, condensation appears on the surface of the evaporator, which is essentially an aluminum radiator. During an hour-long trip, up to 2-3 liters of liquid can form - it all depends on the air humidity. To prevent this liquid from dripping inside the cabin (the evaporator is located directly under the dashboard), it has a drainage tube through which water is discharged outside. This tube, as well as the evaporator cells themselves, are the first enemies of cleanliness. A wet evaporator attracts dust, like an aquafilter, and along with it bacteria and fungal spores. After turning off the car air conditioner, the temperature of the evaporator rises, creating an ideal humid and warm environment for the development of microorganisms. This is why most often this is where the spread of mold within the climate system begins.

Article on the topic: Is it possible to install air conditioning on a Logan

The second source of trouble is hidden inside the air ducts of the ventilation system, which is adjacent to the evaporator. It works in tandem with an air conditioner, and is also not closed - bacteria, viruses or dust can get inside it. They fall and settle on the walls, and when the air flow passes, they fly straight into the cabin. What about the cabin filter? When replaced in a timely manner, it only catches the largest contaminants, but if you do not change the filter on time, it itself can become a source of mold or pathogenic microorganisms. Thus, cleaning only the car air conditioner is half the battle; the air ducts themselves should also be kept clean.

- Dirty split system filters

- Air conditioner drain pump problems

- Problems with the air conditioner drainage system

- Freon (refrigerant) leaks in air conditioners

- Damage to the freon line of the air conditioner

- Dirty heat exchanger of the external unit of the split system (condenser)

- Dirty heat exchanger of the split system indoor unit (evaporator)

- Dirty fan of the split system indoor unit (turbine)

- Malfunctions of switching and air conditioner control board

- Cleaning of duct air conditioners

- Cleaning window air conditioners

- Cleaning cassette air conditioners

Other articles

Clogged heat exchanger of the indoor unit (evaporator).

The evaporator is one of the most important parts of an air conditioner. It is in it that the refrigerant boils, as a result of which the coil and aluminum plates (fins) of the radiator and, accordingly, the air passing through it are cooled. Obviously, for better heat transfer, these plates must be in direct contact with passing air, and any contamination of these plates significantly impairs this contact and, consequently, heat transfer.

Article on the topic: Who is the car air conditioner?

Unlike filters, cleaning the evaporator radiator is not as easy or convenient. Actually, filters are designed primarily to protect the evaporator from contamination. However, no matter how well designed filters are, they cannot capture all contaminants . For example, they cannot completely block tobacco smoke (which contains very sticky tars) or kitchen fumes containing microscopic particles of fat, acids, etc. (this is why it is not recommended to install split systems in kitchens, at least not equipped with hoods). Resins, grease and sticky moisture that settle on the evaporator fins act as a kind of adhesive for dust. As a result, the evaporator can literally become covered with a crust of dirt, completely preventing air from passing through the radiator.

To clean a slightly dirty evaporator, it is enough to simply remove dust from its plates, but for more complex situations the solutions are more complicated. You can use a steam cleaner or vacuum cleaner, but sometimes there is no other option but to completely disassemble the indoor unit to thoroughly clean the heat exchanger and fan. The need for cleaning should never be neglected and, of course, it should only be performed by a specialist. Completely dismantling the indoor unit, cleaning the heat exchanger and everything else, and then reassembling everything and starting the air conditioner again is definitely not for amateurs.

VIDEO. “Extended” cleaning of the indoor unit

It’s not very clear what exactly is so “extended” about this purge. This is the most minimal preventative option. The argument “we don’t remove the pallet, otherwise it will be awkward to put back in place”) is interesting. They also promised to remove the turbine, but they didn’t. So what is this “advanced” cleanse compared to? Compared to “just wash the filters”?

Article on the topic: How to turn on the haier air conditioner

Signs of heavy pollution

The air conditioner, as a rule, itself “tells” the owner about the need for preventive maintenance. The main signs of pollution include:

- The appearance of a leak from the internal module;

- Unpleasant odor that occurs after switching on (this was mentioned above);

- Increased noise, crackling or unstable sound;

- Poor cooling quality, spontaneous temperature changes.

