Every modern car has a camshaft position sensor. It is a very important part of any vehicle as it helps ensure that the engine runs properly. The camshaft position sensor is built next to the engine just under the hood. Typically, different car manufacturers and brands have their own unique location for mounting the sensor near the engine. You can find it either at the back of the cylinder head or near the engine.

In this article we will look at DPRV. Many people confuse it with the crankshaft position sensor because they are very similar. But you must understand the difference, because they perform different functions in the car and have different symptoms and causes of problems.

What is a camshaft position sensor

The camshaft position sensor is also called the cylinder sensor or camshaft sensor. In sequential fuel injection systems, the electronic control unit must determine which cylinder should be injected next. This information affects engine operation and comes from the DPRV. As the engine rotates, the DPRV sends a signal to the on-board computer whenever a particular cylinder is at top dead center (TDC). Thus, the duration of pulse injection is estimated, for which the camshaft sensor is responsible.

In simultaneous fuel injection systems, the on-board computer is not used to determine the cylinder and injection order, since this is not necessary for the operation of the system. When a signal is received from the crankshaft or distributor, the exact cylinder is determined by recognizing the mechanical positions of the crankshaft, camshaft and valves.

Types of sensors used

The most popular are 2 types of DPRV, which look almost the same and differ slightly in design:

- inductive;

- Hall Sensor.

An inductive sensor is needed to register the cylinder and can be located inside the camshaft. Therefore, a device with a magnet is mounted near it. Each time a magnet passes through the DPRV, its magnetic field changes and the resulting pulse is sent to the on-board computer for subsequent processing.

The Hall sensor may be located inside the camshaft. A screen with a socket and a magnet is installed on the shaft. When the screen passes between the magnet and the hall sensor, the DPRV turns on and off. While the socket is in front of the DPRV, the voltage returns to the amplifier through the third signal cable. As long as there is a solid sector of the screen in front of the sensor, the feedback voltage is interrupted as the magnetic field disappears.

Phase sensor design

Currently, DFs based on the Hall effect are used - the appearance of a potential difference in a semiconductor wafer through which a direct current flows when it is placed in a magnetic field. Hall effect sensors are quite simple to implement. The basis is a square or rectangular semiconductor plate, to the four sides of which contacts are connected - two input, for supplying direct current, and two output, for receiving a signal. For convenience, this design is made in the form of a microcircuit, which is installed in the sensor housing along with a magnet and other parts.

Read also: Pumping the trapezius muscle

There are two design types of phase sensors:

— Slotted; — End (rod).

The slot phase sensor is U-shaped; a camshaft reference (marker) passes through its section. The sensor body is divided into two halves, one contains a permanent magnet, the second contains a sensitive element, both parts contain specially shaped magnetic circuits that ensure a change in the magnetic field when passing the benchmark.

The end sensor has a cylindrical shape, the camshaft reference passes in front of its end. In this sensor, the sensitive element is located at the end, above it there is a permanent magnet and magnetic circuits.

It should be noted here that the camshaft position sensor is integral, that is, it combines the sensing element described above, which generates the signal, and a secondary signal converter, which amplifies the signal and converts it into a form convenient for processing by the electronic control system. The converter is usually built directly into the sensor, which greatly simplifies installation and configuration of the entire system.

Where is the sensor located

The location of the DPRV varies depending on the make of the car. In most cases, you can find it in the following places:

- near the cylinder head;

- near the wiring connectors on the front of the motor;

- near the toothed belt mount;

- on the rear side of the cylinder head;

- special compartment under the hood;

- inside the cylinder head.

First, consult your vehicle's manufacturer's repair manual. This contains all the necessary information.

Working principle of the camshaft position sensor

The task of the DPRV is to work with the crankshaft sensor to determine the exact position of its drive. Thanks to the combination of both sensor signals, the engine control unit knows when the first cylinder is at top dead center.

This information is needed for 3 purposes:

- To start fuel delivery during sequential injection.

- To activate the solenoid valve signal for the pump injection system.

- To control cylinder detonation.

The DPRV operates in accordance with the Hall principle. It scans the ring gear on the camshaft. Rotation of the ring gear changes the Hall voltage IC in the DPRV housing. This voltage change is transmitted to the control unit and evaluated there in order to set the required data.

Problems that a faulty camshaft sensor can create

The camshaft's job is to control the consumption of gasoline and the emission of vapors from the exhaust system. Compensation vanes are installed on the camshaft, which control the exhaust and intake valves. The timing belt and chain connect the camshaft to the crankshaft. The vehicle's engine control unit monitors the rotating position of the camshaft using a component called a "camshaft position sensor." Based on the information transmitted by the DPRV, the engine control unit will determine how much fuel should be introduced into the combustion chamber. There are many symptoms of a bad camshaft sensor in your car.

