Published: 01/28/2021

- Purpose and device

- Correct setting of the throttle position sensor

- How to learn to drive a manual manual yourself

- TPS adjustment

- How to find out about a malfunction of the throttle position sensor on a VAZ 2110?

- Signs of a bad throttle valve

- TPS design

- What throttle sensors can do

- 15 Truths That Can Change Your Life and Possibly Make You Mentally Stronger

- Sequence of action

- Common Sensor Problems

- Possible causes of TPS malfunction

- How to Diagnose a Throttle Position Sensor Using a Multimeter

- Recommendations for choosing TPS

- TPS problems and their diagnosis

- Which to choose?

- The Legend of Lake Teletskoye

Purpose and device

In some devices, chokes are installed in order to pass pulse currents of a certain frequency range. This range depends on the design of the inductor, that is, on the wire used in the coil, its cross-section, the number of turns, the presence of a core and the material from which it is made.

Structurally, the inductor is an insulated wire wound around a core. The core can be metal, made up of insulated plates, or ferrite. Sometimes the choke can be made without a core. In this case, a ceramic or plastic frame for the wire is used.

The throttle valve is present in the carburetor. It regulates the supply of the combustible mixture, representing a potentiometer. To check the throttle sensor in a car, determine whether the input voltage of the device corresponds to the throttle position.

The multimeter is set to dialing mode. The sensor connector contacts are connected to the multimeter probes and create the appearance of the damper moving (with your fingers). At the same time, check how the sensor reacts in the extreme positions of the damper. There should be a clear signal without wheezing.

How to check TPS yourself?

It is quite possible to diagnose the throttle sensor without the help of specialists. All you need in terms of tools is a multimeter. So, turn on the ignition and look at the instrument panel. If the “Check Engine” light is not on, lift the hood and look for the damper sensor.

Now we take a multimeter in our hands and check for the presence of a “minus”. To do this, you need to turn off the ignition and find ground among the wires. This is not difficult to do. Then turn on the ignition again and find the power wire. This will ensure that the sensor is receiving power.

Correct setting of the throttle position sensor

If the damper has no mechanical damage, proceed to the adjustment procedure. To do this, you need to loosen its mounting screws, lift it and release it sharply. Here we should hear a blow against the stop. Next, we adjust the tension of the screws until the “biting” of the part disappears. After this, fix the screws with nuts and loosen the sensor bolts. Then we carefully rotate its body and set its position so that the voltage changes only with the opening of the throttle valve. After this, you can fix the bolts back and start operating the car. As you can see, adjusting the throttle valve and its position sensor is not at all a difficult process, which almost every car owner can handle. At the same time, it is enough to spend no more than 10-15 minutes of free time on the entire repair.

Superficial intervention or deep cleaning?

There are two ways to clean the throttle valve. The first is a superficial intervention that does not require complete removal of the entire device. And the second is a complete cleaning, which must be performed in cases where your car’s engine is not working well.

To perform the first type of cleaning, you will need a pre-purchased cleaning product and a fine brush. Open the hood, remove the corrugation, it goes from the air filter housing to the throttle valve. You will see a valve - it is easy to recognize by its completely round shape. Treat it with a chemical and let it sit for a few minutes, then remove the dirt with a brush. If necessary, use a rag. Repeat the procedure several more times until the flapper valve turns a bright color. This work can be carried out once every 3–5 thousand kilometers, fortunately, it does not take much time.

For more detailed cleaning of the throttle valve in a VAZ 2110, you need to completely remove the entire injector mechanism. It is also recommended to replace the gasket and O-ring, which are included in the throttle valve repair kit, which is easy to buy at any auto store. Before starting cleaning work, remove the terminals from the battery.

Then disconnect all air pipes connected to the throttle body. After this, remove the fastenings of the throttle cable and unscrew the throttle valve itself. It is attached to two bolts that are screwed into the engine housing.

Electronic sensors must be disconnected carefully to avoid damaging them.

After that, take a chemical and treat the entire body and all the grooves of the throttle body. Do this until you completely get rid of the dirt. You can also clean the air flow meter sensor. To do this, carefully treat its hairs with a cleaning product and remove the dirt with a brush. Give the entire device time to dry completely before reassembling. Do not forget to change the gasket and ring, which are located in the corrugation

Also pay attention to whether all air pipes are intact. Perhaps some require replacement with new ones

For maximum effect, you can also replace the air filter.

If you find an error, please select a piece of text and press Ctrl+Enter.