Any of the listed symptoms is enough to begin inspecting the device and cleaning its elements. If you neglect the need to perform preventive maintenance, the risk of failure of certain parts and the inability to use the equipment increases. In such a situation, you cannot do without calling specialists and additional costs.

Practice shows that many issues related to air conditioner maintenance can be resolved at home. In this case, no special tool is needed.

In addition, useful information on servicing a particular model is provided in the instructions. It shows a diagram for removing the indoor unit, as well as basic cleaning principles.

Ways to prevent unpleasant odors

To minimize costly and time-consuming cleaning of the air conditioning system, it is enough to follow simple recommendations. Firstly, change the cabin filter more often - it is this that acts as a barrier to dust and dirt suspended in the air.

Secondly, try to dry the interior and cooling system more often, not by turning on the heater, but in a natural way. This can be achieved by turning off the air conditioner 5 - 7 minutes before turning off the fan - during this time it will have time to thoroughly dry the air conditioning system before the car stops. If you adapt to perform a similar operation after each trip, the accumulation of condensate in the evaporator can be minimized and thereby significantly delay the appearance of persistent unpleasant odors.

Types of precision air conditioners

Depending on the functional equipment and various combinations of technological units, the market range of equipment of the type in question is divided into different types.

Modifications by type and quantity of coolers

The cooler is the main structural element of a vapor compression unit. Depending on the design and number of coolers, the following models are available for sale:

- with 1 direct evaporation cooler - such systems consist of a direct cooling unit (evaporator) and a remote air cooling unit (condenser);

- with a liquid air cooler, where the source of cold is a chiller (coolant refrigeration machine) - liquids can be used in the equipment: water, ethylene glycol, propylene glycol;

- combined designs with direct cooling freon circuit and liquid cooler.

Classification by air flow direction

In different design solutions, the air flow may differ in the direction of discharge. On this basis, air conditioners are divided into:

- supplying flow upward - Up;

- with air supply down – Down;

- with front feed – Front;

- direct supply inside the refrigerated cabinet - InRow.

Modifications on site

Manufacturers produce equipment in several versions, which can be divided according to installation features.

- Ceiling and wall mounting systems designed for small equipment and server rooms. The power of such models is up to 15 kW. Devices from the Emerson and Midea brands are in demand in this category.

- Cabinet-type equipment with 1 and 2 doors. Such systems are characterized by greater productivity and power - up to 100 kW, therefore they are used in large rooms. The best representatives are considered to be models from brands such as Daikin, Climaveneta, Hiref, Dantex.

- The monoblock version with a power of up to 20 kW is in demand for laboratories and medium-sized production facilities. Examples of brands are Uniflair and Stulz.

How does an inverter air conditioner work?

The peculiarity of this unit is continuous operation, but not at the limit of capabilities, as in a conventional air conditioner.

The inverter saves energy and extends the life of the compressor, since it operates smoothly rather than jerkily. Smooth operation is ensured by no need to turn off the device to save energy. An inverter model will be more economical than any other device if it works for at least several hours without turning off. The inverter model has two blocks - external and internal. The external one contains a compressor, a freon system, a fan and a condenser. The indoor unit consists of an evaporator, a fan, blinds, a filter and a special tray for the condensate formed.

Ship evaporators, device, principle of operation

An evaporator is a heat exchange device in which water evaporates. The design and principle of operation of ship evaporators are varied and several criteria are used to classify them.

According to the principle of operation - surface evaporators and with a surface-free evaporation chamber or adiabatic. The heating elements are located inside in surface evaporators and are made external in non-surface evaporators.

The nature of evaporation is boiling, film and non-boiling. In film evaporators, the evaporated water is applied in a very thin film to heating surfaces, is heated and evaporates. Non-boiling evaporators include so-called air evaporators. They have heating and condensing sections inside.

