Let's start with the fact that the function of coolant in internal combustion engines is performed by special compounds known among motorists as TOSOL or antifreeze. The use of distilled water in cooling systems has long been abandoned, since water freezes at subzero temperatures, causes increased corrosion of channels in the cylinder block and cylinder head, causes scale formation, etc.

Today, various antifreezes or antifreezes can be available in two versions:

- in the form of a concentrate, which must be further diluted with distilled water in specified proportions;

- a ready-to-use product that can be immediately poured into the cooling system without additional manipulation;

In any case, engine coolant not only protects the engine from overheating and does not freeze in winter (unlike water), but also prevents the start of active corrosion processes in the liquid cooling system of the internal combustion engine, keeps the channels clean, and extends the service life of individual elements (pump, thermostat , radiator, etc.)

It is important to take into account that antifreezes vary in composition, and also lose and change their properties during operation. This means that they cannot be mixed freely. Also, the liquid has a strictly limited service life, that is, it is necessary to periodically replace antifreeze or antifreeze, as well as regularly monitor the condition of the coolant.

What is antifreeze and what is it for?

Antifreeze (from the Greek “anti” (against) and the English “freeze”) is a common name for all automotive fluids that do not freeze at low temperatures. Such fluids are used to cool engines operating at low temperatures, as anti-icing fluids in aviation, and as glass cleaners. It is based on water with the addition of glycerin, monohydric alcohols, ethylene glycol or propylene glycol and other additives.

Antifreeze

Antifreeze not only has a significantly lower freezing point compared to water, but also a lower coefficient of expansion. Water turns into a solid state with a volume expansion of up to 9%, and antifreeze with different ratios of ethylene glycol expands by 1.5%-3.5%, which is practically safe for engine elements.

General information

Coolants are liquid media that perform the function of heat transfer in engine cooling systems and other units, mechanisms and devices.

The first cooling liquids were ordinary water taken from open bodies of water - ponds, lakes, streams and even roadside puddles.

Water is characterized by high heat capacity and high fluidity, so its use is quite effective.

However, water has some properties that make it impossible to use in modern machines:

- High freezing point. Already at 0 °C, water begins to turn into ice, which cannot circulate through the system. In addition, expanding in a closed volume, it can easily rupture and disable any system

- Low boiling point. This parameter also does not make it possible to use water in modern systems, where the medium temperature reaches +105-110 °C

- Water promotes the formation of corrosion spots on the walls of the system

- Untreated water from open reservoirs is a source of formation of solid deposits - scale. At the same time, the efficiency of the cooling or heating system drops sharply

Modern coolants serve not only for cooling, heating and heat transfer, but also perform a number of other important functions.

They lubricate the system, protect it from the formation and development of scale deposits and corrosion, prevent the system from “freezing” at subzero temperatures, etc.

Coolant composition

The first antifreezes were based on methyl or ethyl alcohol. This mixture boiled already at 82°C, the alcohol vapor evaporated and ignited. Later, glycerin-based antifreezes appeared with better performance properties, but too high a viscosity. To improve fluidity, ethyl or methyl alcohols were added. Antifreezes based on hydrochloric acid also did not have the proper properties.

Composition of coolant concentrate

Modern antifreezes are made on the basis of ethylene glycol or propylene glycol and a package of additives that give the liquid anti-corrosion, anti-foam and fluorescent properties. Ethylene glycol is a dihydric alcohol, odorless, colorless, sweetish in taste, but very poisonous. Due to its sweet taste, there have been cases of poisoning of children with the liquid, so some countries have required manufacturers to add additives that make it bitter.

Propylene glycol is also a colorless liquid that tastes sweet, but is safe for the body if ingested. It has a low density compared to ethylene glycol.

Non-compliance with the stated characteristics

In some cases, antifreeze can let the car owner down, failing to cope with its responsibilities. In this case, operating conditions may comply with the instructions. Why is this happening? There are at least two reasons for this:

- The product may be of poor quality or even counterfeit. In this situation, it will probably be possible to find substances in the composition that reduce the quality of the glycol base, as well as cheap analogues of additives. Such a concentrate can seriously damage the cooling system.

- The possibility of a vehicle malfunction should not be ruled out. Breaks in sealed connections often lead to microparticles getting into the antifreeze, which negatively affect its properties.

What is the difference between Antifreeze

You can often hear different names for coolants: antifreeze, antifreeze, or simply “antifreeze.” Antifreeze is an ethylene glycol-based coolant developed during Soviet times. Among drivers from the countries of the former Soviet Union, this name has long become a household name. There are two brands of Antifreeze - 40 and 65. These numbers show the freezing point of the liquid. They differ in color: red or blue.