Ignition problems – The mixture of air and fuel in an internal combustion engine requires a spark to ignite. In some vehicles, if the DPRV fails, there will be no spark, which is the first sign of a DPRV malfunction. If you can't create a spark, then you can't start the engine. Unfortunately, it is quite difficult to determine the source of the malfunction, especially if it is a DPRV. But don't be surprised that it might be him.

Reduced Power – If the DPRV fails in a vehicle with an automatic transmission, you may experience a transmission lock-up fault. The only thing you can do is turn off the engine, wait a few seconds and start it again. This is just a temporary solution that allows you to quickly deliver your car to the nearest auto store. If you do not replace the DPRV, the gear shifting problem will definitely return.

Poor engine performance - a faulty DPRV will lead to incorrect fuel injection into the cylinder chamber. Since the engine depends on the correct mixture of air and fuel, problems will immediately arise in its operation. When you press the gas pedal, the acceleration of the car will be significantly less. You probably won't be able to go faster than 50-70 km. at one o'clock. Moreover, the car may begin to move jerkily.

Lada Priora Hatchback BLACK -STAR (former) › Logbook › replacing the camshaft sensor

A faulty phase sensor (PF) can only be determined using a diagnostic tool. If the sensor fails, the engine characteristics do not change in any way, except for a slightly increased fuel consumption (0.5 l), which is easily hidden behind the driving style. Another symptom is a delay in starting the engine for 2 seconds due to waiting for a signal from the sensor. Afterwards the ECU will switch to pairwise parallel injection.

If, due to this malfunction, the car stalls and idles unstably, and also becomes “dull” during acceleration, then it is worth checking whether the toothed pulley on the crankshaft (which goes to drive the generator and other systems) has turned. To check, it is necessary to set the first cylinder to top dead center (TDC). The crankshaft position sensor should look at the beginning of the 20th tooth from the two missing ones.

If everything is in order with the pulley and operation, then you need to reset the error on the ECU and see under what conditions it appears again. If an error does not occur when the engine is idling, all connections and wires must be checked. This is done by wiggling the terminal and wiring harness. If an error appears during this operation, then you need to look for a bad contact, it has nothing to do with the sensor.

If the error occurs 15 seconds after the reset during smooth operation, then you can safely change the sensor. For reliability, it can be checked (a test diagram is available on the Internet), but the price of a new sensor is about 200 rubles - for this money it is easier to buy a known good one, and, even if it turns out not to be the problem, have a spare one.

So, we are convinced that the problem is in the sensor and we will change it.

To replace the phase sensor on cars of the Priora, Kalina and Grant families with a 16-valve engine, we will need:

“10” wrench (preferably a “10” head) “5” hexagon “17” wrench Phase sensor for a 16-valve VAZ 1 engine. The sensor is installed on the front side of the engine (radiator side) next to the intake camshaft pulley shaft It is not visible from above. We determine the position by the wiring harness suitable for this location.

Determining the position of the phase sensor

2. Disconnect the terminal. Using a 10mm wrench, unscrew the two bolts. Unscrew carefully, as they tend to “run away” under the car and into the generator along with the washers.

3. Remove the sensor and inspect it. In this case, mechanical damage was found on it from the camshaft pulley. It is necessary to remove the protective plastic casing and check the condition of the entire mechanism. If the DF has no traces of contact with the pulley, then simply replace the sensor with a new one and reassemble it in the reverse order.

Inspecting the removed sensor

4. I’ll immediately make a reservation that in this case there was a problem with the generator pulley (the gear ring of the crankshaft sensor turned). The crankshaft sensor determined the TDC position with an error, the engine vibrated strongly, which led to the breakdown of the phase sensor. And only then did the error light up on the instrument panel.

5. Unscrew the screws securing the casing using a 5mm hexagon. They are located at the top and along the edges, one in the center below the lip and one on the left edge of the casing below. We take out the screws along with the casing. We inspect the condition of the timing belt (in the photo below, for clarity, the cover has already been removed).

6. Set the first cylinder to top dead center. To do this, either put the car in 4th gear and drive, or turn the crankshaft or camshaft bolt with a key. The marks on the camshaft pulleys should fall under the slots on the plastic boot (indicated by arrows).