The evaporated water constantly irrigates the heating elements using a circulation pump. During the heating process, part of the water evaporates without boiling. Air is constantly circulated in the evaporator using a fan. The air is also heated and, due to an increase in its moisture saturation, absorbs water vapor when heated. In the condensation section, the air cools, its moisture-saturating ability decreases, it becomes supersaturated and gives off excess moisture. This process is reminiscent of dew falling in nature.

According to the location of the heating elements - with internal and external submerged heating elements.

By location - horizontal and vertical. A vertical boiling evaporator with internal immersed heating elements is shown in Fig. 124.

The evaporator body is welded cylindrical, made of steel and attached with foundation feet. A pipe and a cap with a filter are welded to the bottom of the housing to blow through the brine and drain the evaporator. The heating battery is made of copper tubular coils and is equipped with brackets with rollers that serve to roll out the battery when disassembling the evaporator.

Above the heating battery there are large diameter pipes for supplying cold water to the evaporator during showering. “Cold shower” is used to remove scale from the surface of heating elements. When showering, the evaporator is dried and high-pressure steam is passed through the heating elements. The tubes, along with the scale, heat up and expand. Then the steam supply stops and cold sea water is supplied to the tubes from above. As a result of cooling, the tubes shrink faster than the scale, which cracks and falls off. A greater effect is achieved by showering the evaporator by supplying cold fresh water into the heated heating elements.

A “cold shower” is performed periodically once a day or after a longer continuous period of operation of the evaporator. After several “showers”, mechanical or chemical cleaning of the heating elements from residual scale is carried out. Mechanical cleaning is accompanied by disassembling the heating battery and moving it out of the evaporator.

The resulting steam in the evaporator always carries with it particles of brine, which determines its salinity. To reduce steam humidity, the evaporator is equipped with two mechanical separators. The lower separator is of a centrifugal type; the separated moisture is removed from it through a drain pipe into the water volume of the evaporator. The upper separator is stuffed with Raschig rings. The use of separators helps to reduce the height of the vapor space of the evaporator by organizing artificial separation of moisture from steam. The steam intake pipe at the top of the evaporator serves to remove steam from it.

Rating 0.00 (0 Votes)

Questions and answers

Is it possible to use a chiller to cool liquid per flow by more than 5 degrees?

Answer:

The chiller can be used in a closed system and maintain a set water temperature, for example, 10 degrees, even if the return temperature is 40 degrees.

There are chillers that cool water through flow. It is mainly used for cooling and carbonating drinks, lemonades.

Question:

What is better: chiller or dry cooler?

Answer:

The coolant temperature when using a dry cooler depends on the ambient temperature. If, for example, it is +30 outside, then the coolant will be at a temperature of +35...+40C. Drycoolers are used mainly in the cold season to save energy. The chiller can achieve the desired temperature at any time of the year. It is possible to manufacture low-temperature chillers to obtain liquid temperatures with negative temperatures down to minus 70 C (the coolant at this temperature is mainly alcohol).

Question:

Which chiller is better - with a water or air condenser?

Answer:

The water-cooled chiller is compact in size, so it can be placed indoors and does not generate heat. But cold water is required to cool the condenser.

A chiller with a water condenser has a lower cost, but may additionally require a dry cooling tower if there is no water source - piped water or a well.

Question:

What is the difference between chillers with and without a heat pump?

Answer:

A chiller with a heat pump can operate for heating, that is, not only cool the coolant, but also heat it. It must be taken into account that as the temperature decreases, heating worsens. Heating is most effective when the temperature drops at least minus 5.

Question:

How far can an air condenser be moved?

Answer:

Typically the capacitor can be carried up to a distance of 15 meters. When installing an oil separation system, the height of the condenser is possible up to 50 meters, provided that the diameter of the copper lines between the chiller and the remote condenser is correctly selected.

Question:

To what minimum temperature does the chiller operate?

Answer:

When installing a winter start-up system, the chiller can operate up to an ambient temperature of minus 30...-40. And when installing arctic fans - down to minus 55.

Replacing the filter

After the dryer, sight glasses are installed to help monitor the condition of the refrigerant inside the cooling system. Tracked by indication color:

- yellow color – excess moisture content;

- green color – the percentage of content is normal.