TPS adjustment

When you are 100% sure that the sensor is working, it needs to be adjusted correctly. Setting up the TPS begins with diagnosing the throttle valve itself; if everything is in order with it, we move on.

- Unscrew the mounting screws, but not completely.

- Then, we rotate the sensor housing to the position in which the voltage will change only when the damper is opened.

- Fix the sensor and hit the road!

That is, you understand, yes, every replacement of such an element must be accompanied by an adjustment procedure, otherwise interruptions in the operation of the car may continue. Don’t be lazy, it won’t always work at random, but it only takes 15 minutes of work!

In general, you understand, when your car breaks down, don’t look for the problem in the complex, it’s better to first look at the simple and, at first glance, unnoticeable! So, you will save money, time, and your own nerves! My advice to you is that a spare sensor, which you should definitely buy, wouldn’t hurt for backup. TPS malfunctions can take you by surprise, no matter where you are away from home! This is where I will end my story. I wish you success, more money, and most importantly, health and a stable engine! See you later!

Signs of a bad throttle valve

The throttle assembly regulates the air supply to the intake manifold, which subsequently creates an air-fuel mixture with parameters that are optimal for the engines. Accordingly, if the throttle valve is faulty, the technology for creating this mixture changes, which negatively affects the behavior of the car. Specifically, signs of a bad throttle position include:

- problematic engine starting, especially “cold”, that is, on an unheated engine, as well as its unstable operation;

- the engine speed value constantly fluctuates, and in a variety of modes - at idle, under load, in the average range of values;

- loss of dynamic characteristics of the car, poor acceleration, loss of power when driving uphill and/or with a load;

- “dips” when pressing the accelerator pedal, periodic loss of power;

- increased fuel consumption;

- a “garland” on the dashboard, that is, the Check Engine indicator light comes on and then goes out, and this repeats periodically;

- the engine suddenly stalls, after restarting it works normally, but the situation soon repeats;

- frequent occurrence of engine detonation;

- a specific gasoline smell appears in the exhaust system, associated with incomplete combustion of fuel;

- in some cases, self-ignition of the air-fuel mixture occurs;

- You can sometimes hear soft popping noises in the intake manifold and/or muffler.

It is worth adding here that many of the listed symptoms may indicate problems with other engine components. Therefore, in parallel with checking the malfunction of the electronic or mechanical throttle, it is necessary to perform additional diagnostics of other parts. Moreover, preferably using an electronic scanner, which will help determine the throttle valve error.

TPS design

The throttle position sensor can be of two types:

- film;

- magnetic or contactless.

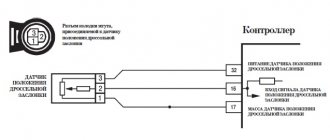

In its design, it resembles an air valve - in the open position the pressure corresponds to atmospheric pressure, in the closed position it drops to a vacuum state. The TPS includes DC and AC resistors (each resistance is 8 ohms). The process of opening and closing the damper is monitored by the controller, with subsequent adjustment of the fuel supply.

If at least one symptom of a malfunction occurs in the functioning system of this sensor, then fuel may be supplied to the engine either in excess or in deficiency. Such malfunctions in engine operation are reflected in the engine of the VAZ-2110 car and on its gearbox.

Why is it needed?

The throttle position sensor is responsible for determining the current throttle position. Depending on this, the fuel supply system changes the amount of fuel supplied under one or another operating mode of the power unit.

If problems arise with it, you can contact a service station so as not to waste your energy and nerves. But in practice, changing the TPS yourself is quite simple, plus you will save a decent amount of money.

The desired regulator is located on the side of the throttle pipe on the throttle valve axis.

Features of work

The TPS is essentially a variable resistor, one output of which is supplied with 5 Volt power. The second contact is connected to ground, and the third is connected to the controller.

When you press the gas pedal, the voltage changes. The sensor monitors the output voltage on the controller, thereby regulating and monitoring the quality of the supplied air-fuel mixture. This directly depends on the opening angle of the damper itself.

If for some reason this regulator fails, a catastrophe will not occur, since another sensor, the mass air flow sensor, will temporarily take over its functions.

This does not mean at all that the TPS can not be changed. Each regulator has its own functions, so there is no point in transferring the tasks of the TPS to the MAF.

What throttle sensors can do

Electronic control is carried out through sensors that transmit the following data:

- Crankshaft rotation indicators

- Air flow and temperature

- Antifreeze temperatures

- Throttle position

- Feedback system (exhaust gas composition)

- Detonation in the engine

- Mains voltage

- Travel speeds

- Camshaft position

- Activating the air conditioner

- Irregularities in the road surface

Let us consider in detail the operation of the PDZ sensor.