It is worth saying that the dye in the coolant (hereinafter referred to as coolant) is added specifically to see the level in the filler tank, as well as to detect the location of the leak. Ethylene glycol itself is colorless.

Organic or inorganic, what's the difference?

Mineral inhibitors simply coat the metal walls of the system with a thin layer of protective film. It may be uneven, and corrosion still appears, although it is spotty.

This “chemistry” works effectively; the aggressive effects of antifreeze are practically reduced to nothing. However, the film conducts heat poorly; as a result, it is not removed by the liquid from the heating zone. Over time, heat transfer becomes worse and the engine overheats, and this is fraught with increased wear of parts, earlier oil changes, and increased fuel consumption.

The chemical composition of such inhibitors: nitrates, borates, silicates, phosphates, amino acids.

Organic inhibitors are based on salts of carboxylic acids. Carboxylates do not “stick” to the metal, so there are no obstacles to heat transfer. The molecules of these substances block only pinpoint corrosion. They act as if targeted, leaving most of the area free from film.

Inhibitors are based on carbonates – organic acids that are neutral to metals. The cost is significantly higher than that of mineral water.

Hybrid additives contain carboxylates (usually more of them) and mineral additives. By using the right combination, coolant manufacturers compensate for the disadvantages of different types of additives without reducing the positive effect.

And finally, the answer to the main question: what is the difference between antifreeze or antifreeze? In fact, the name does not convey information about the composition or compatibility with different types of engine. The argument that antifreeze is poured into carburetor engines, and the injector runs exclusively on antifreeze, is groundless.

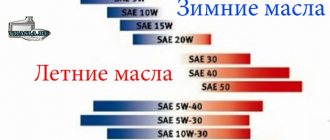

Properties and characteristics

The properties of antifreeze and its freezing point will depend on the ratio of water and ethylene glycol, as well as the set of additives. Pure ethylene glycol begins to crystallize already at a temperature of -12.3°C. A mixture with water forms a eutetics with a maximum freezing point of -75°C (75% ethylene glycol and 25% water). Most antifreezes have a percentage of 35% to 50% water, with temperatures of 65°C and 40°C respectively. The boiling point of such a mixture also rises to 110°C, and under pressure it is even higher.

It cannot be said that there is a single standard for all antifreezes. They are different in every country. Here is a list of the most famous standards:

- Russia: GOST 28084-89.

- USA: ASTM D 3306.

- UK: BS 6580: 1992.

- France: AFNOR NF R15-601.

- Japan: JIS K2234.

- Austria: ONORM V5123.

- Sweden: G-11.

The properties of antifreeze are greatly influenced by the quality and, as already mentioned, the ratio of raw materials. The quality of the water (plain, distilled, deionized) is important, as is the purity of the ethylene glycol. Cheap coolants often use various low-grade surrogates that last a limited period and lack chemical stability.

According to GOST, antifreeze must have the following characteristics and properties:

- Freezing temperature (beginning of crystallization) . In Russia, OZh-40 and OZh-65 with the corresponding freezing temperature are taken as the standard for this indicator. This indicator in foreign marks can be anything. Again, it all depends on the proportion between ethylene glycol and water, as well as the proportion of additives.

- Boiling temperature . The average boiling point is 110°C-135°C. The pressure in the cooling system is within 1.5-3 atmospheres, which increases this indicator.

- Foamability . It is worth noting that under pressure, foam will not form at all as a result of circulation. This indicator is important for manufacturers at the time of filling coolant or other manipulations.

- Anti-corrosion properties . Ethylene glycol itself does not have anti-corrosion properties, rather the opposite. They are provided by various additives. For example, G11 antifreeze, which will be discussed below, uses phosphates, nitrates, nitrites, silicates, borates and amines. These substances create a protective layer on the surface. G12 class antifreezes use carboxylic acids, which act on the source of corrosion itself when it appears. This improves heat transfer.

- Impact on rubber elements . The system contains many plastic and rubber hoses and connections. Antifreeze should protect the rubber from cracking and scattering. In this regard, red antifreeze with carbon additives such as G12 and G12+ has proven itself well.

Features of using liquid

Coolant is now sold in two types - a ready-made diluted mixture, and ethylene glycol concentrate, which must be diluted before use.

There are no particular problems with using a ready-made solution. Liquid is purchased in the quantity specified in the technical documentation for the car in the section on filling containers. The type of liquid used is also indicated there. In this matter, it is better not to experiment, but to purchase the liquid recommended by the car manufacturer.