The presence of bubbles determines:

- the pressure level on the filter is low;

- the refrigerant is not supercooled;

- insufficient amount of freon in the circuit.

Replacement criteria:

- Sight glass indicator color – yellow;

- presence of bubbles in the sight glass;

- replacement of thermostatic valve, compressor;

- after each opening of the cooling system.

In many cases, a filter drier for an air conditioner seems to be a necessary mechanism that can prevent common breakdowns and malfunctions. Its installation will allow you to save on expensive repairs and replacement of split system elements.

Basic air conditioner malfunctions and their symptoms

- Refrigerant leak. Freon is characterized by high volatility, and therefore gradually disappears from the system at the slightest leak. Even on a sealed system, the air conditioner needs to be recharged every 3-5 years. Most often, a leak occurs when the condenser honeycomb is damaged, due to the natural loss of elasticity of rubber seals (rings on tubes, hose crimps, compressor shaft seal).

- Broken condenser clutch. The normal resistance of a working winding is 4-6 Ohms.

- Faulty wiring, air conditioning relay. The most common occurrence is a banal fuse blown and the formation of oxides on the contacts.

- Condenser clogged. The main sign of a malfunction is low compressor performance, increased pressure in the high-pressure circuit.

- Malfunction of the high/low pressure switch in the system. All modern systems use a combined pressure sensor. Thanks to the PWM signal, the control unit constantly monitors the actual pressure in the system.

- Evaporator clogged. Through a clogged evaporator, less air enters the cabin. Naturally, the air conditioner will not blow cold from the deflectors.

- Sticking thermostatic valve.

- Compressor failure. This happens due to natural wear or operation without oil.

Often the compressor does not turn on after a long period of inactivity. Therefore, if you are wondering whether it is possible to turn on the air conditioner in your car in winter, the answer is definitely yes. Periodic activation allows the oil to disperse throughout the system and lubricate the compressor elements. It is a well-known fact that air conditioning dries the air, and therefore helps prevent windows from fogging up in winter.

Noise in the cabin when the air conditioning is turned on

If you take into account the fact that of the entire air conditioning system, only its evaporator is located in the cabin, then there are very few reasons for noise.

1. The evaporator is leaking and we have refrigerant leaving the system with a characteristic hissing sound. To be honest, this is a very rare case, since the evaporator does not experience any physical impact. Stones don't fly into it like they do into a condenser. Therefore, by itself it almost never fails.

Note. In simple language, a condenser is a radiator that stands in front of the radiator of the engine cooling system in the engine compartment. And the evaporator is a radiator that is installed in the car interior after the cabin filter.

But still, cases of loss of tightness by the evaporator occur. Especially when the car owner ignores the installation of the cabin filter or due to mechanical damage to the evaporator, for example, when replacing the cabin filter or other work performed in the area near the evaporator.

But this reason is characterized by the following features:

- in this case, all the refrigerant will very quickly leave the system and the air conditioner will stop turning on in the very near future

- You can smell it in the cabin

If your air conditioner has been turning on and hissing for several days and there is no smell, then this is not your case.

Operating principle of a car air conditioner

To understand the principle of operation of a car air conditioner, consider the order of changes in the state of aggregation of the refrigerant.

- Freon from the low pressure circuit in a gaseous state is sucked in by the compressor.

- Inside the compressor, the refrigerant is compressed, as a result of which its temperature rises - the gas passes into the liquid phase.

- The freon, heated by compression, is sent through a high-pressure circuit to the condenser. The purpose of the condenser is to dissipate excess heat from the refrigerant. Cooling the compressed freon prevents the formation of excess pressure.

- The cooled freon in the liquid phase is sent to the dryer. After passing through a reservoir with a moisture-absorbing filler (silica gel), moisture is removed from the freon. The dryer also contains a filter element that captures compressor wear products (chips, Teflon) and other debris circulating in the line.

- Purified freon under high pressure and high temperature is supplied to a throttle or expansion valve (depending on the type of design).