This is a device for precise dosing of the fuel mixture supplied to the combustion chamber of the engine. Its operation increases the efficiency of the motor and the efficiency of movement.

The position angle of the remote control is converted into current voltage and transmitted to the control zones of the electronic unit. Based on the valve angle, the voltage value changes, which is recognized by the controller, which sends signals for certain actions to the injection mechanism. At the same time, after processing the signals from the sensors, the ECU determines the optimal parameters for the economy mode - they adapt the program to the driving style, to the given engine, etc. Essentially, the sensors record the parameters of the dependence of the throttle valve position with changes in voltage in the circuit.

There are two types of damper sensors:

- contact (film resistor) - which are directly connected to the damper axis, during the rotation of which the sensor contacts move along the slides. In this case, high resistance and voltage changes are overcome, which is ultimately the signal emanating from the sensor. The design is simple and easy to diagnose. However, it wears out quickly due to constant exposure to friction.

- non-contact - a moving magnet is located at the contact points, and the indicators of the alternating magnetic field are converted into an electronic signal by Hall sensors. Non-contact sensors have an increased service life, however, they are difficult to diagnose.

Sequence of action

The verification procedure is as follows:

- The Vk toggle switch turns on. In this case, the multimeter needle should deflect to the middle of the scale;

- depending on the inductance of the coil, the position of the variable resistor R5 is set. The left position corresponds to less, and the right to greater inductance. When checking coils with inductance less than 15 mH, you must additionally press the Kn2 button;

- The inductor terminals are connected to the Lx terminals and contact Kn1 is closed with a button. In this case, if there are no turns in the winding that are short-circuited with each other, the multimeter needle should deviate towards higher values or slightly deviate towards smaller values. If the winding has at least one short circuit between the turns, the arrow returns to zero.

Sometimes the cause of a coil malfunction can be a broken or damaged core. The material from which the core is made, its size and position relative to the coil affect the inductance.

Let's talk about the features of the gearbox

In English, sequential means “sequential”. In such a box you can only change gears from high to low or from low to high. This principle is provided for in motorcycles with foot control. When changing gears with your foot, it is problematic to perform complex manipulations. That is why in this case a simple algorithm is used: if the lever moves up, the gear increases, if down, it decreases. This option is very convenient.

The sequential gearbox differs from the standard one in that it only comes with two shafts. In this case, there are no synchronizers, and the gears are always straight-cut. They are needed in order to advance the clutches that directly engage the gears. The differences lie not only in terms of design, but also in operation. In order to engage a gear in the gearbox, you need to disengage the clutch. In a sequential gearbox, when going uphill or moving in a straight line, it is possible to change gears without disengaging the clutch.

Common Sensor Problems

Very often, over time, the throttle sensor fails due to a malfunction of the substrate, which is covered with a resistive layer. When this layer wears off or loses its properties, the sensor begins to act up. In this case, it is necessary to replace the substrate so that the sensor can easily read the linear movements inside the mechanism.

Another important detail is the slider. The cause of the problem may be a violation in the contacts between the slider and the resistive layer

As a result, scratches form on the surface of the layer, which interfere with the operation of the mechanism.

The best option is to completely replace the old throttle sensor with a new one. There is no point in changing individual parts, since after a certain period of time the problems may return and it will be more difficult to eliminate them. On such car models as VAZ 2110, VAZ 2114, 2112, you can reinstall TPS without any problems.

A common problem is contact oxidation. In this case, a special liquid can help, which must be used to treat all existing contacts.

It also happens that the damper does not close completely, as a result of which the fuel supply may be distributed unevenly and incorrectly. This difficulty can be easily overcome by slightly filing the outer parts of the mechanism so that the valve closes tightly on both sides.

Many motorists, having discovered breaks in contacts or cracks in this area, resort to using conductive glue. Of course, for some time the operation of the mechanism is restored, but the sensor itself will never be the same, so it is more advisable to simply purchase a new device to avoid problems in the future.

Most auto mechanics use film-resistor throttle valves, since they have a relatively low cost and are sold in all stores. Replacing the sensor is a simple procedure, but requires care and judgment.