Next, the purchased liquid must be poured into the system through a radiator or expansion tank, after draining the used antifreeze.

Recommendations for choosing antifreeze

It is important to consider that antifreeze, like any liquid, tends to expand when heated, so you should not fill the system so that its level in the tank is “full.” Usually the tank has a maximum fill mark on the tank; if there is none, it should not be filled more than halfway. It is worth saying that the level in the tank must be maintained after the system is completely filled.

If you purchased a concentrate, then before filling it will need to be diluted with distilled water. You cannot use the concentrate without first diluting it with water; do not forget that the crystallization temperature of pure ethylene glycol is not that low.

Before breeding, you need to decide on the proportions. The optimal proportion is considered to be 1 to 1. Such a mixture will have a freezing point of -40°C, which is quite enough for most of our latitudes.

The frequency of antifreeze replacement largely depends on the chemical composition and additives. Some fluids can last 250 thousand km. In general, it is believed that the fluid life is 100-200 thousand km.

You should also not completely trust manufacturers that their liquid is capable of working out a significant resource. After all, this resource is indicated for liquid poured into a completely clean engine. And when replacing the fluid, a part of the used fluid always remains in the engine, which, when mixed with the new one, reduces its properties and affects its service life.

Types and classification

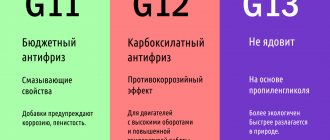

There are no specific global standards for antifreeze, but as a rule, the classification developed by the VAG concern is taken as a basis. So there are three classes:

- G11;

- G12;

- G13.

G11

These are traditional antifreezes based on ethylene glycol and various silicone additives that protect against corrosion. They are also called silicone antifreeze.

G11, G12, G13

Due to the formation of a protective layer, they can significantly reduce heat transfer, as well as form abrasive particles (falling off of the layer from the walls). Antifreeze of this class needs to be changed at least once every two years.

G12, G12+, G12++

G12 was the next stage in the development of antifreeze. Mainly, they solved the problem of the formation of a layer that interfered with heat transfer. This class uses carboxylic acids. The downside is that these acids attack corrosion after it occurs, not before. Increased heat transfer and service life up to 5 years.

Effect of carboxylate antifreeze G12+, G12++

Such coolants are marked:

- G12.

- Carboxylate coolants.

- OAT (Organic Acid Technology).

In the subsequent generation G12+ and G12++, they also solved this problem by combining organic and mineral additives together. Such coolants are often called lobrid and are labeled:

- Lobrid coolants.

- SOAT coolants.

G13

This class appeared in 2012 and differs from previous ones in the use of propylene glycol as a base. As already mentioned, this substance is safe for humans and the environment. This is where the differences, in general, end.

Corrosion inhibitors in antifreeze

Now on to the additives used in car coolants. One of the most important additives is corrosion inhibitors. This type of additive, as the name implies, is designed to prevent the appearance of corrosion spots inside the cooling system.

Nowadays several types of such liquid additives are used and each of them has its own designation.

The first are additives, which are called traditional, since they were the first to be used in antifreeze. Liquids with this type of inhibitor have no additional designation.

Traditional inhibitors consist of inorganic substances - silicates, phosphates, nitrites, borates, as well as their compounds. Such additives form a thin protective layer over the entire internal surface of the system, preventing direct contact of the liquid with the metal.

At the moment, liquid manufacturers are trying to abandon this type of inhibitors. The reason for this is their short service life - no more than two years. An additional negative quality is their poor tolerance to high temperatures; they begin to break down at temperatures above +105°C.

The second type of corrosion inhibitors that are used in coolants are carbon-based organic substances. Liquids with such additives are called carboxylate antifreezes, their designations are G12, G12+.

The peculiarity of such inhibitors is that they do not form a protective layer over the entire surface. Such inhibitors chemically interact with the source of corrosion. As a result of the interaction, a protective layer is formed on top of this source, without affecting the surface without corrosion.

A feature of this type of inhibitors is their long service life - more than 5 years, while they are impervious to high temperatures.

The third type of inhibitor additives is hybrid. They include both carboxylate elements and traditional inorganic ones. Interestingly, based on the country of origin, you can find out what inorganic elements the hybrid inhibitor contains. Thus, European manufacturers use silicates, American manufacturers use nitrites, Japanese manufacturers use phosphates.

The service life of inhibitors is longer than traditional ones, but they are inferior to carboxyl additives - up to 5 years.