- Passing through the throttle/expansion valve, the gas enters the evaporator. Due to a sharp decrease in pressure in the system, the gas returns to a state of thermodynamic equilibrium and evaporates. In other words, after forced compression and a resulting increase in temperature, we allowed it to evaporate. Since the boiling point of freon R134a is -26.5°C, during evaporation the gas actively absorbs heat upon contact with the walls of the evaporator.

- The air forced by the heater fan passes through the cooled evaporator.

From the description of the operating principle it is clear: all types of car air conditioners do not generate cold, but only absorb the heat of the air flow from the stove fan.

Processes in the external block of a split system

The external unit of the air conditioner is constantly blown with outside air. As a result, soot, dust, insects, leaves, seeds and poplar fluff form a dense coating on all parts of the outdoor unit of any air conditioner. Over time, this layer becomes thicker and denser, which prevents the normal removal of excess heat from the condenser.

This situation leads to overheating of the compressor, an emergency situation and triggering of the automatic protection. The capabilities of any device are not limitless - sooner or later the compressor will fail. Replacing a compressor is a technically complex and expensive procedure; the price is sometimes comparable to half the cost of a new air conditioner.

Advantages and disadvantages of precision air conditioners

Precision air conditioners belong to the category of high-precision equipment, or rather, reliable and durable devices with high power. The purchase of such a unit will definitely solve the problem of controlling the temperature in the room.

Advantages of precision devices:

- Ability to maintain a precise temperature threshold. In average air conditioners of this type, the change step is 0.5 degrees.

- Humidity control within 3%. Exclusively for devices with a built-in humidifier.

- Capable of uninterrupted operation without the need for a shutdown or any reboot.

- Many models have an additional backup unit, which begins to function after the main one is turned off.

Modern server room and a range of precision devices

These devices also have their disadvantages, which include:

- The pricing policy is too high. Precision air conditioners are difficult to manufacture and require a lot of components and appropriate assembly and configuration specialists. Therefore, each device has a high cost.

- Difficult installation. To connect precision devices, you should call specialists who will not only deliver the air conditioner and install it, but also set up its operation.

- They have large dimensions. Which implies appropriate transportation and delivery to the installation site.

- Not designed for household use. Relevance for use only as a source of cooling for technical or process rooms.

How to disassemble an air conditioning compressor

Dismantling the compressor on different brands of cars takes place in a different order. But when the part is already on the workbench, do the bulkhead according to this scheme:

- Clean the assembly from dirt.

- Disconnect the electrical coupling wires.

- After unscrewing the central nut, remove the drive pulley (you need a special holding key).

- Remove the clutch disc (use a universal puller).

- Remove the snap ring holding the pulley bearing.

- Use a three-fingered puller to pull the pulley and bearing off the compressor.

- Remove the retaining ring that holds the clutch solenoid in place.

- Remove the solenoid.

- In front of you is the compressor itself. Unscrew the bolts of the front cover - it will come away from the body.

- Remove the cover with the shaft, remove the support bearing and its lower race.

- Remove the piston group, support bearing and seat.

- Remove the spring and key.

- Turn the part over and unscrew the fasteners of the compressor rear cover.

- Throw away the gasket you find: it will need to be replaced.

- Remove the valve disc and the seal underneath.

How to disassemble an air conditioning compressor

Now you just have to disassemble the cover with the shaft. Pull out in order: dustproof and retaining rings, key, shaft with bearing

Now it is important not to lose details

Cleaning the indoor unit of the air conditioner

When understanding the principle of operation, special attention is paid to the module located indoors. Removing dust and dirt from the split system will improve the air in the room and remove unpleasant odors and noise. They start by studying the design features of the equipment

They start by studying the design features of the equipment.

Indoor unit design

The module includes main and auxiliary units and parts:

- front panel in the form of a plastic case with a grille with latches;

- coarse and fine filter – polymer fine mesh;

- a part containing activated carbon to eliminate unpleasant odors (it is not cleaned, but replaced once every 4 months);

- zeolite mineral layer for collecting chemical compounds;

- filters: electrostatic, plasma, ultraviolet, photocatalytic, antibacterial, antioxidant - washed when dirty;

- fan with 3-4 rotation speeds;

- evaporator;

- vertical and horizontal blinds for directing air flows;

- indicator panel for setting operating parameters;

- moisture collection tray;

- drainage hose – drains liquid;

- electronic control board – located to the right of the indoor unit and equipped with a terminal group;

- fitting connections are located at the bottom at the rear.