Removing the throttle assembly

Dismantling the remote control will be necessary in any case. If there are malfunctions, the unit is replaced with a new one, but if there are no problems other than contamination, then the gasket on the damper is changed, and then a thorough cleaning is performed. For dismantling you will need a set of screwdrivers and a 13mm socket wrench. You also need to purchase a special cleaning fluid, which can be found at any car store. An excellent option would be a product for carburetors - Arbo. Dismantling is carried out only on a “cold” motor.

The work proceeds according to the following scheme:

- Raise the hood and remove the plastic engine cover.

- Next we need to reduce the pressure in the cooling system. To do this, you need to remove the expansion tank cap.

- Unscrew the clamps and loosen them.

If, during a visual inspection, deformation of parts was noticed, then the best solution would be to replace the unit. If only cleaning is required, then move on to the next section.

Possible causes of TPS malfunction

Possible causes of TPS malfunctions:

- Oxidation of contacts on the terminals of the device. The phenomenon is often caused by temperature changes and exposure to moisture. To prevent such damage, you need to periodically clean the contacts with a cotton swab or swab treated with WD-40.

- Erasing the coating on the working surface, in particular, in the segment where the slider begins to move. This ensures that the voltage parameter does not change during sensor operation due to the lack of resistance.

- Mechanical damage to the controller tips. With this problem, burrs will appear on the lining. The contact elements continue to work, but the substrate itself wears out much faster. This fault will cause the slider and the resistive layer to fail to contact.

- Failure of the slider. Natural wear is typical for this sensor part during prolonged use.

Channel “Engine Repair! And interesting!” spoke in detail about the causes and symptoms of malfunctions in the controller.

How to Diagnose a Throttle Position Sensor Using a Multimeter

- Find the TPS on your car. Since it monitors the position of the throttle valve, look for the sensor on the throttle body.

In the picture below, the red arrow points to this sensor.

For demonstration purposes, I removed the air supply pipe so you can see how the throttle assembly works. This will help you when checking the sensor.

- In older cars, a mechanical lever is used on the throttle body, which is connected to the gas pedal in the cabin via a cable drive (newer cars use an electronic accelerator pedal).

- The throttle body has a plate (circular disc) installed that acts as a door for air to enter the engine.

- When the throttle is closed (the gas pedal is not pressed), the throttle is in a fully closed state.

When the throttle is wide open (the gas pedal is pressed to the floor), the throttle is fully open, allowing maximum air flow into the engine.

- The next step is to ensure conditions for the correct operation of the TPS. To do this, start by disconnecting the electrical connector from the sensor.

Connect the black lead of the multimeter to the negative terminal of the battery and set the meter to DC mode.

Measure the voltage at the middle pin where the signal wire is usually connected. It should also display approximately 0 volts.

Connect to the third pin, which should show about 5 volts. This is our reference voltage. If, when connecting to the third contact, you do not see 5 volts on the multimeter, the throttle position sensor is not receiving the required voltage, and this is a sign of a wiring defect on the way to the sensor. Check it for mechanical damage.

It is important to note that as long as there is 5 volts on one contact and approximately 0 volts on the other two, you do not have to worry about the integrity of the wiring. Remember that the signal pin is usually the middle pin in the connector and remember where 5 volts and ground are located

- Connect the wiring connector to the TPS and connect the multimeter probes to the signal and ground contacts using paper clips (see photo below).

- Connect the multimeter's positive (red) lead to the signal wire (middle pin) and the black lead to the ground wire. Set the multimeter to constant current (DCV) mode

With this connection, the multimeter should read approximately 0.9 volts

Exact numbers may vary depending on the car model. Rotate the throttle body lever and notice the voltage change. If you are not comfortable doing this, you can place the multimeter on the windshield with the screen facing the car's interior, sit behind the wheel and press the gas pedal

The result will be similar. If the throttle position sensor is working correctly, you will see a smooth change from the base voltage (in our situation about 0.9 volts) to the maximum value (about 4.47 volts). Turn the lever or slowly press the gas pedal, try to see the voltage “peaks”. Sudden surges or drops in voltage are what interests us. For example, if you press the gas pedal about halfway and the display shows about 2.5 volts, sharp spikes above 4 volts or drops to 1 volt indicate a faulty TPS.

This occurs due to physical wear and tear on the throttle sensor. If you find an area where the voltage jumps every time you pass it (either on the way up or down), this is a sign that the resistor is worn out. Information about this voltage surge is transmitted to the electronic control unit, causing the computer to think that you suddenly pressed or released the gas pedal.

If the TPS check shows that the sensor is faulty, replacing it will not be difficult. As a rule, it is secured with only two bolts. You just need to disconnect the electrical connector, unscrew the mounting bolts, pull out the sensor and install a new one.