Setting the first cylinder to top dead center

7. Both marks should be at the top. To check the correct alignment of the crankshaft, there is a window in the gearbox, but it is made for an 8-valve engine, and in the 2112 engine it is very difficult to navigate through it. It’s easier to check by the ring gear on the auxiliary pulley. The crankshaft sensor (CSC) should look at the beginning of the 20th tooth after the gap (the arrow on the right shows the gap, the arrow on the left indicates the CSC):

Possible causes of malfunction

DPRV is a pulse generator that creates a very weak signal. There is a small chance that the current will gradually weaken the integrity of its winding. However, vibrations caused by magnetism travel through the gear teeth. When the camshaft is turned, the force changes just like the signal generated. These vibrations cause microscopic movements within the DRV, creating weak points in essential parts, especially the winding in the case of inductive type DRV.

With a Hall-type sensor it is a completely different story. This type of DPRV is a solid-state device, that is, its electronic component, such as a diode or transistor. Voltage can damage the sensitive parts of the DPVR. Short circuits and incorrect connections can also damage it. And remember that you need a polarity sensitive power supply.

How to check the camshaft position sensor

When troubleshooting a suspected DPRV fault, you should follow the diagnostic guidelines in the vehicle manufacturer's literature to isolate the faulty component when a DTC is present. There is no other way to know what is causing the problem (spark, bad ignition module, coil, computer, bad wiring or ignition switch).

Magnetic DPRVs can be checked by disconnecting the electrical connector and checking the resistance between the terminals. For example, on a GM 2.3L Quad 4, the sensor should show a voltage between 500 and 900 ohms. When testing DPRV, always take into account the technical specifications of the vehicle manufacturers. Obviously, if you see zero resistance (short circuit) or infinite (open) resistance, this means that the DPRV is not working and needs to be replaced.

How to determine a malfunction without diagnostics

Determining the problem using a diagnostic computer is quick and easy and will show error codes that indicate a faulty camshaft sensor. But the breakdown can be determined without connecting a scanner.

To find the fault you need a multimeter. The easiest way to change the sensor. The replacement procedure is not at all complicated - unscrew the old one and screw on the new one. But hardly anyone has a new device in stock. To buy a new one, you need to know for sure what is broken in the car.

- To determine whether the sensor is faulty, you need to install needles as probes on the multimeter (included on some models).

- If not, you need to sharpen the ones you have.

- Having pierced the insulation of the wires, identify the two power wires and measure the voltage on them.

- There will always be more voltage on two wires - this is the coil.

- If the voltmeter shows a voltage of about 13.4 V, then the coil is working. In this case, the multimeter will show 12 V on the signal wire.

If the device indicates no voltage, what to do then. Then it’s worth checking the sensor’s reaction to metal. To check, you need to remove the sensor without disconnecting the wires.

With the ignition turned on, bring any metal object near the device. The multimeter must be connected to the signal wire at this time. As the iron approaches the sensor, the voltage should decrease to almost zero, no more than 0.5 V.

If this happens, it means the sensor is working. In general, to accurately determine the performance of the DPRV device, use an oscilloscope. Who has it hidden in the garage? In practice, the considered method using a multimeter is sufficient.

Testing a two-wire inductive sensor

There are a number of common signs of a faulty DPRV. If you have these problems, you may need to replace it. These same symptoms can be caused by problems with the ignition or fuel injection systems. Thus, before replacing the DPRV, it is worth conducting tests to determine the real source of the malfunction.

If the check light comes on, your ECU is recording a trouble code. You can check for errors using a special diagnostic tool. Codes between P0335 and P0338 correspond to DPR problems.

This is probably the easiest and most accurate way to test and determine the problem of the DPRV. Unfortunately, the DPRV, as a rule, fails much earlier than the corresponding indicator lights up. To be constantly aware of the car's problems, it is worth conducting other types of testing.

RPM is the next method for checking the DPRV, which also requires a diagnostic tool. One of the scanner settings allows you to read the engine speed in revolutions per minute (RPM). Set up the scan tool to read engine speed and start it. The scan tool should read between 100 and 500 rpm. A low value indicates that the DPRV is not working properly. “0” means that the DPRV is completely out of order.

Multimeter testing

Of course, not everyone has access to a scanner (although they can sometimes be rented from parts stores). A multimeter is a more common and very useful tool for diagnosing many of your vehicle's electronic components. The multimeter can measure voltage, current and resistance.

You can remove the DPRV and then check the resistance. Attach one end of the multimeter to each DPRV wire. A resistance of 0 means there is a short circuit. Infinite resistance means there is an open circuit. Any of these readings indicate that the DPRV is not working. For any other value, check the manufacturer's instructions. If the reading does not match the recommended resistance, you must replace the DPRV.