Cleaning Tools and Materials

When figuring out how to clean an air conditioner at home with your own hands, you need to prepare:

- vacuum cleaner;

- water container;

- warm water;

- dishwashing soap without fragrances or softeners;

- rags

- an old toothbrush and a brush with soft bristles;

- Phillips screwdriver;

- wire up to 50 cm long.

The master will need a film to protect the wall and floor, a solid base and a table for laying out the elements.

Disassembling the indoor unit

Before washing the air conditioner in the apartment, it must be disconnected from the power supply, then:

Press on the plastic clips

They are located on the side walls. Remove the plastic casing. Take out the filter meshes. Unscrew the screws securing the housing, remove the element by pulling it slightly up

Carefully tie the body to the inside of the module with wire or rope. This makes it more convenient to work without breaking the wires and cables that are connected to the display

Disassembly is complete, you can start washing.

Cleaning air conditioner filters

Sequence of work:

- open the cover on the front of the split system;

- remove mesh structures - there can be many of them;

- dilute warm water with soap in a basin;

- put the modules in a container, give time for dust and dirt to soak;

- after half an hour, inspect the parts, if there is any debris left, wash them with a toothbrush;

- Rinse the elements with running water, then wipe with a dry cloth.

After this, the parts are left for 1-1.5 hours for additional drying and upon completion of work they are installed in place. Knowing how to clean air conditioner filters at home, it will not be difficult for a technician to cope with the task.

Cleaning the internal fan

The device looks like a cylindrical shaft equipped with blades to move air flows. A thick coating of dust and dirt slows down the speed of the rotor module and can completely block the operation of the unit.

To remove layers, dissolve a little soap in water, then carefully spray the liquid onto the blades. As soon as the deposits are loosened, turn on the lowest power

After 2 minutes, turn off and clean off the remaining dirt with your hands using a brush, brush and soap composition

The process is carried out carefully so as not to damage the integrity of the blades - one crack is enough for a complete replacement

Cleaning the air conditioner radiator

The procedure is performed with special care - there is a high risk of plate breakage.

How to properly clean the air conditioner radiator at home, stages of work:

Remove the nozzle from the vacuum cleaner and process the module. The pipe must not touch the plates. Clean the elements with a soft long-bristled paint brush. To eliminate microbes, experts recommend cleaning all surfaces with chlorhexidine. Do not dilute the pharmaceutical product, dip the brush and remove dirt from the plates. Fat layers and plugs are washed with hydrogen peroxide and a concentrated soap composition.

Scale that is too thick is removed with a thin knife; the layers are removed carefully so as not to damage the modules. After removing carbon deposits, rinse the part with clean water and wipe dry.

Cleaning your car air conditioner at home

Cleaning the air conditioner involves disinfecting it with special means. It is worth dwelling in more detail on how to use them and what processing methods exist.

Types and sequence of system cleaning

The car air conditioner can be cleaned in one of the following ways:

In the first case, aerosols and foam are used. It is worth considering that with aerosol products you can only disinfect the air conditioning system, but with foam you can also clean it. The mechanical method is resorted to if chemical agents do not give the desired result and an unpleasant odor remains in the cabin. The procedure is difficult because you have to remove the evaporator in the heater block. For chemical treatment of the device in question, you can use products from the following manufacturers:

Chemical method

After choosing a foam or aerosol, you can begin cleaning the air conditioner. Basically, all products are equipped with a tube. Aerosol treatment is performed as follows:

If you have to use foam products, the process consists of the following steps:

Video: cleaning a car air conditioner with foam

Available means

Depending on the disinfectant chosen, you will have to pay about 150–1000 rubles. per can. Inexpensive cleaners can not only be ineffective, but also fill the interior with a not very pleasant odor that is difficult to remove. However, for effective antibacterial treatment it is not necessary to buy expensive products: you can also use improvised ones. To help deal with the nasty smell in the cabin:

The essence of the treatment is to prepare a working solution from a powdered substance, for example, Chloramine B, which is diluted with water (1 tablespoon per 1 liter of water).