What is TPDZ

? How to check TPS? You will get answers to these and many other questions in this article. Interesting? Then read on!

First, I suggest you understand the abbreviation. TPS stands for throttle position sensor. TPS is a potentiometer, the task of which is to promptly report the position of the throttle valve to the controller. The throttle position changes depending on how much the driver presses the accelerator (gas) pedal.

Carrying out adjustment work

The test begins with connecting to the control connectors. For accurate readings, you must start the engine. Measurements are taken at the signal contact. The tester screen should show voltage data no higher than 0.7 V. If it is exceeded, you will need to reorient the sensor to the required position. This is done by loosening the mounting bolts. This way the initial position of the sensor is tested.

During the test, we disconnect the connector and test the conductivity between the contacts of the device. The absence of control signals indicates that the sensor needs adjustment and configuration.

It is also advisable to check the throttle valve clearance. This is done with a probe, which should fit between the screw and the lever. In this zone, the voltage is measured with a multimeter. Its value must be zero. If present, you will need to replace the sensor.

By rotating the damper until it is fully open, the current data and the final value are tested. The reference voltage parameters at the terminals are specified in the technical documentation for the device.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling

the breakdown is obvious if you notice that its speed is in a “floating” state;:

- Quickly release the gas pedal:

- Pick up speed:

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

Handling and off-road capabilities

Compared to the Toyota Land Cruiser, the new Mercedes-Benz GLE Coupe is inferior in terms of off-road capabilities. But, despite this, the German model stands out from most competitors with its capabilities. Built-in all-wheel drive combined with active air suspension, on-board electronics and 202 mm ground clearance provide the crossover with enviable maneuverability. In particular, the built-in equipment is capable of automatically controlling the movement of each wheel, thereby minimizing the likelihood of slipping.

The steering of the GLE Coupe is also characterized by excellent qualities. This is also greatly facilitated by on-board electronics, which can, if necessary, drive a car without human intervention. Large dimensions do not prevent the crossover from maneuvering at high speeds, while maintaining stability when taking sharp turns.

Which to choose?

Please note that the VAZ-2114 throttle position sensors cannot be repaired. This element is changed entirely on the car

There are several:

- “Sche.

- "Omega".

The latter is installed on the Lada from the factory. It lasts long enough

When choosing, you need to pay attention to contactless elements. They cost about 600-900 rubles

Replacement and selection of sensor - non-contact or film?

If the element fails, then its complete replacement will most likely save the situation. One of the important points of this stage is the correct choice of a new device. Of course, if you do not want to carry out all the operations again in a short period of time, then you should give preference only to high-quality products, and even more so avoid cheap Chinese counterfeits. In addition, do not stop your choice on film-resistive models. They are short-lived, and such savings can cost you a pretty penny. But contactless throttle position sensors are more reliable. They only cost a few dollars.

Article on the topic: Knock sensor: what is it

Non-contact TPS

The film model has resistive tracks, while the non-contact model works on the principle of the magnetic effect. Its components are a stator, a rotor and a magnet. On the first, the magnetic field has a huge impact. The material of the second one is chosen such that the magnet does not have any influence on it. The distance between the TPS elements does not change and is selected at the assembly stage. Needless to say, the contactless sensor cannot be repaired.

The replacement itself will take you much less time than choosing a device. But despite the fact that the process is quite simple, let’s consider it in detail. We prepare a Phillips screwdriver, an O-ring for the throttle pipe and, of course, the part itself. The replacement begins by turning off the ignition if the car has been started. Open the hood and do not forget to disconnect the battery. To do this, remove the negative terminal.

Installation of TPS

Now we find the sensor on the throttle pipe and remove the block with wires from it; most likely you will have to press out the special plastic latch. Then unscrew the mounting bolts and dismantle the device. There is a foam ring between the TPS and the pipe, and it definitely needs to be replaced. And only after this can the sensor itself be installed. Fix the device firmly with bolts, otherwise the vibration will not do it any good and will cause failure. Reconnect the block with all the wires. Sometimes people forget to disconnect the battery; in this case, it is necessary to de-energize it for at least five minutes after installing the new device and connecting the plug to it.

You can check whether the element is working correctly as follows. Open the damper and pull the throttle cables to turn the TPS drive sector. If the position of the sector does not change, then the sensor should be installed again. At the same time, we rotate it 90 degrees relative to the damper axis. And finally, check the voltage with a tester; if its values coincide with those indicated above, then the device is working.