Recently, another type of inhibitors has appeared - also hybrid, but they are based on organic materials, and mineral substances are added to them. This type of inhibitors has not yet been fully defined, so they appear everywhere as lobrids. Antifreezes with such additives are designated G12++, G13.

It should be noted that this classification is not entirely generally accepted; it was introduced into use by the German concern VAG, but so far nothing else has been invented, and everyone uses this designation.

Antifreeze color

The palette of coolants is quite wide, so it’s easy to get confused. It is impossible to say with absolute certainty that this class of coolant is always blue or red, but there are some patterns.

- There are two colors for Antifreeze: blue and red.

- G11 – blue, green or shades of green.

- G12 – red and its shades (orange, lilac).

- G13 – purple or pink.

When choosing a coolant by color, you need to rely on technical recommendations for the car and contact materials. For radiators made of copper or brass, red (carboxylate G12+) antifreeze is better. For aluminum radiators, it is better to choose green or blue (silicate). G13 will suit any car.

Other additives, dyes

Anti-cavitation and anti-foam additives are needed to maintain the fluid in a state that will ensure maximum heat removal. After all, cavitation is the formation of air bubbles in a liquid, which in the case of antifreeze will only cause harm. The presence of foam is also not desirable.

Dyes in antifreeze perform several functions. It makes it easier to find out the level in the system. Car expansion tanks are often made of white plastic. The level of a colorless liquid in such a tank would be invisible, but one that has a certain shade is easily visible.

Another property of the dye is an indicator of suitability for further use. Over time, the antifreeze in the system will develop its additives, causing the liquid itself to change color. A change in color will signal that the liquid has exhausted its resource.

As for the shades of antifreeze, they can be very diverse. Our most common shades are blue and red. Moreover, the temperature stability of the liquid is often tied to color. Thus, antifreeze with a blue tint most often has a freezing threshold of -40°C, with a red tint -60°C. However, this is not always the case; you can also purchase a liquid with a red tint, whose temperature threshold is -40 degrees.

But these are not all the shades that antifreeze can have. There are also liquids with a yellow, green, or orange tint. In this matter, everything depends on the manufacturer. As for the temperature stability of antifreeze, you should not rely only on color. This indicator may differ for different manufacturers, despite the fact that the color of the liquid may be the same.

You may also be interested

At what temperature does antifreeze freeze?

Antifreeze is designed to resist low and high temperatures, remaining in the same consistency. It should not boil when the engine heats up and harden in cold weather. But for many drivers, despite all the tricks, antifreeze freezes in the cold season. Let's talk to experts about why this is happening?

High-quality antifreeze is a guarantee of safe operation of your car

Antifreeze refers to the coolant necessary for the functioning of a car engine. Antifreeze allows you to cool the structural components of a car engine to the required temperature, preventing their deformation and failure. Before the invention of antifreeze, ordinary water was used as a coolant, but the water circulating in the cooling circuit tended to freeze, and when it freezes, the water increases in volume. Water expansion […]

Criteria for choosing antifreeze: briefly about the main thing

- Effective cooling;

- High boiling point;

- Low crystallization;

- Anti-corrosion properties;

- Good heat capacity;

- Environmental friendliness and safety for humans;

- Price.

No self-respecting car enthusiast will choose antifreeze in damaged packaging. Make sure that it indicates the manufacturer’s details, expiration date and manufacture of antifreeze. The liquid should be free of sediment or flakes. Shake the canister: the foam that appears should disappear after 3-4 seconds. If you press on the container, there should be no liquid or air escaping from it.

How to drain the liquid

The answer to this question is very simple. The coolant requires draining in the following cases:

- If necessary, replace according to the season.

- When replacing the cooling radiator.

- When installing a new thermostat.

The work is done in two steps, since there is antifreeze in the radiator and in the engine. This work has already become familiar to owners of domestically produced cars.

You need to start draining the fluid from the radiator:

- Turn off the engine.

- Wait 15 minutes for the engine to cool down slightly.

- Switch the interior heater control to the extreme right position. This will open the stove drain valve.

- Next, you need to open the expansion tank cap.

- Unscrew the radiator drain plug.

- Wait about 10 minutes until the liquid is completely drained.

Coolant is drained from the engine as follows:

- Take a spanner and unscrew the drain plug on the engine block.

- Wait about 10 minutes until the liquid is completely drained.

- Wipe the drain plug and check the quality of the rubber seal, replace it if necessary, and screw the plug into place.

When draining antifreeze, care must be taken as this liquid has a sweetish odor that attracts children and pets. Therefore, antifreeze or antifreeze must be poured into a container and disposed of, and not poured onto the ground.