Another way to check the DPRV using a multimeter is to check the output voltage using a motor. To do this, you will need an assistant. Strip the connectors and measure the output voltage in AC millivolts. Typically, this reading is about 200 millivolts, but may vary depending on the brand of car. Check the specifications in the user manual. If there is no output voltage, then obviously your sensor is not working properly.

These tests will help you determine the source of the problem. They will either prevent repairs you don't need or confirm that the repairs you are about to make are the ones you actually need. If testing really confirms that your DPRV is faulty, you will have to replace it.

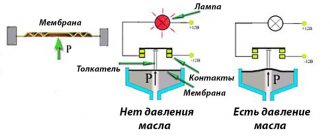

How the device works

Electrical diagram of the sensor location

The operation of the crankshaft location sensor is based on an effect discovered by the American physicist Edwin Herbert Hall. The device monitors the slightest changes in the strength of the magnetic field induced by a piston magnet installed in the device body. Metal notches (teeth), which are located on the camshaft wheel or on the drive shaft disk, change the strength of the magnetic flux, which is fixed by a semiconductor element.

The camshaft sensor transmits electronic commands to the vehicle's control unit. Based on the data received, the control system accurately calculates the exact angular position of the cylinder piston. Thanks to the accuracy of this process, the gas distribution mechanism of the vehicle operates in optimal mode, effectively supplying the cylinders with an air-fuel mixture and carrying out the timely removal of exhaust gas.

Causes of breakdowns and frequency of regulator replacement:

The camshaft sensor is equipped with a semiconductor chip, the service life of which is reduced when overheated. Due to the fact that the sensor is located on the valve cover, the chip is exposed to increased temperature, which can cause sensor failure.

Over time, the mounting tabs can break, causing the sensor to become dislodged.

Short circuit of the semiconductor chip.

Broken toothed disc, etc.

There are reasons why a sensor can fail at the wrong time.

To ensure that the problem does not take you by surprise, you should practice periodic replacement of the sensor at least once every five years, or after the car has driven 100 thousand. km.

Replacement must be carried out even with smooth and stable engine operation. If the engine stalls for no apparent reason or problems appear with the ignition system, installing a new camshaft sensor is a top priority.

Checking three-wire DPRV

Steps to test a three-wire DPRV:

- remove the air filter cover;

- disconnect the 3-pin connector in the DPRV;

- turn on the ignition;

- using a multimeter and cables from the kit, measure the voltage between terminals 1 and 3 of the sensor connector;

- recommended value: 4.5 to 5.5 V;

- turn off the ignition;

- check the wires between the test box and the 3-pin open circuit connector;

- Recommended wire resistance: max. 1.5 Ohm;

- check the wires for short circuit, to battery (+) and ground (GND);

- If the wires and voltage are ok, replace the camshaft position (CMP) sensor.

Engines 1.8L:

IMPORTANT! Before starting any test, the battery voltage must be at least 11.5 volts.

- disconnect the 3-pin camshaft position sensor connector;

- switch DMM to voltage measurement position;

- connect the DMM between the external terminals of the connector;

- Switch the ignition to the “ON” position, but do not start the engine. You should see a minimum of 4.5 volts;

- Now turn the ignition “OFF”;

- connect the VAG 1598/22 test unit to the ECM connector;

- Check the wiring between the test block and the ECM connector using the wiring diagram. Checks must be performed on each of the following points:

- Wire 1 and socket 11.

- Wire 2 and socket 76.

- Wire 3 and socket 67.

- For each of the above tests, the maximum resistance should not exceed 1.5 ohms.

- Check all wires for short circuits.

- when connected and there is voltage between terminals 1 and 3, replace the camshaft position sensor.

- If the wiring is OK but there is no voltage between terminals 1 and 3, replace the ECM.

Location of the DPRV on the engine

To check the camshaft position sensor, you need to know where it is located. As a rule, on eight-valve engines the DPRV is usually mounted at the end of the cylinder head. On sixteen-valve engines it is also mounted on the cylinder head, usually in close proximity to the first cylinder.

As for popular domestic VAZ cars, their owners call such units phase sensors. Their location in these motors is similar. So, on eight-valve engines, the sensor is located on the left side of the cylinder head (when viewed in the direction of travel of the car). On sixteen-valve engines - on the right front part of the engine. In the latter case, the sensor is not directly visible visually; its location can only be assessed by the signal and power wires suitable for it. The VAZ 2114 phase sensor is fixed in close proximity to the air filter, near the cylinder head.