The resulting liquid is poured into a suitable container with a sprayer. During treatment with the listed means, all doors in the car should be open. The disinfection process is similar to using foam.

If the above methods fail to remove the unpleasant odor from the interior, the air conditioner must be cleaned mechanically.

Video: a budget way to clean your car air conditioner

Mechanical method

When performing mechanical antibacterial treatment of the air conditioning unit, tools will be required to dismantle the dashboard. It will also not be superfluous to replace freon, seals and pipes. The cleaning process is performed in the following sequence:

Despite the complexity of the process, the mechanical method is more effective.

Replacing the cabin filter

The main purpose of the cabin filter is to clean the air entering the vehicle. The correct operation of the heater, air conditioner, and ventilation system directly depends on the condition of this element. The need to replace the filter occurs when the windows fog up, an unpleasant odor appears, and the performance of the stove and air conditioner deteriorates.

It is recommended to change the filter element every 10–25 thousand km. mileage, depending on the operating conditions of the vehicle.

Most often, the filter is located near the evaporator. The element in question is made from corrugated paper with cellulose or synthetic fibers, often impregnated with carbon and shaped like a rectangle. To replace the cabin filter on a specific car, you need to read the owner's manual. The process itself consists of dismantling the used product and replacing it with a new one.

Video: replacing the cabin filter using the example of Toyota Corolla

Cleaning air conditioning system elements

The cabin climate system includes such basic elements as an evaporator, a radiator, a cabin filter and air ducts. Let's look at cleaning each of them.

Cleaning the radiator and air ducts

First of all, the air ducts and radiator of the system in question are cleaned, removing dust and dirt from them. To do this, an air compressor is used to supply compressed air to the system elements. The procedure consists of two stages:

After completing the described steps, you can begin to disinfect the evaporator of the car air conditioner.

Video: cleaning the air conditioner radiator on a Mazda 3

Cleaning the evaporator

A large number of different bacteria settle on the evaporator, causing an unpleasant odor. Therefore, by cleaning a car air conditioner, many mean the evaporator, the treatment of which was discussed above.

Cleaning

Cleaning of the evaporative heat exchanger along with other elements of the indoor unit of the split system is carried out twice a year - in spring and autumn. Cleaning air filters depends on the condition of the air inside the apartment. If it is too dirty, there are pets, dust particles, animal hair will clog the filtration system faster. It is carried out once every 1-3 months.

Signs of a clogged heat exchanger:

- the cooling properties of the air conditioner have deteriorated;

- energy consumption increased while production capacity decreased;

- unpleasant smell when turning on the climate control device.

In addition to the evaporator, the fan mechanisms and drainage system must be cleaned. The internal space of the module, on the surface of which mold, mildew, etc. can also form. You can clean the internal mechanisms of the air conditioner yourself, or call the appropriate specialists.

The air conditioner evaporator is cleaned with special antibacterial and disinfectants. Use must be in accordance with the instructions on the manufacturer's label. I produce the products in the form of an aerosol and foam.

They contain surfactants that have good cleaning ability. Also, depending on the scope of use, metal, etc., they may include acidic, alkaline additives, and biologically active components.

Service prices

Air conditioner repair and maintenance services charge a lot of money for their work. To provide guidance on this issue, average prices in Moscow for several services were analyzed:

| Type of service | Minimum price (in rubles) |

| Cleaning the drainage system | 500 |

| Dry cleaning of the outdoor unit condenser | 1300 |

| Cleaning the fan blades of the indoor unit | 1400 |

| Cleaning the evaporator of the indoor unit with an antibacterial composition | 1500 |

| Cleaning the outdoor unit condenser using a washing machine | 3000 |

The evaporator is an important part in the operation of the air conditioner, so timely maintenance will allow it to function for many years without breakdowns.

Cleaning scheme

Typically, cleaning an evaporative heat exchanger is not particularly difficult. You need to do the following:

- disconnect the unit from the power supply;

- open the front panel;

- remove air filters;

- Rinse the coarse filter under cold running water (hot water can deform it), leave to dry;

- Apply an antibacterial cleaning agent to the heat exchanger, strictly following the manufacturer’s instructions;

- if necessary, rinse off the product with water;

- turn on the ventilation mode to dry the heat exchanger elements;

- install all elements in reverse order;

- insert air filters (be sure to be completely dry);

- close the front panel;

- connect to the power supply and start the system.

Antibacterial agents effectively cope with mild to moderate contamination. If the evaporator is very dirty, these products will help little. Moreover, the volume is designed for use 1-2 times. This neglected condition can best be corrected by specialists. Further maintenance can be carried out independently, provided that it is carried out in a timely manner.

In addition to store-bought products, you can clean the air conditioner evaporator with chlorhexidine. This is an antiseptic solution that is used in medicine. It copes well with disinfection and inhibits further proliferation of bacteria, fungi, and other microorganisms. The cost is much lower than special antibacterial agents.

An evaporative heat exchanger is designed to cool the air that is forced through it by a fan. In this case, the room air flow transfers heat to freon gas through the heat exchange surface

It is important to monitor the correct functioning of this mechanism, because the cooling properties of the air conditioner depend on it. Timely cleaning and periodic preventative maintenance will extend the service life of not only the evaporator, but also the entire cooling system as a whole.

How to clean the air conditioner in a car yourself at home

Cleaning the car air conditioner yourself video

To clean a car air conditioner, in principle, it is not necessary to buy expensive special products. There are two alternatives using medications. However, both of them allow only disinfection. Therefore, if you want to get rid of the problem for a long time, it is better to purchase products that will allow you to clean the evaporator from dirt.

How to clean an air conditioner evaporator with Lysol

In addition to using products specially designed for cleaning the air conditioner, many car enthusiasts (and not only them) use a product called “Lysol” for these purposes. It is also a “Cresol” solution based on soap and oil. The active ingredient is phenol.

It is used for professional disinfection (they produce disinfectants for hospital operating rooms, surgical instruments, air conditioners). Also often used in restaurants to remove unpleasant odors from grills. Therefore, there is no need to doubt its effectiveness.

For subsequent antibacterial cleaning of the car air conditioner evaporator, it is necessary to obtain Lysol in concentrated or diluted form. This thing is quite expensive, so it is advisable to use medical solutions. They even come with flavors. Kon is diluted in a ratio of 1:100, and surgical - 1:20. To work, you will need approximately 300...400 grams of the finished solution. Next, the procedure will be performed according to the following algorithm:

In most cases, such cleaning is enough to reliably get rid of the unpleasant odor from the air conditioner. In extreme cases, you can repeat the procedure again in about a day. Ideally, in addition to the described algorithm, it is also advisable to dismantle the interior elements in order to get to the evaporator and apply the Lysol solution directly to it.

Cleaning the air conditioner with chlorhexidine

Chlorhexidine has the same properties as Lysol described above. This drug is also used for disinfection in medical institutions. To clean your car air conditioner with chlorhexidine, you can buy a ready-made 0.05% solution of this product at the pharmacy. To increase its effectiveness, dilute with alcohol 1:1.

Cleaning the air conditioner with chlorhexidine is carried out according to the algorithm described above (sprayed from a sprayer onto the evaporator while the system is running). Please note that it is best to perform treatment with chlorhexidine at an ambient temperature of more than +20°C.

Instead of chlorhexidine solution, you can use other similar products, for example, Lysomorphine 3000. This is a Russian-made drug. Used for disinfection for medical purposes, including especially dangerous infections. To obtain a ready-made solution for cleaning the air conditioner, you need to dilute 50 ml of the product in one liter of water.

Another remedy is Chloramine B. Sold in the form of a white powder. To obtain the finished solution, you need to dilute one tablespoon of powder in one liter of water. Use according to the above algorithm. The main thing is to apply the product to the evaporator!